Method for rapidly preparing gradient metal ceramic composite material by laser induction hybrid cladding

A laser induction, cermet technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of reducing the temperature gradient, no cracks in the structure, and eliminating the interface stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

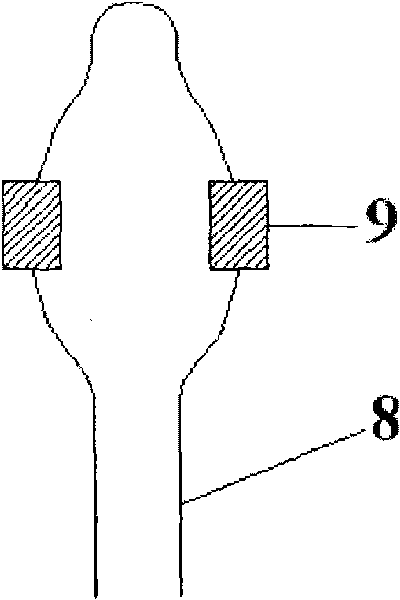

[0045] Preparation of NiCrAlY-ZrO 2 Gradient metal-ceramic composite parts, the part has the structure of an aeroengine blade, the root of the blade is made of NiCrAlY alloy, and ZrO is used from bottom to top 2 The mass percentage varies from 0% to 100%, and the tip of the blade is pure ZrO 2 Material.

[0046] The implementation process of this embodiment is:

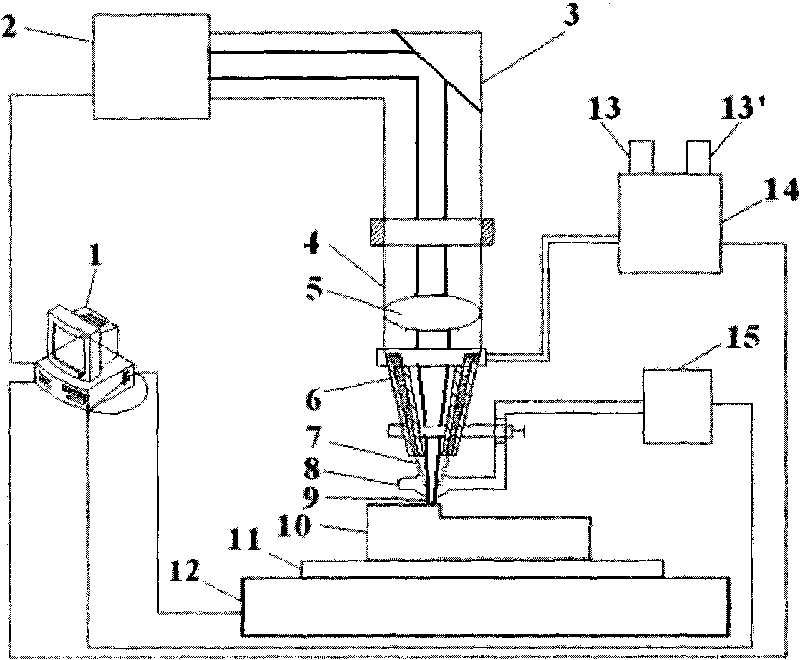

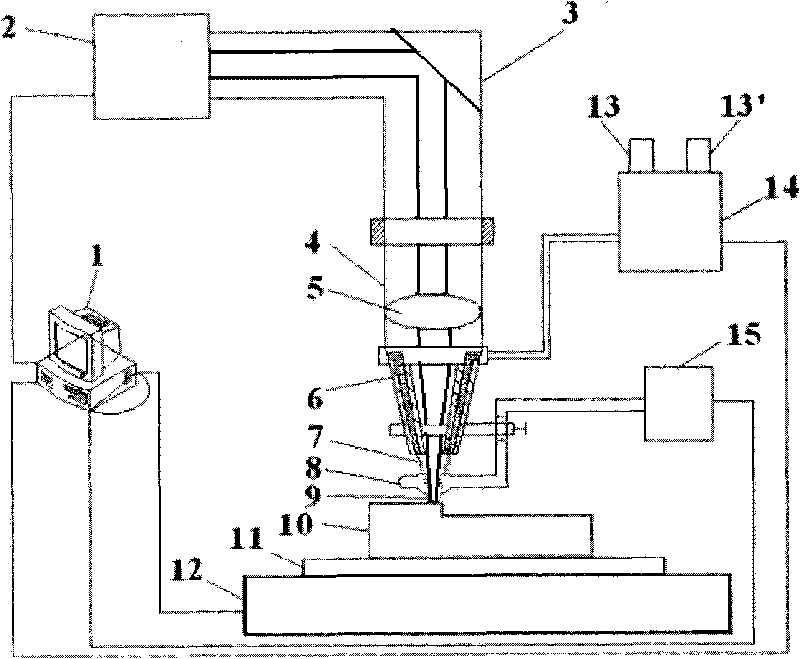

[0047] (1) First, NiCrAlY-ZrO is paired by computer 1 2 Model design and layered "slicing" processing of aviation blade material parts: generate a 3D CAD model of the part in computer 1, and cut the model into a series of thin slices with a certain thickness and parallel to each other according to the requirements of processing accuracy and gradient structure design , that is, "slice" processing, so as to convert the three-dimensional data information of the part into a series of two-dimensional plane data information, form a series of scanning tracks of the laser induction composite cladding heat source parallel t...

example 2

[0054] Prepare Sellite6-WC hollow shaft gradient cermet composite parts, the inner surface of the part is Sellite6 alloy, the mass percentage of WC particles changes from 0% to 100% along the radial direction from the inside to the outside, and the outer layer is pure WC Material.

[0055] (1) First, carry out model design and layered "slicing" processing on the Sellite6-WC hollow shaft gradient metal-ceramic composite part through computer 1: generate a 3D CAD model of the part in computer 1, and perform the processing according to the machining accuracy and gradient structure The design requires that the model be cut into a series of thin slices with a certain thickness and parallel to each other, that is, "slicing" processing, so as to convert the three-dimensional data information of the part into a series of two-dimensional plane data information, forming a series of laser sensors parallel to the X-Y plane. The scanning trajectory of the composite cladding heat source is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com