A tensile-strengthened connection method for metal pipe fittings

A technology of metal connection and connection method, which is applied to non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc. It can solve problems such as inconvenient construction, low strength of crimping parts, and insufficient pulling force, etc., to achieve Improve the efficiency of connection construction, reduce processing costs, and enhance the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

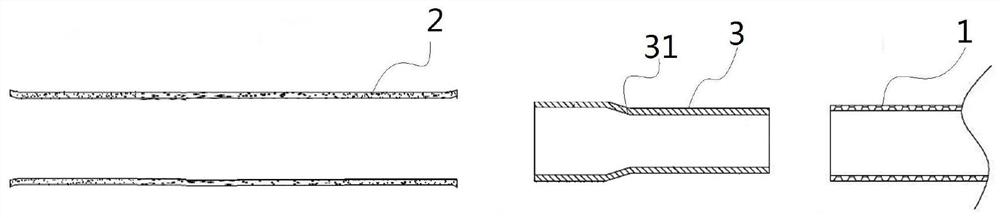

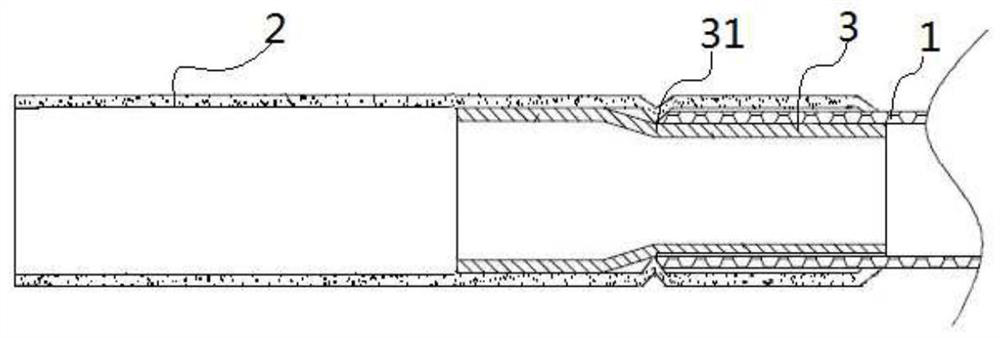

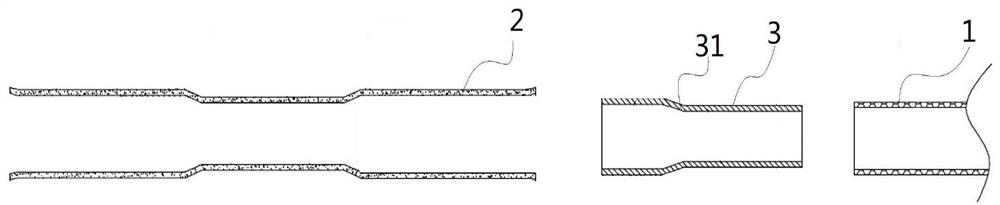

[0017] The invention relates to a tensile-strengthened connection method for metal pipe fittings, which is used for the sealed pull-out connection between the metal pipe 1 and the metal connecting pipe 2. The usual practice is that the metal pipe 1 and the metal connecting pipe 2 are connected This kind of press-fit connection is only a double-wall connection, and the pull-out resistance brought by the press-fit is not strong enough in special cases. Therefore, this solution provides an intermediate reinforcement pipe 3, which can be used to strengthen the metal pipe material 1. The connection strength and sealing performance between the metal connecting pipe 2 and the metal connecting pipe 2 can avoid the above problems. One end is flared to form an intermediate reinforcement tube 3 with two sizes of diameters. The middle part of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com