SCR (Selective Catalytic Reduction) flue gas denitration device and flue gas denitration method

A technology for flue gas and denitrification, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems affecting the mixing distance of ammonia injection grids and denitrification efficiency, increase flue gas resistance, and poor injection rigidity, etc., to achieve Improve the mixing effect and denitrification efficiency, reduce the smoke resistance, and reduce the effect of mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

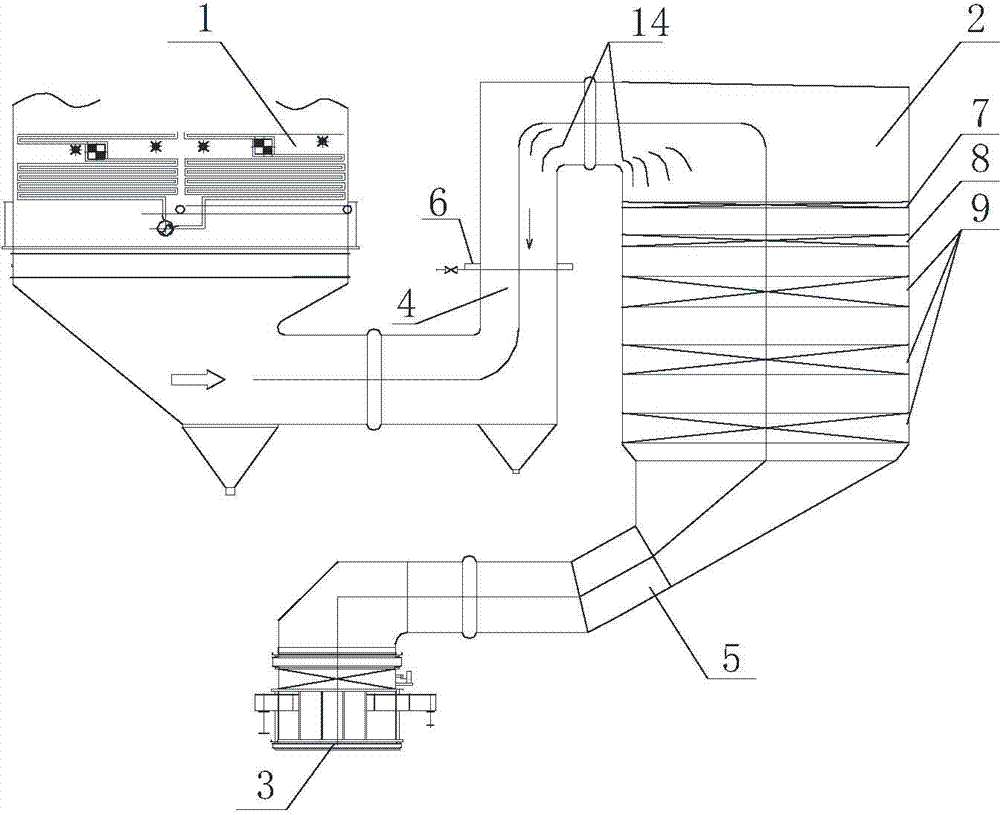

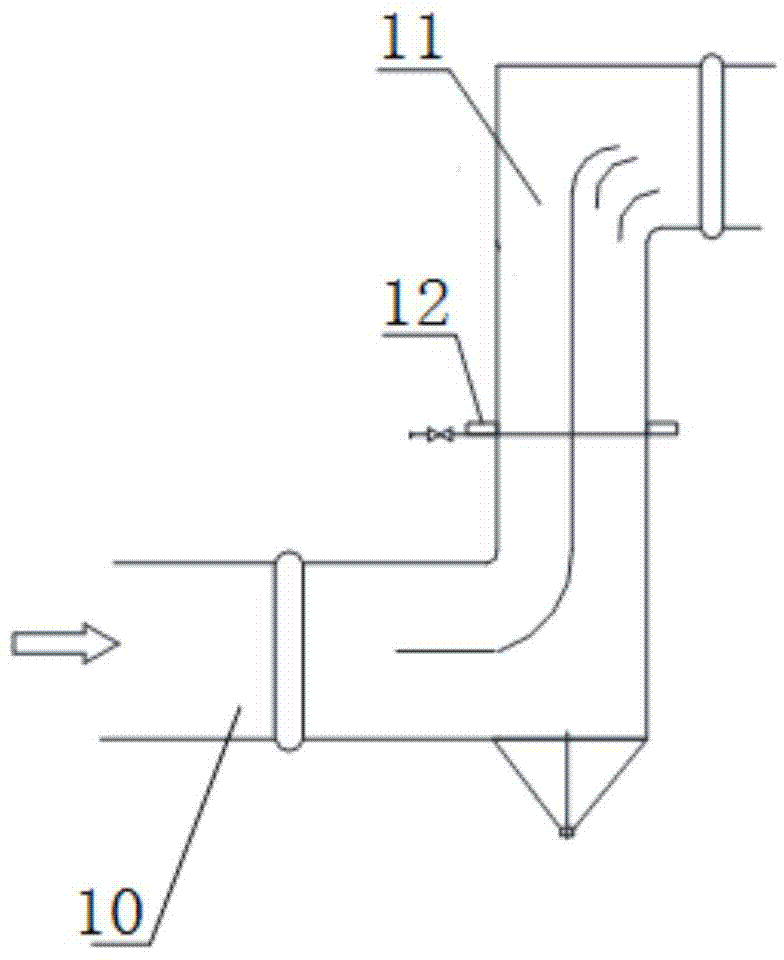

[0033] Embodiment 1 of the present invention: as figure 1 As shown, an SCR flue gas denitration device includes an economizer 1, a denitration reactor 2 and an air preheater 3. The bottom of the economizer 1 is connected to the top of the denitration reactor 2 through an inlet flue 4, and the denitration reaction The bottom of the device 2 is connected to the air preheater 3 through the outlet flue 5, the ammonia injection device 6 is installed in the inlet flue 4, and the ash crushing device 7, the rectifying layer 8 and the catalyst are installed in the denitrification reactor 2 from top to bottom. Layer 9.

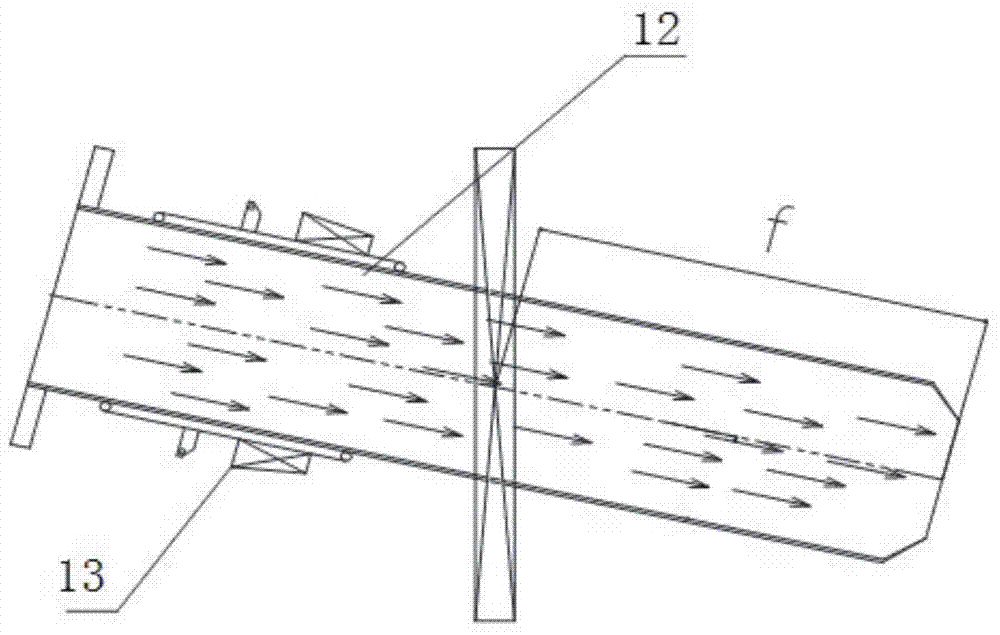

[0034] Such as figure 2 As shown, the ammonia injection device 6 includes a nozzle 12 and an angle adjustment baffle 13, the angle adjustment baffle 13 is installed on the nozzle 12, and the angle between the opening direction of the nozzle 12 and the flue gas flow direction is -60°~+60° °, the length f of the nozzle 12 deep into the inlet flue 4 is 0mm.

[0035] Su...

Embodiment 2

