Patents

Literature

45results about How to "Reduce investment in environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

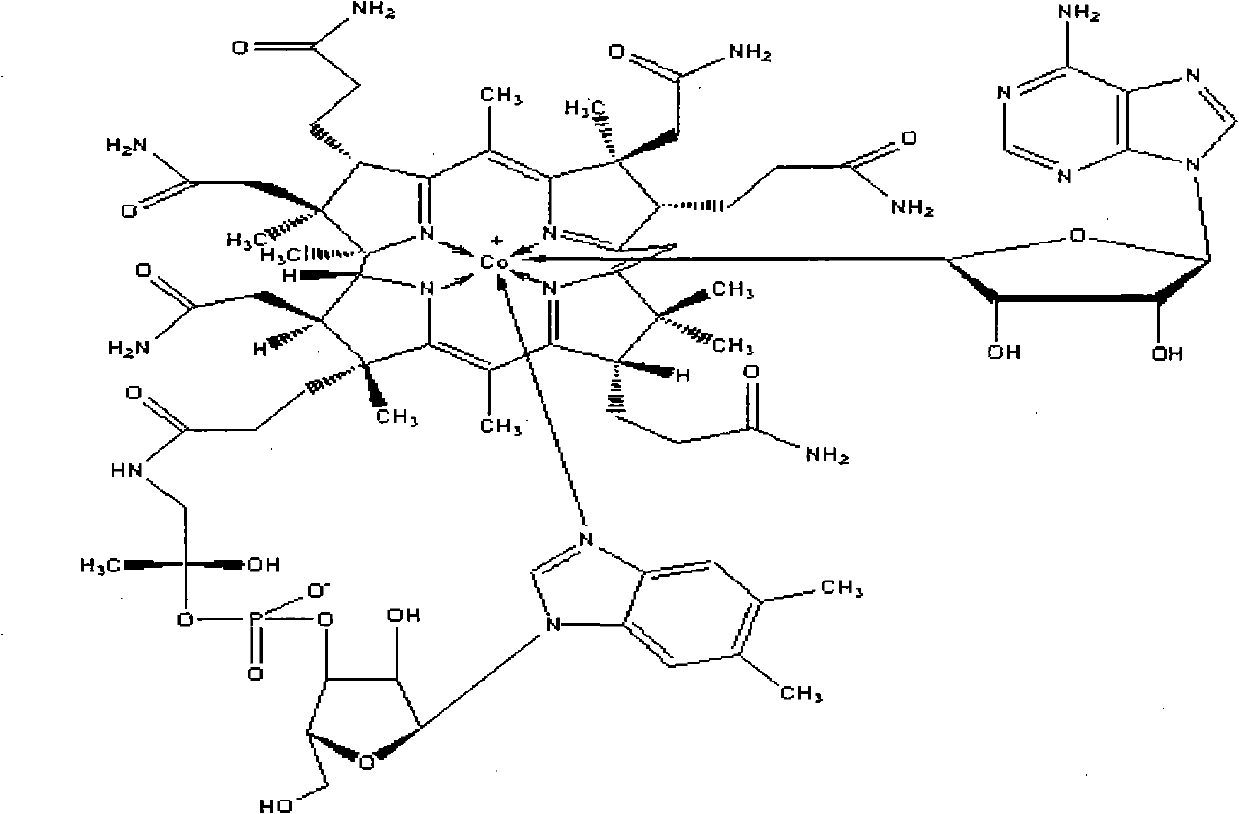

Method for extracting cobamamide

ActiveCN101948494APromote flocculationAdd concentration and purification stepsSugar derivativesSugar derivatives preparationDesorptionVitamin B12

The invention relates to a method for preparing cobamamide. The method comprises the following steps of: a, taking vitamin B 12 fermentation solution, and hydrolyzing and filtering under the light-resistant condition; b, adsorbing filter liquor by using a macroporous resin column, and washing and desorbing to obtain primary desorption solution; c, evaporating and concentrating the primary desorption solution to obtain concentrated solution; d, adding a flocculating agent into the concentrated solution for filtering to obtain purification solution; e, adsorbing the purification solution by using a chromatographic resin column, and developing and desorbing to obtain secondary desorption solution; f, adsorbing the secondary desorption solution by using an aluminum oxide column, and developing and desorbing to obtain crystallizing stock solution; and g, adding acetone into the crystallizing stock solution with stirring for crystallizing, and filtering and drying to obtain a finished product. The impurity content of a product obtained by the method is below 1.0 percent, the cobamamide content is over 98.0 percent, the yield of the product is over 50 percent, and the total yield of vitamin B 12 is over 80 percent. The method has the characteristics of simplicity, convenience, easy operation, high extraction yield, high purity of the product and low production cost.

Owner:HEBEI HUARONG PHARMA

Energy-saving and high-efficiency rare earth ore concentrate sulfuric acid stepped roasting method

InactiveCN104561539AGuaranteed liquidityReduce unit consumptionProcess efficiency improvementHydrofluoric acidWater vapor

The invention relates to an energy-saving and high-efficiency rare earth ore concentrate sulfuric acid stepped roasting method, and belongs to the technical field of wet metallurgy and thermometallurgy. The energy-saving and high-efficiency rare earth ore concentrate sulfuric acid stepped roasting method comprises the following steps: mixing rare earth ore concentrate with sulfuric acid with the mass concentration of more than or equal to 92.5% according to weight ratio of 1 : (1.0-1.3); pelletizing, and charging particles into a first-section roasting kiln to roast, so that fluorine ions and water in the rare earth ore concentrate are completely volatilized; condensing the gasified fluorine ions and water, recovering hydrofluoric acid, roasting defluorinated dry ore particles, and charging the roasted particles into a second-section roasting kiln to separate; washing and absorbing separated sulfuric acid gas during roasting, recovering sulfuric acid, and directly leaching roasted ores to obtain a sulfuric acid rare earth solution. According to the energy-saving and high-efficiency rare earth ore concentrate sulfuric acid stepped roasting method, after the stepped roasting process is utilized, waste gas generated in pelletizing step is water vapor and can be directly discharged; compared with the prior art, the stepped roasting method has the advantages that a waste gas washing and absorbing system is reduced to more than 70% and the environmental protection input is reduced to more than 80%.

Owner:包头市锦园化工科技有限公司

Method for preparing 4-aminophenyl-beta-hydroxyethyl sulfone sulfate

InactiveCN101255128AReduce productionEasy to handleOrganic chemistryOrganic compound preparationChlorosulfuric acidNitrobenzene

The invention relates to a preparation method for 4-(beta-sulfatoethyl sulfone sulfonyl) aniline, and relates to a preparation method for a sulfuric ester. The invention solves the problems that chlorosulfonic acid is greatly overused and environmental protection cost is high in the preparation process of para-ester at present. The preparation method of the invention comprises: condensing nitro halogeno benzene and beta-mercaptoethanol to produce 4-(beta-sulfatoethyl sulfone sulfide) nitrobenzene, adding hydrogen peroxide in aqueous medium after separating out dissolvent, water and salts to produce 4-nitrobenz-beta-hydroxyethyl sulfone by catalytic oxidation, deoxidizing nitro of 4-nitrobenz-beta-hydroxyethyl sulfone to be amino by catalytic hydrogenation reaction, and homogeneously esterifying with sulfuric acid to obtain the product. The method does not use chlorosulfonic acid, generation amount of waste waters is little and easy to treat, by-product is few and easy to separate. The purity of the product is high, the amino number and ester number are higher than 97. 0and 95. 0respectively, the difference between the two number is less than 2, and the product has light color and pure tint.

