High polymer material ultraviolet laser 3D (three-dimensional) printing method and device for precise temperature control

一种高分子材料、打印装置的技术,应用在激光焊接设备、制造辅助装置、固体材料增材加工等方向,达到降低卷曲、避免麻烦的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

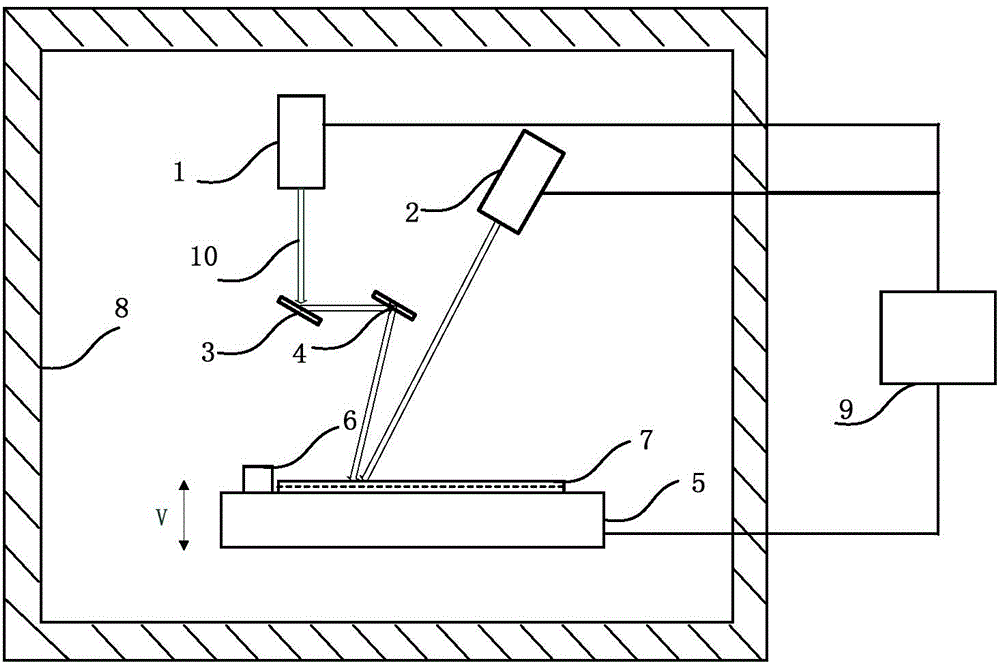

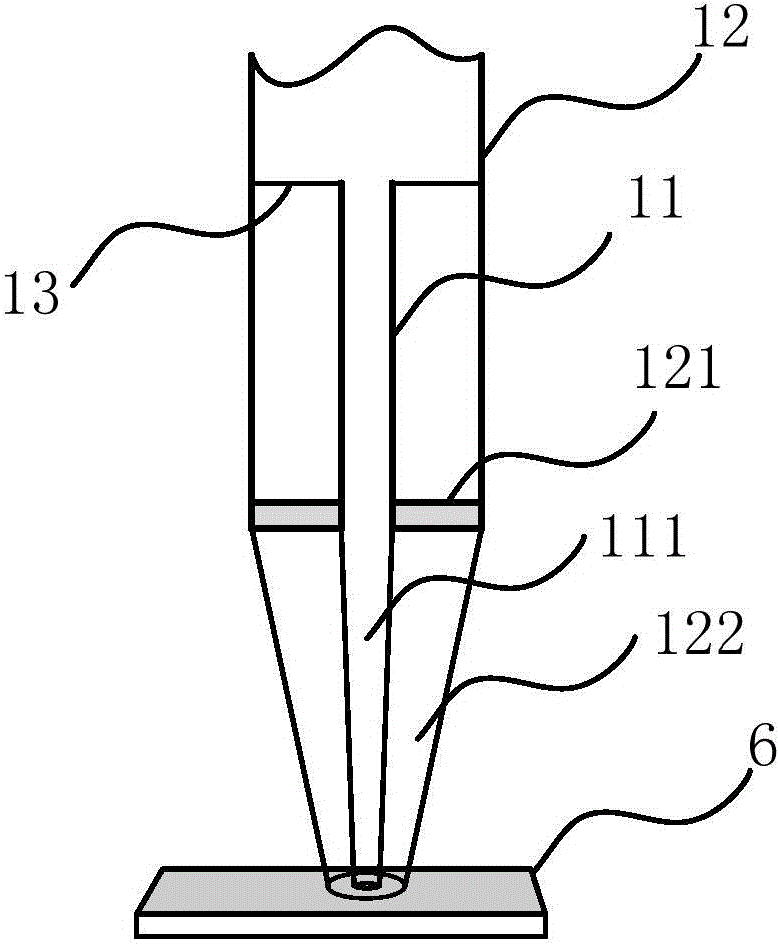

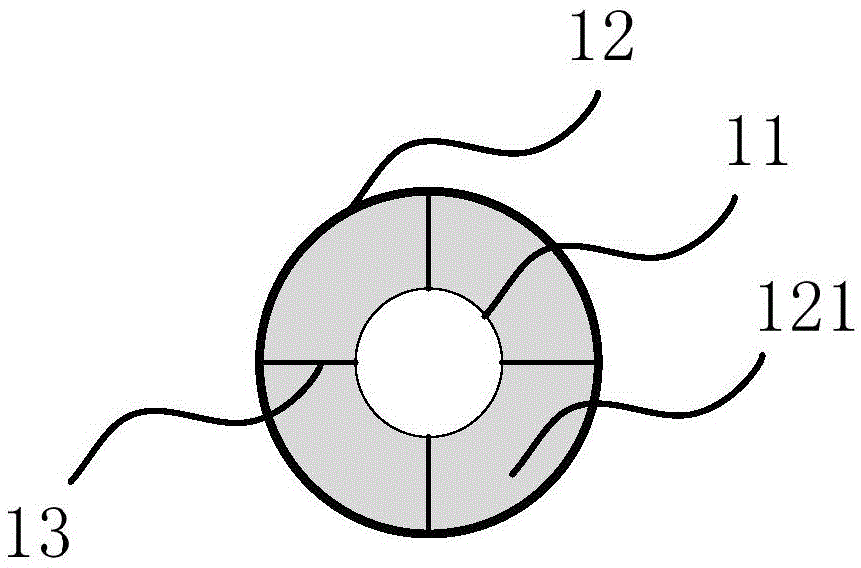

[0032] The invention provides a device for precise temperature control of ultraviolet laser 3D printing of polymer materials: where figure 1 shows a printing and forming device as an embodiment of the present invention, wherein the printing and forming device includes a thermostat 8, wherein the function of the thermostat 8 is to maintain the temperature of the polymer material to be processed during the printing process The temperature of the working environment is kept constant to reduce the influence of the change of the external environment temperature and cause the change of the process parameters, wherein the thermostat 8 can be made of a ceramic material with good heat insulation performance, and the temperature ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com