Dual-beam laser selective melting and moulding equipment with exchangeable powder cylinder

A laser selective melting and forming equipment technology, applied in the field of additive manufacturing, can solve the problems of affecting the forming quality, uneven distribution of induced current, difficulty in ensuring the uniformity of powder preheating and forming efficiency, etc., to achieve energy stability and reduce components Deformation and cracking, stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

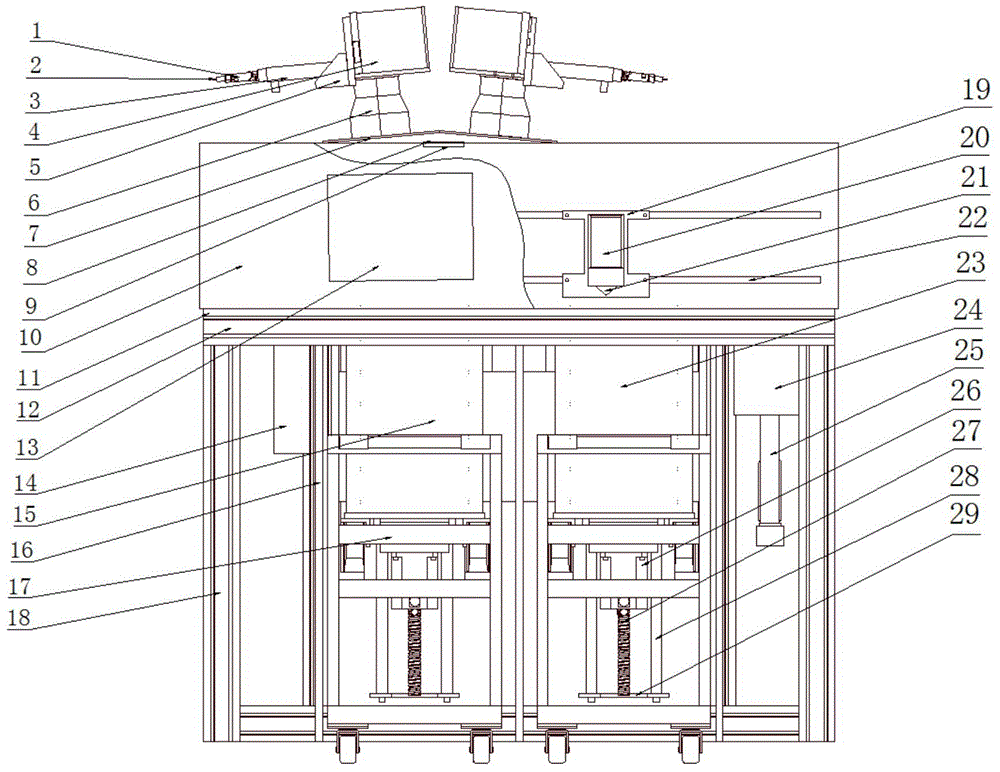

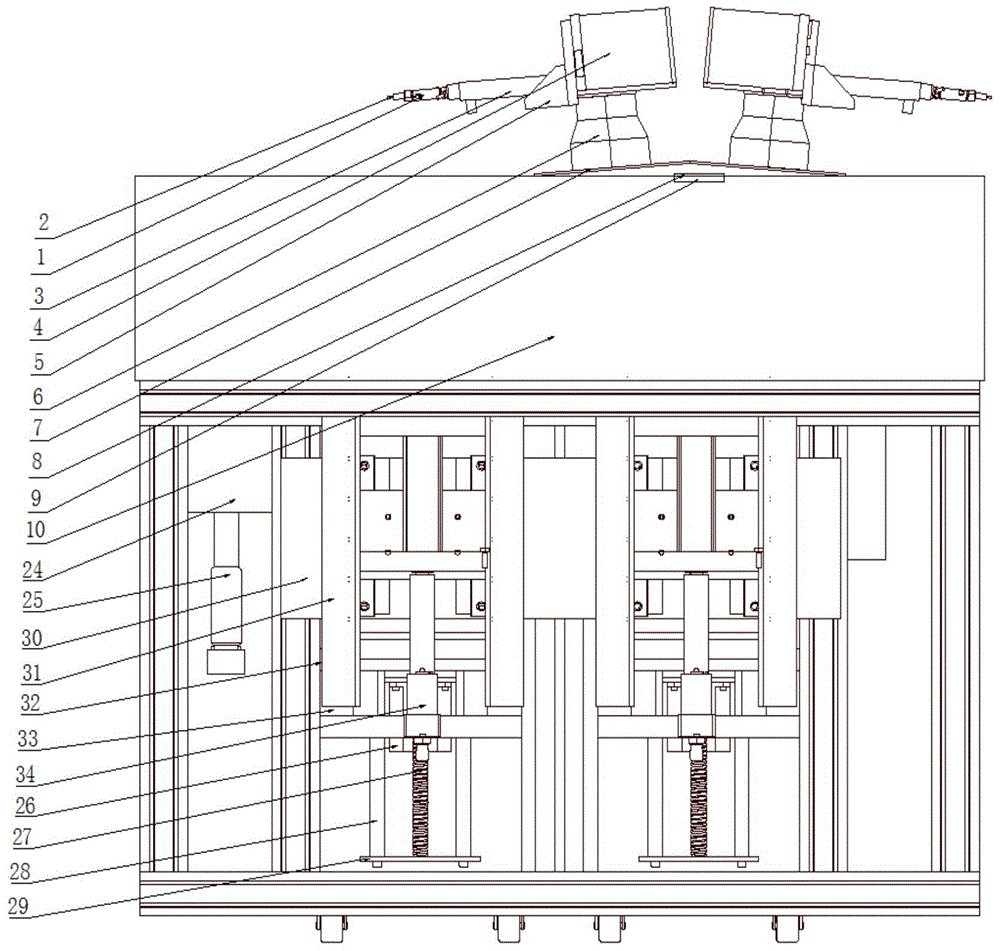

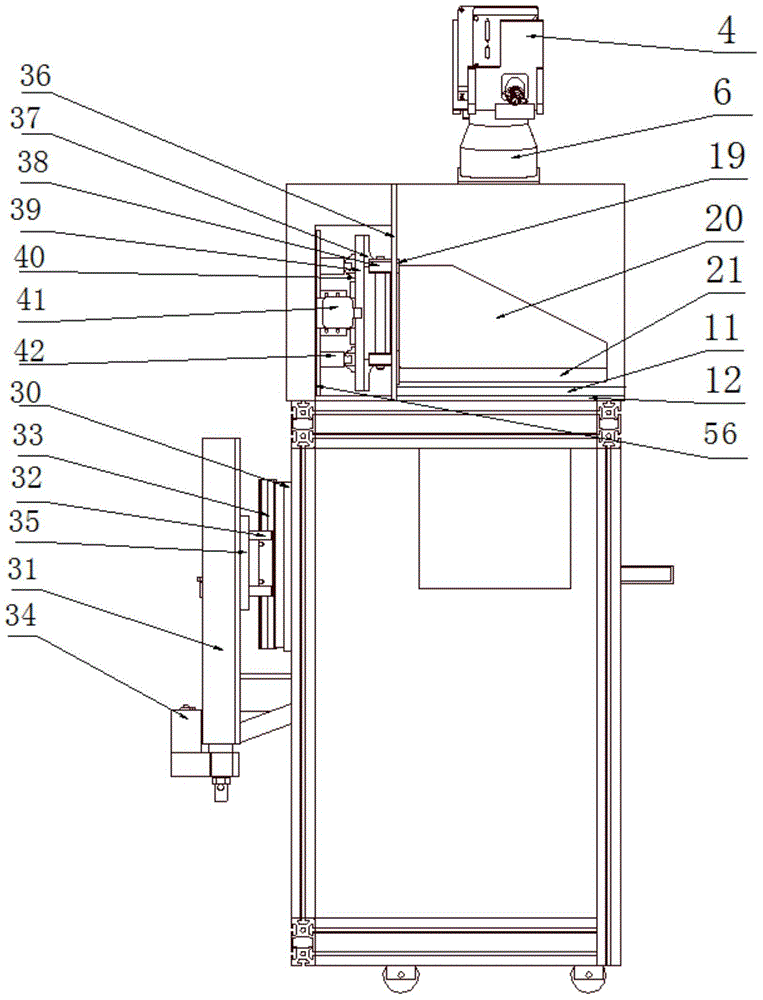

[0038] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , the replaceable powder tank dual-beam laser selective melting forming equipment described in the present invention includes two optical path systems, a frame 18, a worktable 11, a powder feeding cylinder 23, a powder storage cylinder 24, a forming cylinder 15, and a powder return cylinder 14 , the forming cavity 10 and two first drive mechanisms that respectively drive the forming cylinder 15 and the powder feeding cylinder 23 to move up and down; the worktable 11 is fixed on the frame 18, the forming cavity 10 is fixed on the upper surface of the worktable 11, and The powder cylinder 14, the forming cylinder 15, the powder feeding cylinder 23 and the powder storage cylinder 24 are fixed on the lower surface of the worktable 11 from left to right, the opening on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com