Low-thermal-conductivity thermal insulation material and preparation method thereof

A technology of thermal insulation material and low thermal conductivity, which is applied in heat exchange equipment, pipelines through thermal insulation protection, mechanical equipment, etc., can solve the problems of low product strength, delamination, large thickness deviation, etc. Promotes uniform distribution and less moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

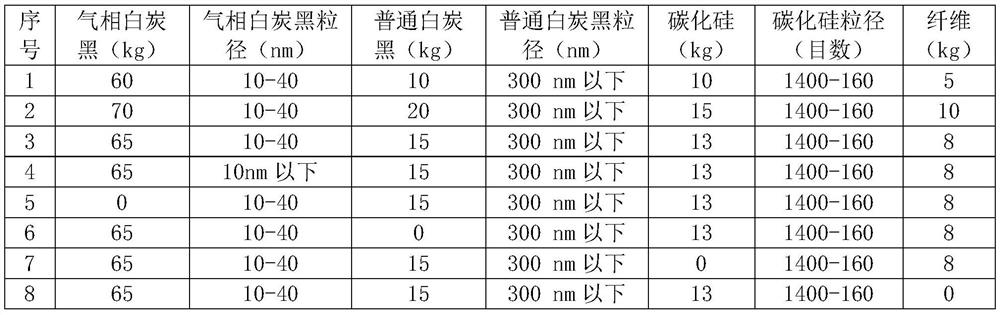

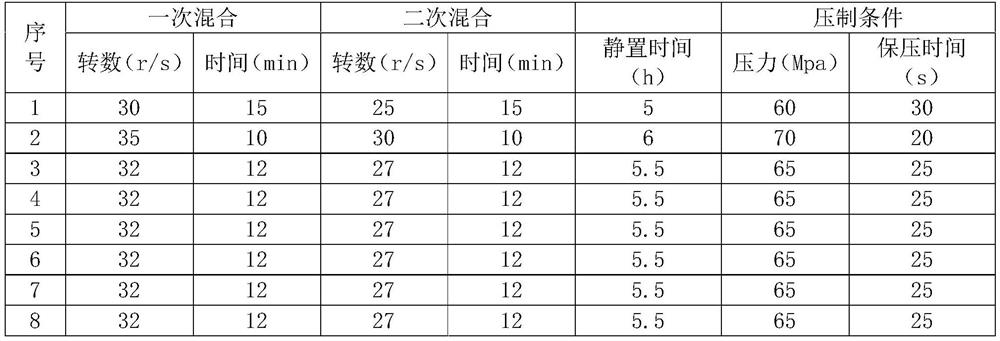

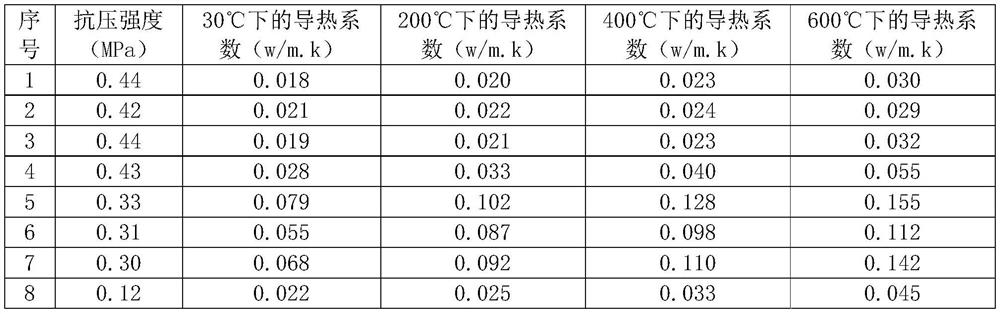

[0019] In order to clearly illustrate the technical features of the present solution, the present application will be described in detail below through specific implementation modes.

[0020] For fumed white carbon black, it is synthesized as follows: Silicon tetrachloride is first rectified in a rectification tower, then heated and evaporated in an evaporator, and the dried air is used as a carrier to send it to a synthetic hydrolysis furnace. The silicon dioxide is gasified at a high temperature of 1000-1800 ℃, and hydrogen and oxygen are introduced to carry out gas phase hydrolysis to generate fumed silica, which is then introduced into the collector to gather into larger particles, which are then collected by the cyclone separator and sent to the degasser. When the acid furnace is purged with ammonia-containing air until the pH value is 4-6, it is fumed silica.

[0021] For the strong ultra-fine ceramic fiber, it is synthesized in the following way: it is prepared by elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com