Mixed-structure field effect transistor and manufacturing method thereof

A technology of field-effect transistors and hybrid structures, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of large channel resistance of SiC MOSFET, and achieve the effect of solving the effect of large inversion channel resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

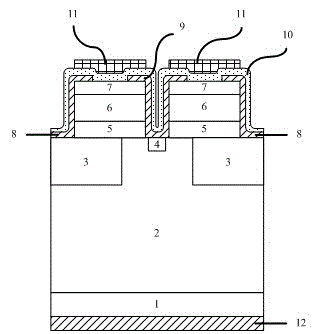

[0052] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, Figure 2 to Figure 8 It is the process schematic diagram of embodiment 1.

[0053] Such as figure 2 First, grow the SiC epitaxial layer 2 on the SiC substrate 1. The SiC epitaxial layer 2 may include a buffer layer with a higher doping concentration. The doping concentration and thickness of the SiC epitaxial layer 2 are set according to the withstand voltage requirements. The selection of SiC substrate 1 can be of the same conductivity type as SiC epitaxial layer 2. At this time, the invention is a unipolar device, similar to a power MOSFET; it can also be of a different conductivity type from SiC epitaxial layer 2. At this time , the invention is a bipolar device, similar to an IGBT.

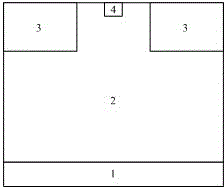

[0054] then follow image 3 , the first region 3 and the second region 4 are formed on the SiC epitaxial layer 2 by ion implantation. The first region 3 is located on both sides of the SiC epi...

Embodiment 2

[0061] image 3 It is a structural schematic diagram of Embodiment 2 of the present invention, Figures 10 to 16 It is the process schematic diagram of embodiment 2.

[0062] Such as Figure 10Firstly, a SiC epitaxial layer 2 , a buffer layer 5 , a GaN layer 6 and an AlGaN layer 7 are grown sequentially from bottom to top on a SiC substrate 1 , and then a sacrificial layer 13 is deposited. The choice of the substrate can be of the same conductivity type as the SiC epitaxial layer 2. At this time, the invention is a unipolar device, similar to a power MOSFET; it can also be of a different conductivity type from the SiC epitaxial layer 2. At this time, the invention It is a bipolar device, similar to an IGBT.

[0063] then follow Figure 11 , etch grooves on the buffer layer 5, the GaN layer 6 and the AlGaN layer 7, and then form the first region 3 by ion implantation, wherein the first region 3 is located on both sides of the SiC epitaxial layer 2, and the first region 3 an...

Embodiment 3

[0069] Figure 17 Shown is Embodiment 3 of the present invention, which differs from Embodiment 1 in that the device is a lateral device. The drain 12 is located on the surface of the device, and the contact region 14 between the drain 12 and the SiC epitaxial layer 2 can be of the same conductivity type as the SiC epitaxial layer 2. At this time, the invention is a unipolar device, similar to a power MOSFET; It can be of a different conductivity type from the SiC epitaxial layer 2, at this time, the invention is a bipolar device, similar to an IGBT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com