Resistance measurement method for transmission pull strip of coke oven reversing machine

A coke oven reversing machine and measurement method technology, applied in the field of coke oven technology, can solve problems such as increase, change of exchange stroke, deformation of oil cylinder foundation, etc., and achieve the effect of simple operation, easy promotion, and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

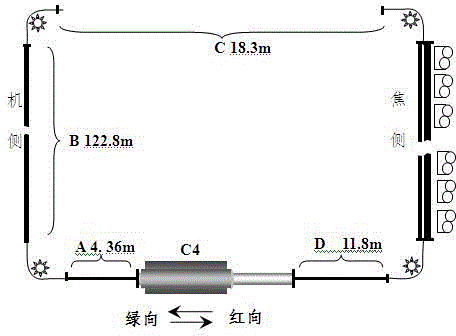

[0030] Example: figure 1 As shown, the 7# coke oven of Taiyuan Iron and Steel Coking Plant adopted the following steps to measure the resistance of the rods in March 2011:

[0031] 1. Collect the original data of the lengths of the 4 transmission rods A, B, C, and D of the exchange transmission system of the 7# furnace respectively. The original data of the length is the length of the 4 transmission rods when they leave the factory. Among them, the length of A is 4.36 meters; the length of B is 122.8 meters; the length of C is 18.3 meters; the length of D is 11.8 meters; L=4.36 meters+122.8 meters+18.3 meters+11.8 meters=157.26 meters;

[0032] 2. Determine the reference point: that is, mark the two end positions of each tie rod under the condition of no force;

[0033] 3. When the green direction is heated, after turning from the red direction to the green direction, the D tie bar is in a stressed state, and the position of the two ends of the D tie bar is measured;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com