Surface molding metal material additive manufacturing method

A metal additive and manufacturing method technology, applied in the field of metal additive manufacturing, can solve problems such as uneven temperature field distribution, warpage and fracture of molded parts, and achieve improved manufacturing efficiency, high controllability, and surface array forming process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

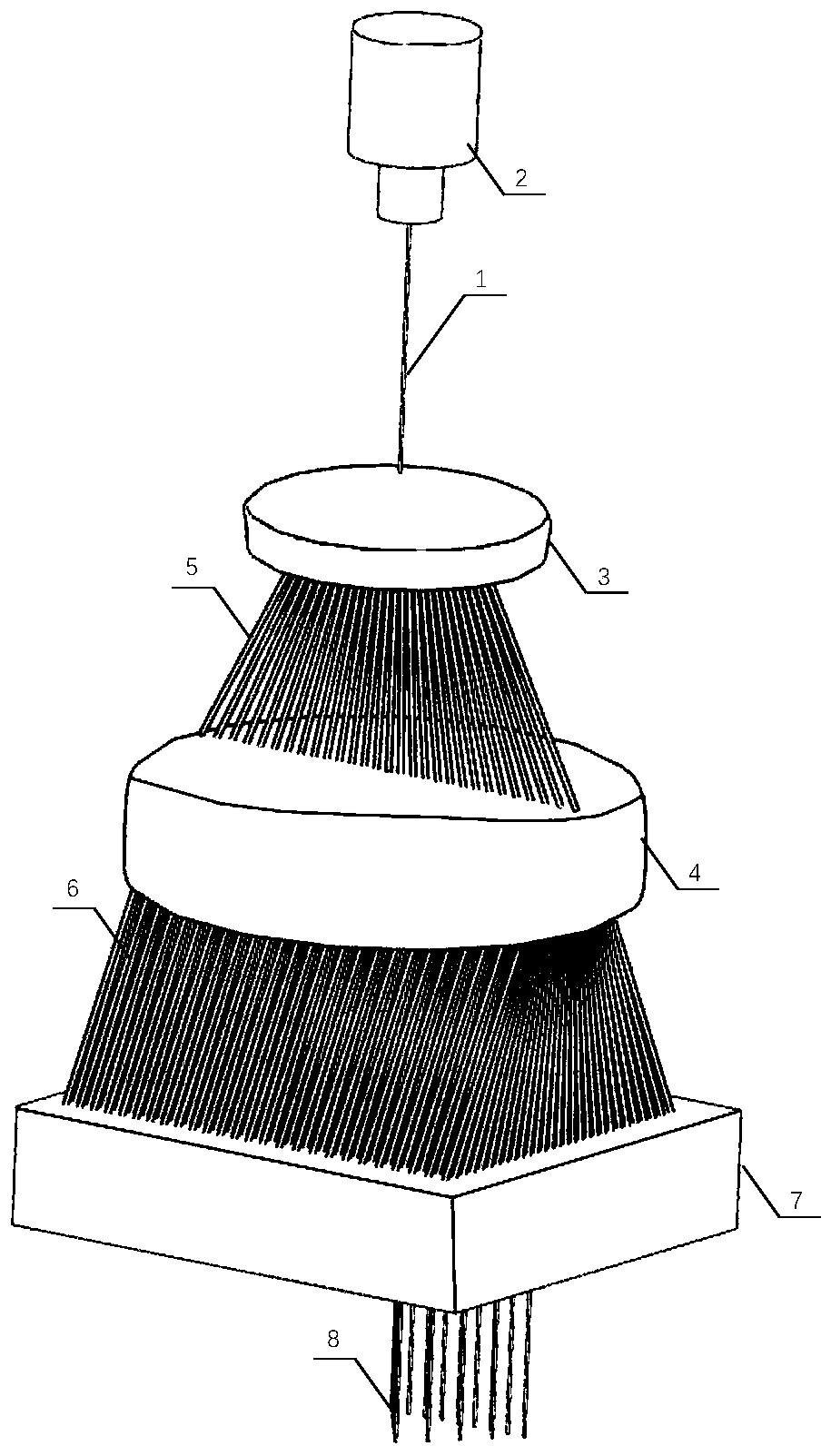

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

