A method for treating distillers' grain waste gas of a Baijiu factory

A technology for waste gas treatment and distiller's grains, which is applied in the field of distiller's grains waste gas treatment in liquor factories, can solve the problems of reducing the gas concentration of emitting odor substances, and the effect of distiller's grain waste gas on life, etc., and achieves the effect of low equipment maintenance cost, low cost, and reduced environmental impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] In this embodiment, a process operation for treating distiller's grain waste gas in a three-retort brewing workshop is taken as an example to illustrate the process of the method of the present invention.

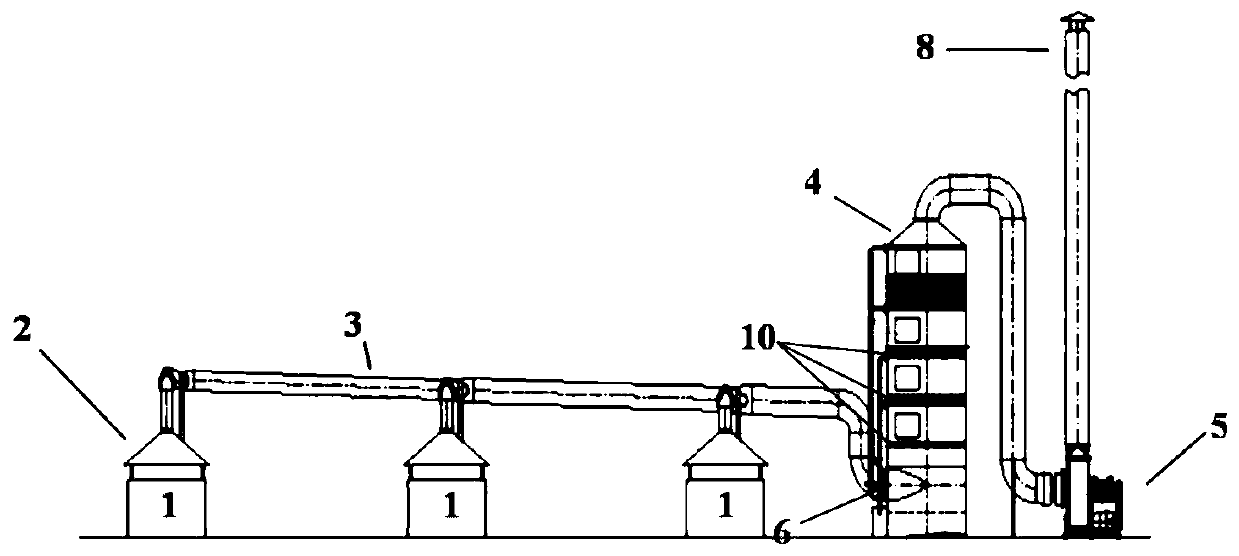

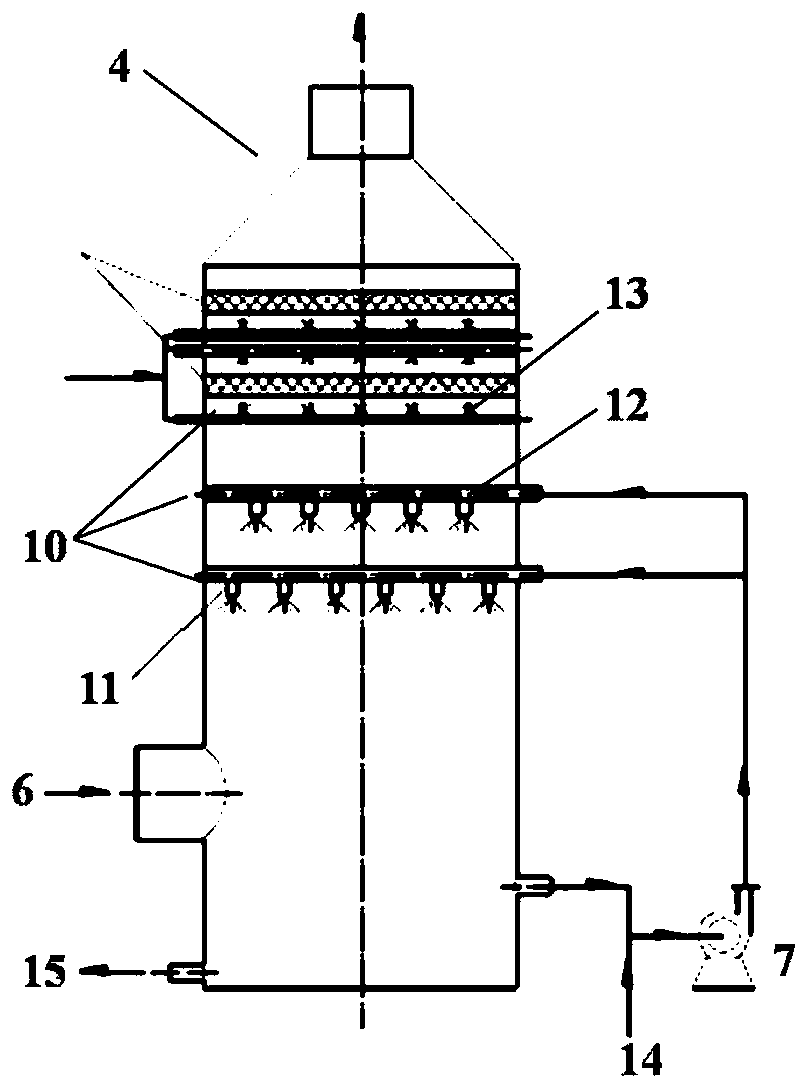

[0015] figure 1 It is a schematic flow chart of the treatment of waste gas from distiller's grains in a three-retort brewing workshop. figure 2 It is a structural schematic diagram of a swirling plate spray scrubber. A detailed description will be given below in conjunction with the accompanying drawings.

[0016] 1) Waste gas collection: Each team cooks 8 retorts per day, and cooks 3 retorts at the same time. When steaming grain, steaming bran, and distilling wine are finished deacidizing the atmosphere, the exhaust gas