Efficient centrifugal reactor

A reactor and centrifugal technology, applied in the field of high-efficiency centrifugal reactors, can solve the problems of excessive gypsum slag toxicity leaching index, reducing copper and arsenic removal efficiency, hydrogen sulfide gas leakage and other problems, shortening the replacement reaction time and reducing environmental protection investment. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

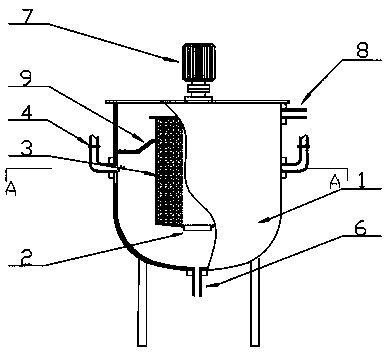

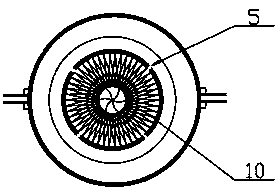

[0016] The shell (1) of the centrifugal reactor has a size of Φ500-800mm, the size of the liquid inlet hole of the rotary bucket (2) is Φ80-120mm, the size of the rotary bucket (3) is Φ250-400mm, the size of the liquid inlet pipe (4) is Φ20-80mm, and the size of the rotary bucket Liquid outlet hole 10×20-30×50 (5), sewage outlet size Φ20-80mm (6), motor (7), liquid outlet pipe (8) size Φ20-80mm, baffle plate (9), drum (3 ) internal mesh mixer (10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com