Owner:HEILONGJIANG INST OF PETROCHEM

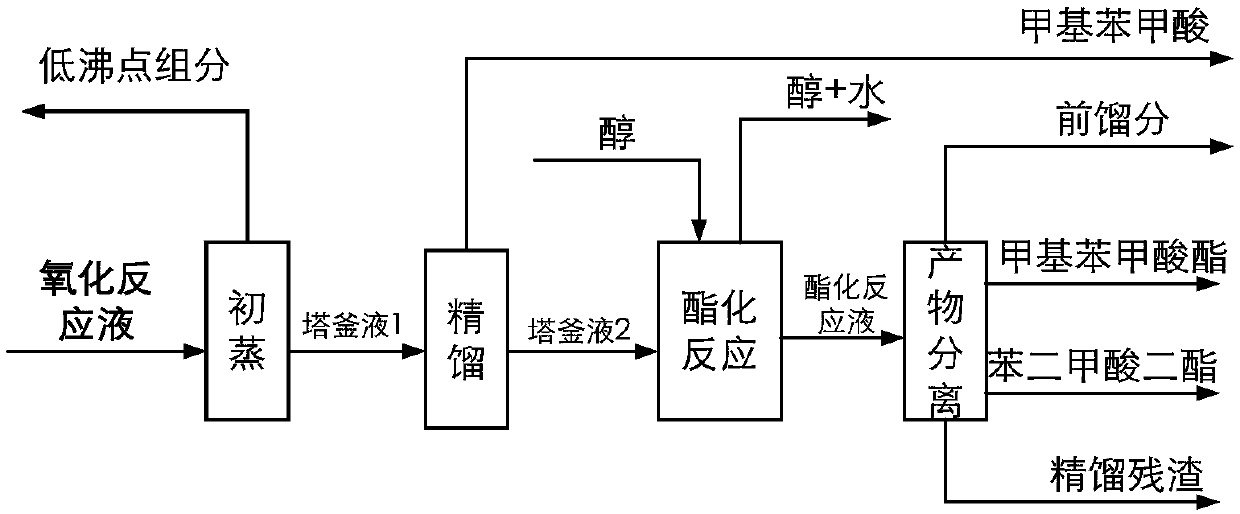

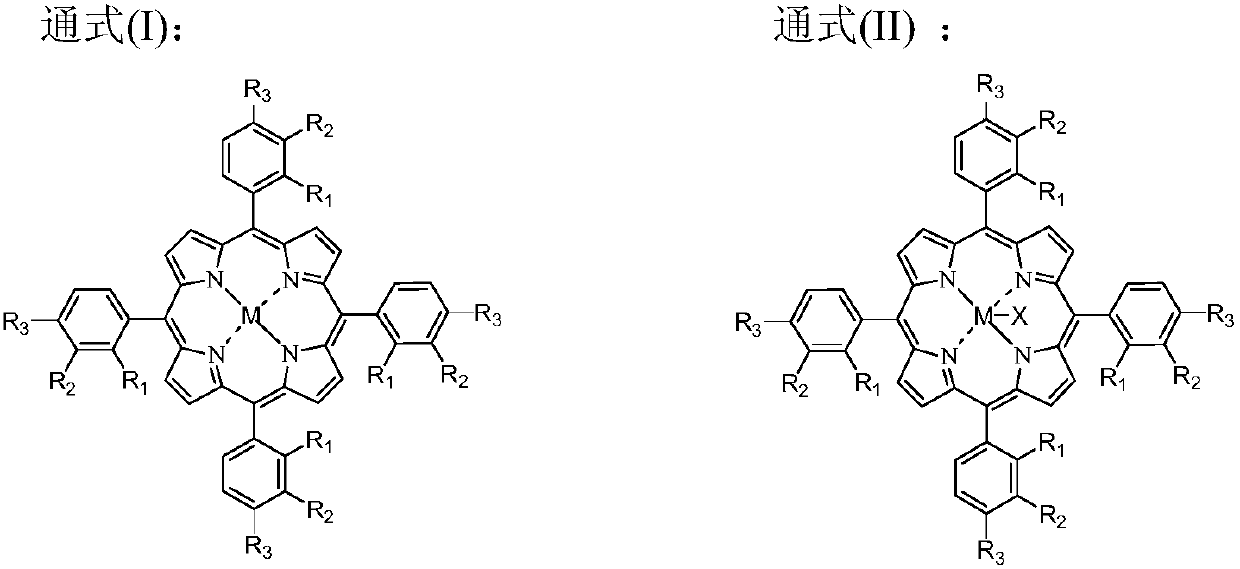

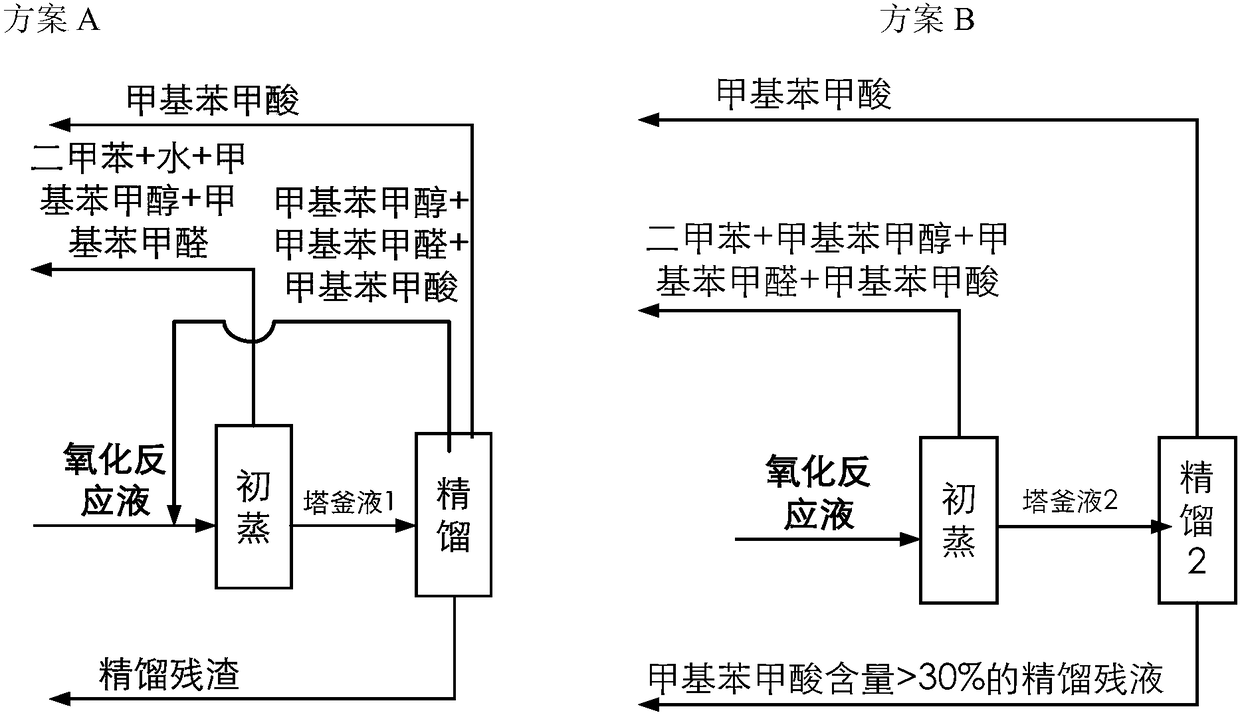

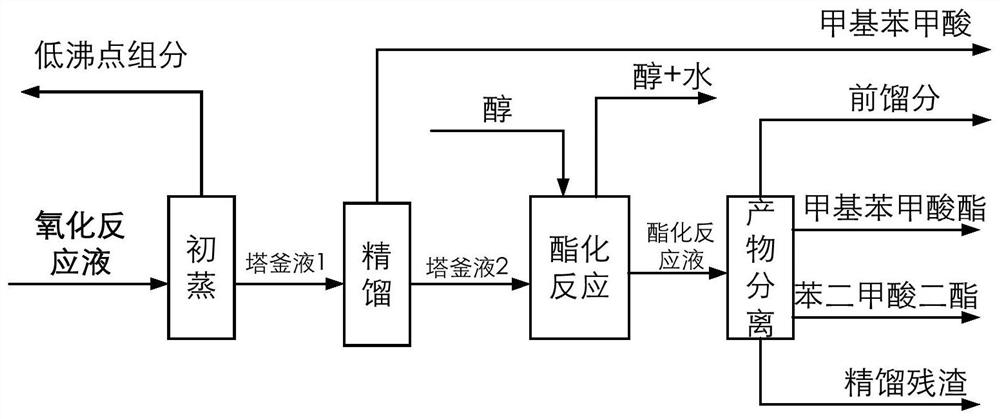

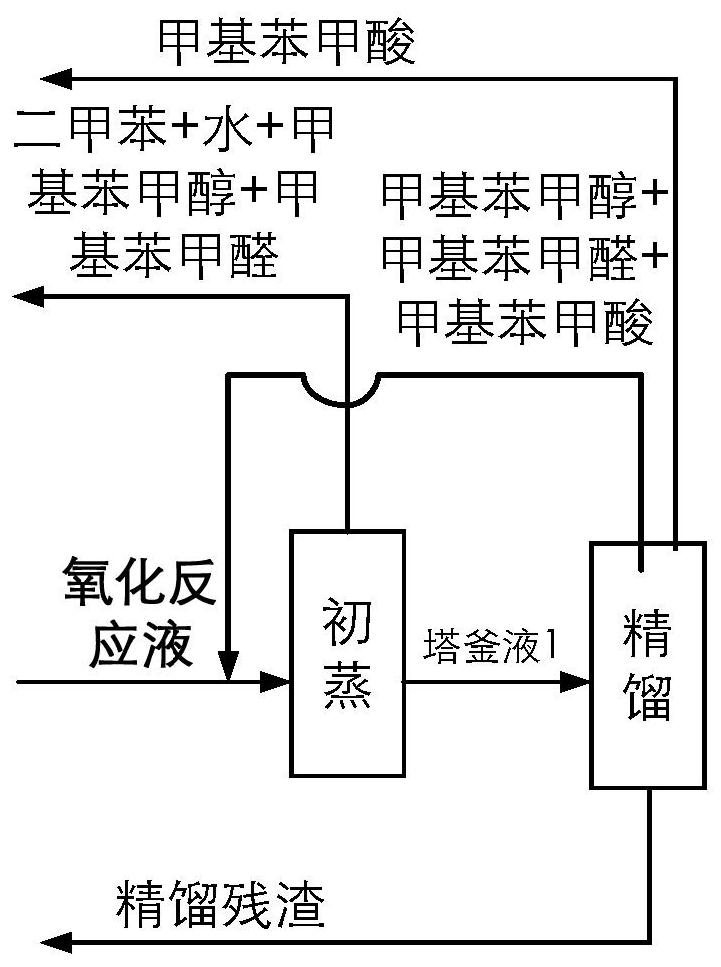

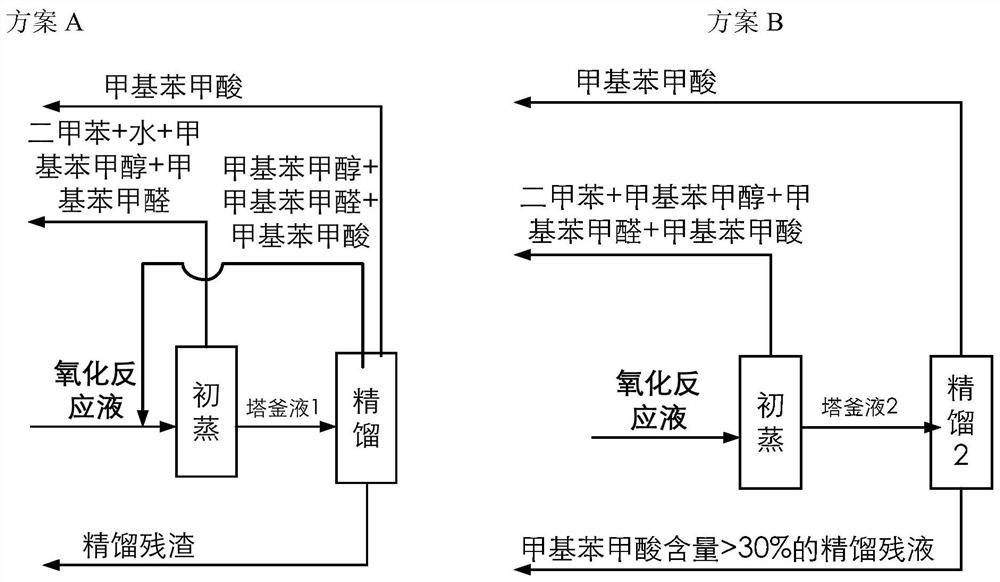

Coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester

ActiveCN108047034ARaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

The invention discloses a coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester. The method comprises the following steps: (1) continuously introducing xylene, a catalyst and oxygen-containing gas into an oxidation reactor for a reaction, and controlling oxygenic concentration in the tail gas to not exceed 5% by controlling introduction amount of the oxygen-containing gas to obtain an oxidation reaction liquid; (2) feeding the obtained oxidation reaction liquid into a predistillation tower for distillation separation to obtain a low-boiling-point component and a predistillation tower bottom liquid; (3) feeding the predistillation tower bottom liquid into a distillation tower for distillation to obtain a methylbenzoic acid product and a distillationtower bottom liquid; (4) mixing the distillation tower bottom liquid and alcohol for an esterification reaction, and controlling the reaction endpoint to be lower than 0.5wt% of the content of methylbenzoic acid to obtain an esterification reaction liquid; (5) performing distillation separation on the obtained esterification reaction liquid to obtain methyl benzoate and benzenedicarboxylic acid diester products. The method has the advantages that the process is simple, equipment investment is low, and the method is environmentally friendly and has good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

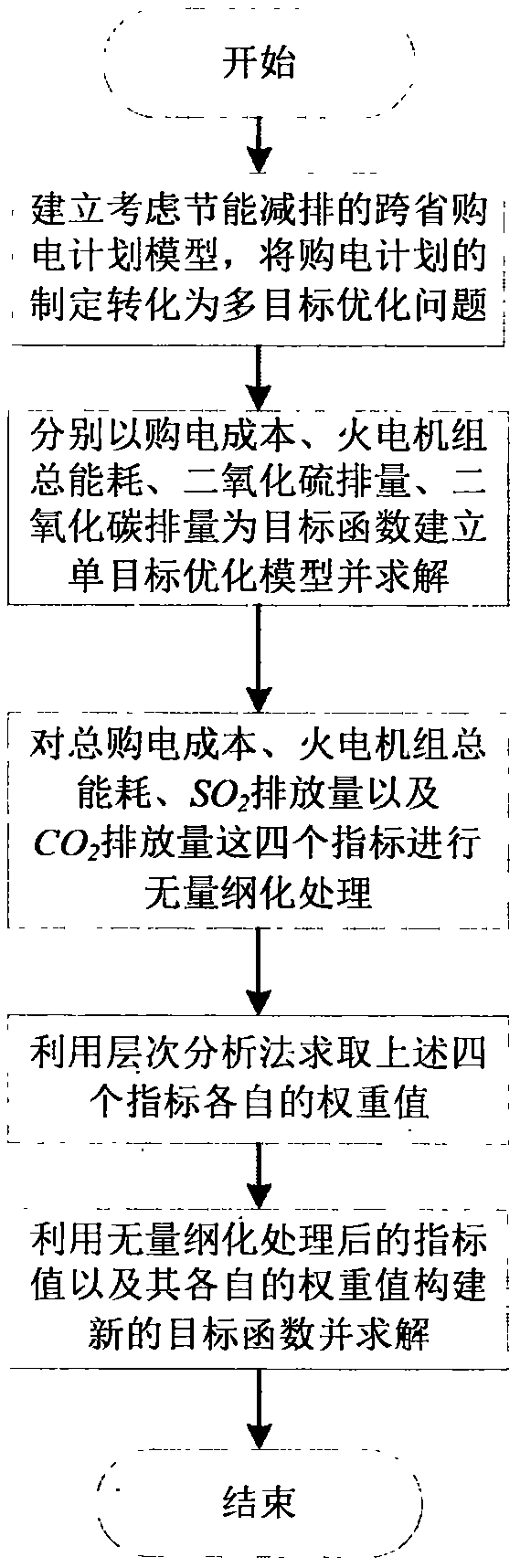

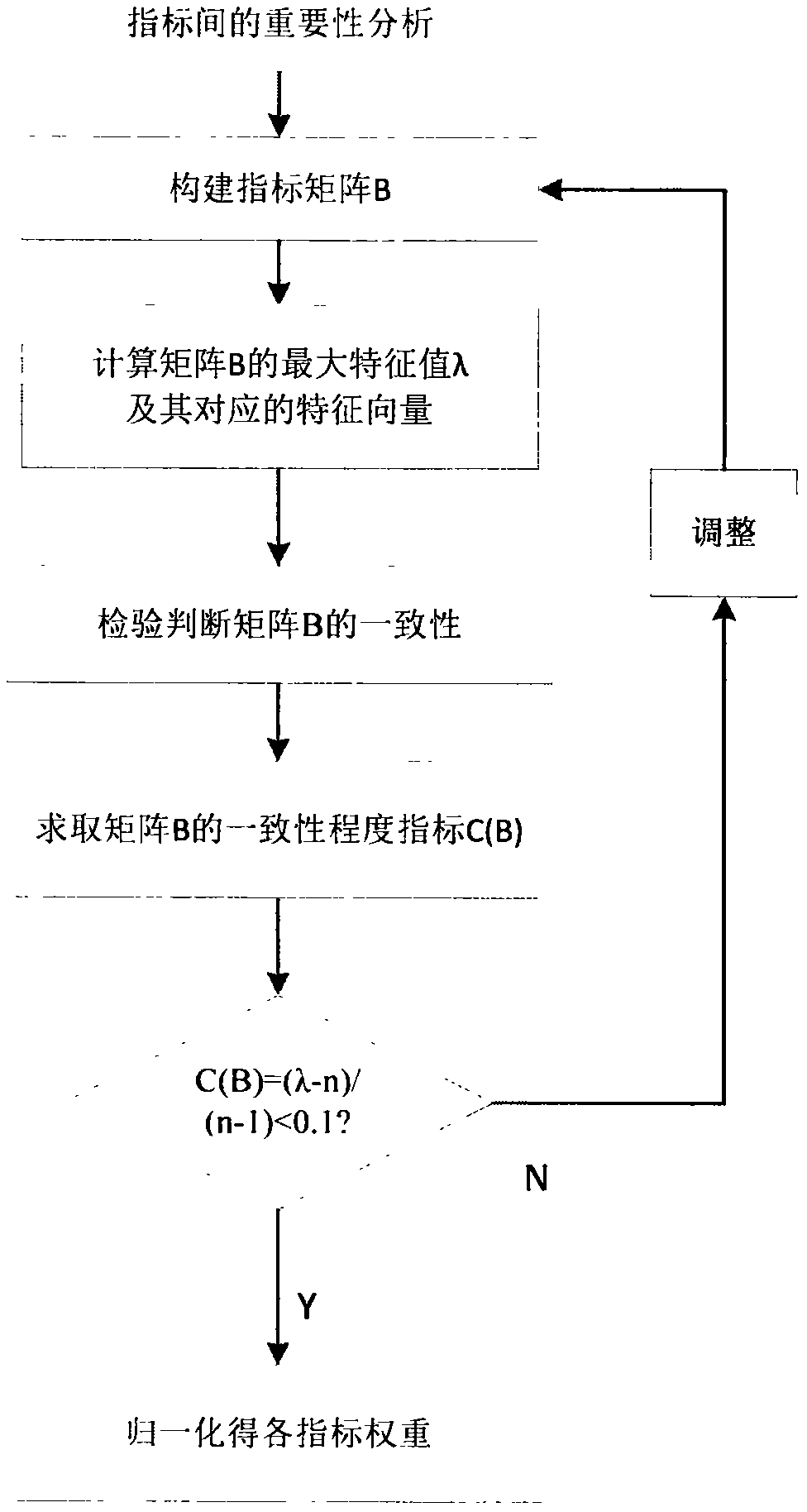

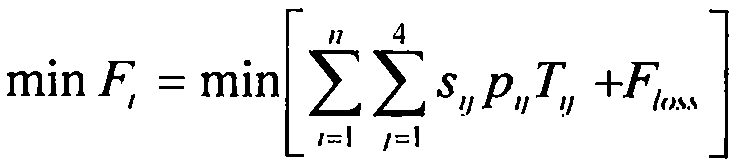

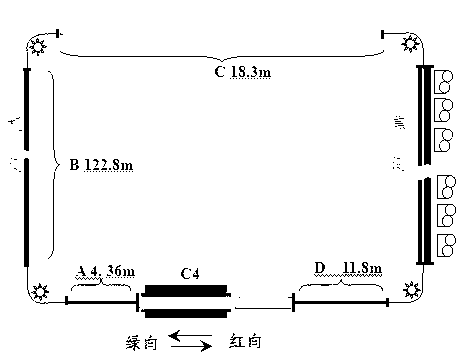

Inter-provincial power purchase plan arrangement method taking regard of energy saving and emission reduction

InactiveCN107784373AReduce electricity purchase costReduce investment in environmental protectionForecastingTechnology managementSingle objective optimization problemPollution

The invention provides an inter-provincial power purchase plan arrangement method taking regard of energy saving and emission reduction. The method comprises steps that I, a multi-target power purchase model comprehensively taking regard of the least total power purchase cost, the least total energy consumption of a thermal power set, the least SO2 emissions and the least CO2 emissions is established; II, single-target power purchase models respectively taking regard of the least total power purchase cost, the least total energy consumption of the thermal power set, the least SO2 emissions andthe least CO2 emissions are established and solved; III, dimensionless processing is carried out based on the four indexes; IV, a weighted value of each index is determined according to actual conditions; and V, the index values after dimensionless processing and the respective weighted value are utilized to establish a target function, a multi-target optimization problem is converted into a single-target optimization problem, the particle swarm optimization algorithm is further utilized for solution, and an inter-provincial power purchase plan taking regard of energy saving and emission reduction is made. The method is advantaged in that for the made inter-provincial power purchase plan, energy consumption of the thermal power set and pollution gas emission are reduced on the condition that the power purchase cost can be reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for efficient utilizing wastes from brewage industry

InactiveCN1562897ASolve pollutionReduce investment in environmental protectionBio-organic fraction processingSolid waste disposalWastewaterIrrigation water

The treatment method for brew waste residue including solid-fluid separating, aerobic fermenting, heating drying, mixing endoplasm and prilling forming to produce fertilizer and adjusting temp. fermenting and chemical mixing endoplasm to provide field irrigation water.

Owner:李善宽

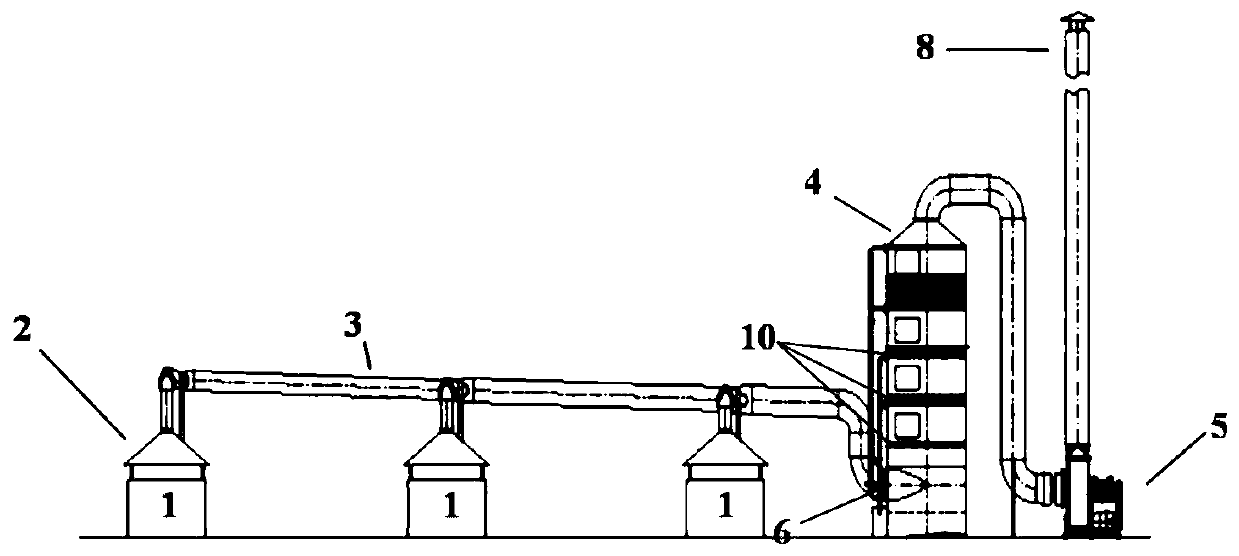

A method for treating distillers' grain waste gas of a Baijiu factory

PendingCN109966867AEfficient removalEasy to handleGas treatmentWater contaminantsEnvironmental resistanceWastewater

A method for treating distillers' grain waste gas of a Baijiu factory is disclosed. The method is characterized in that: a waste gas collecting cover is mounted above a steamer pot and / or waste grainstacking tank to collect waste gas; the waste gas is conveyed into a rotational flow plate-type spraying washing column and subjected to atomized water spraying adsorption treatment; washing wastewater is centralized to a wastewater treatment station for treatment and for cyclic use; and waste gas is then discharged in high altitude. According to the method, distillers' grain gas generated is firstly collected from the source and is treated for removal, and the organic matter removal rate is not less than 90%, thus effectively reducing environment influences caused by distillers' grain waste gas, reducing the risk of environment pollution and facilitating promotion in the Baijiu industry.

