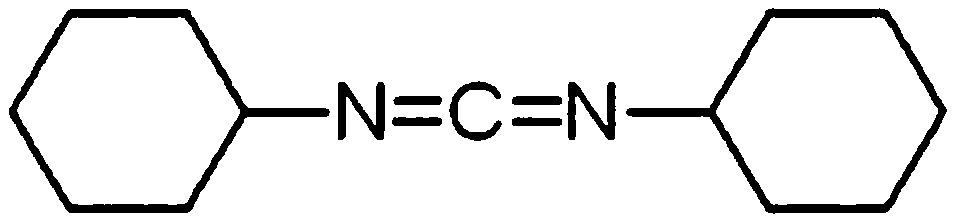

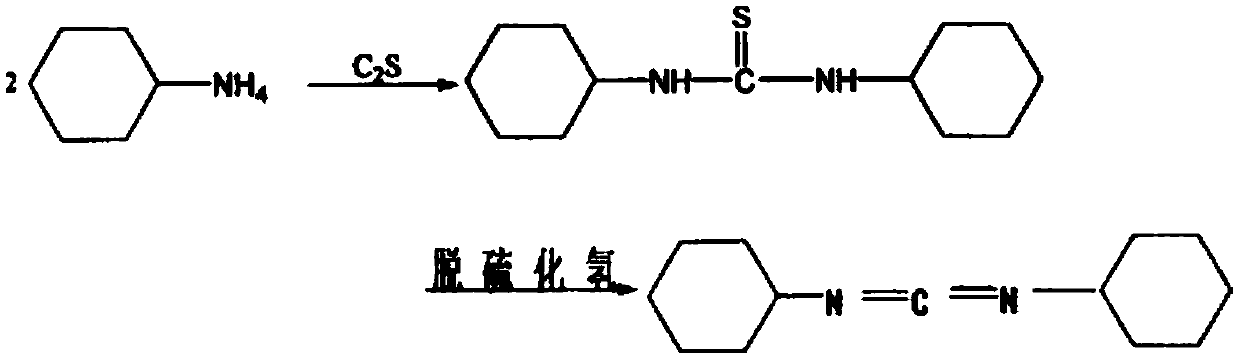

Method for reducing waste residues of N,N'-dicyclohexylcarbodiimide product

A technology for dicyclohexylcarbodiimide and products is applied in the field of reducing N,N'-dicyclohexylcarbodiimide product waste residue, which can solve problems such as difficult desulfurization, achieve simple and reliable control, improve appearance, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add potassium carbonate accounting for 1.5% of the total material mass to the crude DCC without solvent, control the temperature at 110° C., stir for 1 h, then reduce the pressure to below -0.09 MPa, and distill under reduced pressure to obtain DCC. The purity is more than 99.63%, the yield is more than 96.5%, and the amount of waste residue is 0.7% of the mass of DCC crude product. The wastewater produced by oxidation is used as cooling circulating water after passing the MVR distillation test.

Embodiment 2

[0020] Add 1% sodium carbonate to the crude DCC without solvent, control the temperature at 100° C., stir for 1 h, then reduce the pressure to below -0.09 MPa, and distill under reduced pressure to obtain DCC. The purity is more than 99.60%, the yield is more than 95.9%, and the amount of waste residue is 0.9% of the mass of DCC crude product. The wastewater produced by oxidation is used as cooling circulating water after passing the MVR distillation test.

Embodiment 3

[0022] Add potassium carbonate accounting for 2% of the total material mass to the crude DCC without solvent, control the temperature at 120° C., stir for 1 h, then reduce the pressure to below -0.09 MPa, and distill under reduced pressure to obtain DCC. The purity is more than 99.58%, the yield is more than 96.1%, and the amount of waste residue is 1% of the mass of DCC crude product. The wastewater produced by oxidation is used as cooling circulating water after passing the MVR distillation test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com