Embedded bolt positioning method and positioning frame applied to same

A technology of pre-embedding bolts and frames, applied in the processing of building materials, infrastructure engineering, construction, etc., can solve the problems of inaccurate bolt positioning, troublesome production, large welding workload, etc., to reduce the construction welding workload, use Flexible and convenient, flexible and accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

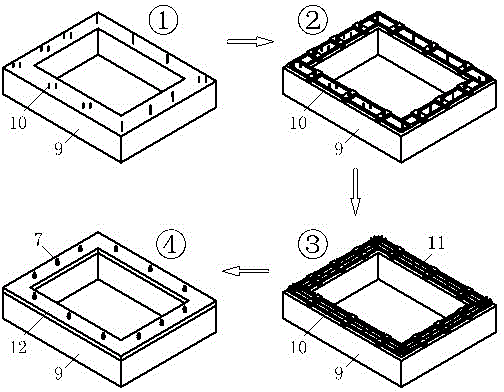

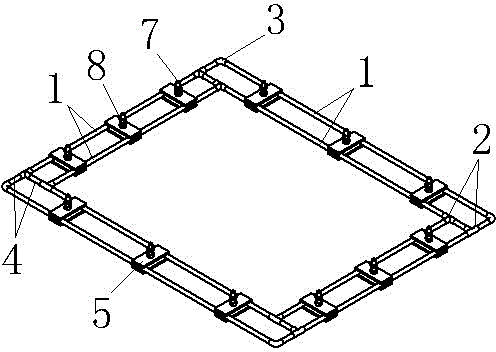

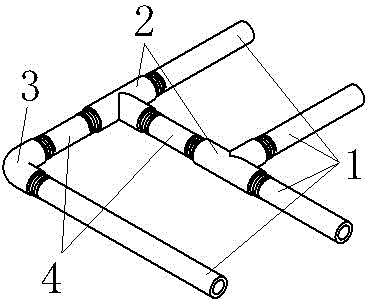

[0021] Example. A method for positioning pre-embedded bolts, the method is to use steel pipes, elbows 3 and tees 2 to form a back-shaped frame, fix a group of pre-embedded bolt assemblies on the parallel steel pipes on the four sides of the back-shaped frame according to design requirements, and then Place the zigzag frame on the top surface of the foundation, with the thread heads of the embedded bolts 7 facing upwards, and pour the zigzag frame fixed with the embedded bolts on the foundation with concrete. The pre-embedded bolt assembly includes two splints 5 arranged at the bottom and top of the zigzag frame. The embedded bolts 7 are passed through the bolt holes 6 of the two splints 5 from bottom to top, and the two splints 5 are adjusted in the zigzag frame. After the upper position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com