Owner:ANHUI XUANJIU GRP

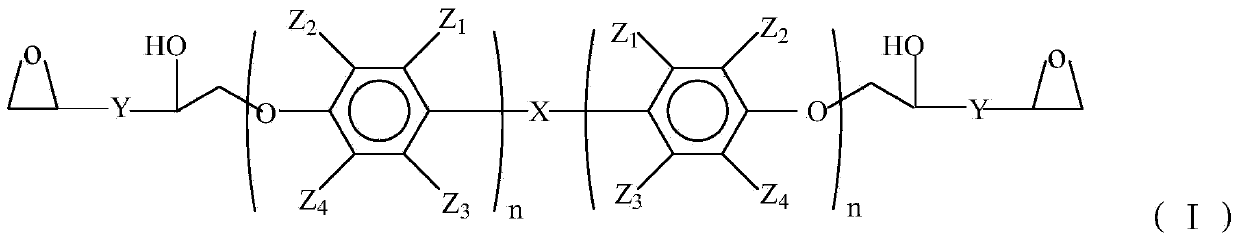

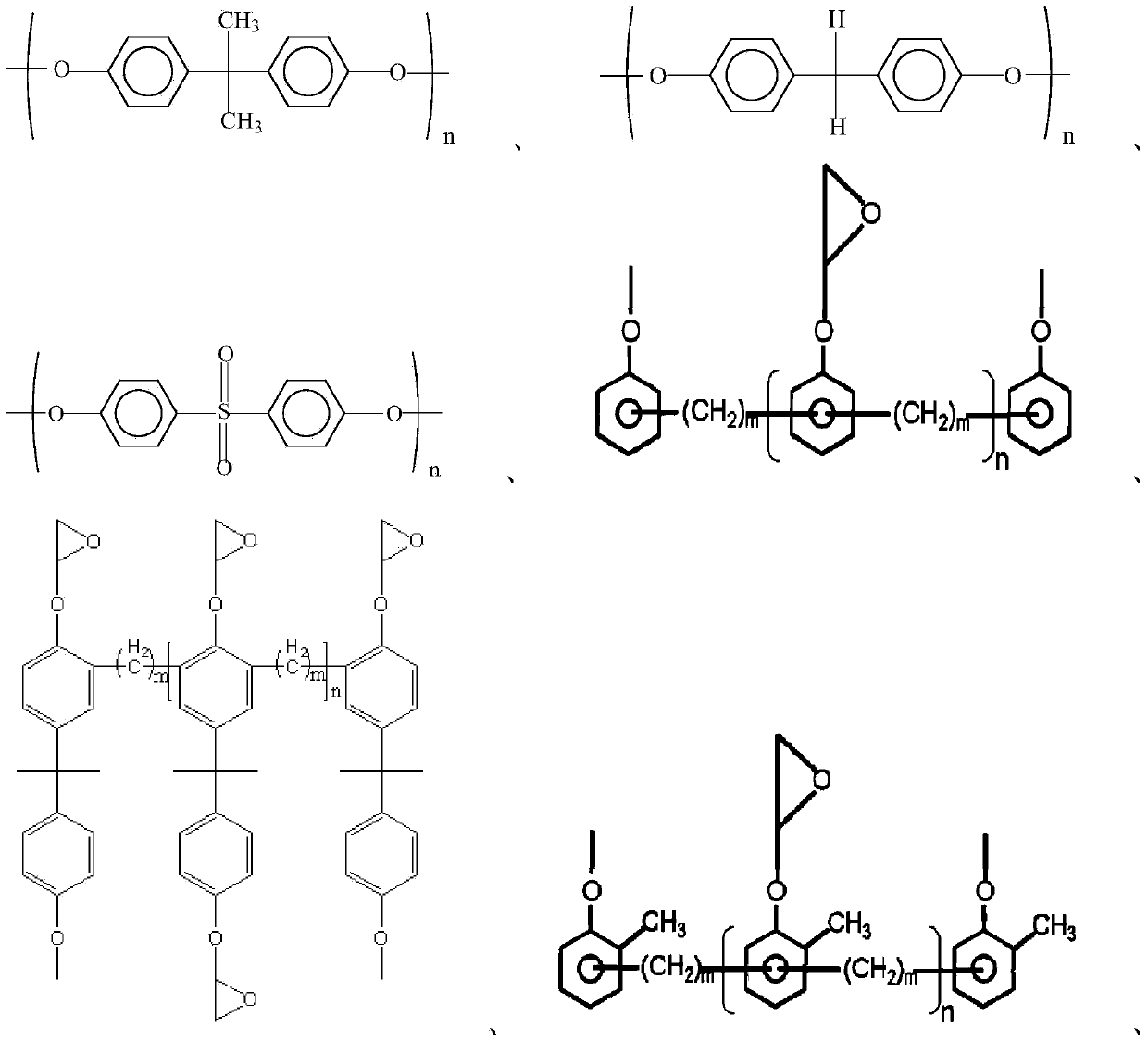

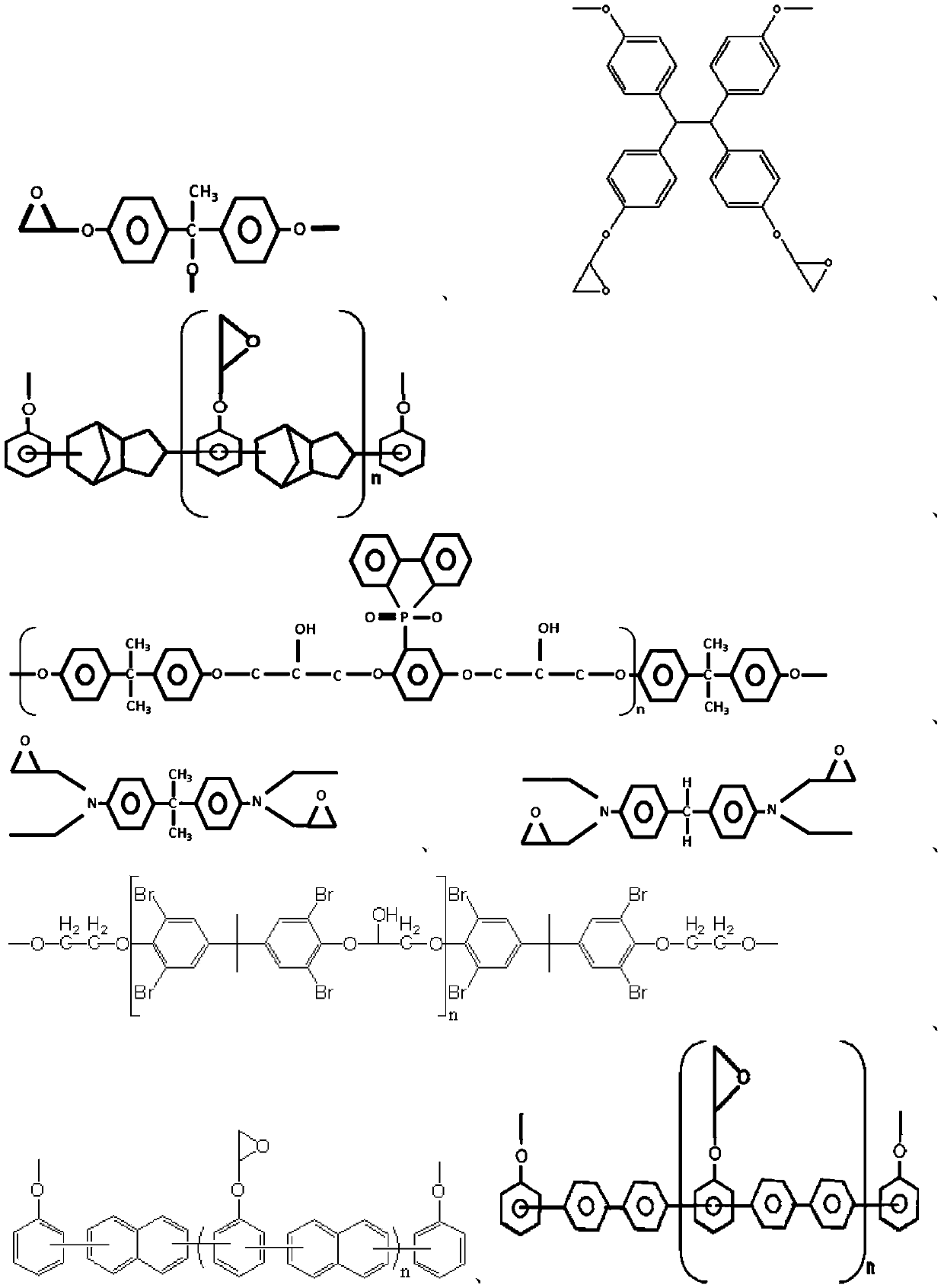

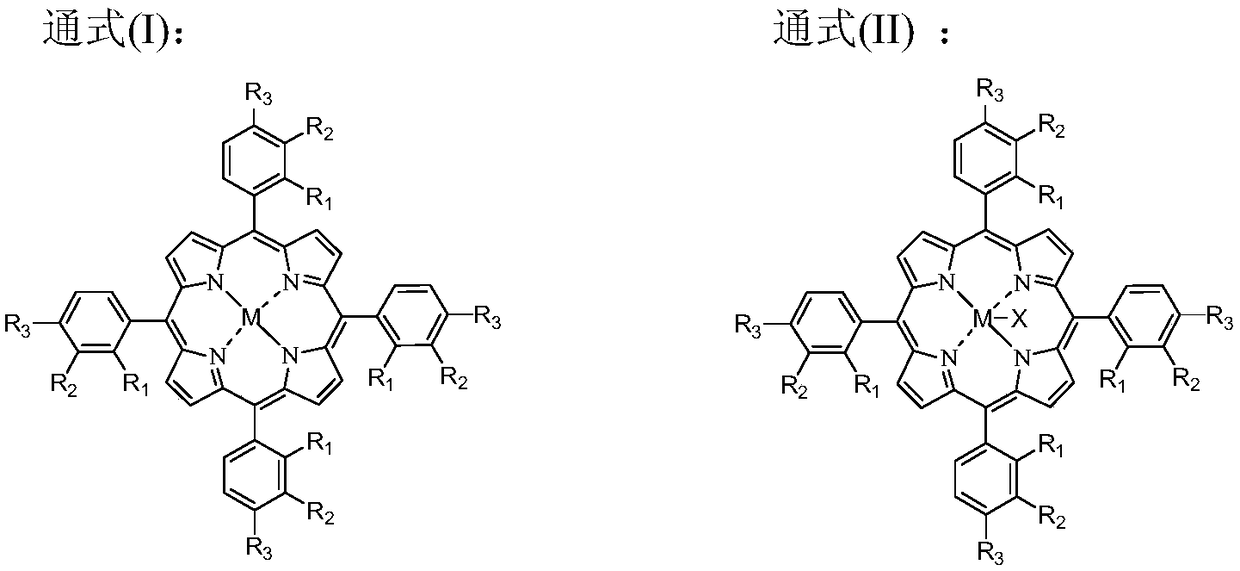

Epoxy modified polyphenylene ether resin, resin composition and its application

ActiveCN102516530BHigh investment in environmental protectionReduce investment in environmental protectionPrinted circuit aspectsCircuit susbtrate materialsEpoxyGlass fiber

