Inflatable Enclosure

a technology of inflatable enclosures and support structures, applied in the field of inflatable enclosures, can solve the problems of current rigid or inflatable systems, inflatable support structures may wrinkle, buckle and even collapse under snow, and only suitable support structures used for shelters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

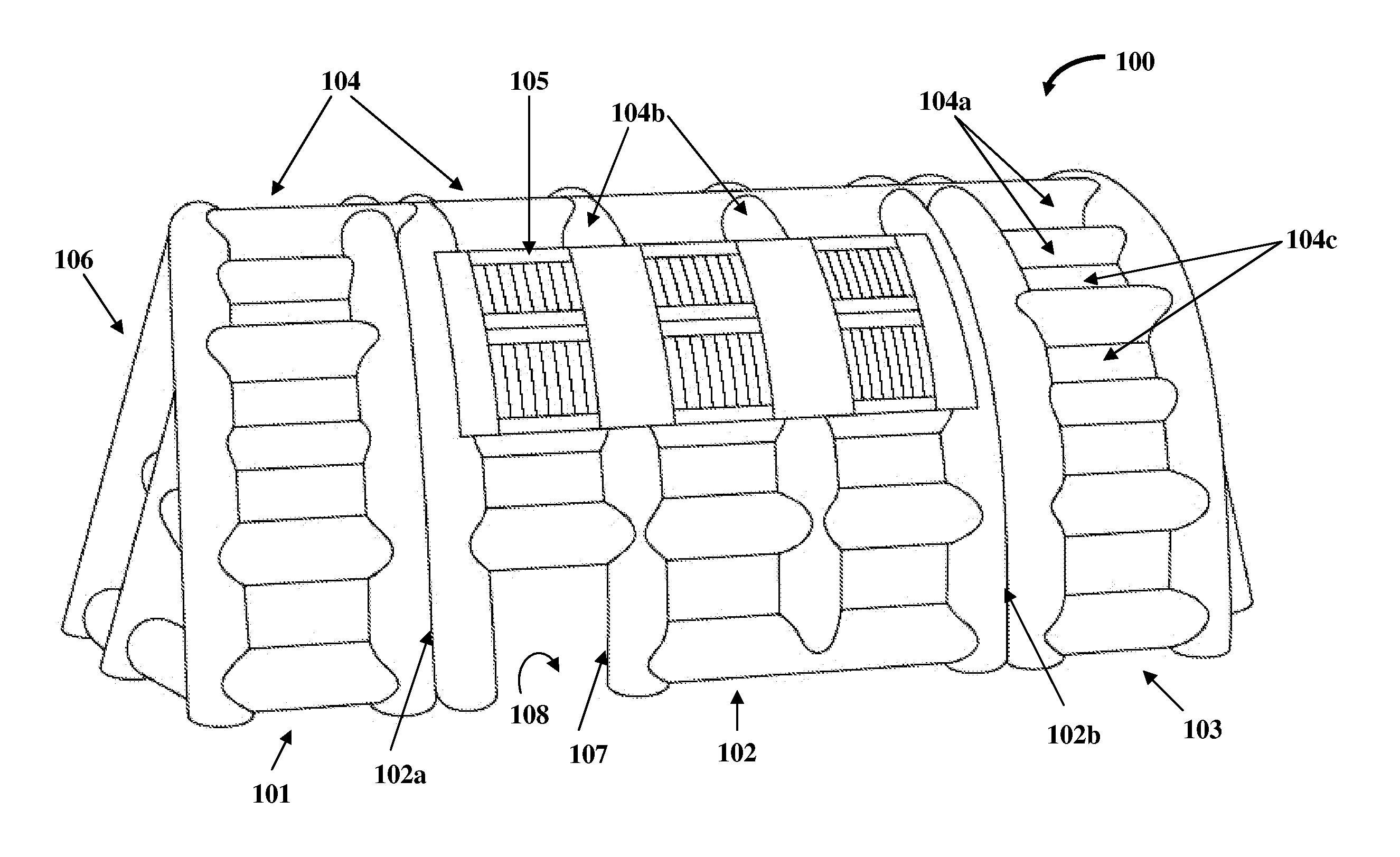

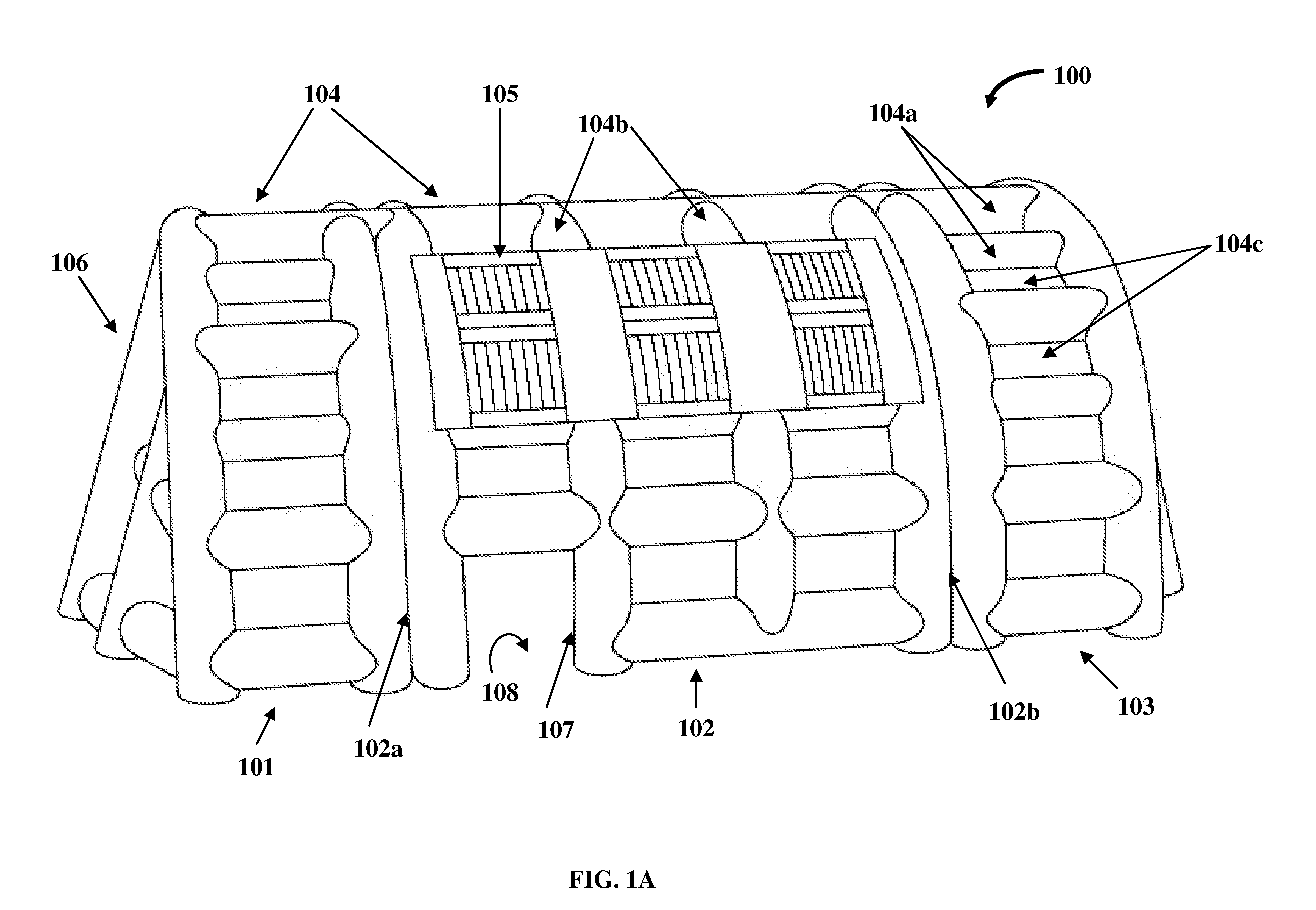

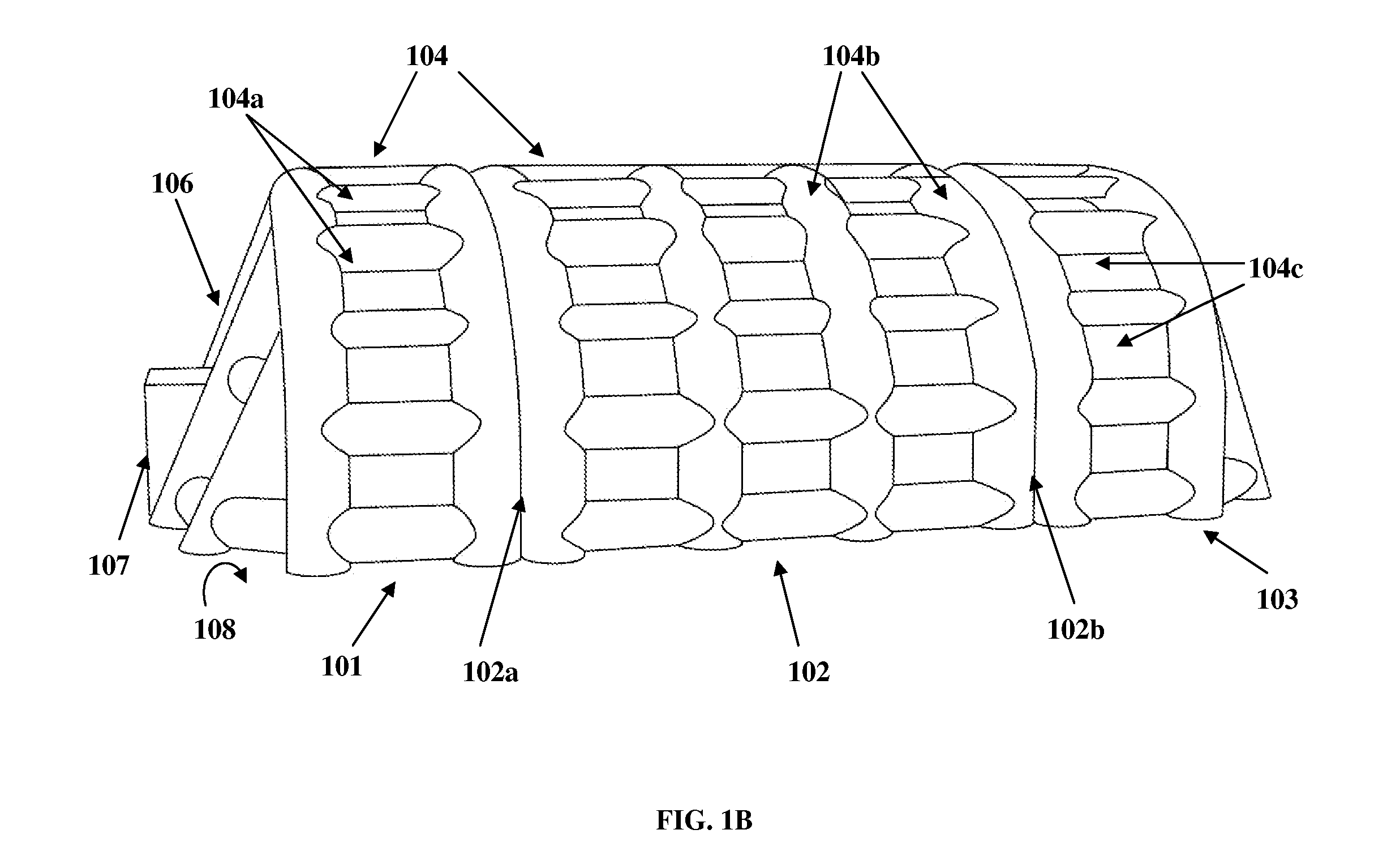

[0024]FIGS. 1A-1B exemplarily illustrate perspective views of an inflatable enclosure 100. The inflatable enclosure 100 disclosed herein is a temporary airframe enclosure erected on a ground surface 108 for different applications and activities such as living, entertainment, sports, manufacturing, storage, recreation, etc. As exemplarily illustrated in FIGS. 1A-1B, the inflatable enclosure 100 comprises an inflatable middle section 102 and one or more inflatable end sections 101 and 103 abutting opposing ends 102a and 102b of the inflatable middle section 102 to enclose a space 401 for which the inflatable enclosure 100 is designed for, for example, a sports court, an exhibition, etc., as exemplarily illustrated in FIG. 4. The inflatable middle section 102 is generally arcuate in shape. Each of the inflatable middle section 102 and the inflatable end sections 101 and 103 comprises an inflatable structural framework 104. The inflatable structural framework 104 comprises a network of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com