Method for extracting cobamamide

A technology of adenosylcobalamin and an extraction method, which is applied in the field of improved adenosylcobalamin extraction, can solve the problems of large waste production, turbidity, inability to start stirring, etc., and achieves the effects of increasing batch processing volume and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

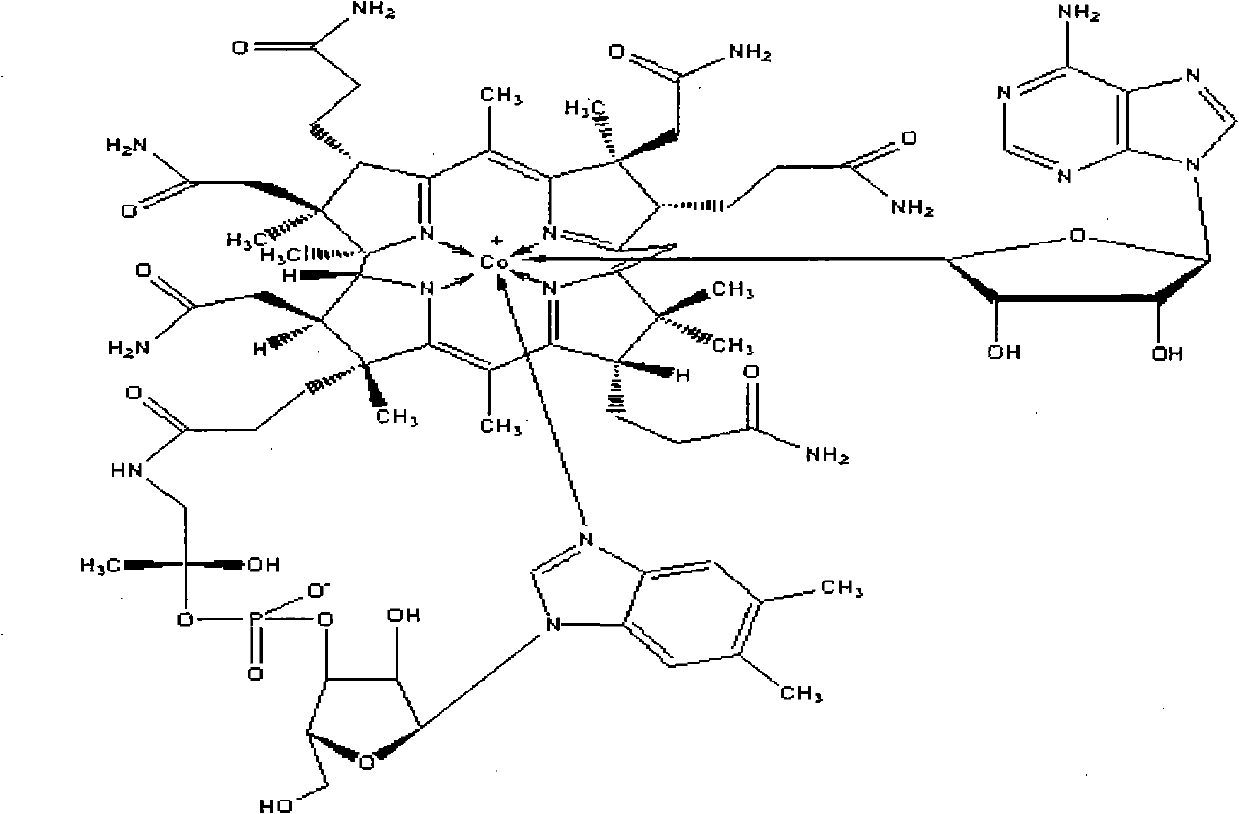

Image

Examples

Embodiment 1

[0029] will contain vitamin B 12 20Kg of fermented liquid is hydrolyzed and filtered to obtain the filtrate, and then the filtrate is adsorbed on about 10m 3 In the macroporous resin, wash and desorb to obtain a solution, and the solution is concentrated to obtain a concentrate; add divalent zinc salt or trivalent aluminum salt, vitamin B 12 : flocculant=20: 1 (molar ratio), adjust pH to 7.5 with 30% sodium hydroxide, after filtering, then suspend filter cake with water and filter again, repeat this operation several times, combine all filtrate vitamin B 12 The purified solution; the purified solution is adsorbed on 3m 3 In the chromatographic resin, use a low proportion of acetone water after washing with water, and the weight ratio of acetone and water can be selected to be 15:100. The solution is developed to obtain other types of vitamin B containing 5.0Kg 12 developing solution, and other types of vitamin B 12 After the ribbon of color is completely removed, then use ...

Embodiment 2

[0031] will contain vitamin B 12 20Kg of fermented liquid is hydrolyzed and filtered to obtain the filtrate, and then the filtrate is adsorbed on about 10m 3 In the macroporous resin, wash and desorb to obtain a solution, and the solution is concentrated to obtain a concentrate; add divalent zinc salt or trivalent aluminum salt, vitamin B 12 : flocculant=10: 1 (molar ratio), adjust pH to 7.2 with 30% sodium hydroxide, after filtering, then water suspension filter cake filters again, repeats this operation several times, merges all filtrate vitamin B 12 The purified solution; the purified solution is adsorbed on 3m 3 In the chromatographic resin, use low proportion of acetone water after washing with water, that is, the weight ratio of acetone and water is 5: 100 solution to develop the layer, and obtain other types of vitamin B containing 4Kg 12 developing solution, and other types of vitamin B 12 After the ribbon of color is completely removed, then use a high proportion o...

Embodiment 3

[0033] will contain vitamin B 12 20Kg of fermented liquid is hydrolyzed and filtered to obtain the filtrate, and then the filtrate is adsorbed on about 10m 3 In the macroporous resin, wash and desorb to obtain a solution, and the solution is concentrated to obtain a concentrate; add divalent zinc salt or trivalent aluminum salt, vitamin B 12 : flocculant=15: 1 (molar ratio), adjust pH to 7.4 with 30% sodium hydroxide, after filtering, then water suspension filter cake filters again, repeats this operation several times, merges all filtrate vitamin B12 The purified solution; the purified solution is adsorbed on 3m 3 In the chromatographic resin, use the acetone aqueous solution of low proportion after washing with water, the weight ratio of acetone and water is 10: 100, carry out development layer, obtain the other type vitamin B that contains 3.8Kg 12 developing solution, and other types of vitamin B 12 After the color band of color band is completely removed, then use the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com