Petroleum heating device

A heating device, oil technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of large temperature gradient, slow heat transfer, and large maintenance, and achieve uniform temperature field distribution and easy control. temperature, the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

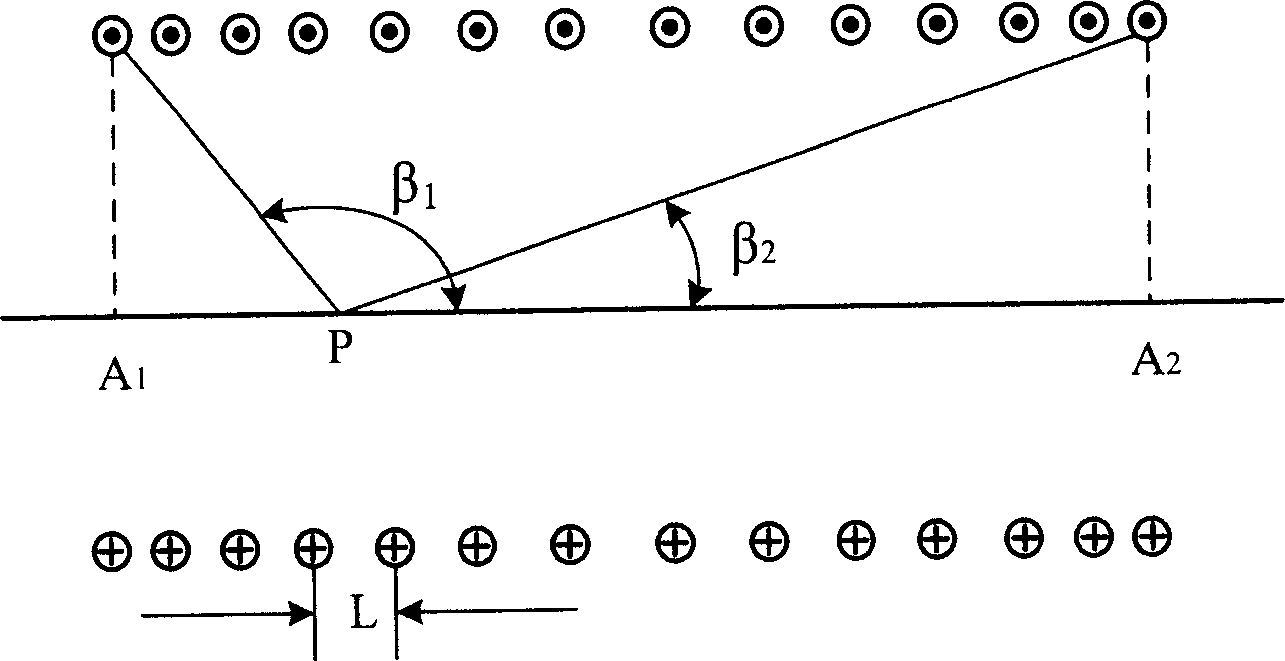

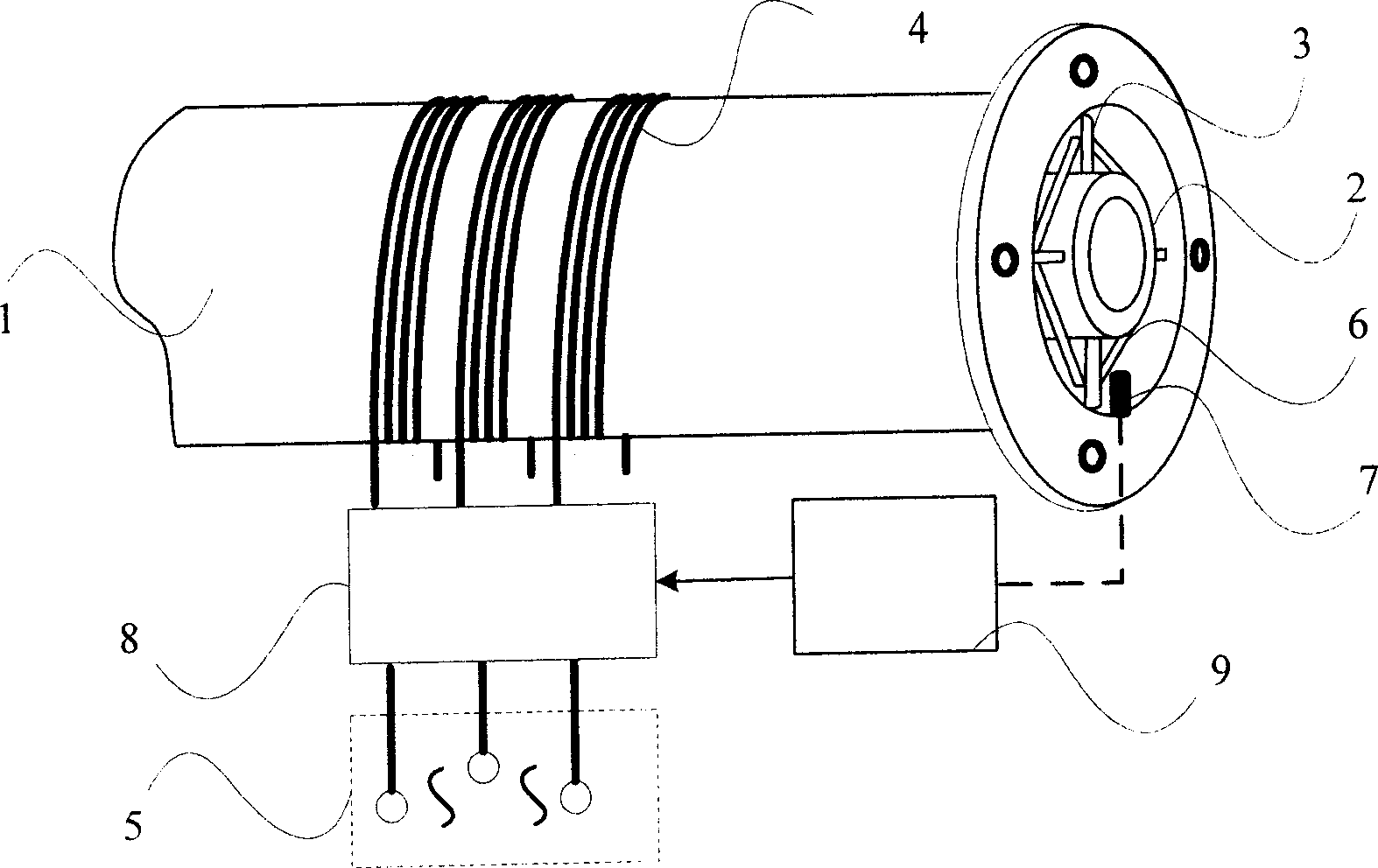

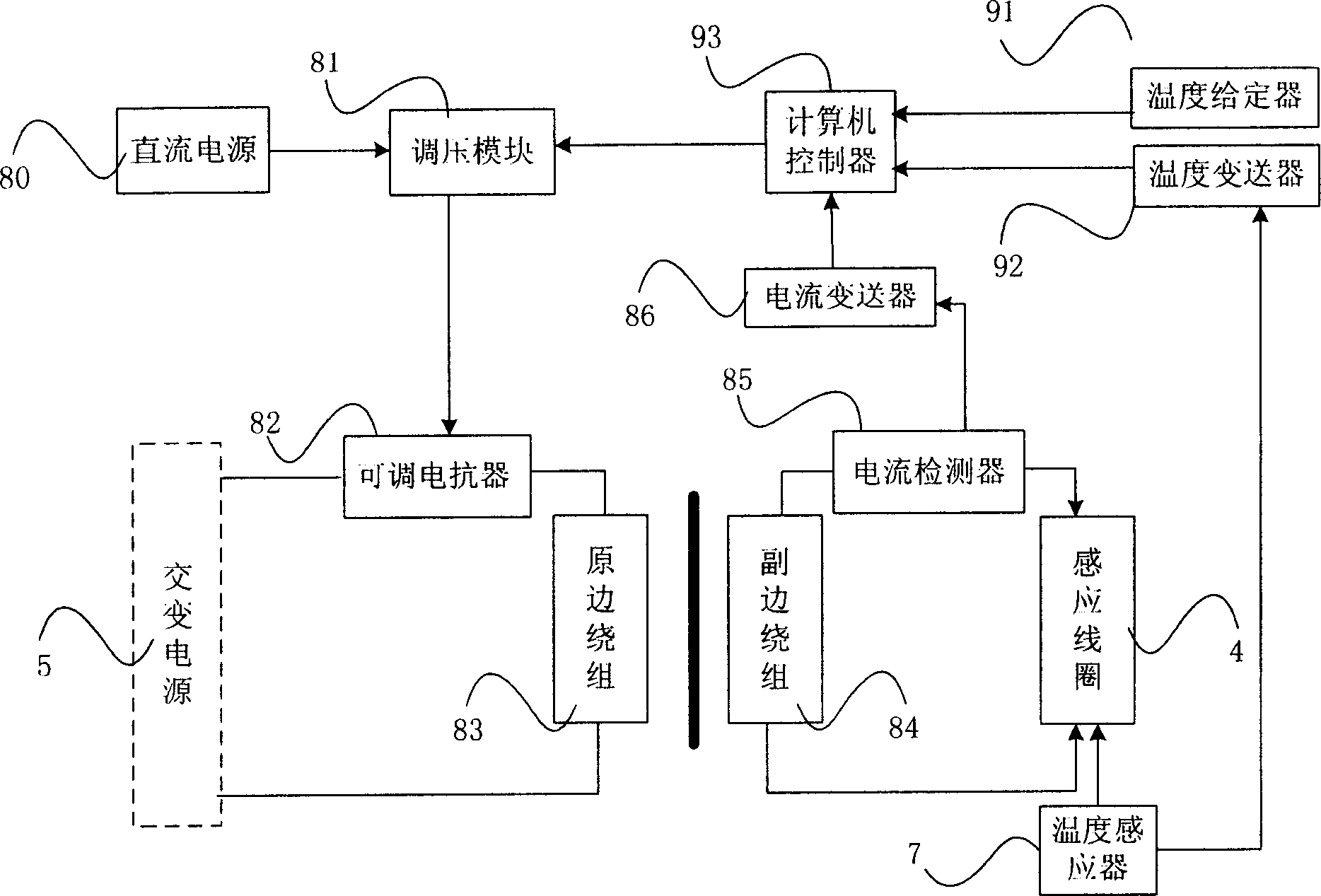

[0025] The present invention adopts the principle of electromagnetic induction heating to heat the oil transported in the heating pipeline from the inside, and the heating principle is as follows: after the alternating current is passed into the helical tubular induction coil, an alternating magnetic field will be generated in the coil, and the magnetic field The magnetic induction intensity is:

[0026] B = μ 2 nI ( cos β 1 - cos β 2 ) · · · ( 1 )

[0027] In the above formula (1), B is the magnetic induction at a certain point P inside the induction coil, μ is the magnetic permeability of the magnetic medium inside the induction coil, n is the number of turns of the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com