Preparation method for large-area lead iodide thick film and implementation equipment thereof

A lead iodide, large-area technology, applied in the field of preparation of large-area lead iodide polycrystalline thick films, can solve the problems of small size, poor uniformity of polycrystalline thick films, and corrosion of crystalline substrates, to overcome crystal orientation The change of the crystallization preferred orientation, the effect of increasing the grain size and junction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

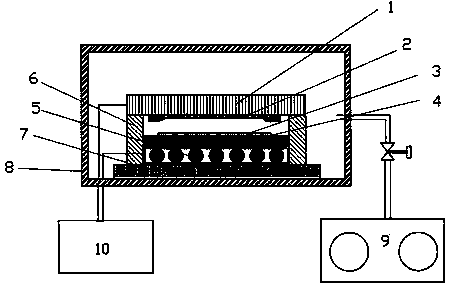

[0032] In this embodiment, the preparation area is 5×5cm 2 , lead iodide polycrystalline thick film with a thickness of 700 microns.

[0033] The processing steps of this example are as follows:

[0034] 1. Put the substrate 2 in ethanol for 30 minutes for ultrasonic cleaning, then put it in acetone for 30 minutes, and then put it in a vacuum oven for drying;

[0035] 2. Install the cleaned substrate on the directional graphite heat dissipation plate 1 to ensure that the upper surface of the substrate is closely attached to the lower surface of the graphite heat dissipation plate to facilitate heat dissipation and substrate temperature uniformity;

[0036] 3. Spread the raw material high-purity lead iodide powder (99.99%) 3 on the raw material carrier graphite plate 4 located on the flat heater 5, the area of the raw material is about 6×6cm 2 , the thickness is between 0.5-1.3 mm; then place the temperature sensor on the edge of the raw material to contact with both the ra...

Embodiment 2

[0040] In this embodiment, the preparation area is 50×50cm 2 , lead iodide polycrystalline thick film with a thickness of 500 microns.

[0041] The technology of the present embodiment is basically the same as the technology of embodiment 1, the difference is that the area of the raw material tiled on the raw material carrier graphite sheet 4 is about 52 × 52 cm 2 , the thickness is between 0.5-1.0 mm, the distance between the lower surface of the substrate and the upper surface of the raw material is 50 mm, and the vacuum degree of the vacuum chamber 8 is 5.0×10 -2 Pa, the heating rate of the plate heater is 5°C / min, the raw material is heated to 300°C, and kept for 60 minutes.

Embodiment 3

[0043] In this embodiment, the preparation area is 20×20cm 2 , lead iodide polycrystalline thick film with a thickness of 1000 microns.

[0044] The technology of the present embodiment is basically the same as the technology of embodiment 1, the difference is that the area of the raw material tiled on the raw material carrier graphite sheet 4 is about 22 × 22 cm 2 , the thickness is between 1.1-2.0 mm, the distance between the lower surface of the substrate and the upper surface of the raw material is 30 mm, and the vacuum degree of the vacuum chamber 8 is 1.0×10 -5 Pa, the heating rate of the plate heater is 3°C / min, the raw material is heated to 220°C, and kept for 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com