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

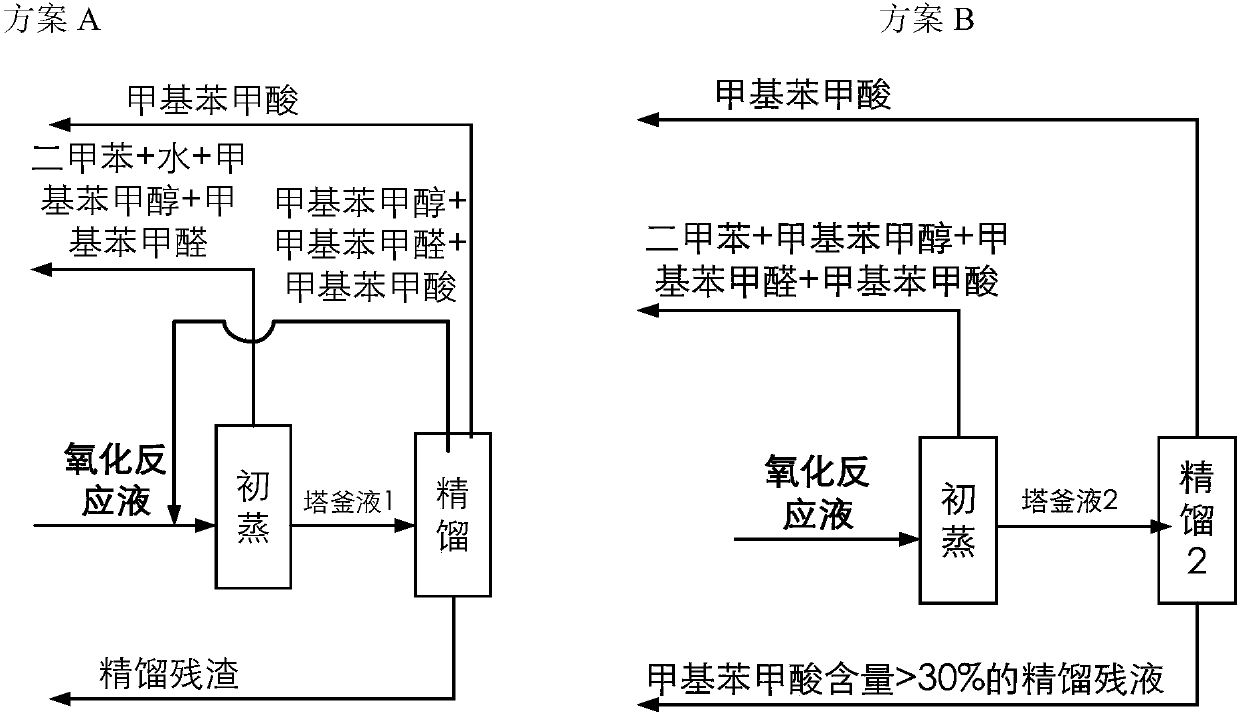

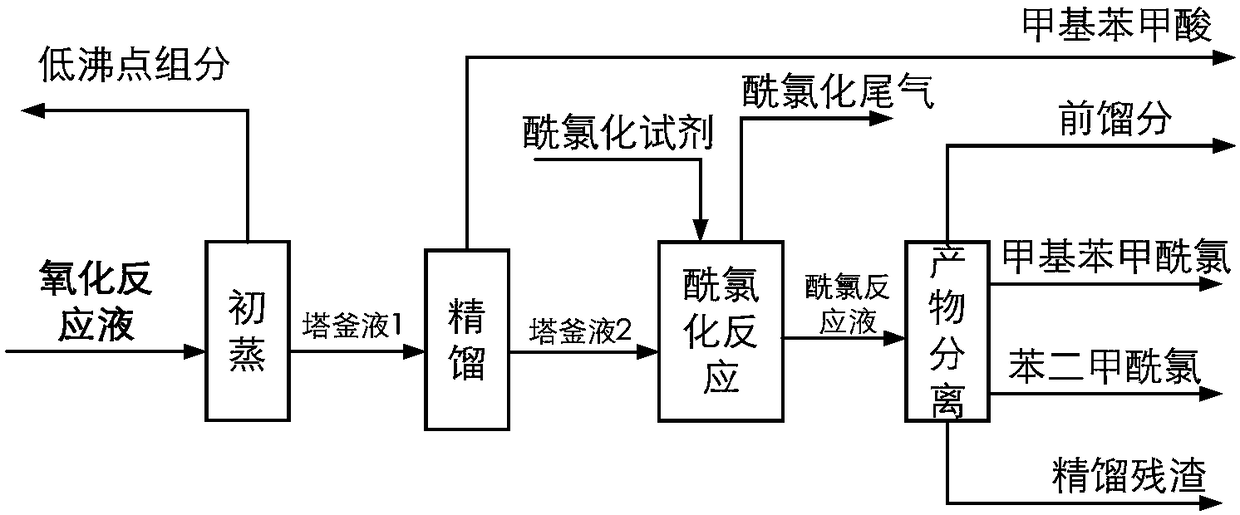

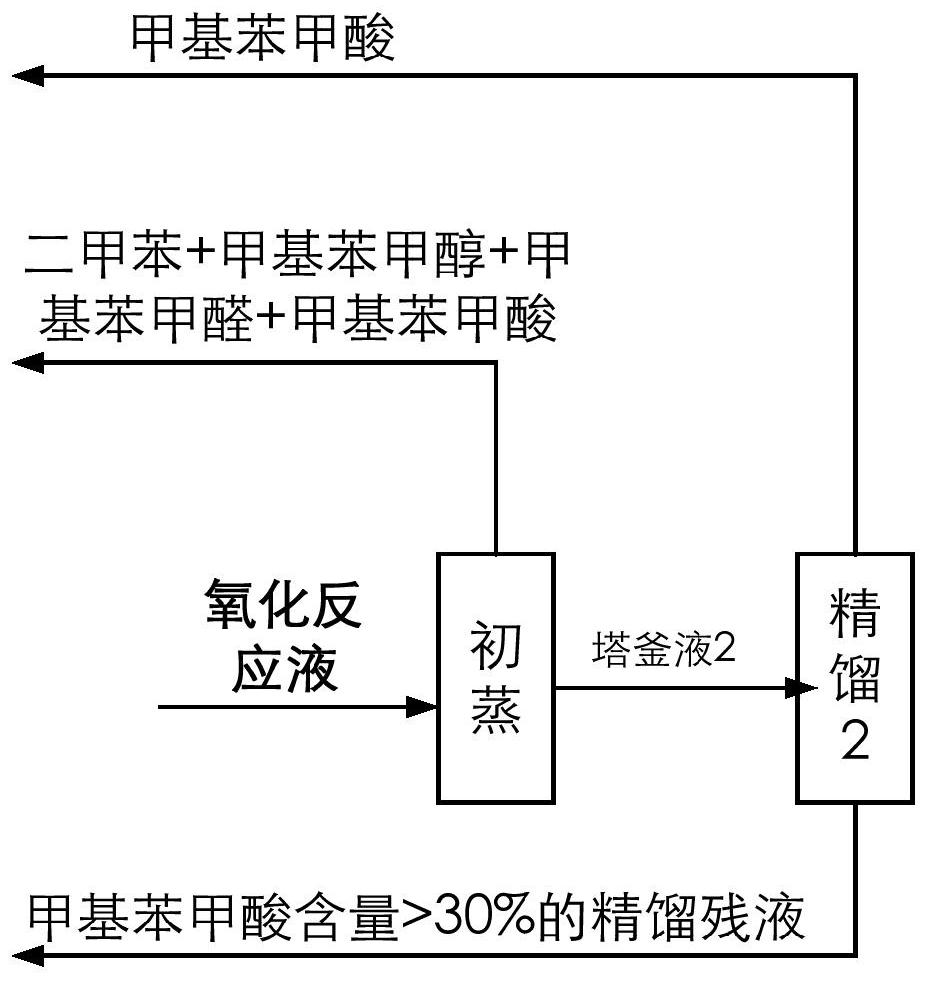

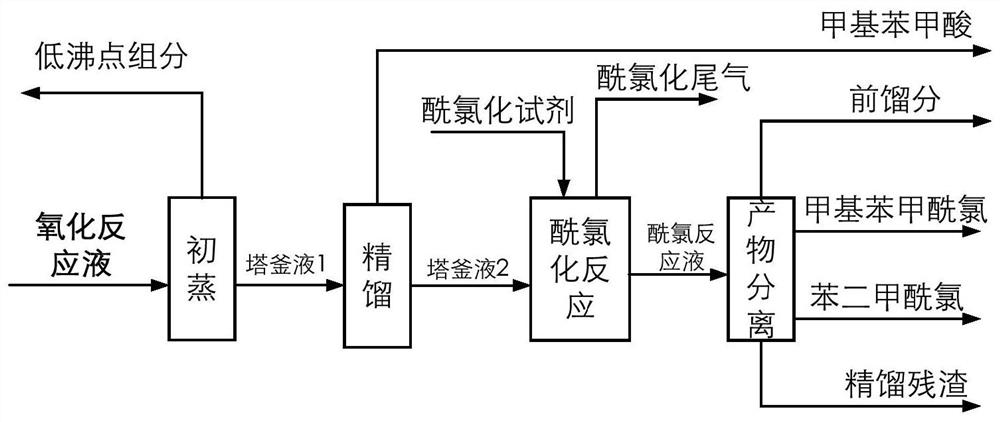

Method of co-producing methyl benzoic acid, methylbenzoyl chloride and phthaloyl dichloride

ActiveCN108117486ALow resolutionSolve the large amount of solid wasteOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidBoiling point

The invention discloses a method of co-producing methyl benzoic acid, methylbenzoyl chloride and phthaloyl dichloride. The method comprises the following steps: (1) continuously introducing xylene, acatalyst and oxygen-containing gas into an oxidizing reactor to react to obtain an oxidized reaction solution; (2) rectifying and separating the oxidized reaction solution to obtain a low-boiling-point component and an initial evaporative tower bottom; (3) rectifying the initial evaporative tower bottom to obtain a methyl benzoic acid product and a tower bottom; (4) carrying out an acylating chlorination reaction on the tower bottom and an acylating chlorination reagent to obtain an acyl chloride reaction solution; and (5) rectifying and separating the acyl chloride reaction solution to separately obtain methylbenzoyl chloride and phthaloyl dichloride products. The method provided by the invention has the advantages of being simple in process, small in equipment investment, green and environment-friendly and good in comprehensive economical benefit.

Owner:JIANGXI KEYUAN BIOPHARM

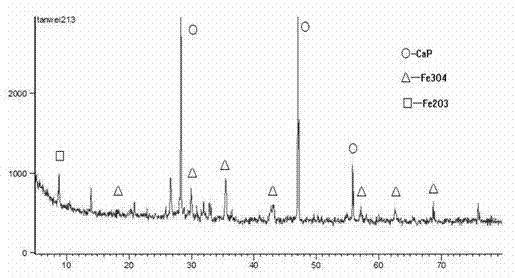

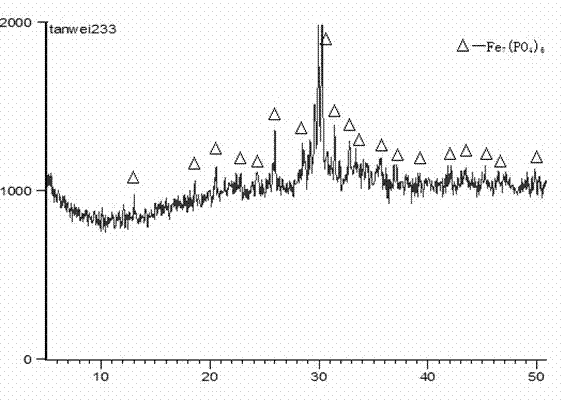

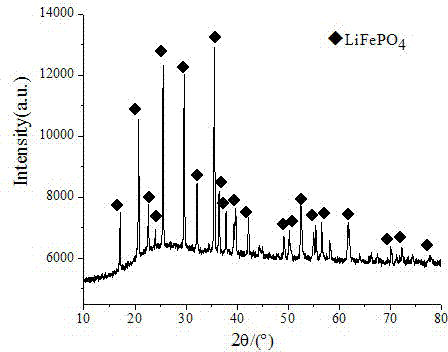

Method for preparing cathode material-lithium iron phosphate of lithium ion battery by utilizing steel slag

InactiveCN103094579ALow costPromote development and utilizationCell electrodesElectrical batterySlag

The invention relates to a method for preparing a cathode material-lithium iron phosphate of a lithium ion battery by utilizing steel slag. The method comprises the steps as follows: mixing the steel slag with a water-soluble carbon source compound water solution, and carrying out microwave heat treatment, reduction and magnetic separation to obtain a steel slag extract; reacting the steel slag extract with a mixed solution of diluted sulfuric acid, hydrogen peroxide and phosphoric acid, and extracting to obtain a calcium-free steel slag filter cake; adding lithium carbonate and the water-soluble carbon source compound water solution into the filter cake to obtain a precursor; and carrying out microwave sintering on the precursor to obtain the cathode material-lithium iron phosphate. Part of conventional raw materials are replaced with the steel slag as raw materials, so that the cost can be reduced by more than 30% and the obtained product is good in cycle performance; the conventional processes of ball-milling, drying and the like are removed, so that the process and the control operation are simple, inert gas does not need to be used in the sintering process, harmful gas such as nitrogen oxide and the like is not generated, the pollution is avoided, and the environment is protected; and the method is widely suitable for industrial production.

Owner:郑州德朗能电池有限公司

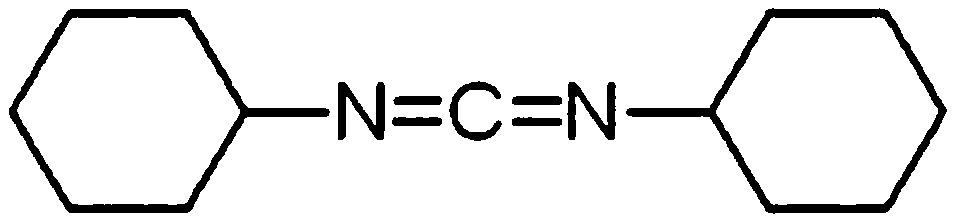

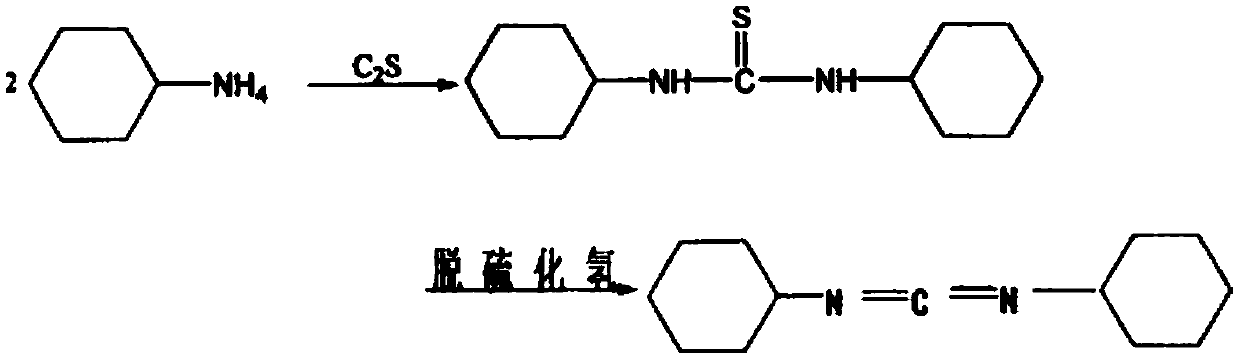

Method for reducing waste residues of N,N'-dicyclohexylcarbodiimide product

The invention discloses a method for reducing waste residues of an N,N'-dicyclohexylcarbodiimide product. The method comprises the following steps: adding potassium carbonate or sodium carbonate intoa crude DCC product in a solvent-free state, controlling a temperature to be 100-120 DEG C, carrying out stirring for 1 hour, controlling a pressure to be less than -0.09 MPa, and performing distilling to obtain qualified DCC. Potassium carbonate or sodium carbonate is added to increase the pH value of a reaction system, and potassium carbonate and sodium carbonate do not react with the product, so the stability of N,N'-dicyclohexylcarbodiimide is facilitated, and the N,N'-dicyclohexylcarbodiimide is prevented from being decomposed at a high temperature; the amount of waste residues produced after DCC distillation can be reduced by 50% and is 1% or less of the mass of the crude DCC product, so environmental protection investment is greatly reduced; the method is simple and reliable to control, and production cost is reduced; and meanwhile, aspotassium carbonate or sodium carbonate is used as a catalyst, the product becomes transparent and colorless from light yellow, so the appearanceof the product is improved.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Method for preparing p-aminophenyl-beta-hydroxyethyl sulfone sulfate

InactiveCN107739323AReduce consumptionIncrease profitOrganic compound preparationSulfide preparationCrystalline oxideIce water

The invention discloses a method for preparing p-aminophenyl-beta-hydroxyethyl sulfone sulfate. The method comprises the following steps: with p-nitrochlorobenzene and mercaptoethanol as basic raw materials, adding into an N,N-dimethylformamide solvent, sufficiently dissolving and uniformly mixing to obtain p-nitrophenyl-beta-hydroxyethyl sulfide, then adding hydrogen peroxide, separating out an oxidization crystallization material, adding solvent water and a palladium-carbon catalyst into the oxidization crystallization material, reacting, filtering to obtain a hydrogenated product and the solvent water, adding the hydrogenated product into an ice-water mixture, diluting, adding pure sulfuric acid, stirring, heating to 150 DEG C, and performing an esterification reaction for 2-3h under avacuum condition to obtain the p-aminophenyl-beta-hydroxyethyl sulfone sulfate after the reaction. The product prepared by the method provided by the invention is high in purity and yield, the raw material consumption is low, the raw material utilization rate is increased, few byproducts are produced and are easy to separate, produced wastewater is easy to treat, and the environmental protection investment is low.

Owner:SUQIAN YUANYANG BIOTECH

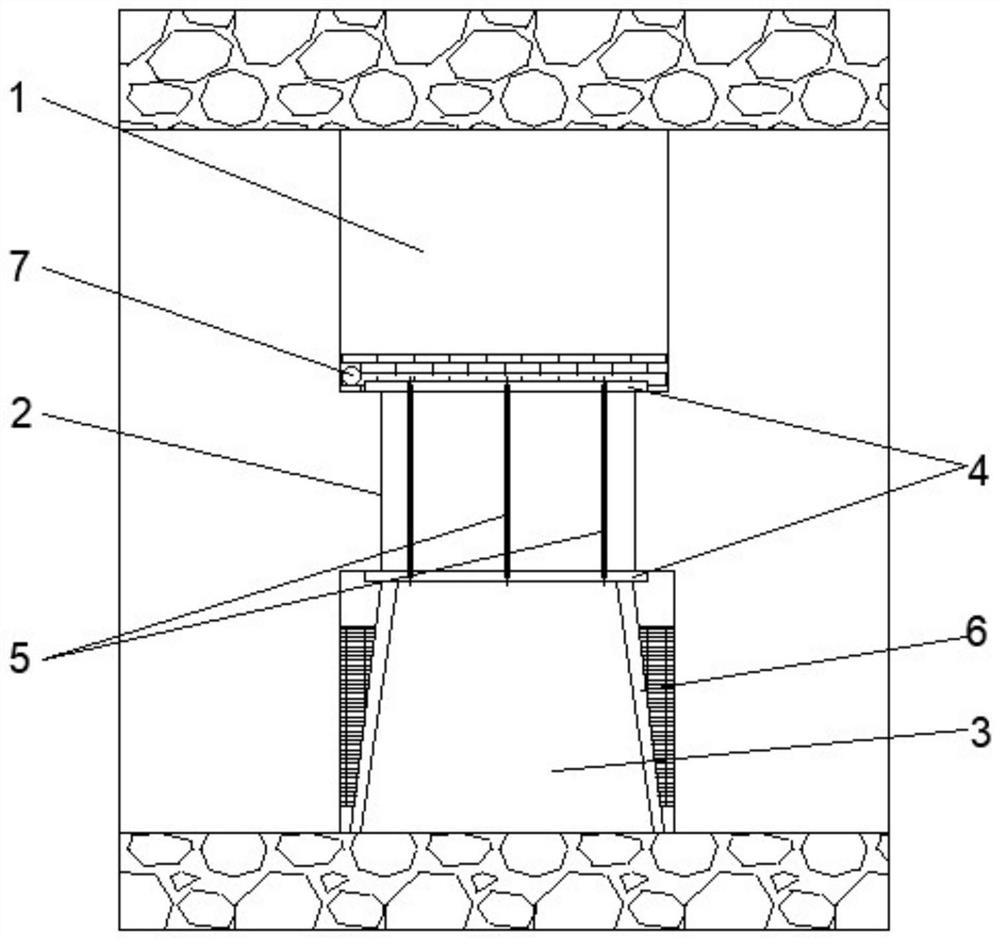

Reinforcing method for loose coal pillar body corrosion-resistant interchange roadway

InactiveCN113137243AProtection stabilityPrevent inflowUnderground chambersDrainageArchitectural engineeringWastewater

The invention discloses a reinforcing method for a loose coal pillar body anti-corrosion interchange roadway. The method comprises the following steps of arranging an I-shaped steel beam support on a top plate of a lower roadway, hoisting by using three anchor cables, and lifting the I-shaped steel beam support by using an I-shaped steel shed at the same time, wherein the length of the portion, positioned on the I-shaped steel beam support of the lower roadway, of each anchor cable is greater than the thickness of a coal pillar to be protected; spouting on the top plate of the lower roadway; and constructing an upper roadway, specifically, when passing through an interchange area, installing an I-shaped steel beam support on an exposed portion of each anchor cable, using an iron drainage pipe to replace a cement ditch, laying a waterproof material on the upper part of the I-shaped steel beam support, and pouring. The method is suitable for supporting when an extra-thick coal seam mine roadway which is deeply buried 800 m or more below the underground and exceeds 9 m passes through an interchange; and two sides of a coal pillar body are protected through the upper and lower roadways, and meanwhile, through pouring, closure and the like, the upper portion effectively prevents waste water on a working face from flowing into a coal pillar, so that the stability and the integrity of the coal pillar body are effectively ensured.

