Catalyst for preparing low alcohol from synthesis gases as well as preparation method and application of catalyst

A catalyst and low-carbon alcohol technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of full utilization of unfavorable raw materials, poor hydrogenation activity, conversion of unfavorable results, etc. The effect of repeatability, low equipment requirements, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

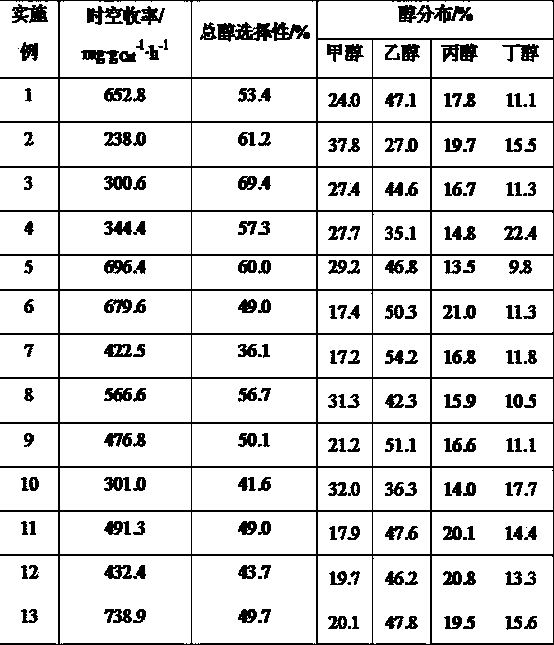

Examples

preparation example Construction

[0029] Carry out a kind of preparation method of the catalyst that is used for synthesis gas to produce low-carbon alcohol, and its described method is carried out according to the component and content thereof of a kind of catalyst that is used for synthesis gas to produce low-carbon alcohol in the above-mentioned embodiment one , the specific method steps are as follows:

[0030] First, dissolve cobalt nitrate, copper nitrate, and cerium nitrate in deionized water or an organic solvent, and stir to make them evenly mixed;

[0031] Next, carbon nanotubes are slowly added to the above-mentioned mixed solution, and stirred to make it evenly mixed;

[0032] Finally, the above mixture is dried, calcined, tabletted and granulated to 40-60 meshes to obtain a catalyst for producing low-carbon alcohols from syngas.

[0033] In the step (1) in the above specific embodiment, the organic solvent used is one of ethanol, acetone and ethylene glycol.

[0034] In the step (3) in the above s...

Embodiment 1

[0040] By expression Cu 12 co 8 Ce 3 / CNT 77 To prepare the catalyst, dissolve the nitrates of Cu, Co, and Ce in deionized water according to the above expression ratio, then slowly add the CNT in the above expression ratio into the above solution, stir and impregnate for 3 h, and then dry at 120 °C for 5 h . then in N 2 Calcined at 400 °C for 4 h in the atmosphere, cooled to room temperature naturally, then pressed into tablets and granulated to 40-60 mesh.

[0041] Take 1.0 g of the prepared catalyst, transfer it into the reaction tube, and heat it with 30% H 2 and 70 %N 2 The mixed gas was subjected to temperature-programmed reduction for 2 h, under N 2 After the flow drops to the reaction temperature, switch to syngas for reaction, the reaction temperature is 300 °C, the pressure is 3.0 MPa, the space velocity is 12000 ml / (h g), the H 2 The / CO volume ratio is 1. The reaction tail gas was sent to the six-way valve of the gas chromatograph through the insulated...

Embodiment 2

[0043] Catalyst is prepared in the manner of embodiment 1, and difference is that catalyst expression is Cu 15 co 8 Ce 3 / CNT 74 . Catalyst evaluation conditions are T=250 °C, P=5.0 MPa, space velocity is 12000 ml / (h g), H 2 / CO=2, all the other are with embodiment 1. The results obtained are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com