Method for preparing high-purity MAX-phase ceramic powder

A ceramic powder, high-purity technology, applied in the field of preparation of high-purity MAX phase ceramic powder, can solve the problems of high product content, long heat treatment time, high sintering temperature, etc., to promote diffusion, excellent shape, and reduce reaction The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

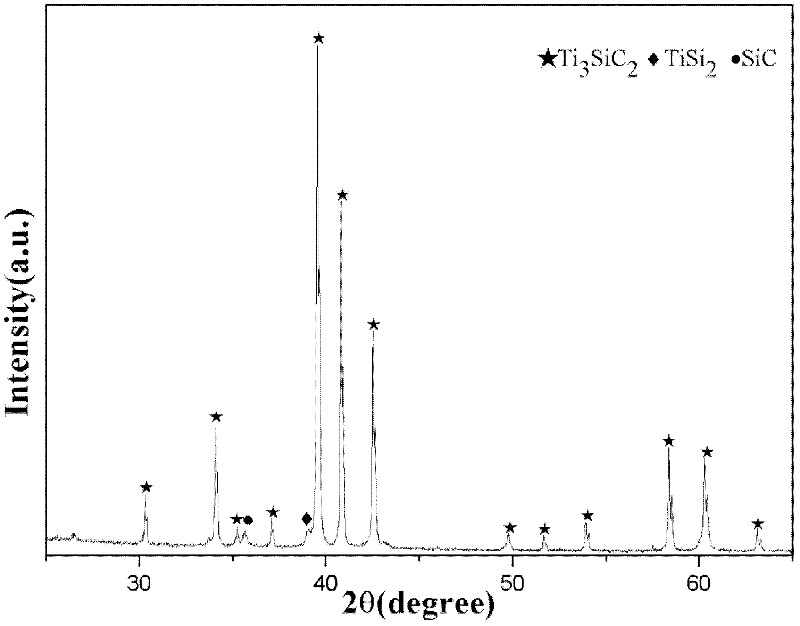

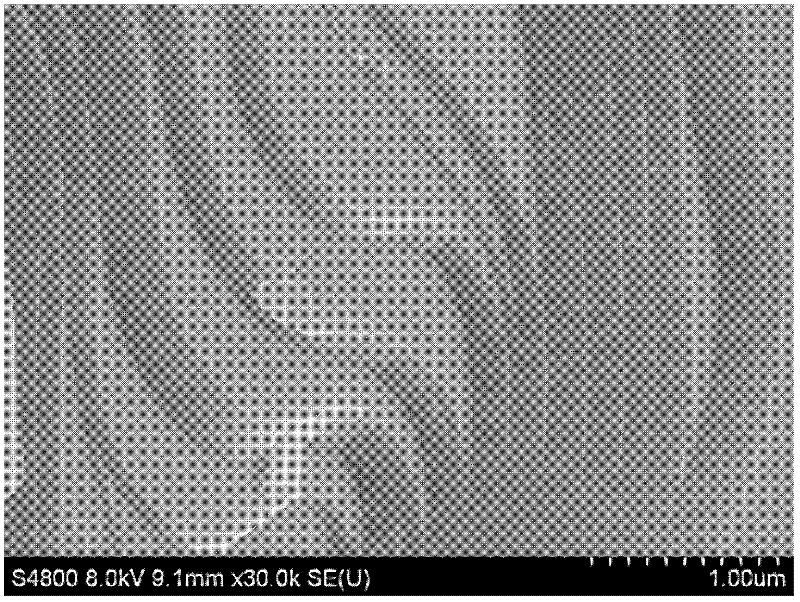

[0025] In this embodiment, the MAX phase ceramic material is Ti 3 SiC 2 , the following is the Ti 3 SiC 2 The specific preparation method of powder:

[0026] Weigh 23.9352g of titanium powder, 5.6180g of silicon powder, and 4.0032g of graphite according to the Ti / Si / C molar ratio of 3:1.2:2, and use agate as a ball on a planetary ball mill at a mass ratio of 1:1 to 80r. / min dry mixing for 12 hours, and sieve the obtained powder after ball milling. A certain amount of sieved powder was weighed and placed in a mold to be pre-pressed at a pressure of 5 MPa, and then microwave sintered in a 2.45GHz-HAMiLab-3V high vacuum microwave sintering furnace. The heating rate was controlled at 5°C / min by adjusting the power. After the temperature was raised to 1400°C, it was kept for 45 minutes, then the microwave source was turned off, and it was cooled with the furnace under an Ar atmosphere. The loose block obtained after cooling is taken out and ground to obtain the MAX phase Ti ...

