Reactor for purifying organic waste gas under cooperation of plasmas and ultraviolet ray catalysis

A plasma and catalytic purification technology, used in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low processing efficiency, low energy utilization, toxic by-products, etc., to promote organic integration and overall structure. Simple and practical, outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

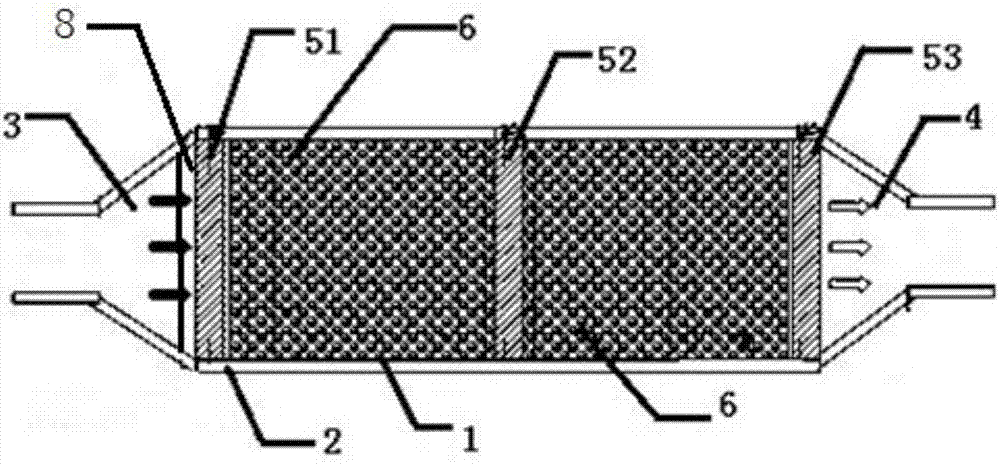

[0024] Such as figure 1 As shown, a reactor for catalytically purifying organic waste gas with plasma and ultraviolet photocatalysis, including a housing 1 and an insulating layer 2, the insulating layer 2 is fixed outside the housing 1, and the housing 1 is provided with two plasma Body discharge unit, air inlet 3, air outlet 4, filter dust removal unit 8, one plasma discharge unit includes stainless steel plate 51, stainless steel plate 52, another plasma discharge unit includes stainless steel plate 52, stainless steel plate 53, two plasma discharge units The bulk discharge unit shares a stainless steel plate 52, the stainless steel plate 52 is connected to high voltage electricity, the stainless steel plate 51, and the stainless steel plate 53 are all connected to the ground, and the filter and dust removal unit 8 is located between the air inlet 3 and the plasma discharge unit. The air port 3 is connected to one end of the filter and dust removal unit 8, and the other end...

Embodiment 2

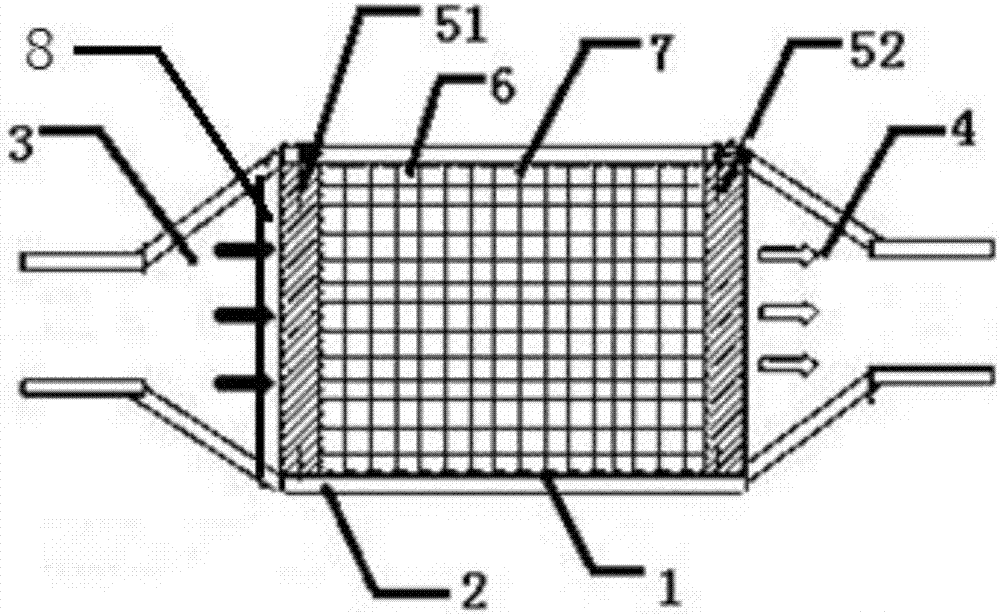

[0031] like figure 2 As shown, a reactor for catalytically purifying organic waste gas with plasma and ultraviolet light, including a shell 1 and an insulating layer 2, the insulating layer 2 is fixed outside the shell 1, and a plasma Discharge unit, air inlet 3, air outlet 4, plasma discharge unit comprises stainless steel plate 51, stainless steel plate 52, stainless steel plate 52 connects high-voltage electricity, stainless steel plate 51 all connects ground, and described filter dust removal unit 8 is positioned at air inlet 3 and the plasma discharge unit, the air inlet 3 is connected to one end of the filter dust removal unit 8, and the other end of the filter dust removal unit 8 is connected to the gas outlet through two plasma discharge units, the stainless steel Both the steel plate 51 and the stainless steel plate 52 are provided with several through holes, and the photocatalyst 6 is filled in the plasma discharge unit. The present invention also includes a carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com