Prism-array jet micro-channel radiator

A technology of array jets and micro-channels, applied in cooling/ventilation/heating transformation, etc., can solve problems such as pressure drop increase and heat removal, and achieve the effect of reducing pressure drop, sufficient heat exchange, and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

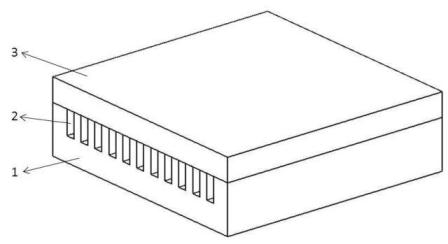

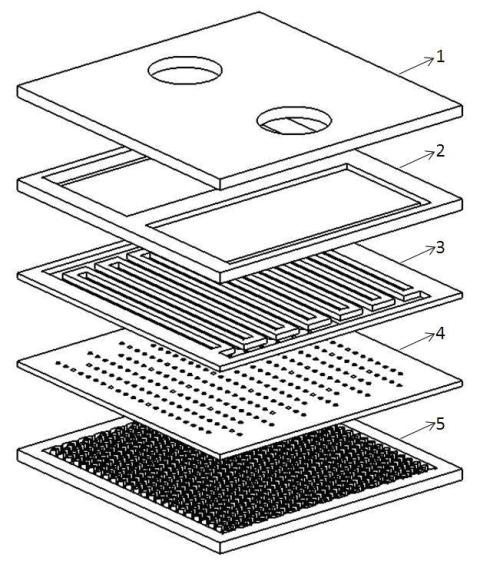

[0025] Embodiment one: see figure 2 , the prism array jet microchannel heat sink is composed of an entrance and exit structure layer 1, a liquid separation structure layer 2, an entrance and exit intersection structure layer 3, a jet structure layer 4, and a prism array structure layer 5. It is characterized in that each layer The corresponding sides have the same size and form a compact whole.

Embodiment 2

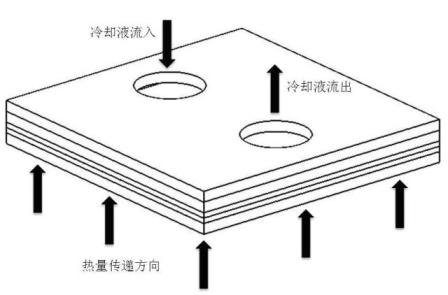

[0026] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: see Figure 4 , the entrances 6 and 7 of the entrance and exit structure layer 1 are round openings, which are convenient for connection with pipelines, and the material is silicon or a material with lower thermal conductivity.

[0027] see Figure 5 , the liquid separation structure layer 2 has non-through grooves 8, 9 aligned with the inlets and outlets 6, 7 and through side gaps 10, 11 on both sides, leading the liquid to the through side gaps 10, 11 on both sides. The width of the middle interlayer of the non-through grooves 8, 9 is determined according to the material properties, so as to avoid heat transfer as much as possible.

[0028] see Figure 6 , the entrance and exit intersection structure layer 3 has two intersecting comb-shaped through-slots 12, 13, the number and size of the comb-shaped through-slots 12, 13 are determined according to actual re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com