Owner:SHANDONG XINJULONG ENERGY

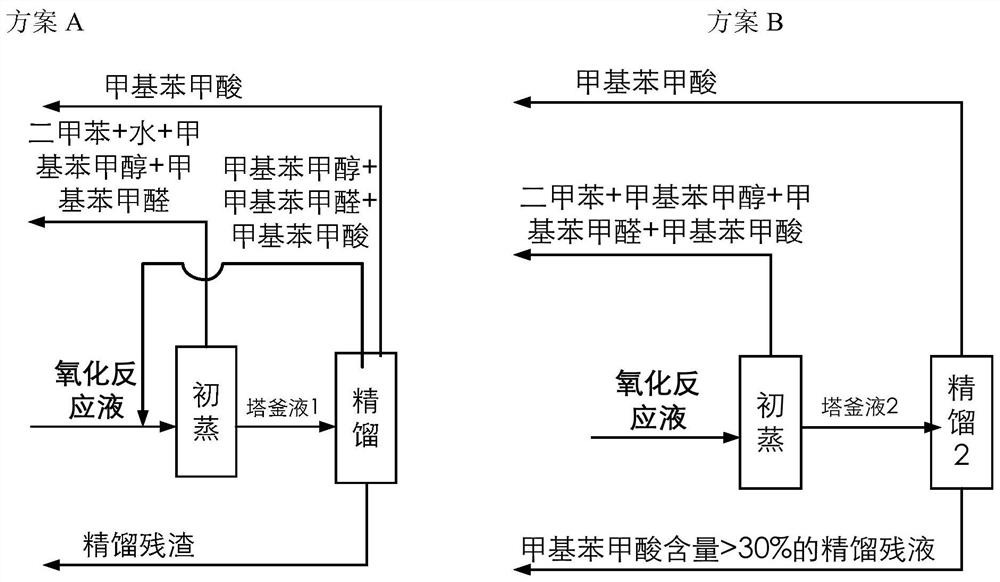

A method for co-producing methylbenzoic acid, methylbenzoic acid ester and phthalic acid diester

ActiveCN108047034BRaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationBenzoic acidXylylene

The invention discloses a method for co-producing methyl benzoic acid, methyl benzoate and phthalic acid diester, comprising: (1) continuously feeding xylene, a catalyst and an oxygen-containing gas into an oxidation reactor to carry out reaction, by controlling the amount of oxygen-containing gas to control the tail oxygen concentration to be no more than 5%, to obtain an oxidation reaction liquid; (2) enter the obtained oxidation reaction liquid into an initial distillation tower for rectification separation, to obtain low boiling point components and initial (3) enter the rectifying tower still liquid into the rectifying tower for rectification to obtain toluic acid product and rectifying tower still liquid; (4) mix the rectifying tower tower liquid with alcohol , carry out the esterification reaction, control the reaction end point to be that the content of toluic acid<0.5wt%, obtain the esterification reaction solution; (5) carry out rectification separation with the esterification reaction solution obtained, obtain methyl benzoic acid ester respectively and diester phthalate products. The invention has the advantages of simple process, less equipment investment, environmental protection and good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

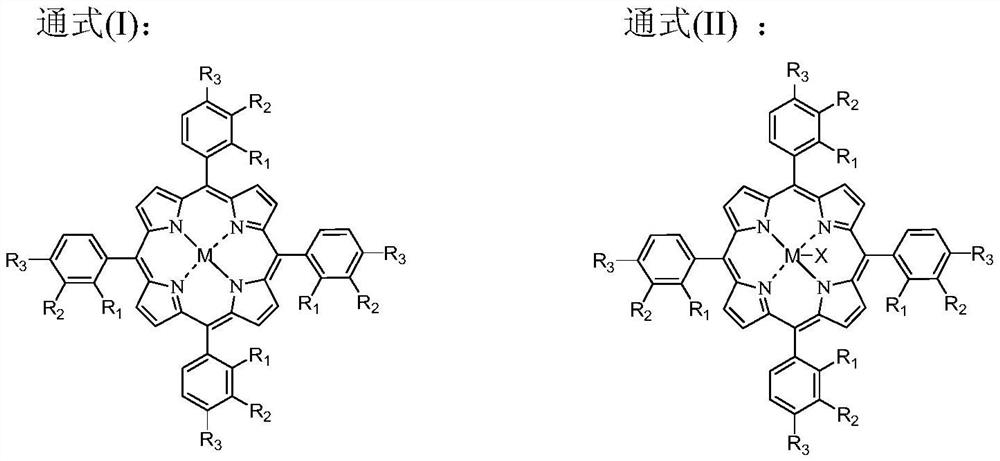

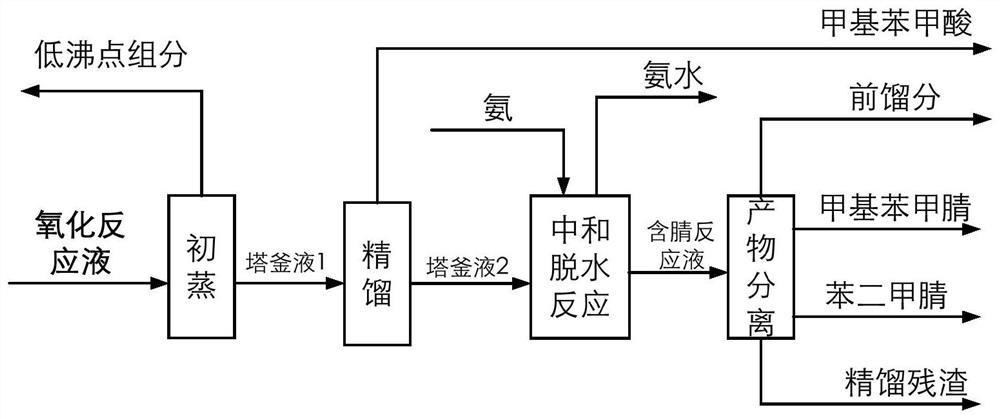

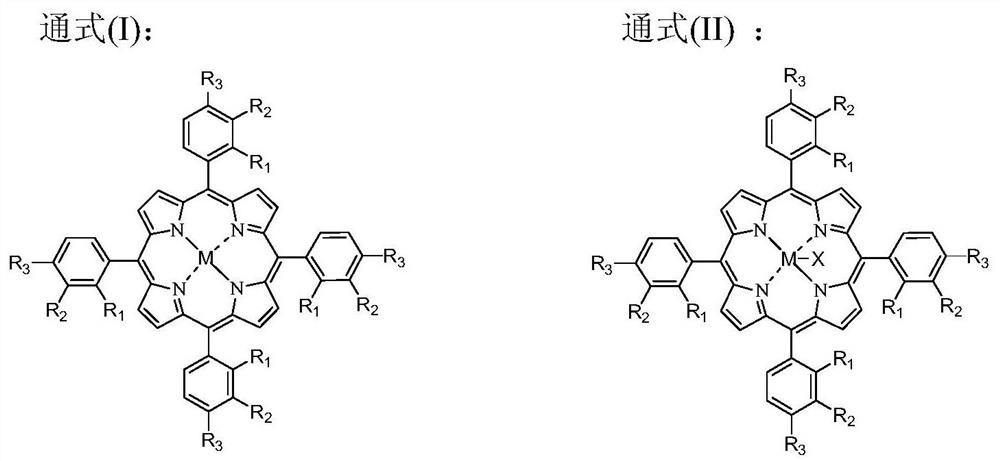

A kind of co-production methyl benzoic acid, methyl benzonitrile and phthalonitrile method

ActiveCN108863757BHigh concentration of production industryImprove concentrationOrganic compound preparationPreparation by ammonia-carboxylic acid reactionBenzoic acidPtru catalyst

The invention discloses a method for co-producing methylbenzoic acid, methylbenzonitrile and phthalonitrile, comprising: (1) continuously feeding xylene, a catalyst and an oxygen-containing gas into an oxidation reactor for reaction, Obtain the oxidation reaction liquid; (2) enter the oxidation reaction liquid into the initial distillation tower and carry out rectification separation, stop the rectification when the methyl benzyl alcohol content reaches 0.01~0.15wt% in the initial distillation tower bottom liquid, obtain low boiling point component and (3) enter the rectification tower with the initial distillation tower still liquid; (3) stop rectification when toluic acid content reaches 30~90wt% in the rectifying tower tower still liquid, obtain formosan (4) mixing the rectifying tower and tower liquid with ammonia to obtain a nitrile-containing reaction liquid; (5) carrying out rectification and separation of a nitrile-containing reaction liquid to obtain methylbenzene respectively Carbonitrile and phthalonitrile products. The invention has the advantages of simple process, less equipment investment, environmental protection and good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

