Negative electrode paste performance improvement method

A negative electrode slurry and performance technology, applied to battery electrodes, electrical components, circuits, etc., can solve problems such as uneven coating on the front and back of copper foil, affecting coating operations, and easy agglomeration of negative electrode slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method for improving the performance of the negative electrode slurry of the present embodiment comprises the following steps:

[0022] A. Pulping:

[0023] a. Add deionized water (deionized water accounts for 70% of the total weight of the slurry) and CMC into the mixing tank, and when the CMC is completely dissolved in the deionized water, start stirring, with rotation at 25Hz, revolution at 40Hz, and stirring for 50min;

[0024] b. Add conductive carbon black to the slurry stirred in step a, start stirring, rotate at 25Hz, revolution at 40Hz, vacuumize to -0.09Mpa, and stir for 80min;

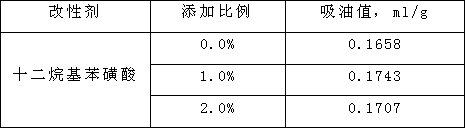

[0025] c. Add negative electrode graphite, DBSA (add 1% relative to graphite) and remaining solvent (30%) to the slurry stirred in step b, vacuumize to -0.09Mpa, start stirring, and rotate at 25Hz, revolution 40Hz, stirring for 140min;

[0026] d. Add the weighed SBR to the slurry stirred in step d, vacuumize to -0.09Mpa, rotate at 25Hz, revolution at 40Hz, and stir for 80min; ...

Embodiment 2

[0034] The performance improvement method of negative electrode slurry of the present invention comprises the following steps:

[0035] A. Pulping:

[0036] a. Add deionized water (deionized water accounts for 85% of the total weight of the slurry) and CMC into the mixing tank, and when the CMC is completely dissolved in the deionized water, start stirring, with rotation at 30Hz, revolution at 45Hz, and stirring for 70min;

[0037] b. Add conductive carbon black to the slurry stirred in step a, start stirring, rotate at 30Hz, revolution at 45Hz, vacuumize to -0.095Mpa, and stir for 100min;

[0038] c. Add negative electrode graphite, DBSA (add 2% relative to graphite) and remaining solvent (15%) to the slurry stirred in step b, vacuumize to 0.095Mpa, start stirring, and rotate at 30Hz and revolution at 45Hz , stirring for 160min;

[0039] d. Add the weighed SBR to the slurry stirred in step d, vacuumize to -0.095Mpa, rotate at 30Hz, revolution at 50Hz, and stir for 100min; ...

Embodiment 3

[0047] The performance improvement method of negative electrode slurry of the present invention comprises the following steps:

[0048] A. Pulping:

[0049] a. Add deionized water (deionized water accounts for 80% of the total weight of the slurry) and CMC into the mixing tank, and when the CMC is completely dissolved in the deionized water, start stirring, with rotation at 25Hz, revolution at 45Hz, and stirring for 60min;

[0050] b. Add conductive carbon black to the slurry stirred in step a, start stirring, rotate at 30Hz, revolve at 40Hz, vacuumize to -0.095Mpa, and stir for 90min;

[0051] c. Add negative electrode graphite, DBSA (add 2% relative to graphite) and 20% of the remaining solvent (add solvent twice) to the slurry stirred in step b, vacuumize to -0.09Mpa, start stirring, and Rotation 25Hz, revolution 45Hz, stirring 150min;

[0052] d. Add the weighed SBR to the slurry stirred in step d, vacuumize to -0.095Mpa, rotate at 30Hz, revolution at 50Hz, and stir for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com