Hardcoat laminate

a technology of hardcoat and laminate, applied in the field of hardcoat laminate, can solve the problems altering the film by the organic solvent, etc., and achieve the effect of partially decreasing the transparency of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

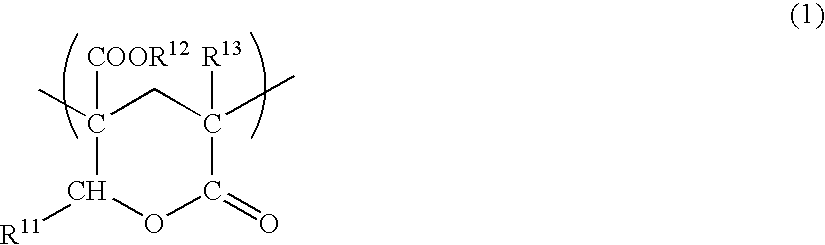

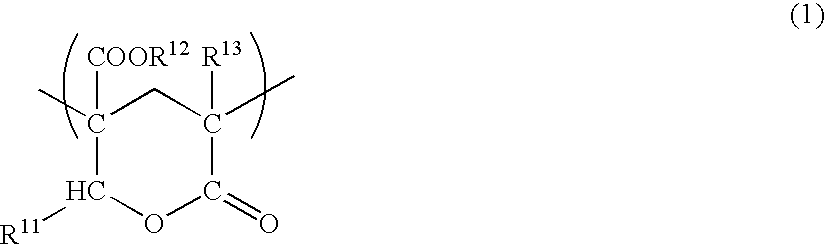

Production of Lactone Ring-Containing Polymer Pellet (P-1)

[0208]Into a 30 L-volume reaction kettle equipped with a stirring unit, a temperature sensor, a condenser and a nitrogen inlet tube, 8,000 g of methyl methacrylate (MMA), 2,000 g of methyl 2-(hydroxymethyl)acrylate (MHMA), 10,000 g of 4-methyl-2-pentanone (methyl isobutyl ketone, MIBK) and 5 g of n-dodecyl mercaptan are charged. While flowing nitrogen thereto, the temperature is raised to 105° C. and when the system started refluxing, 5.0 g of tert-butylperoxyisopropyl carbonate (“Kayacarbon Bic-75” (trade name), produced by Kayaku Akzo Corp.) is added as an initiator and as the same time, a solution containing 10.0 g of tert-butylperoxyisopropyl carbonate and 230 g of MIBK is added dropwise over 2 hours, thereby effecting solution polymerization under reflex (from about 105 to 120° C.). Furthermore, ripening is performed over 4 hours.

[0209]To the obtained polymer solution, 30 g of a stearyl phosphate / distearyl phosphate mix...

synthesis example 2

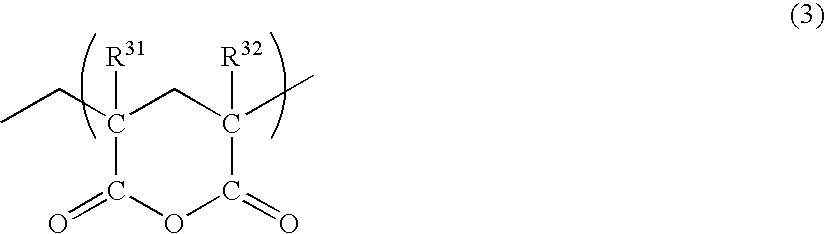

Production of Glutaric Anhydride Unit-Containing Acrylic Thermoplastic Copolymer Pellet (P-2)

[0211]20 Parts by mass of methyl methacrylate, 80 parts by mass of acrylamide, 0.3 parts by mass of potassium persulfate and 1,500 parts by mass of ion exchanged water are charged into a reaction vessel, and the system is kept at 70° C. while displacing the inside of the reaction vessel with a nitrogen gas until the monomers are completely converted into a polymer, whereby an aqueous methyl methacrylate / acrylamide copolymer-based suspension agent solution is produced.

[0212]A solution obtained by further dissolving 0.05 parts of the obtained aqueous methyl methacrylate / acrylamide copolymer-based suspension agent solution in 165 parts of ion exchanged water is fed to a stainless steel-made autoclave and stirred, and the inside of the system is displaced with a nitrogen gas. Thereafter, the following monomer mixture is added while stirring the reaction system, and the temperature is raised to ...

production example 1

Production of Support (SP-1)

[0216]Pellet (P-1) and an acrylonitrile-styrene (AS) resin (TOYO AS AS20″ (trade name), produced by Toyo Styrene Co., Ltd.) are kneaded using a single-screw extruder (φ=30 mm) in a mass ratio of P-1 / AS resin=90 / 10 to obtain a transparent pellet. The glass transition temperature of the obtained pellet is 127° C. This pellet is dissolved in methyl ethyl ketone (MEK), and Film (SP-1) of 60 μm is produced by a solution casting method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| TG | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com