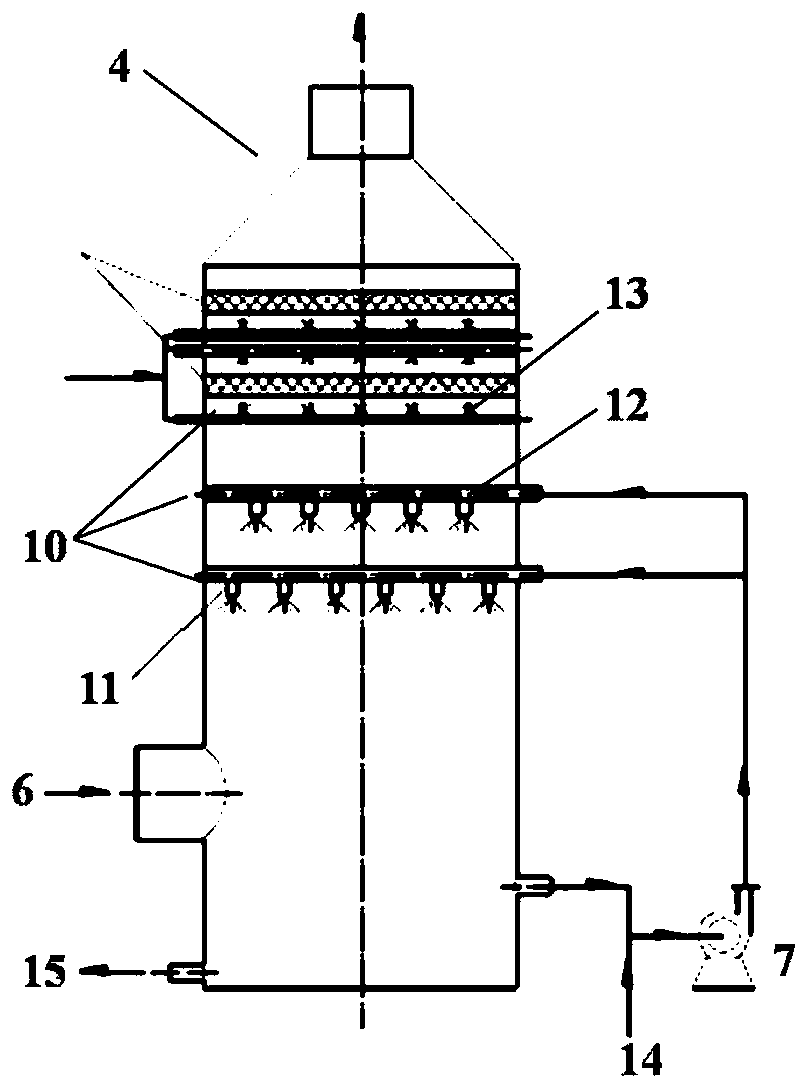

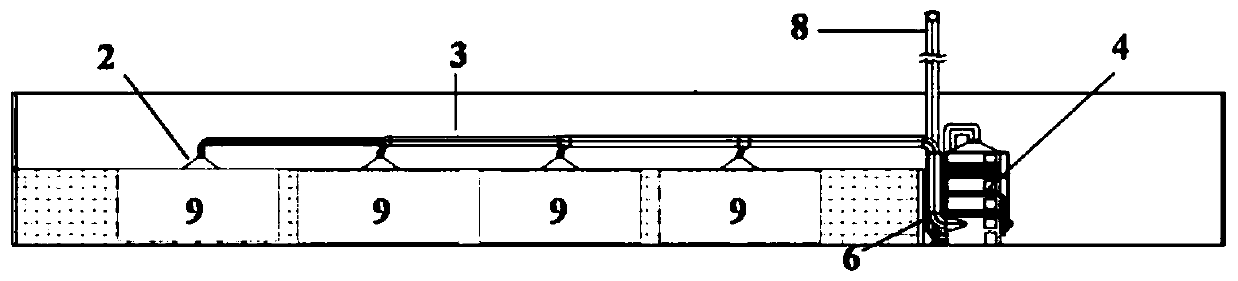

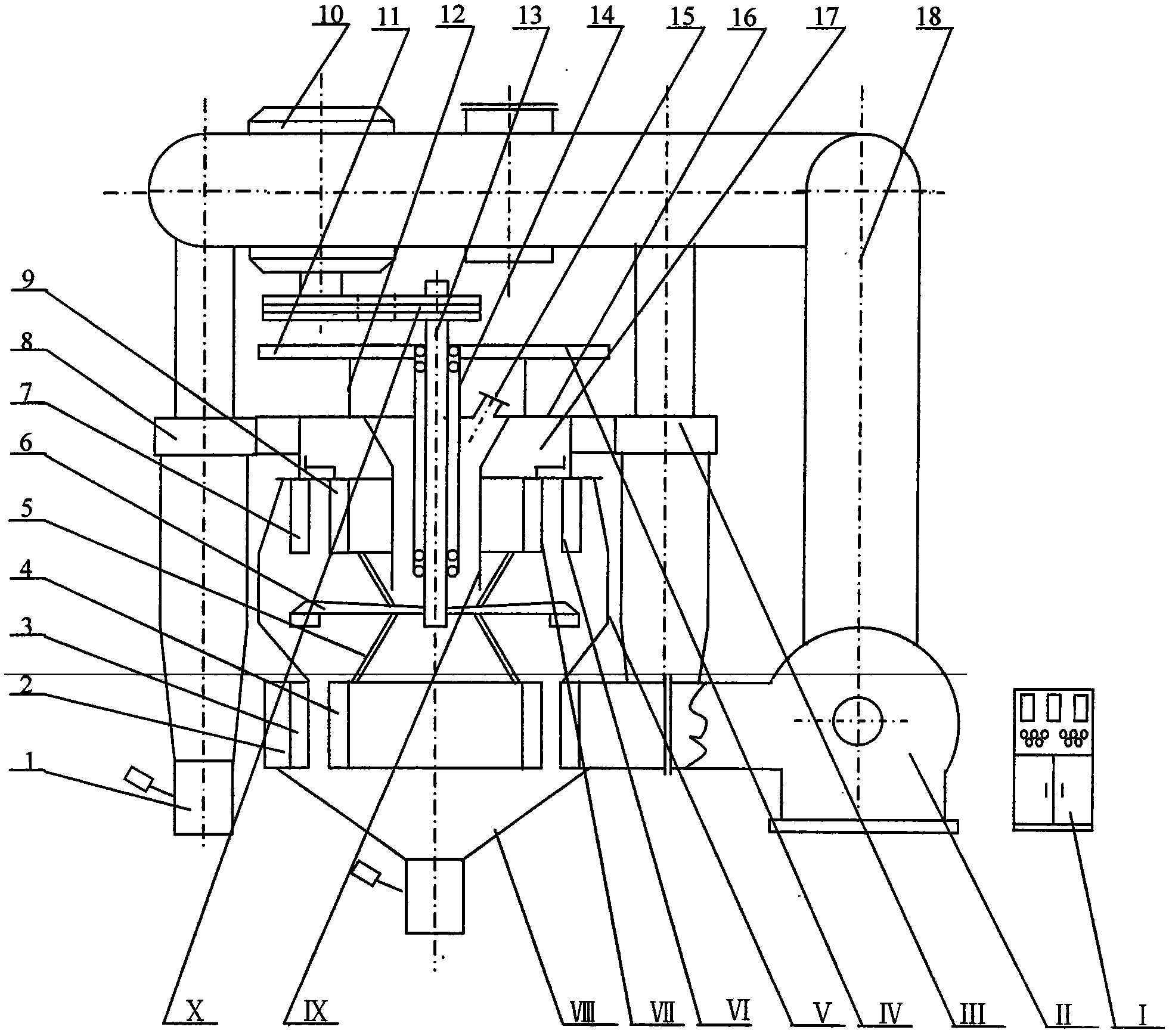

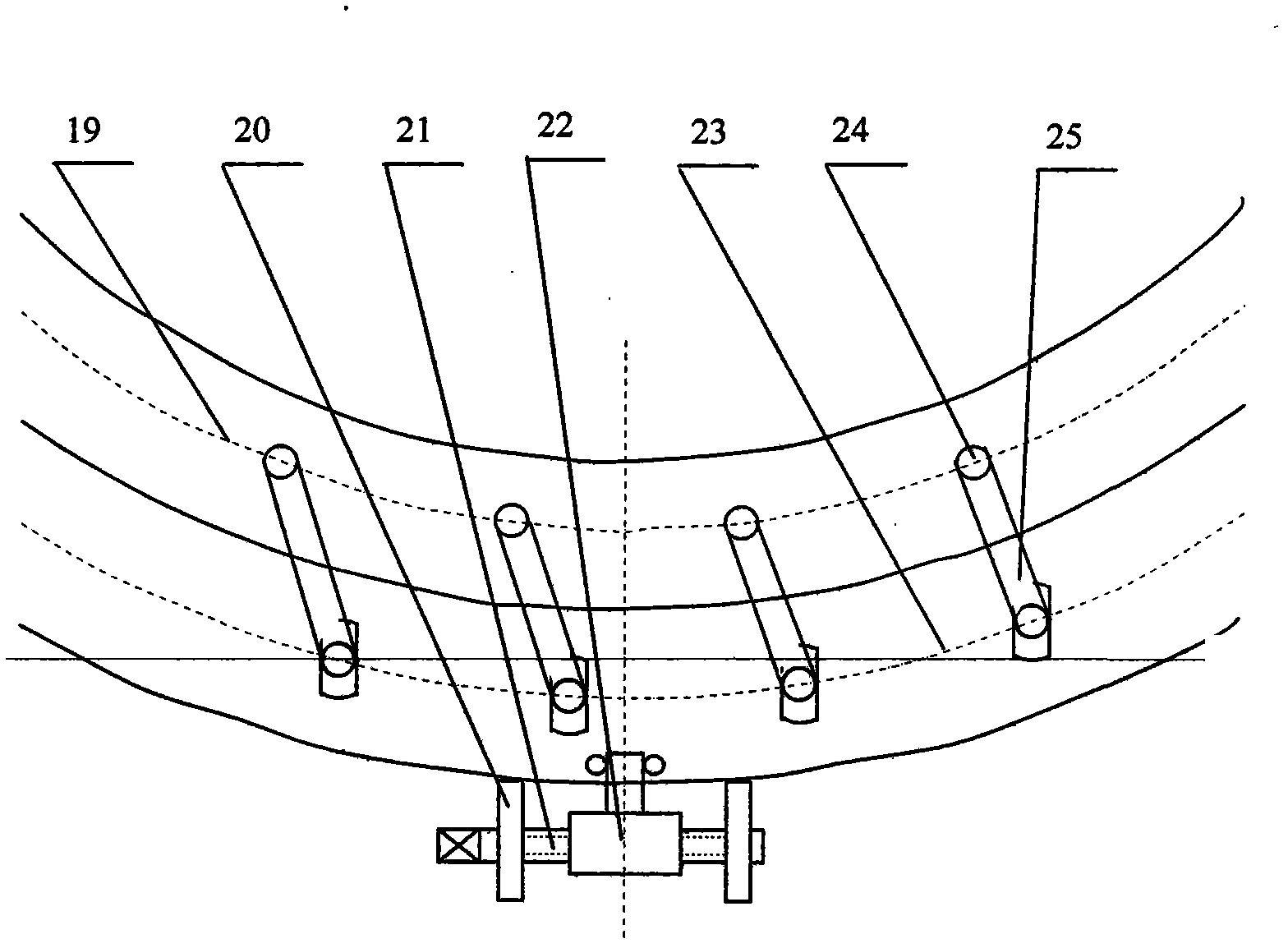

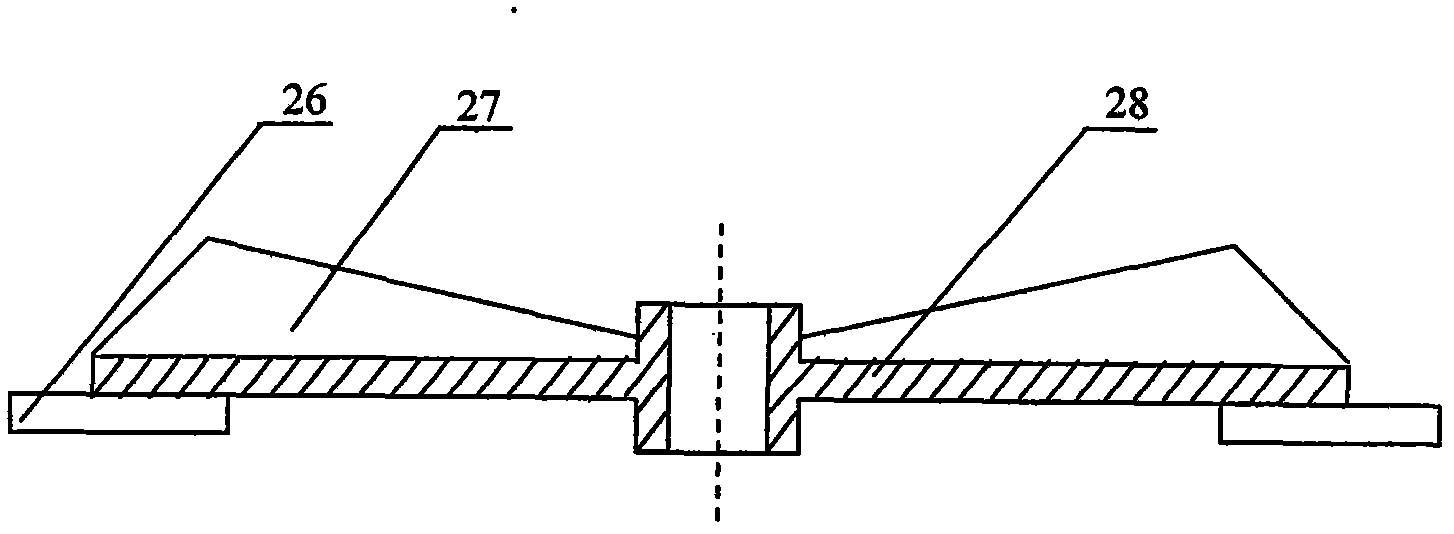

Blast furnace slag micro powder compound type vortex superfine separator

InactiveCN102847680AExpand market demandIncrease productivityGas current separationCycloneHigh energy

The invention discloses a blast furnace slag micro powder compound type vortex superfine separator which solves the technical problems of low production efficient, high energy consumption, serious air leakage and material collapse, low powder yield, low stability of specific surface area and the like of the field of micro powder separator relatively well by use of multiple innovative technologies such as vortex powder selection sealing, compound type superfine separation, micro powder cyclone separation, guide vane adjustment, snail-shaped direct air inlet, motor variable-frequency speed regulation and the like. The blast furnace slag micro powder compound type vortex superfine separator has the outstanding characteristics of simple structure, low price, high production efficiency, good powder selection quality, high powder yield and the like, is convenient to operate, avoids secondary pollution, is adapted to the technical transformation, equipment replacement and production capacity expansion, and improves the market demand of the product quality. The blast furnace slag superfine powder separated by the separator provided by the invention can replace cement clinker in a large proportion to be directly mixed in cement, and also can be used as fine powder component to be directly mixed in super-level concrete.

Owner:SIPING HUAYUAN ENVIRONMENTAL PROTECTION MACHINERYMFG

Method for promoting purity of N,N'-dicyclohexyl carbodiimide product

InactiveCN109503429AReduce contentImprove oxidation yieldOrganic chemistryFiltrationAmmonium hydroxide

The invention relates to a method for promoting purity of N,N'-dicyclohexyl carbodiimide product. The method comprises the following steps: adding ammonium hydroxide into a DCC crude product containing solvent, controlling temperature at 0-50 DEG C, and stirring for washing; standing by for 1 hour after the ending of washing; cooling and performing suction filtration; reducing pressure and distilling, thereby acquiring high-purity DCC. Ammonium hydroxide is used for washing, so that the content of residual cyclohexyl isothiocyanate in DCC can be effectively reduced, the content of side-productcyclohexyl isothiocyanate in the product is controlled below 50ppm, the product purity is promoted and the purity is above 99.7%; a reaction system is optimized, ammonium hydroxide is used for washing and reaction occurs in a homogeneous reaction system, so that the reaction yield is increased, the DCC oxidizing yield is increased to 95% or above, and the reaction can be easily controlled; the yield is increased, so that the use ratio of raw materials is increased, the volume of wastes is reduced, investment in environmental protection is reduced and production cost is lowered.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Method for reducing distillation residues of 5-acetylacetamidobenzimidazolone mother liquor

ActiveCN111763174AImprove solubilityPrevent oxidationOrganic chemistryProcess efficiency improvementO-Phosphoric AcidDistillation

The invention relates to a method for reducing distillation residues of 5-acetylacetamidobenzimidazolone mother liquor. The method comprises the following steps: with water as a solvent, adding mercaptoacetic acid, 5-aminobenzimidazolone and activated carbon, carrying out mixing, performing stirring for a certain time at a certain temperature, and conducting filtering to obtain a 5-aminobenzimidazolone filtrate; and dropwise adding diketene into the 5-aminobenzimidazolone filtrate at a certain temperature, keeping the temperature for a certain period of time to obtain 5-acetylacetamidobenzimidazolone, and distilling mother liquor for reuse. According to the invention, an organic acid solvent is used for replacing sodium hydrogen sulfite and phosphoric acid, so inorganic salt and phosphorus-containing substances in wastewater can be reduced; mercaptoacetic acid in the wastewater can be extracted by using the organic solvent and is recycled, so cost is reduced; and since the wastewater is subjected to MVR treatment and distillation before reuse, and the waste residue amount of the distilled wastewater is greatly reduced. The purity of an obtained product is greater than or equal to 99%, the yield of the product is greater than or equal to 80%, and the amount of acylation mother liquor distillation residues is reduced by about 30%, so quality and yield are ensured, environmental protection investment is reduced, and the purposes of energy conservation and emission reduction are achieved.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Resistance measurement method for transmission pull strip of coke oven reversing machine

ActiveCN103292937AAvoid failureEasy to operateForce measurement by elastic gauge deformationPull forceCoke oven

The invention relates to a resistance measurement method for a transmission pull strip of a coke oven reversing machine and belongs to a coke oven process. The resistance measurement method comprises a first step of measuring deformation delta L of the transmission pull strip in a stressed state and a second step of calculating pulling force F of the transmission pull strip according to the equation that F=E*S*delta L / L, wherein E is elasticity modulus; S is the sectional area of the transmission pull strip; the unit is mm2; delta L is the deformation of the transmission pull strip in the stressed state; and L is an original length of the transmission pull strip. According to the resistance measurement method, faults of an exchange transmission system can be avoided. The resistance measurement method is simple to operate and easy to popularize, and only a ruler or a measuring tape is required.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for synthesizing N, N'-diisopropylcarbodiimide by using oxygen as oxidant

InactiveCN112142624AReduce productionSolve problems that are difficult to deal withOrganic chemistryXylylenePtru catalyst

The invention relates to a method for synthesizing N, N'-diisopropylcarbodiimide by using oxygen as an oxidant, which comprises the following steps: adding N, N'-diisopropylthiourea and a xylene solvent into a high-pressure reaction kettle in a mass ratio of 1-2:1; adding a MoO3 or Sb2O4 catalyst, wherein the use amount of the MoO3 or Sb2O4 catalyst is 1-3% of the amount of the added materials; introducing oxygen, wherein the mass ratio of the N, N'-diisopropylthiourea to the oxygen is 1:0.2-0.4, and an oxidation reaction is carried out for 3-4 h under the conditions that the pressure is controlled to be 5-10 MPa and the temperature is controlled to be 110-120 DEG C; and cooling to 5-15 DEG C, carrying out suction filtration, decolorizing, and carrying out reduced pressure distillation toobtain the DIC. Oxygen is used as an oxidizing agent, the reaction selectivity is high, the risk is low, meanwhile, the wastewater yield is greatly reduced, treatment is easy, and the problem that waste brine in a traditional process is large in amount and difficult to treat is solved; and the method is easy to control, the reaction yield is increased, and the production cost is reduced.

