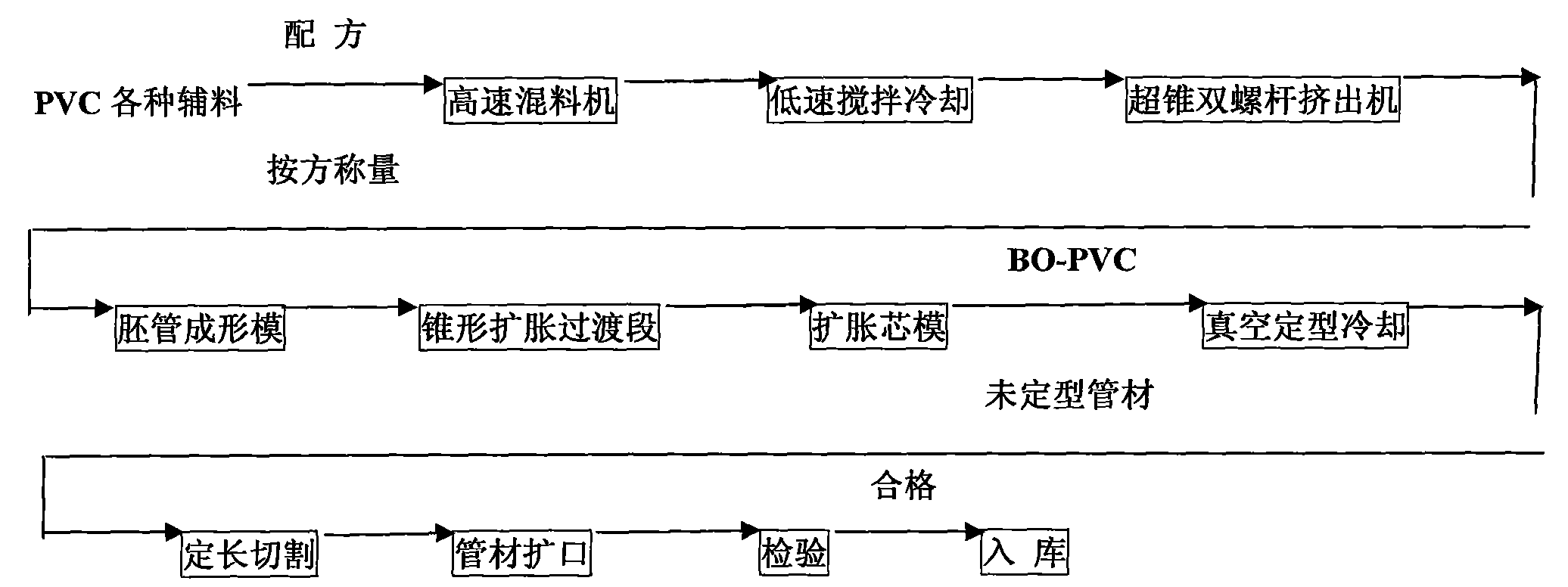

Production process for biaxially orienting polyvinyl chloride pressure-bearing pipe material on line

A polyvinyl chloride, biaxial orientation technology, applied in the field of polymer molding processing, to achieve the effect of reasonable process, continuous molding processing, and excellent formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, DN25PN 2.0 BO-PVC pressure pipe production steps

[0030] 1) Prepare materials in parts by mass:

[0031] Material name Proportion (part)

[0032] PVC resin (K value 69-72) 100

[0033] Calcium zinc compound stabilizer 3~4

[0034] HB-600E 0.4~0.6

[0035] Composite processing aid 0.8~1.2

[0036] Composite impact modifier 3~4

[0037] Composite filler 5

[0038] Anatase titanium dioxide 2.5

[0039] 2) Mixing: Put the above-mentioned prepared materials into a high-speed (1200r / min) kneader, and knead at a high speed until the material temperature reaches 120°C;

[0040] 3) Stirring and cooling: Put the above-mentioned mixed material into a low-speed (500r / min) cold mixer for stirring, and discharge it into the storage tank when the material temperature reaches 50°C for standby;

[0041] 4) Extrusion: Put the material in the storage barrel into a high-efficiency twin-screw extruder (SJSZ-60), and extrude at a temperature of (165-190) °C and a screw...

Embodiment 2

[0045] Embodiment 2, DN200PN1.6 BO-PVC pressure pipe production steps

[0046] 1) Prepare materials in parts by mass:

[0047] Material name Proportion (part)

[0048] PVC resin (K value 66-70) 100

[0049] Calcium zinc compound, organic tin stabilizer 3~4

[0050] HB-600E 0.6~08

[0051] Composite processing aid 0.8~1.0

[0052] Composite impact modifier 0~2

[0053]Composite filler 8~10

[0054] Anatase titanium dioxide 1.5

[0055] 2) Mixing: Put the above-mentioned prepared materials into a high-speed (1200r / min) kneader, and knead at a high speed until the material temperature reaches 115°C;

[0056] 3) Stirring and cooling: Put the above-mentioned mixed material into a low-speed (500r / min) cold mixer for stirring, and discharge it into the storage tank when the material temperature reaches 50°C for standby;

[0057] 4) Extrusion: Put the material in the storage barrel into a high-efficiency twin-screw extruder (SJSZ-80), and extrude at a temperature of (165-190) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com