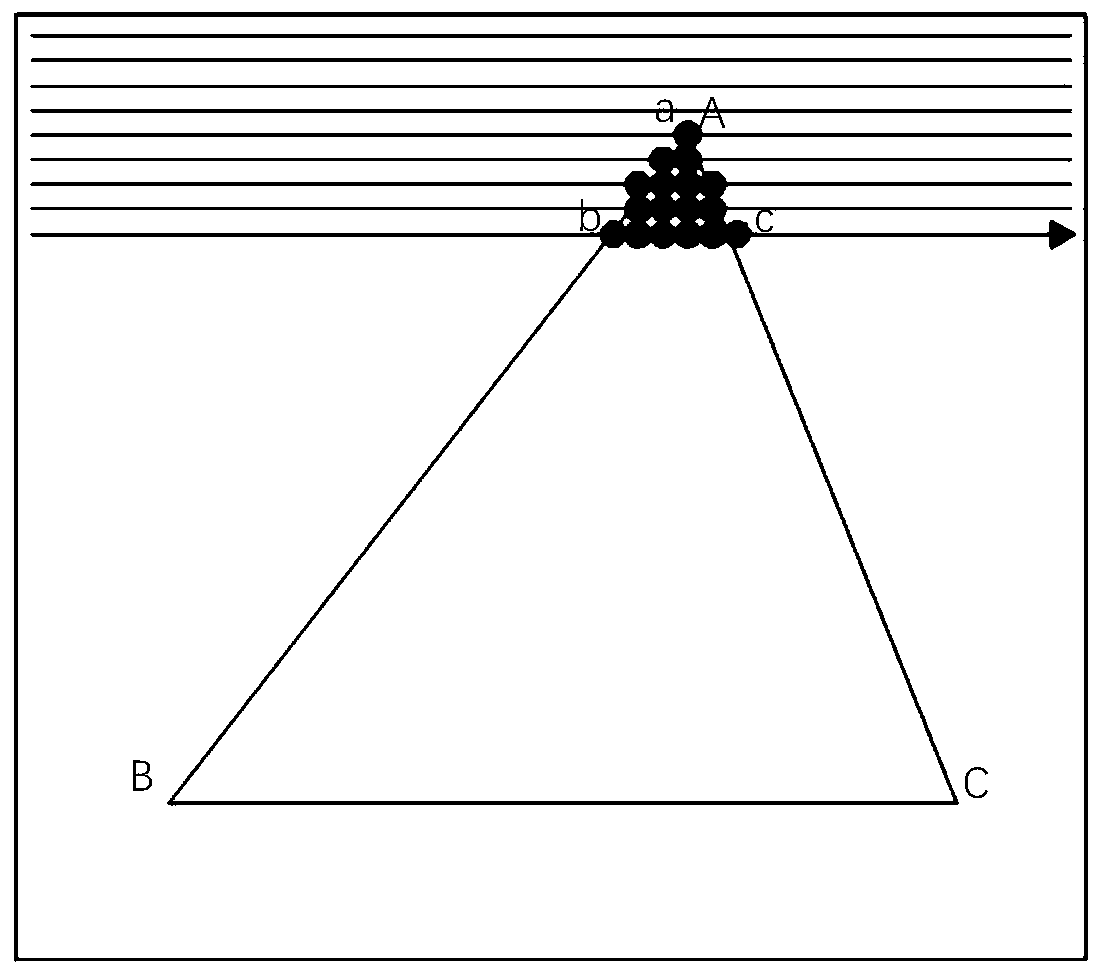

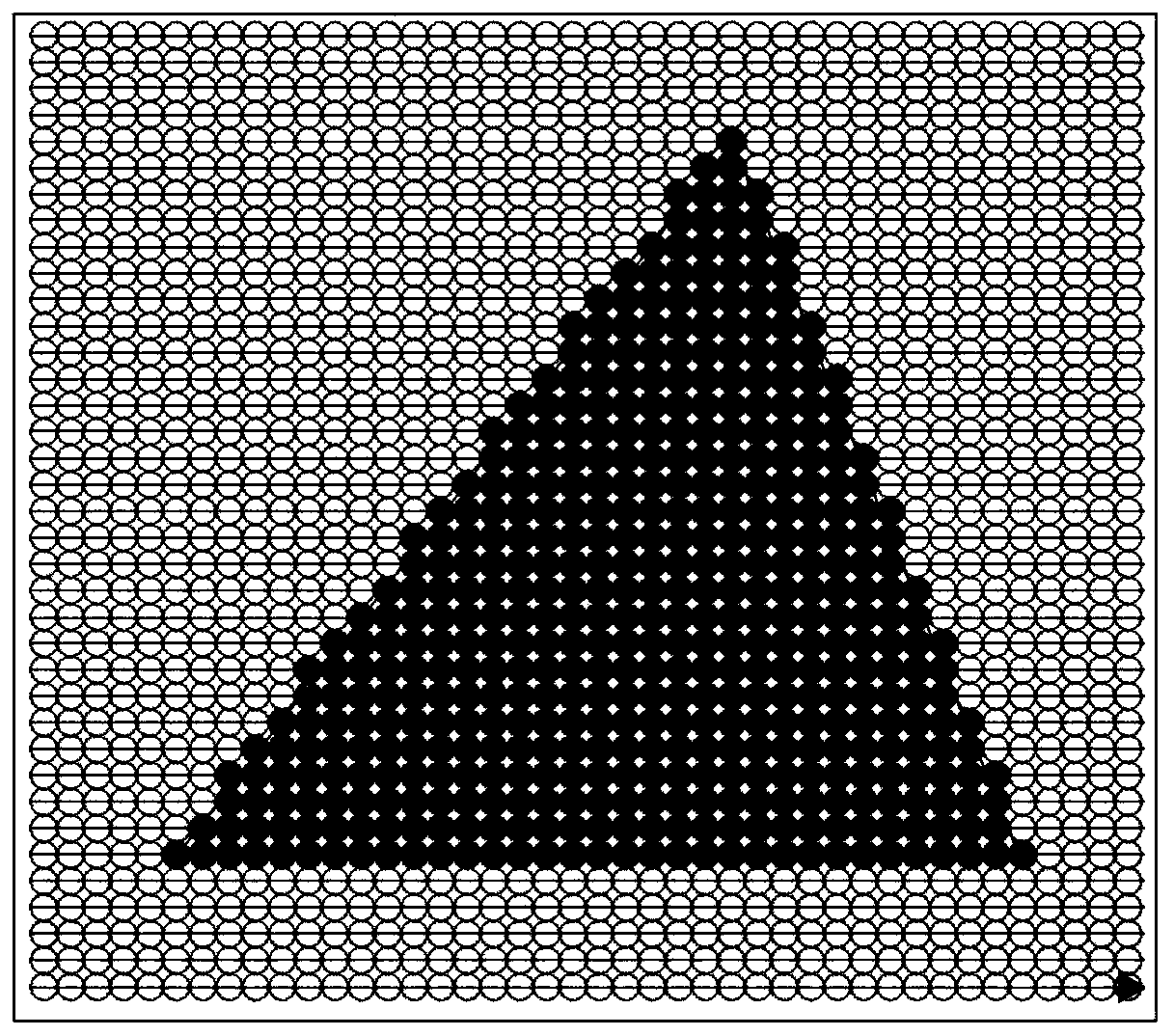

[0029] refer to Figure 1 to Figure 6 , a surface forming metal additive manufacturing method, comprising the following steps:

[0030] 1) Parameter setting: Compared with the parameter setting of traditional metal additive manufacturing, the present invention needs to perform parameters related to laser beam control. According to the molding requirements, the number m of laser beams in the x direction and the number n of laser beams in the y direction should be set first; secondly, the spot size of the original laser beam should be set according to the precision and shape of the molded part to control the beam splitting The spot size of the laser; finally, the appropriate laser power, linear energy density, scanning speed and other parameters should be set according to different molding materials.

[0031] 2) Slicing processing: import the printable CAD model of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com