Methods for manufacturing and installing steel stair temporary safety guardrail

A technology for safety guardrails and installation methods, which is applied to the treatment of railing posts, stepped structures, and building materials, and can solve the problems of high cost of guardrail materials, complicated structure of stair guardrails, and inconvenient production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for making and installing the temporary safety guardrail for steel stairs of the present invention comprises the following steps:

[0030] a. Manufacturing method of temporary safety guardrail for steel stairs.

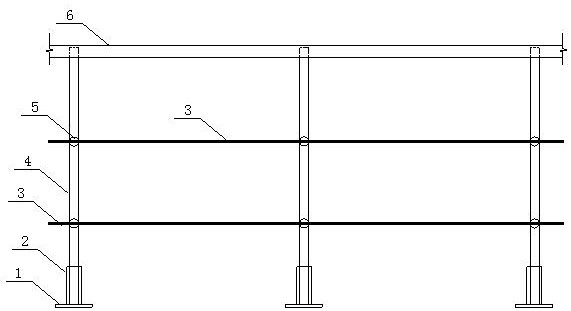

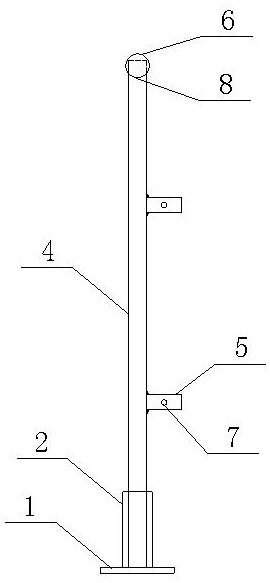

[0031] see now figure 1 and figure 2 , figure 1 It is the structural representation of the steel stair temporary safety guardrail of the embodiment of the present invention, figure 2 for figure 1 Side view of the neutral pole. As shown in the figure, the guardrail includes several bases 1, uprights 4, main cross bars, and auxiliary cross bars. The rod is made of Ø40*2.75mm steel pipe, and the height of the vertical rod is ≥1100mm. Two horizontal connecting rods 5 are welded at intervals up and down on the vertical rod, and a through hole 7 with a diameter of 16mm is drilled on the horizontal connecting rod to facilitate the penetration of the subsequent auxiliary horizontal rod; The horizontal bar adopts Ø60*3 steel pipe as the main horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com