Surface microstructure array with water mist collecting function and molding method thereof

A microstructure array and molding method technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve the problems of low water mist collection efficiency, low molding efficiency, and difficulty in forming functional surface microstructures, and achieve improved The effect of water mist recycling efficiency, reducing molding time, improving molding accuracy and molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

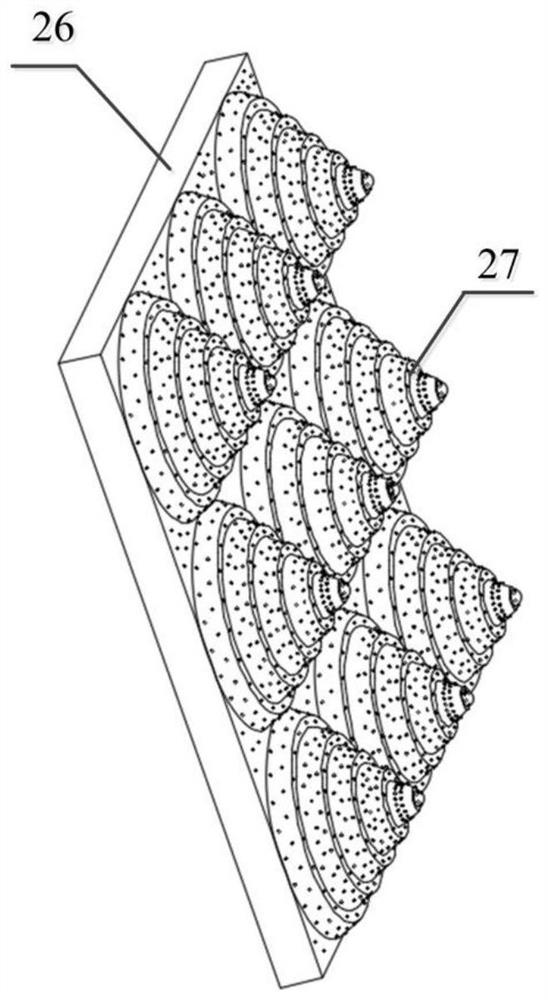

[0021] See attached Figure 1~4 , the single microstructure of the surface microstructure array with water mist collection function is a conical pyramid structure 28, the structure is a multi-layer conical superimposition, the material is photosensitive resin 7, and the radius at the bottom of each layer of conical frusta is decreasing layer by layer, respectively 5µm, 4µm, 3µm, 2µm, 1µm; the inclination angle of the conical bus bar of each layer is constant at 64°, and its height is constant at 1µm; the horizontal and vertical spacing between two adjacent microstructures is 2µm; on the surface of the microstructure, there are Nanoparticles 17 form a micro / nano composite structure with the frusto-pyramidal structure 28; a plurality of the above-mentioned composite structures are evenly distributed on the target surface 27 of the molding to form a surface microstructure array 26.

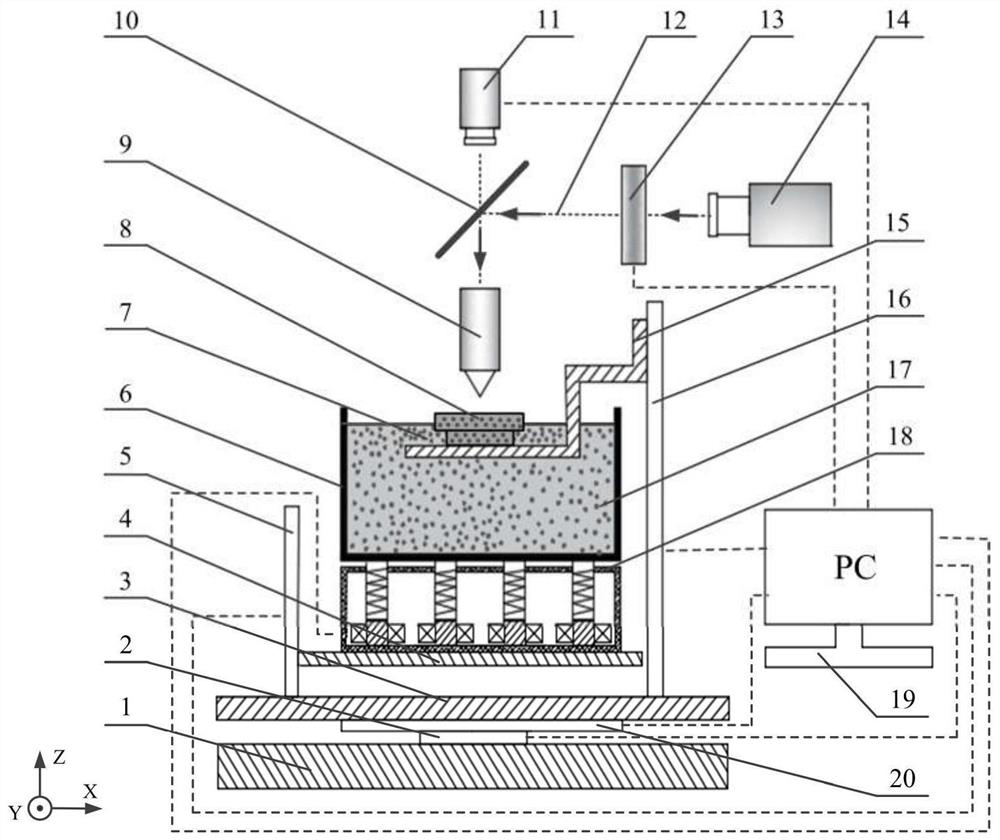

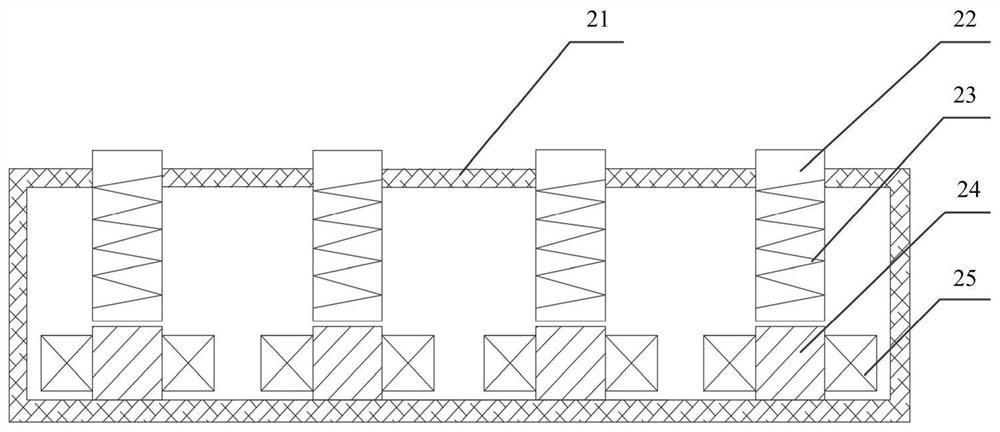

[0022] The forming method of the surface microstructure array 26 with the function of collecting w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com