Short pipe-flange/sleeve/elbow full-automatic coupling and welding workstation

A workstation, short tube technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency, high defective rate, poor product group pairing accuracy and welding quality consistency, etc. Ensure defective rate and ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

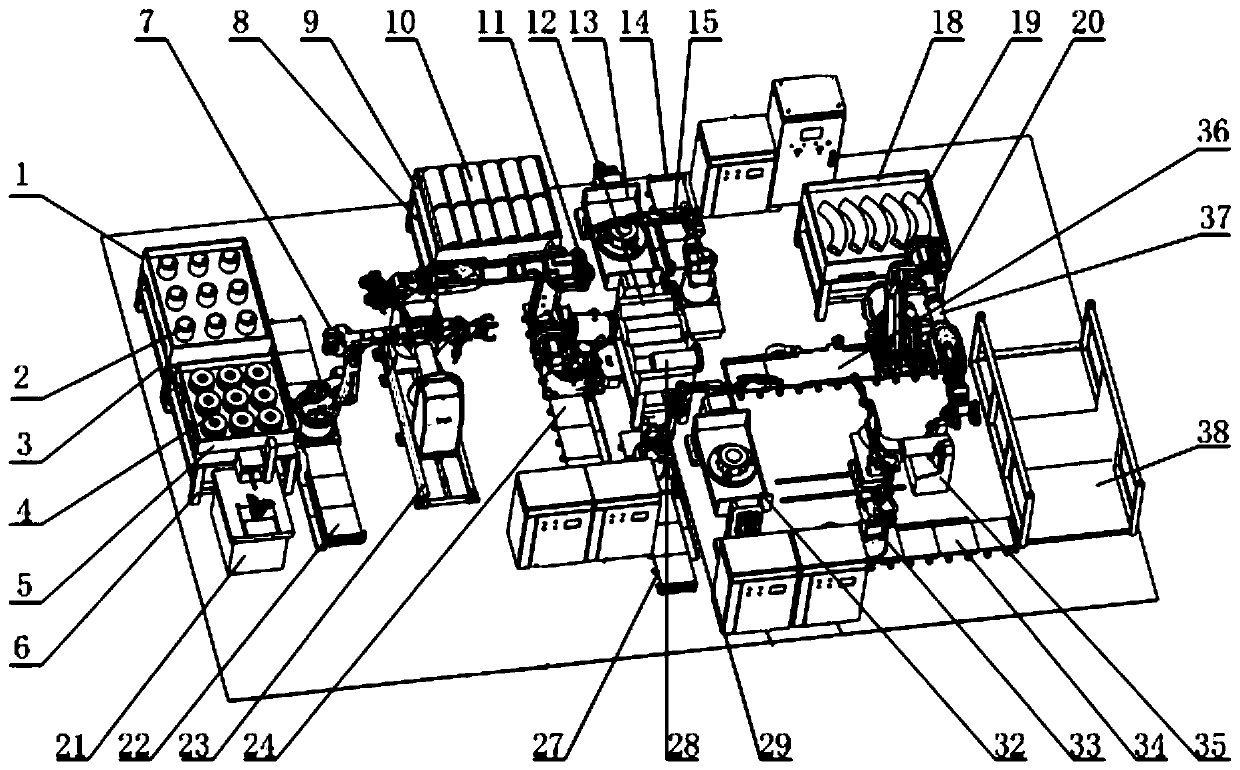

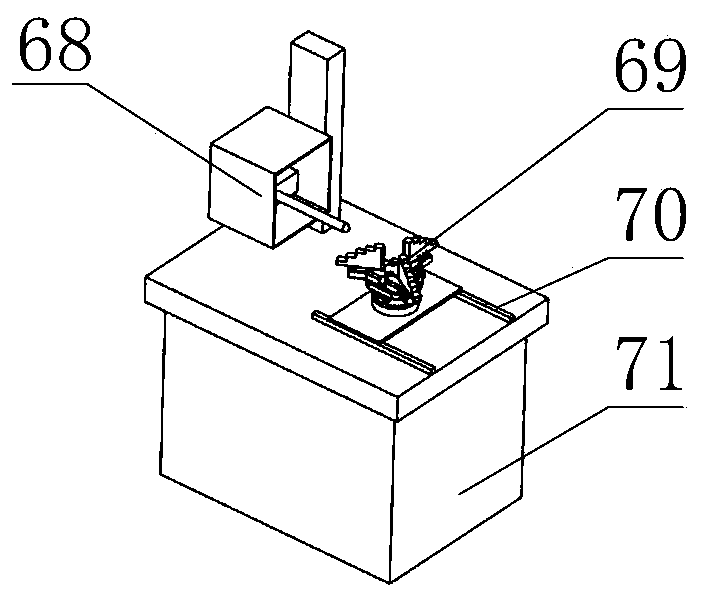

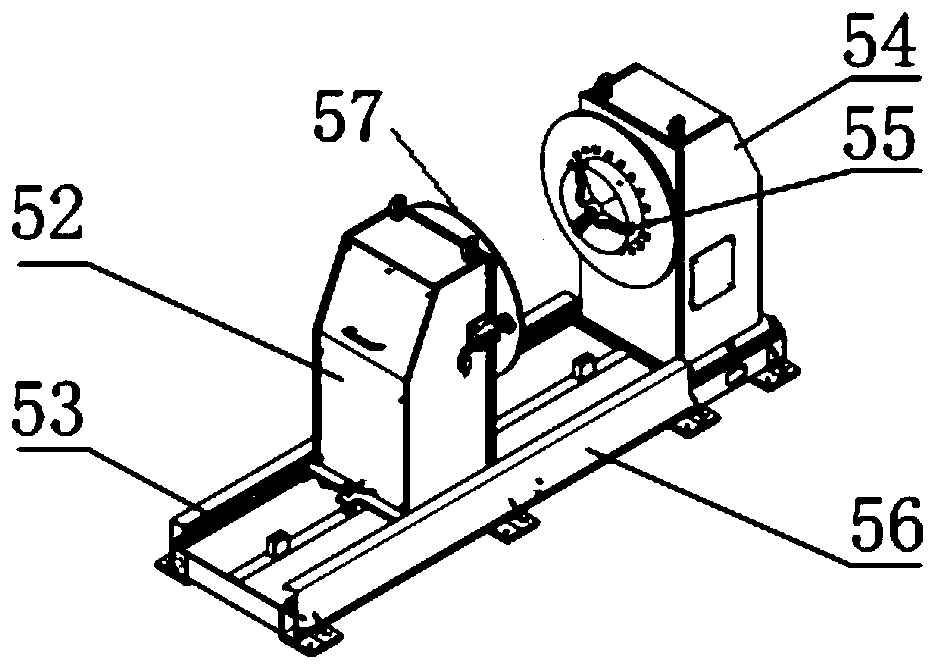

[0021] combine figure 1 , a short pipe-flange / casing / elbow fully automatic butt welding workstation of the present invention, including a casing material table 3, a flange material table 6, a short pipe material table 8, and a grasping / welding robot 7 , automatic marking machine 21, head and tail type automatic assembly machine 23, first handling robot 11, transfer positioning platform 12, first welding robot 15, second welding robot 29, first rotary positioner 13, second Rotary positioner 32, bending material table 18, second handling robot 37, pipe clamp positioner 35, third welding robot 33, finished material frame 38;

[0022] The casing material table 3, the flange material table 6, and the short pipe material table 8 are close to the grabbing / welding robot 7; the grabbing / welding robot 7 is used to grab the flange 4 on the flange materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com