absorption cover 2 matching the corresponding caliber of retort 1 is placed on the Above each retort, utilize the negative pressure of the centrifugal fan 5 to collect waste gas; the air volume of the centrifugal fan used in this embodiment is 218...

Embodiment 2

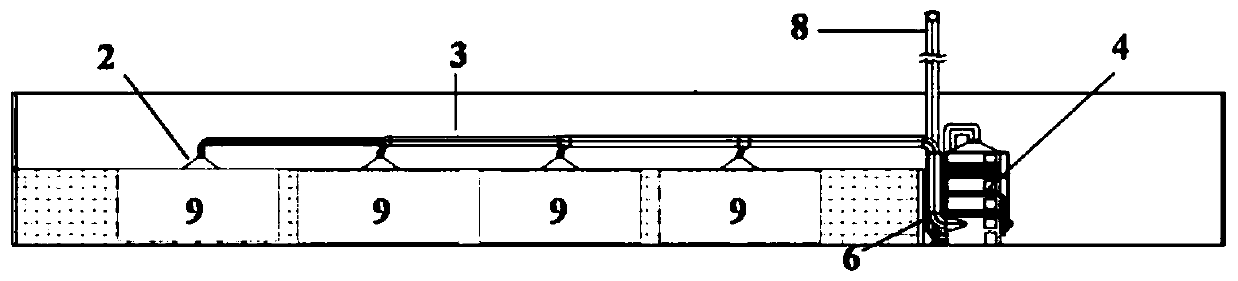

[0023] This embodiment takes a waste gas treatment process of a four-box type waste grain dump as an example to illustrate the specific implementation process of the distiller's grain waste gas treatment method of the present invention in the waste grain dump of a liquor factory.

[0024] image 3 It is a schematic diagram of the waste gas treatment process of the method of the present invention in a four-box type waste dregs dump.

[0025] 1) Waste gas collection: when the waste grains stacking box 9 contains waste grains, start the absorption cover 2 above it that is the same size as the stacking box caliber, and use the negative pressure of the centrifugal fan 5 to collect the waste gas; the centrifugal fan 5 used in this embodiment Fan, the air volume is 19404-33958m 3 / h, wind pressure 2619-1834Pa, motor power 30KW;

[0026] 2) Exhaust gas transportation: the fan generates suction to collect and summarize the exhaust gas and transport it to the purification treatment eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com