Heat management coupling system of power lithium battery pack

A technology of a battery management system and a coupling system, applied in the field of thermal management of new energy power lithium batteries, can solve the problems of shortened cycle life, poor environmental temperature adaptation, battery performance degradation, etc., and achieve the effect of convenient temperature field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

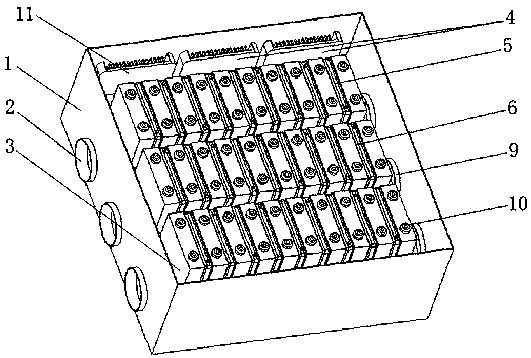

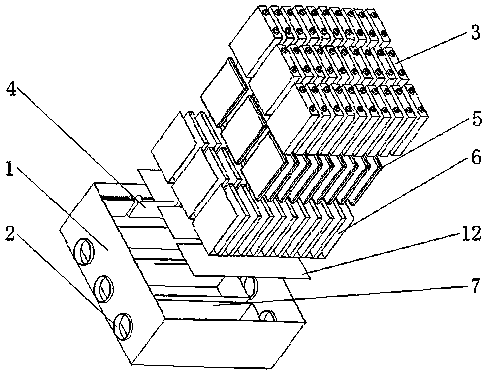

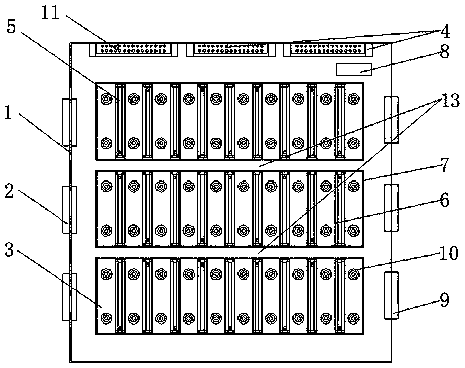

[0024] The present invention will be further described below in conjunction with drawings and embodiments. see Figure 1 to Figure 7 , a thermal management coupling system for a power lithium battery. Multiple rows of tanks 7 are vertically fixed in the box 1, and a certain interval is left between adjacent tanks 7, which defines the air flow path. space13. Each group tank body 7 is equipped with a thermal management coupling device inside, and the thermal management coupling device includes a battery module 3 , a phase change material 5 , a heat conduction plate slot 6 and an electric heating film 12 . Among them, the electric heating film 12 is made of heat-conducting silica gel, and then placed horizontally on the inner bottom surface of the group tank body 7, and the heat-conducting plate groove 6 is placed horizontally on the electric heating film 12, and the bottom surface is in contact with it, and its front side, rear side, left side, and right side The surfaces are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com