Owner:SHANDONG HUIHAI PHARMA & CHEM

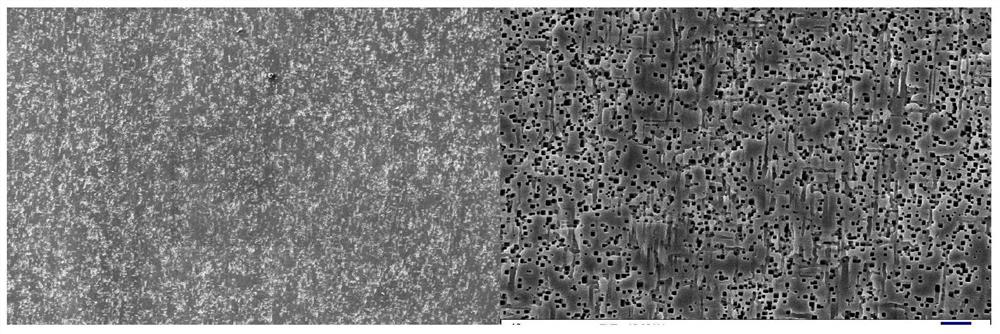

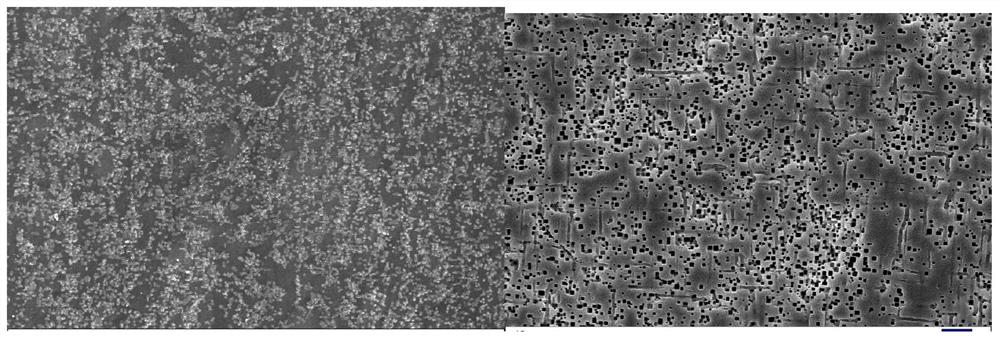

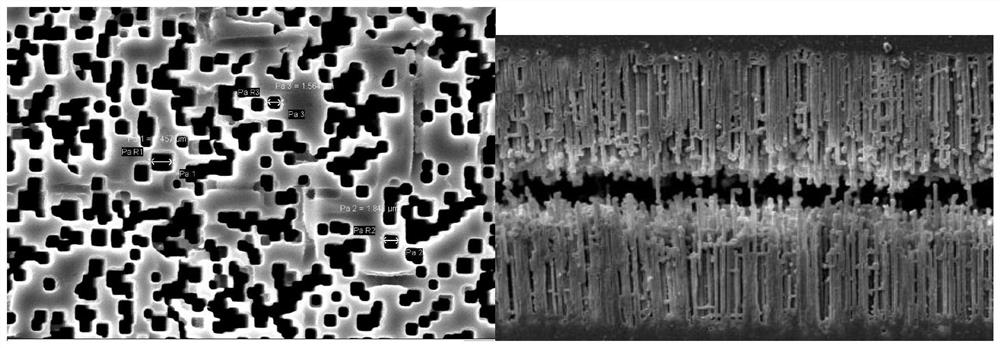

Corrosion process of anode foil for high-voltage aluminum electrolytic capacitor

ActiveCN112038100AImprove appearance qualitySolve discolorationElectrolytic capacitorsElectrolysisAluminum foil

The invention relates to a corrosion process of an anode foil for a high-voltage aluminum electrolytic capacitor. The invention discloses a corrosion process of an anode foil for a high-voltage aluminum electrolytic capacitor. The corrosion process comprises the following steps: sequentially carrying out pre-treatment, cleaning, electrolytic five-time hole forming, chemical hole expansion and post-treatment on an aluminum foil which is subjected to annealing treatment and has the purity of 99.99%. According to the invention, the corrosion process of the anode foil for the high-voltage aluminumelectrolytic capacitor is a high-efficiency, low-cost and phosphorus-nitrogen-free corrosion production process, can be applied to production of the corrosion process of the anode foil for the aluminum electrolytic capacitor, is high in production efficiency, high in capacity and low in cost, and can meet the requirements of existing customers.

Owner:乌鲁木齐众荣电子材料科技有限公司

Powder coating for motorcycle hub coating and coating process thereof

InactiveCN111793412APromote environmental protectionReduce investment in environmental protectionPretreated surfacesAnti-corrosive paintsPolymer scienceFirming agent

The invention relates to a powder coating for motorcycle hub coating. The powder coating is prepared from the following raw materials in percentage by mass: 65 to 75 percent of polyester resin, 4 to 6percent of a curing agent, 0.8 to 1.2 percent of a leveling agent, 0.3 to 0.8 percent of benzoin, 0.5 to 2 percent of a silane coupling agent, 5 to 15 percent of titanium dioxide, 0.1 to 0.5 percentof carbon black and 8 to 20 percent of a filler (barium sulfate), wherein the viscosity of the polyester resin is 4000 to 5000 mPa.s / 200 degrees, the acid value is 27 to 33 mpa.s / 200 degrees, the curing agent is triglycidyl isocyanurate, the leveling agent is an acrylic copolymer, and the molecular weight of the acrylic copolymer is 3000-4000. After the powder coating forms a paint film, the paintfilm has excellent properties such as high weather resistance, good leveling property, high gloss, and the like. The high-leveling and high-resistance powder coating is used for replacing three coatings (base powder, priming paint and finishing paint) of a traditional coating process, the coating process is simplified, energy is saved, the cost is reduced, waste water and waste gas are not generated, the environment-friendly property is greatly improved, and the environmental protection investment of enterprises is reduced.

Owner:幻彩星瀚(南京)新材料科技有限公司 +1

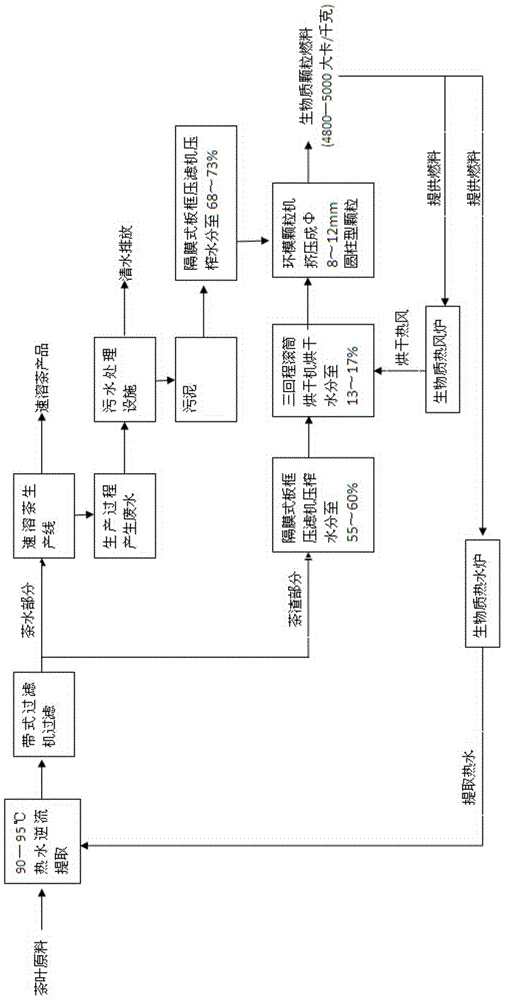

Energy-saving and environment-friendly comprehensive utilization method of tea resources

The invention discloses an energy-saving and environment-friendly comprehensive utilization method for tea resources. The energy-saving and environment-friendly comprehensive utilization method comprises the following steps: (1), taking tea raw materials, and extracting by hot water to obtain a tea water part and a tea residue part after solid-liquid separation; (2), preparing the tea water part into an instant tea product through an instant tea production line, wherein wastewater is generated in a production process; (3), carrying out sewage treatment onto the wastewater, separating clear water which reaches emission standards and sludge after the treatment, and discharging clear water; (4), drying the sludge through pressing by a diaphragm type plate-and-frame filter press; (5), drying the tea residue part obtained in the step (1) through pressing by the diaphragm type plate-and-frame filter press; (6), placing the dried tea residue into a three-pass stoke roller dryer for drying; (7), carrying out extrusion forming on the dried sludge obtained in the step (4) and the dried tea residue obtained in the step (6) by a ring-mould granulator after mixing to obtain a tea residue biomass particle fuel; and (8), using the tea residue biomass particle fuel as a fuel for a biomass water heater and a biomass hot air furnace.

Owner:南京融点食品科技有限公司

Paper coloring device

InactiveCN105155349ASolve the pollution problemEasy to operatePaper/cardboardPulp material addition processesWastewaterProcess engineering

The invention relates to the technical field of papermaking equipment and in particular provides a paper coloring device, which adopts a process of drying, then coloring and then drying products. Dual guide rollers are adopted to drive blankets and operate in opposite directions to enable paper to be clamped between the blankets, and a paper coloring process is completed by spraying onto the blankets through pump circulation. The paper is prevented from being deformed and ruptured and is kept in an original state, and the color can be freely adjusted. Then, excessive coloring dye is absorbed by using a vacuum pump, the color of the paper is enabled to be uniform and bright, the quality is good, the dye cost is low, the dye is enabled to be circulated in a coloring tank, can be collected and utilized and does not leak outside, and the pollution is precluded. The equipment cost is low, the operation is simple, the coloring speed is fast, the output is high, the situation that a great amount of wastewater is produced due to pollution caused by the dye is precluded, the sewage treatment expense is reduced, the safety performance is good, no potential hazard exists, and the device is very good novel, environmental-friendly, energy-saving equipment which benefits the nation and the people at present.

Owner:ANHUI JINYIHE SPECIALTY PAPER CO LTD

Utilizing method of wastes in brewing industry

InactiveCN103524154ASolve pollutionReduce investment in environmental protectionClimate change adaptationBioloigcal waste fertilisersSocial benefitsEnvironmental engineering

The invention relates to a utilizing method of wastes in the brewing industry. The method comprises the following steps of carrying out solid-liquid separation, aerobic fermentation, heating and drying, inner-material allocation and granulation and moulding treatment on brewing dregs for producing fertilizers as well as carrying out thermoregulation and chemical substance treatment on the brewing dregs for providing water for farmlands. The wastes in the crop brewing industry are effectively utilized by the method, so that not only can the pollution problem be solved, but also the environmental protection input is saved for enterprises. The method has better economical and social benefits.

Owner:王安振

Printed circuit board liquid cleaning device and printed circuit board processing system

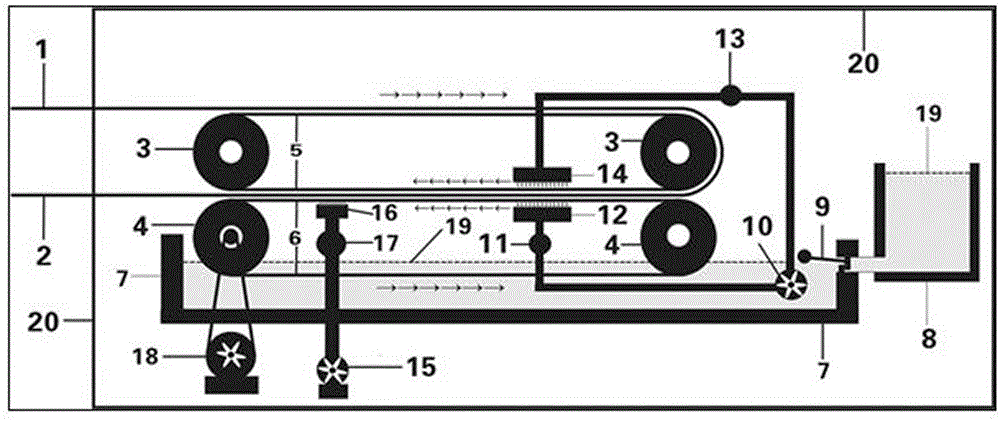

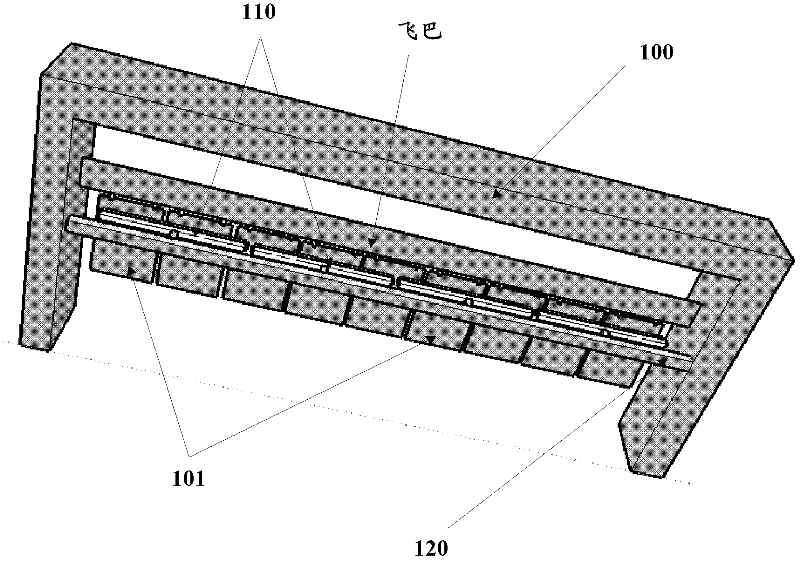

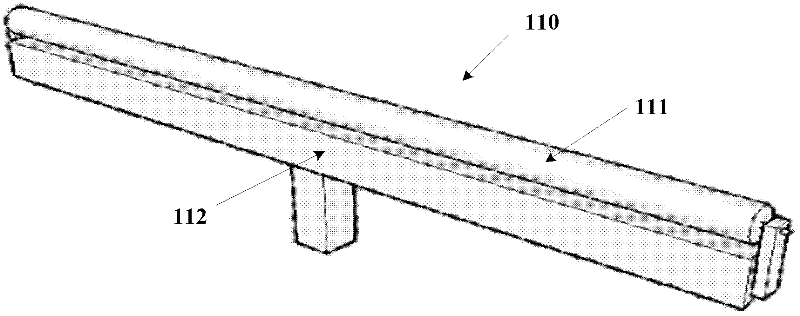

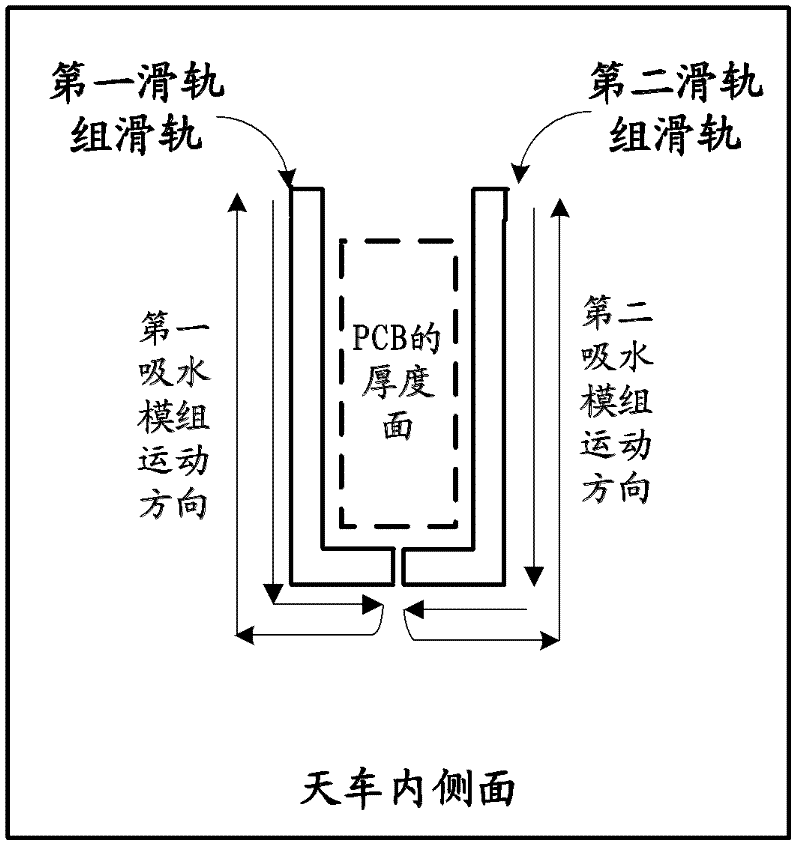

ActiveCN102296347AReduce maintenance costsReduce concentrationCellsEngineeringMechanical engineering

The invention discloses a cleaning device for a printed circuit board by using a lotion and a printed circuit board processing system. The cleaning device for the printed circuit board by using the lotion is arranged on a crown block, the cleaning device comprises a first motor, a first water suction module group, a first crossbeam, a first slide rail group; the first slide rail group comprises two strips of slide rails which are respectively installed on medial surface of two sides of the crown block, two ends of the first crossbeam are respectively slip connected with two strips of slide rails of the first slide rail group; the first water suction module group is arranged on the first crossbeam; when the printed circuit board suspended on a feiba of the crown block is hoisted from the lotion, the first motor drives the first crossbeam to slid on the first slide rail group, so that the first water suction module group is contacted with a first panel of the printed circuit board. The technical scheme of the invention is beneficially to the reduction of the lotion carrying-out amount of PCB during the process of lotion processing.

