Blast furnace hearth and blast furnace hearth pouring long life prolonging method

A blast furnace and hearth technology, which is applied in the field of blast furnace hearth and its casting longevity improvement field, can solve the problems of shortening the casting life of the hearth, affecting the heat transfer of the hearth, and reducing the heat transfer effect, so as to improve the casting effect, The heat transfer effect is good, and the effect of improving the longevity of the hearth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

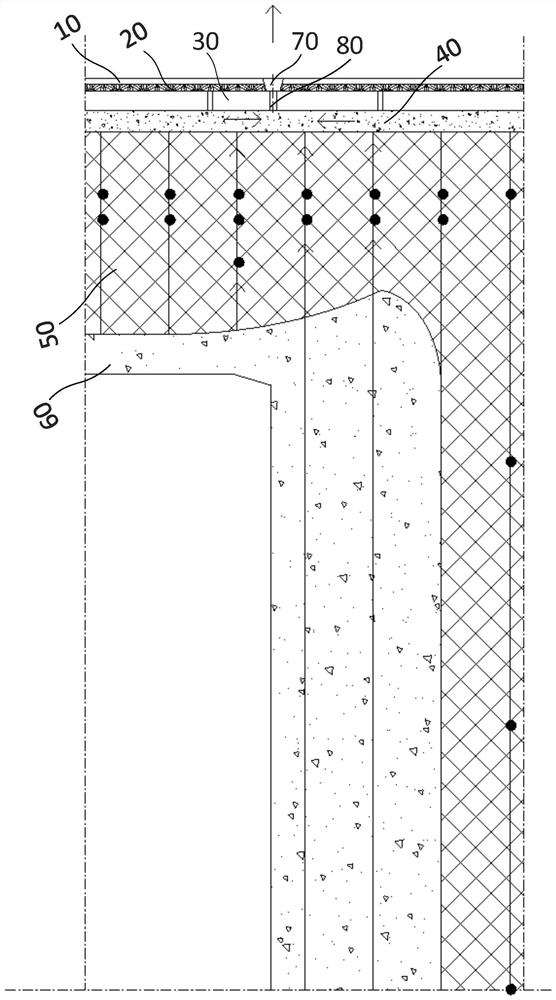

[0045] The present invention has been used in Baowu Group Shaoguan Iron and Steel 1050m 3 Blast furnace hearth quick repair upper matching application. In the hearth cleaning process of the blast furnace, there are 12 holes drilled in the hearth area, and the depth of the holes is 250mm (the thickness of the furnace shell 10 is 50mm+the thickness of the pouring layer 20 between the furnace shell 10 and the stave 30 is 40mm+ The thickness of the stave 30 is 160 mm); the furnace hearth is poured and the middle stage of baking is started to open the drain valve successively for exhausting and draining. In the later stage of baking (total baking 108 hours), there are 6 drain valves with continuous discharge of air or water. Anhydrous carbon material (resin bonded) is selected as the press-in material, and the single press-in quantity is controlled to be ≤50kg, with a total press-in of 210kg; at present, it has been in production for more than half a year, and the heat transfer ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com