Embodiment 2

[0029] In this embodiment, the MAX phase ceramic material is Ti 3 SiC 2 , the Ti 3 SiC 2 The specific preparation method of powder:

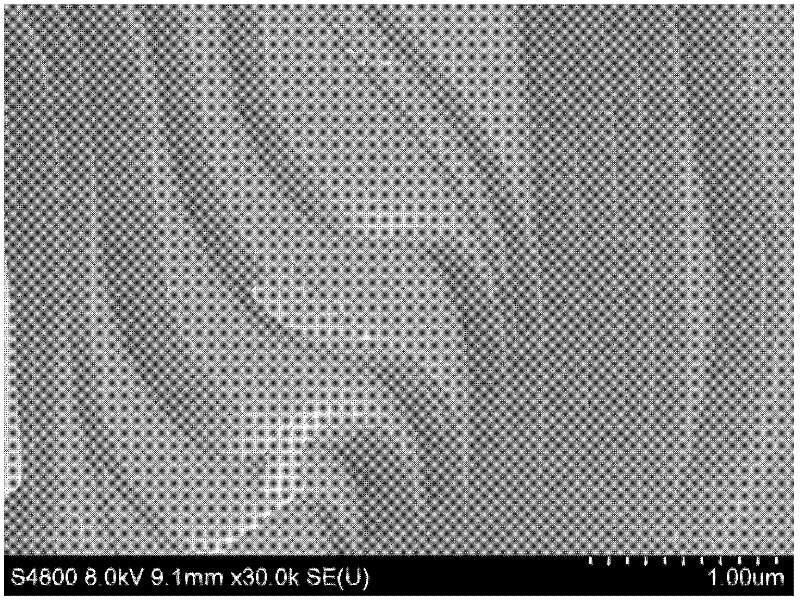

[0030] Weigh 23.9352g of titanium powder, 4.6817g of silicon powder, and 4.0032g of graphite according to the Ti / Si / C molar ratio of 3:1:2, and use agate as a ball on a planetary ball mill at a mass ratio of 2:1 to 100r / min dry mixing for 10 hours, and the resulting powder was sieved after ball milling. A certain amount of sieved powder was weighed and placed in a mold to be pre-pressed at a pressure of 10 MPa, and then microwave sintered in a 2.45GHz-HAMiLab-3V high vacuum microwave sintering furnace. The heating rate was controlled at 10°C / min by adjusting the power, and the temperature was raised to 1350°C and then kept for 60 minutes, then the microwave source was turned off, and the furnace was cooled in an Ar atmosphere. The loose block obtained after cooling is taken out and ground to obtain the MAX phase Ti 3 SiC 2 Powder.

[00...

Embodiment 3

[0033] In this embodiment, the MAX phase ceramic material is Ti 3 SiC 2 , the Ti 3 SiC 2 The specific preparation method of powder:

[0034] Weigh 23.9352g of titanium powder, 7.0226g of silicon powder, and 4.0032g of graphite according to the Ti / Si / C molar ratio of 3:1.5:2, and use agate as a ball on a planetary ball mill at a mass ratio of 3:1 to 120r. / min dry mixing for 6 hours, and the resulting powder was sieved after ball milling. A certain amount of sieved powder was weighed and placed in a mold to be pre-pressed at a pressure of 20 MPa, and then microwave sintered in a 2.45GHz-HAMiLab-3V high vacuum microwave sintering furnace. The heating rate was controlled at 15°C / min by adjusting the power, and the temperature was raised to 1450°C and then kept for 30 minutes, then the microwave source was turned off, and the furnace was cooled in an Ar atmosphere. The loose block obtained after cooling is taken out and ground to obtain the MAX phase Ti 3 SiC 2 Powder.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com