Energy-saving and environment-friendly comprehensive utilization method of tea resources

An energy-saving, environmental-friendly, tea technology, applied in tea extraction, biofuels, waste fuels, etc., can solve the problems of unresolved tea residue utilization, eutrophication, etc., to reduce production costs and environmental pollution, fully burn environmentally friendly, reduce The effect of environmental protection investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

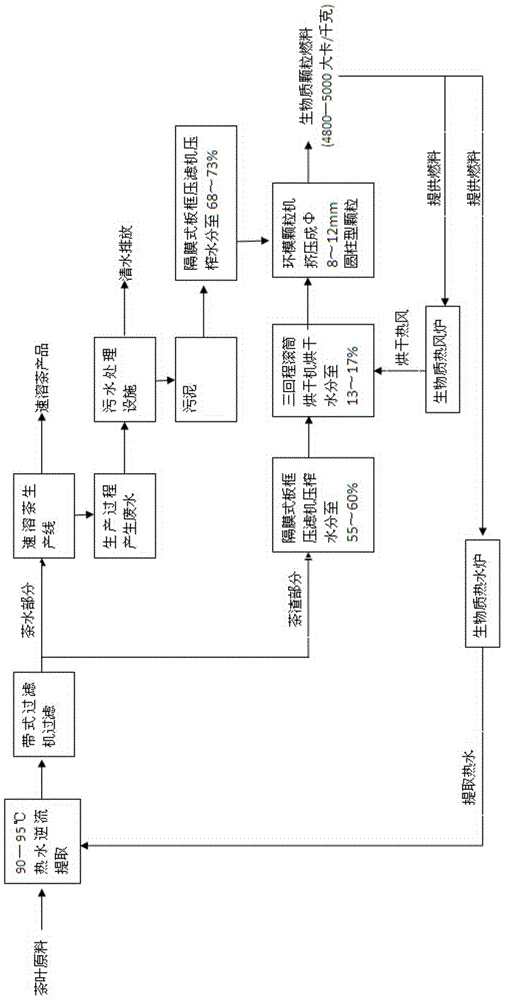

Image

Examples

Embodiment 1

[0033] Take 10 tons of green broken tea raw materials and add 170 tons of hot water at 93°C for countercurrent extraction for 30 minutes. After the extraction is completed, it is filtered into two parts: tea water and tea residues through a belt filter. ton; the tea residue part is first squeezed to a moisture content of 58wt% (pressing pressure 1.3Mpa, pressing time 30 minutes) by a diaphragm type plate and frame filter press, and then dried by a three-return drum dryer to a moisture content of 15wt% (drying). The air inlet temperature is 480° C., and the drying time is 12 minutes), and 7.05 tons of dried tea residues are obtained; the dried tea residues are mixed into the dirt that is squeezed by the diaphragm filter press to 70wt% (pressing pressure 1.4Mpa, pressing time 30 minutes). 0.47 tons of mud, and then the mixture was extruded into Φ8mm cylindrical pellets through a ring die pellet machine, and 7.46 tons of biomass pellet fuel was obtained, and the detected thermal c...

Embodiment 2

[0035] Take 20 tons of black tea raw materials and add 360 tons of hot water at 92°C for countercurrent extraction for 25 minutes. After the extraction is completed, it is filtered into two parts, tea water and tea residue, through a belt filter. The tea water part is passed through the subsequent instant tea production line to obtain 4.85 tons of instant tea powder; The tea residue is first pressed by a diaphragm type plate and frame filter press to a moisture content of 60wt% (pressing pressure 1.3Mpa, pressing time 28 minutes), and then dried by a three-pass drum dryer to a moisture content of 17wt% (drying air intake). The temperature is 450°C, and the drying time is 10 minutes) to obtain 14.3 tons of dried tea residues; the dried tea residues are mixed into the sludge of 0.9 wt. ton, and then extruded the mixture into Φ10mm cylindrical granules through a ring die pellet machine, and obtained 15 tons of biomass pellet fuel, which was tested to be 4880 kcal / kg; another 360 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com