[0046] Embodiment 2 of the present invention: as figure 1As shown, an SCR flue gas denitration device includes an economizer 1, a denitration reactor 2 and an air preheater 3. The bottom of the economizer 1 is connected to the top of the denitration reactor 2 through an inlet flue 4, and the denitration reaction The bottom of the device 2 is connected to the air preheater 3 through the outlet flue 5, the ammonia injection device 6 is installed in the inlet flue 4, and the ash crushing device 7, the rectifying layer 8 and the catalyst are installed in the denitrification reactor 2 from top to bottom. Layer 9.

[0047] Such as figure 2 As shown, the ammonia injection device 6 includes a nozzle 12 and an angle adjustment baffle 13, the angle adjustment baffle 13 is installed on the nozzle 12, and the angle between the opening direction of the nozzle 12 and the flue gas flow direction is -60°~+60° °, the length f of the nozzle 12 deep into the inlet flue 4 is 250mm.

[0048] S...

Embodiment 3

[0059] Embodiment 3 of the present invention: as figure 1 As shown, an SCR flue gas denitration device includes an economizer 1, a denitration reactor 2 and an air preheater 3. The bottom of the economizer 1 is connected to the top of the denitration reactor 2 through an inlet flue 4, and the denitration reaction The bottom of the device 2 is connected to the air preheater 3 through the outlet flue 5, the ammonia injection device 6 is installed in the inlet flue 4, and the ash crushing device 7, the rectifying layer 8 and the catalyst are installed in the denitrification reactor 2 from top to bottom. Layer 9.

[0060] Such as figure 2 As shown, the ammonia injection device 6 includes a nozzle 12 and an angle adjustment baffle 13, the angle adjustment baffle 13 is installed on the nozzle 12, and the angle between the opening direction of the nozzle 12 and the flue gas flow direction is -60°~+60° °, the length f of the nozzle 12 deep into the inlet flue 4 is 500mm.

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com