Infrared inhibiting device for smoke extraction of gas turbines of ships

A technology of gas turbine and infrared suppression, which is applied in the direction of exhaust device, turbine/propulsion device cooling, noise reduction device, etc. It can solve the problems affecting the internal flow field of the engine, many additional equipment, and takes up a large space, so as to achieve the effect of exhaust cooling Good, low impact, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

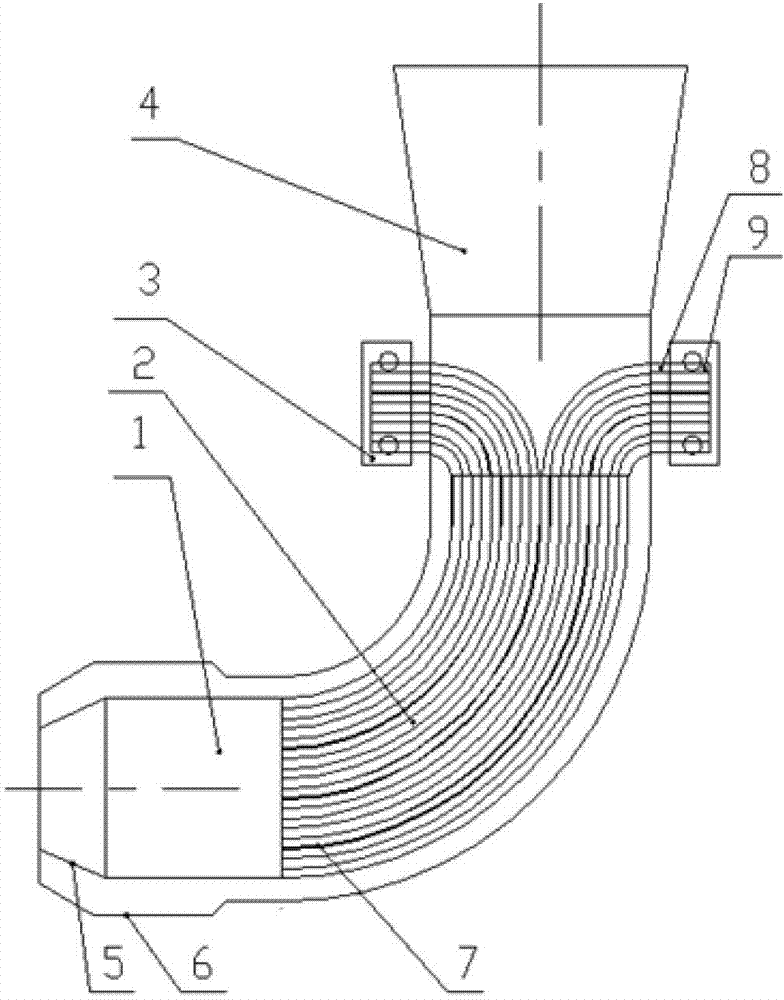

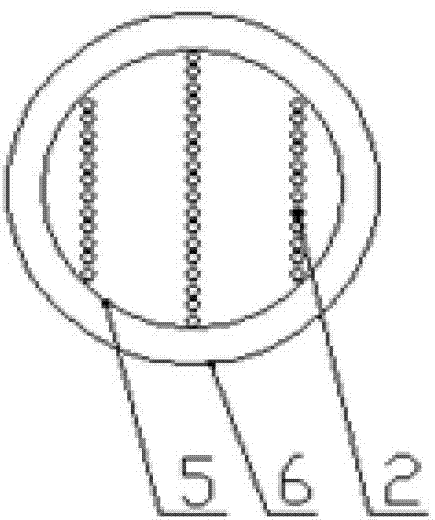

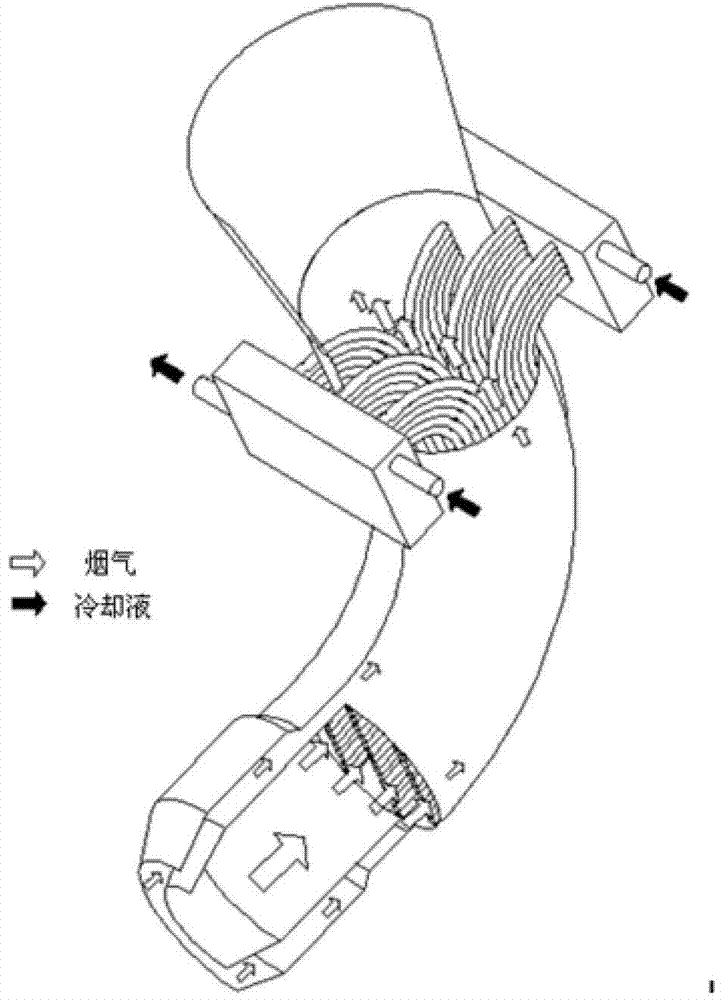

[0018] combine Figure 1~5 ,like figure 1 As shown, the smoke exhaust heat pipe suppression device of the present invention includes an exhaust straight bend pipe 1 , an exhaust diffuser pipe 4 , heat pipe rows 2 distributed in parallel and a cooling device 3 . The exhaust straight elbow 1 is a double-walled cylinder, which is formed by nesting the inner wall 5 and the outer wall 6, wherein the area surrounded by the inner wall 5 is the main flow area, and the area enclosed by the inner wall 5 and the outer wall 6 is the ejection area. At the corner of the exhaust straight elbow 1, there are heat pipes distributed in parallel in the main flow area. Each heat pipe in the pipe row 2 includes an evaporation section 7 with a special surface depression treatment, a transmission section 8, and a cooling device 3 for condensation. The condensation section 9. The heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com