Intelligent cooling water passage system for concrete

A concrete and cooling water pipe technology, which is applied in the field of concrete water cooling temperature control system, can solve the problems of limited detection data, lagging control, poor monitoring environment, etc., and achieve the effects of reducing temperature tensile stress, preventing cracks, and reducing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

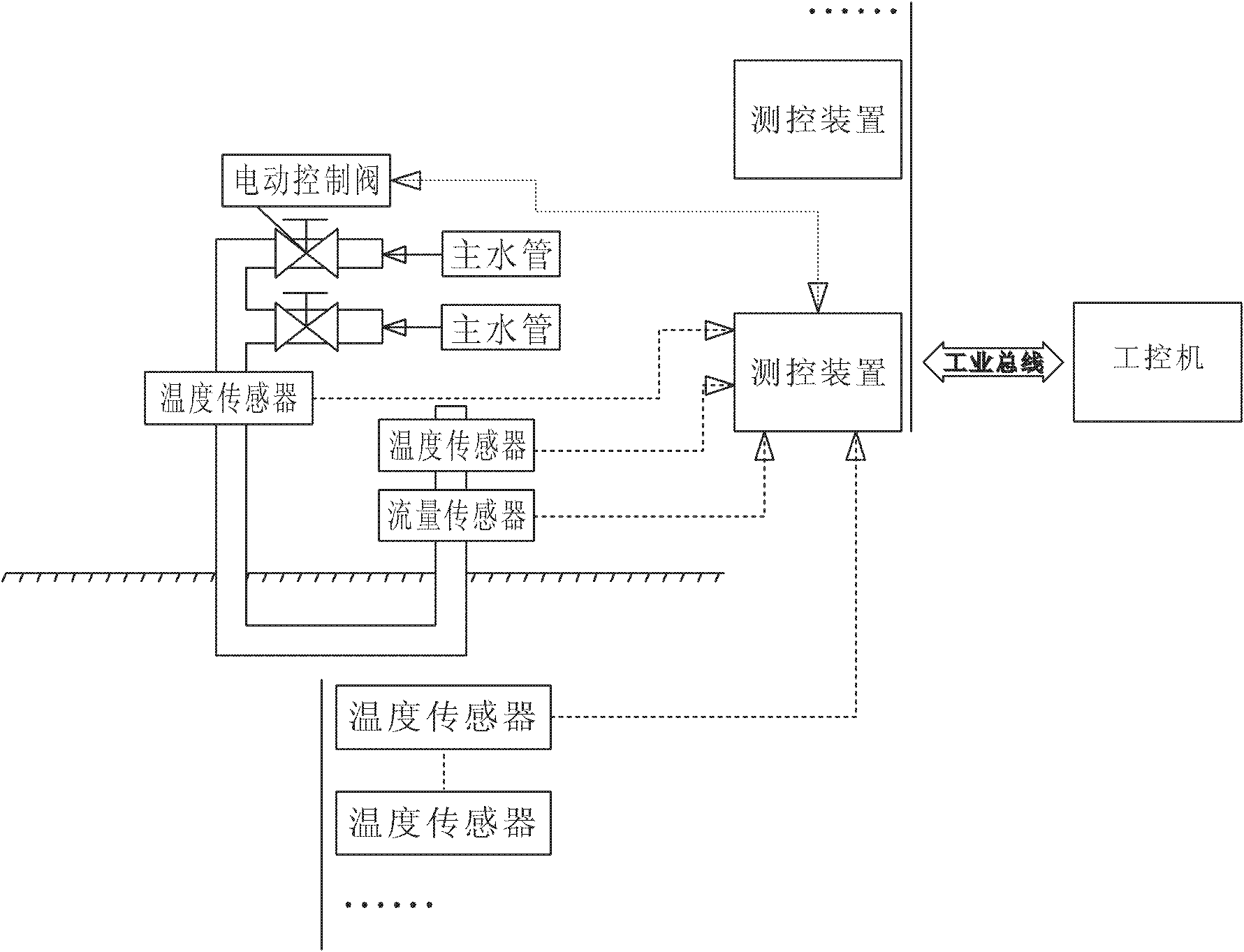

[0017] Embodiment 1: Take the structure of a control unit of the concrete intelligent cooling and water supply system as an example: 1) Install a temperature sensor in the concrete to measure the actual temperature of the concrete; 2) Install an electric control valve and a flow sensor on the cooling water pipe. A temperature sensor is installed; 3) A measurement and control device is installed near the electric control valve, and the measurement and control device is connected to the sensor and the electric control valve through a cable to obtain the temperature information of the concrete, the temperature and flow information of the cooling water pipe, and the opening information of the electric control valve. And send control signals to the electric control valve; 4) Multiple measurement and control devices are connected to the industrial computer through the industrial bus, and each measurement and control device can control up to 50 measurement and control units, and the to...

