Logistics system for collecting paper of large-format offset press

A logistics system and offset printing machine technology, applied in the direction of object supply, sending objects, pile separation, etc., can solve the problems of increased logistics workload, high production costs, and low work efficiency, so as to improve competitiveness, reduce logistics costs, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

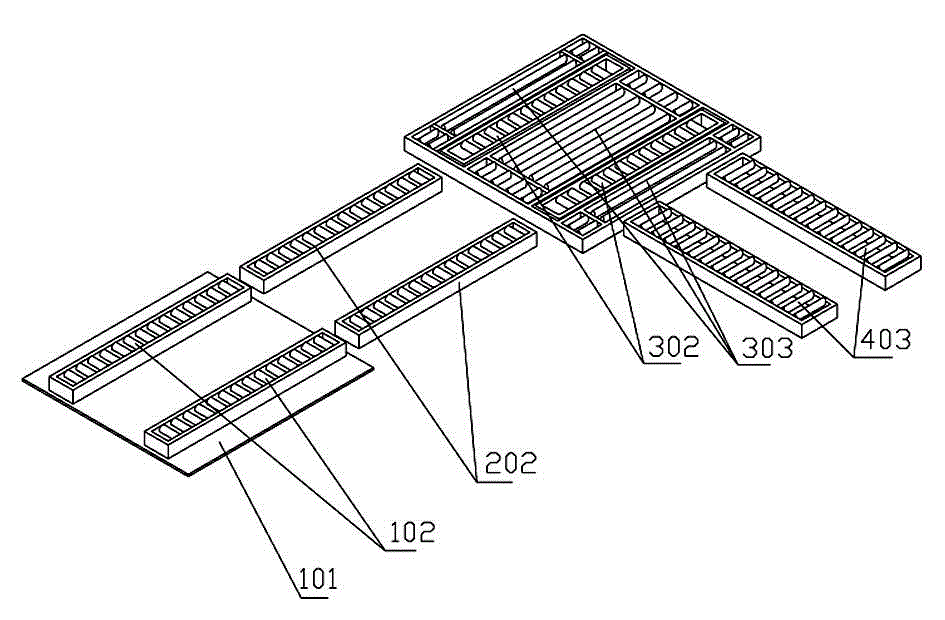

[0022] Such as figure 1 As shown, the logistics system for delivery of large-format offset printing machines of the present invention includes a delivery unit, a transition unit, a steering unit and a delivery unit connected in sequence;

[0023] The paper delivery unit of the delivery table is a horizontal paper feed roller table 102 arranged horizontally on the paper delivery table 101; the roller table can be designed as two narrow roller tables with a width of 200mm (or a width of 700~800mm) arranged in parallel at an interval of 400mm. set wider roller table); the 400mm space left in the middle is convenient for workers to stand and cross;

[0024] The transition unit is a horizontal transition roller table 202 laid on the ground on the paper delivery side of the delivery table, whose height and width are compatible with the horizontal paper feed roller table 102; since the paper delivery table of the offset printing machine needs to move up and down, the collection Alth...

Embodiment 2

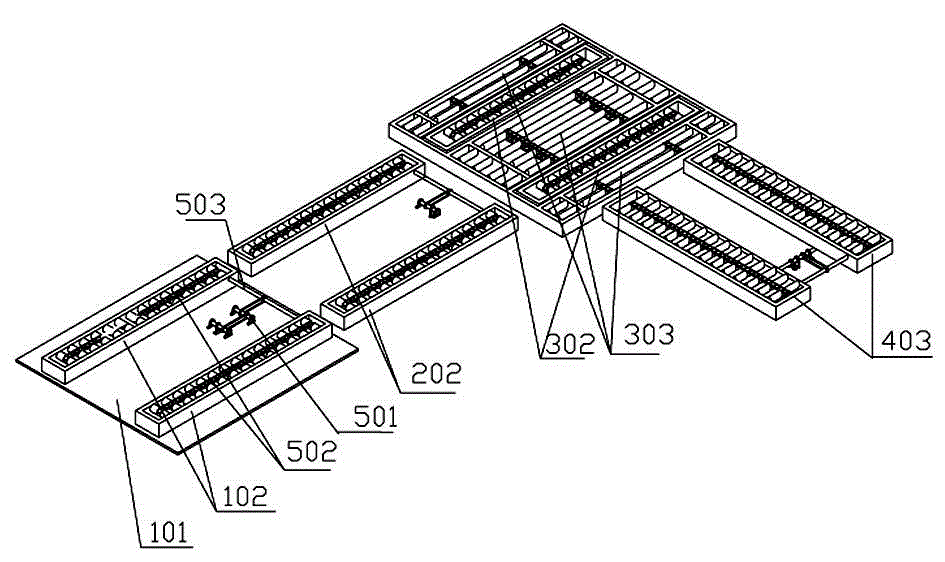

[0031] In order to improve work efficiency and reduce the labor cost of transferring paper piles, in the logistics system of embodiment 1, that is, in the horizontal paper feeding roller table 102 of the paper delivery unit of the delivery table, the horizontal transition roller table 202 of the transition unit, and the horizontal transition roller table 202 of the steering unit The horizontally running roller table 302 and the vertically running roller table 303, and the vertically sending out roller table 403 of the sending unit are respectively equipped with a power drive device 501 to realize fully automatic logistics from the delivery table to the storage area.

[0032]In actual manufacture, the power drive device can adopt the following structure:

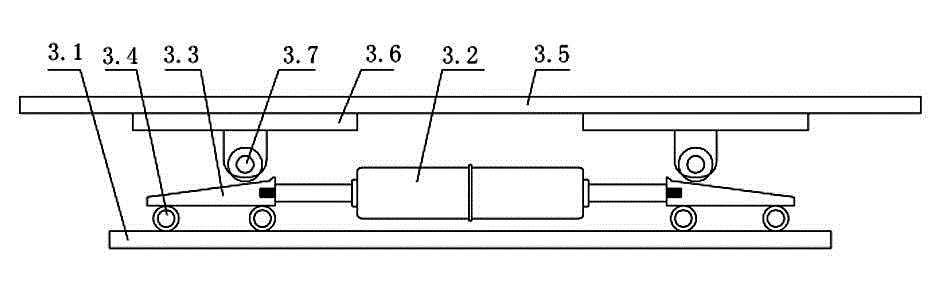

[0033] Open an annular groove on the center (short roller shaft) or both ends (long roller shaft) of the roller shaft (diameter 60mm), such as image 3 , Figure 4 As shown, a power chain 502 with a width of 30mm, a height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com