Check valve for jacking construction of concrete-filled steel tubular column and using method of check valve

A technology for steel pipe concrete columns and steel pipe columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of non-reusable and cumbersome procedures, achieve rapid installation and removal, ensure construction efficiency, and save steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0083] Such as Figure 1-19 As shown, the present invention includes a concrete-filled steel pipe column jacking method construction check valve and its use method, including a steel pipe concrete column jacking method construction check valve and its use method.

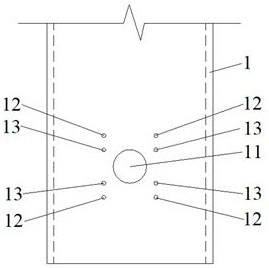

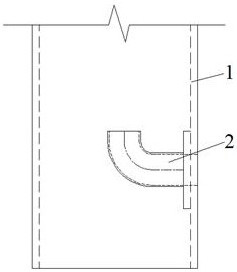

[0084] Such as Figure 1-14 As shown, a steel pipe concrete column jacking method construction check valve includes a steel pipe column 1, a diversion device 2, a gate 3, a pressure plate 4, a first-type high-strength bolt 5, a pouring pipe 6 and a second-type high-strength bolt 7 .

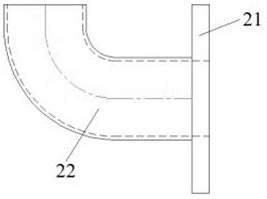

[0085] Such as Figure 1-4 As shown, the steel pipe column 1 and the diversion device 2 are first manufactured in the factory, wherein the steel pipe column 1 reserves a concrete pouring hole 11 during manufacture, and the concrete pouring hole 11 is located in the center of the steel pipe column 1 wall. The diversion device 2 is welded by the diversion device end plate 21 and the diversion pipe 22, and the welds are welded around. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com