Owner:SHENNAN CIRCUITS

A method for co-producing methylbenzoic acid, methylbenzoyl chloride and phthaloyl chloride

ActiveCN108117486BHigh concentration of production industryRaw materials are easy to getOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidXylylene

The invention discloses a method of co-producing methyl benzoic acid, methylbenzoyl chloride and phthaloyl dichloride. The method comprises the following steps: (1) continuously introducing xylene, acatalyst and oxygen-containing gas into an oxidizing reactor to react to obtain an oxidized reaction solution; (2) rectifying and separating the oxidized reaction solution to obtain a low-boiling-point component and an initial evaporative tower bottom; (3) rectifying the initial evaporative tower bottom to obtain a methyl benzoic acid product and a tower bottom; (4) carrying out an acylating chlorination reaction on the tower bottom and an acylating chlorination reagent to obtain an acyl chloride reaction solution; and (5) rectifying and separating the acyl chloride reaction solution to separately obtain methylbenzoyl chloride and phthaloyl dichloride products. The method provided by the invention has the advantages of being simple in process, small in equipment investment, green and environment-friendly and good in comprehensive economical benefit.

Owner:JIANGXI KEYUAN BIOPHARM

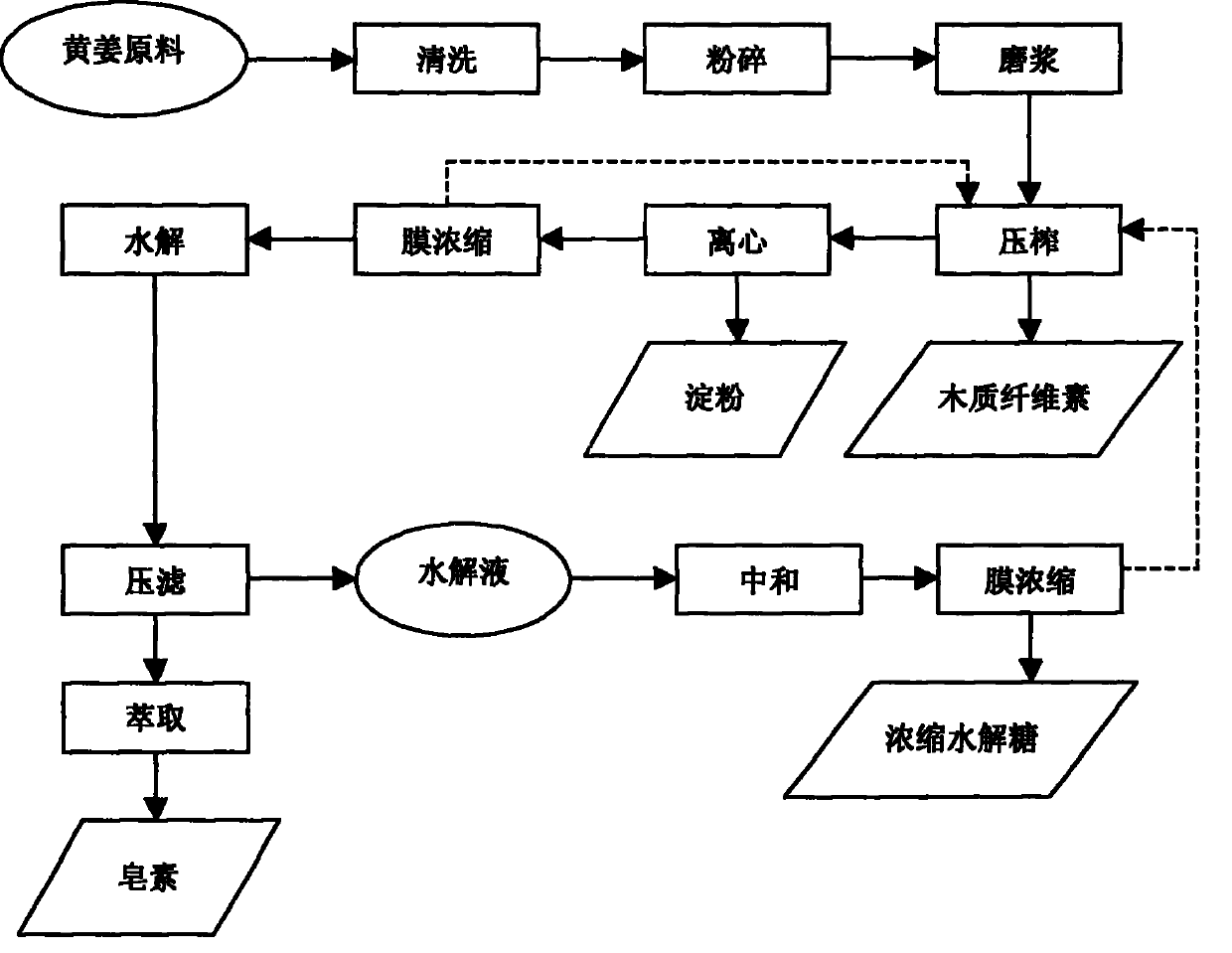

Method for cleanly producing yellow ginger

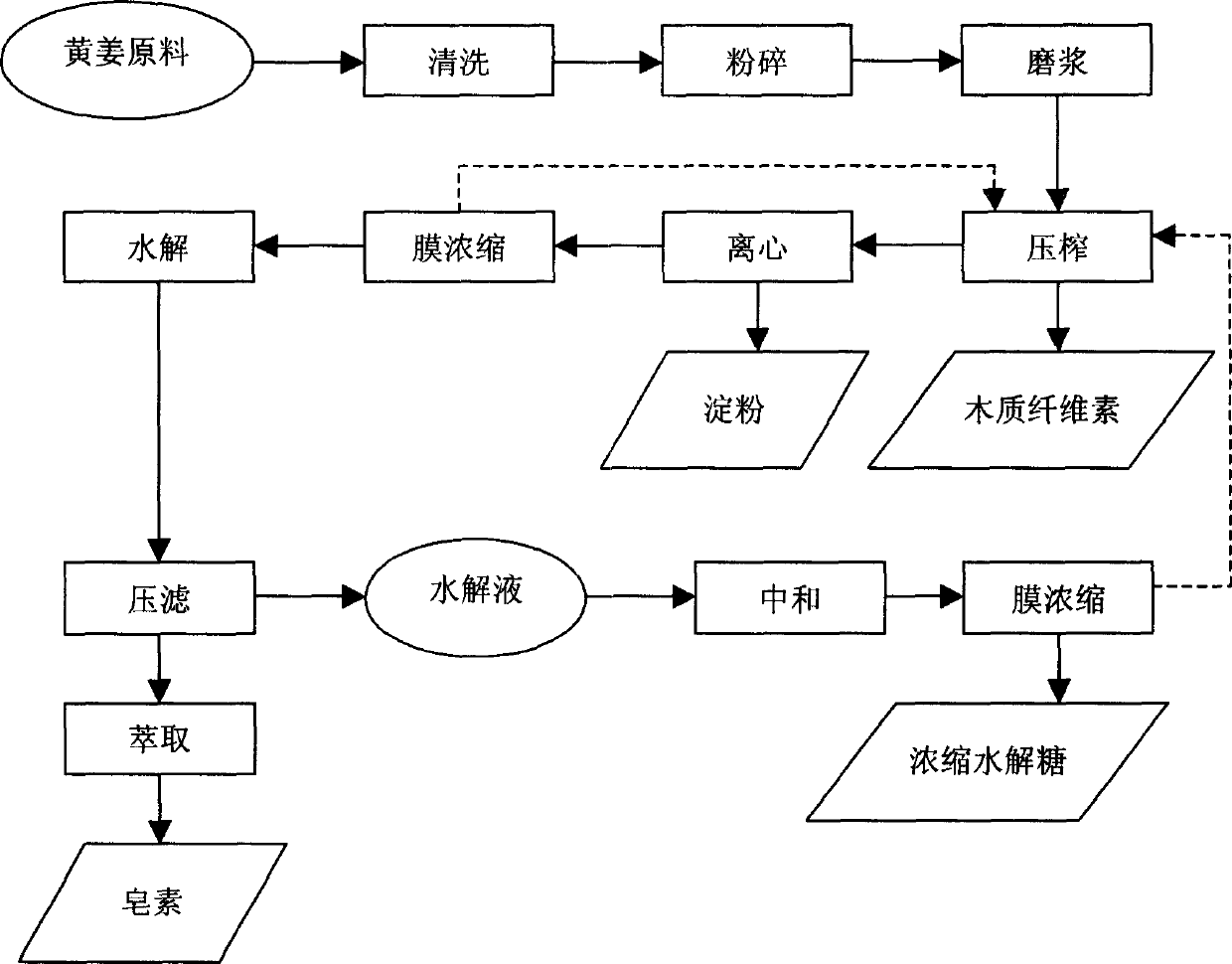

InactiveCN1849909BAchieving zero emissionsReduce processing costsSteroids preparationFood preparationUltrasonic assistedFiltration

The present invention relates to a clean production processing method of turmeric. Said method includes the following steps: cleaning turmeric raw material, pulverizing, ultrasonic auxiliary grinding, pressing, centrifugal separation, first membrane concentration, hydrolysis, press filtration, extraction, neutralization and secondary membrane concentration.

Owner:朱江

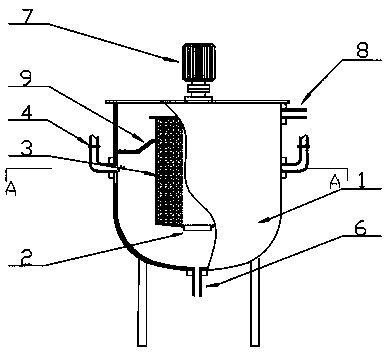

Efficient centrifugal reactor

PendingCN109110831AReduce consumptionWell mixedWater contaminantsWater/sewage treatmentMotor driveEngineering

The invention belongs to the field of applications of metallurgical acid sewage heavy metal ion treatment technologies, and relates to an efficient centrifugal reactor, which comprises a shell (1), arotating barrel (3), a baffle (9), a motor (7), a mesh-like mixer (10) and the like, wherein the center of the shell is provided with the motor-driven rotating barrel, the bottom portion of the rotating barrel is provided with a liquid inlet hole (2), and the upper portion is provided with a plurality of liquid outlet holes. According to the present invention, the motor drives the rotating barrelto operate at a high speed, such that the acidic sewage containing heavy metal ions (such as copper, arsenic and the like) and the sodium sulfide solution are highly mixed so as to strengthen the conversion reaction and saving the sodium sulfide solution.

Owner:兰州山水环保科技有限责任公司

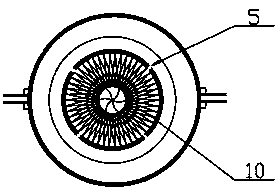

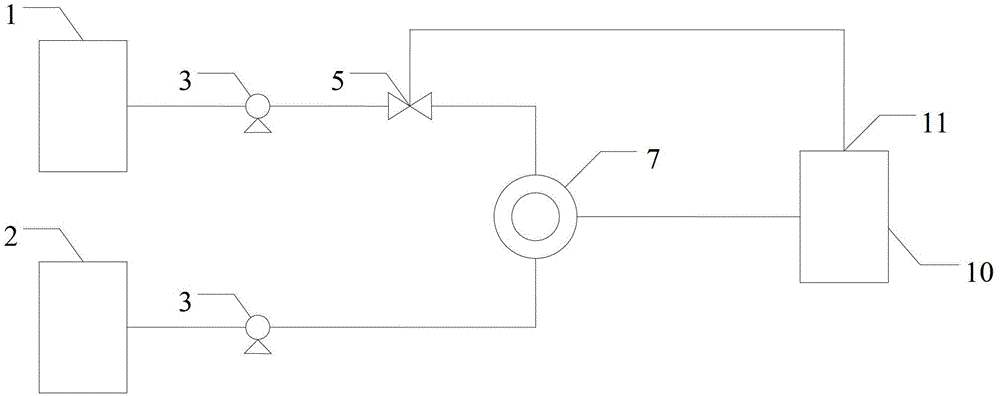

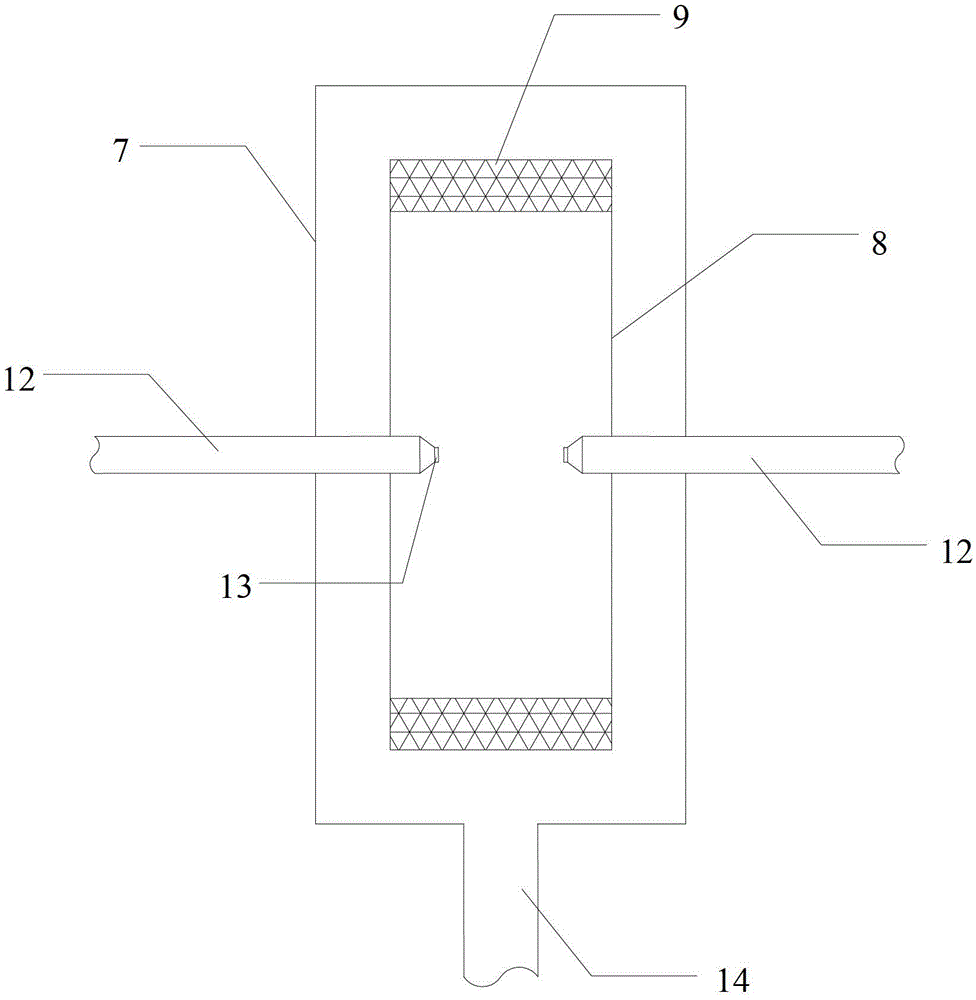

Smelting gas acid-production wastewater treatment system

InactiveCN103288199BLow construction costLow running costWater/sewage treatmentDrugs solutionLiquid storage tank

The invention discloses a smelting gas acid-production wastewater treatment system which comprises a wastewater storage tank (1), a drug storage tank (2), a supergravity reactor (7) and a liquid storage tank (10), wherein the wastewater storage tank (1) is used for storing heavy metal wastewater; the drug storage tank (2) is used for storing a drug solution reacting with the heavy metal wastewater; the supergravity reactor (7) is communicated with the wastewater storage tank (1) and the drug storage tank (2); the heavy metal wastewater in the wastewater storage tank (1) reacts with the drug solution in the drug storage tank (2) in the supergravity reactor (7); the liquid storage tank (10) is connected with a liquid outlet (14) of the supergravity reactor (7); and the liquid after reaction in the supergravity reactor (7) is discharged into the liquid storage tank (10) through the liquid outlet (14). By adopting a novel mass transfer technology, the smelting gas acid-production wastewater treatment system disclosed by the invention can reduce a sodium sulfide reaction tank, enhance the mass transfer and improve the treatment efficiency of heavy metal and arsenic in the acid water, and is particularly suitable for a place with limited height and size.

Owner:LANZHOU JEFF BIO ENVIRONMENT PROJECT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com