Embodiment 2

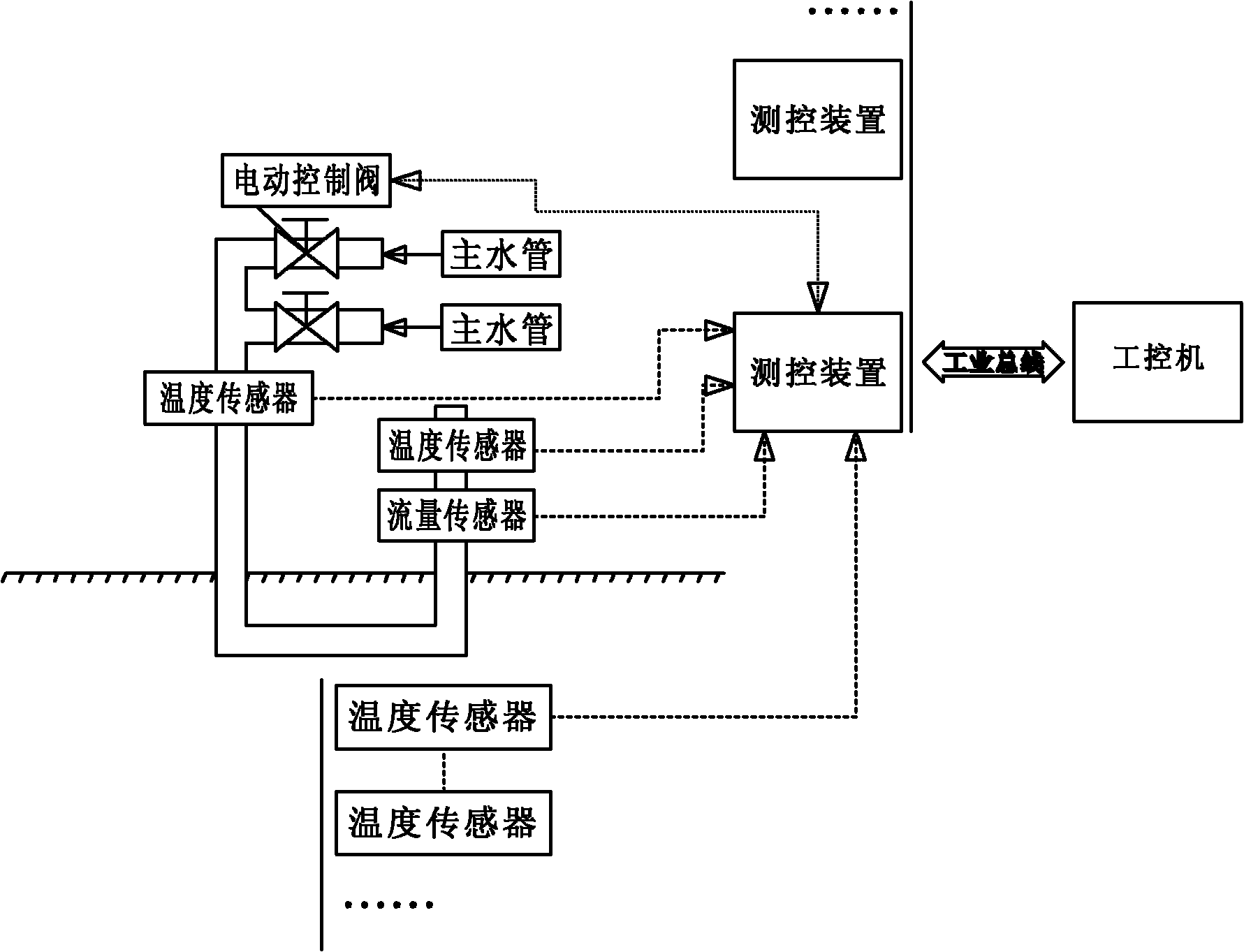

[0018] Example 2: It should be noted that different concrete blocks require cooling water at different temperatures for cooling, so in many projects more than one set of cooling water pipe systems will be arranged, usually two cooling water pipes with different water temperatures. As an optimized solution, compared with the previous embodiment, two or more electric control valves are installed at the water inlet or outlet of the cooling water pipe, which communicate with main water pipes with different water temperatures respectively.

[0019] Such as figure 1 Among them, taking a control unit structure as an example, the sensor data that needs to be collected include flow rate, water inlet temperature, water outlet temperature, and concrete temperature; what needs to be controlled is an electric control valve, and the collection and control signals are all passed through the measurement and control device, field bus and industrial computer. Connect to realize automatic data c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com