Method for preparing cathode material-lithium iron phosphate of lithium ion battery by utilizing steel slag

A technology for lithium-ion batteries and cathode materials, which is applied to battery electrodes, circuits, electrical components, etc., to achieve the effects of quality assurance, uniform mixing, and obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

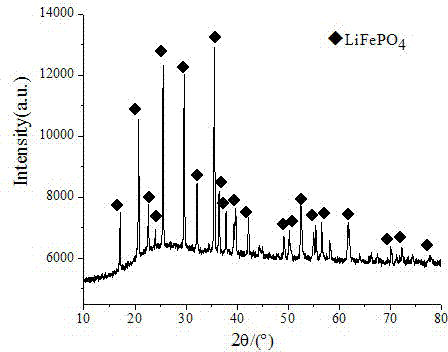

[0037] Embodiment one : Using steel slag to prepare lithium-ion battery cathode material LiFePO 4 method, including the following steps:

[0038] (1) Weigh 80 Kg of steel slag, crush it into a powder with a particle size of less than 100 mesh; weigh 4 Kg of glucose, add 10 Kg of water, stir and dissolve to obtain an aqueous glucose solution; add the aqueous glucose solution to the steel slag powder, put it into a mixer and stir evenly , to obtain the mixture; wherein the chemical composition of steel slag is shown in Table 1, the same below;

[0039] Table 1: Chemical composition of steel slag (mass fraction%)

[0040] Element CaO FeO Al 2 o 3 SiO 2 MgO MnO P 2 o 5 content 30-60 15-26 3-8 8-23 4-9 5-10 0.5-2

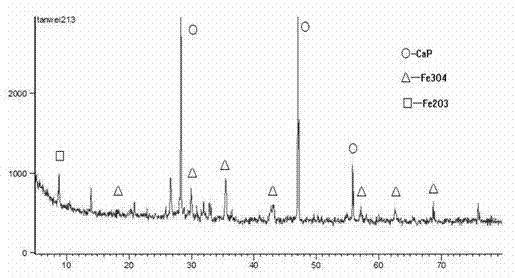

[0041] (2) Put the prepared mixture into a silicon carbide crucible, then put it into an industrial microwave oven, use microwaves to raise the temperature to 550°C at a rate of 10°C per minute, and keep it at this tempera...

Embodiment 2

[0046] Embodiment two : Using steel slag to prepare lithium-ion battery cathode material LiFePO 4 method, including the following steps:

[0047] (1) Weigh 80 Kg of steel slag, crush it into a powder with a particle size of less than 100 mesh; weigh 3 Kg of citric acid, add 8 Kg of water, stir and dissolve to obtain a citric acid aqueous solution; add the citric acid aqueous solution to the steel slag powder, and stir evenly to obtain Mixture;

[0048] (2) Put the prepared mixture into an alumina crucible, put it into an industrial microwave oven, and use microwaves to raise the temperature to 600°C at a rate of 8°C per minute, and keep it at this temperature for 12 minutes; Magnetic separation in a magnetic separation tube of / m to select 30Kg of steel slag extract;

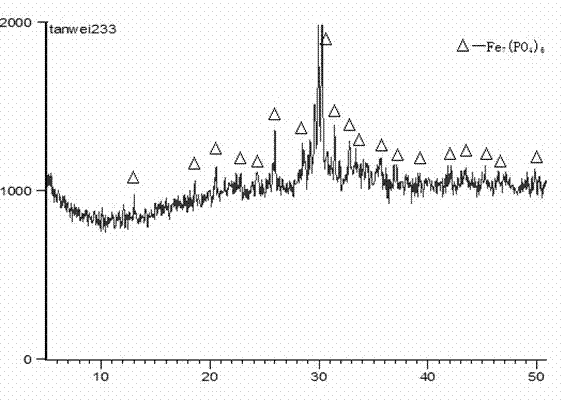

[0049] (3) Add 100Kg of 30wt% dilute sulfuric acid solution to the steel slag extract, stir and react at 80°C for 4h; let it stand for 1h, then suction filter and wash to obtain the filtrate, add 6Kg hydrog...

Embodiment 3

[0053] Embodiment three : Using steel slag to prepare lithium-ion battery cathode material LiFePO 4 method, including the following steps:

[0054] (1) Weigh 90 Kg of steel slag, crush it into a powder with a particle size of less than 100 mesh; weigh 4 Kg of oxalic acid, add 10 Kg of water, stir and dissolve to obtain an aqueous oxalic acid solution; add the aqueous oxalic acid solution to the steel slag powder, and stir evenly to obtain a mixture;

[0055] (2) Put the prepared mixture into an alumina crucible, put it into an industrial microwave oven, use microwaves to raise the temperature to 600°C at a rate of 10°C per minute, and keep it at this temperature for 15 minutes; Magnetic separation in a magnetic separation tube with a strength of 55KA / m to select 40Kg of steel slag extract;

[0056] (3) Add 120Kg of 30wt% dilute sulfuric acid solution to the steel slag extract, stir and react at 80°C for 4h; let it stand for 1h, then suction filter and wash to obtain the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com