Variable-pressure-ratio piezoelectric fuel injector

A technology of supercharging ratio and fuel injector, which is applied in the direction of machine/engine, fuel injection device, engine components, etc., can solve the problems of complicated structure of electromagnetically controlled fuel injector and difficult flexible control of fuel injection rate, etc. The effect of improving economy and power, improving flexibility, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

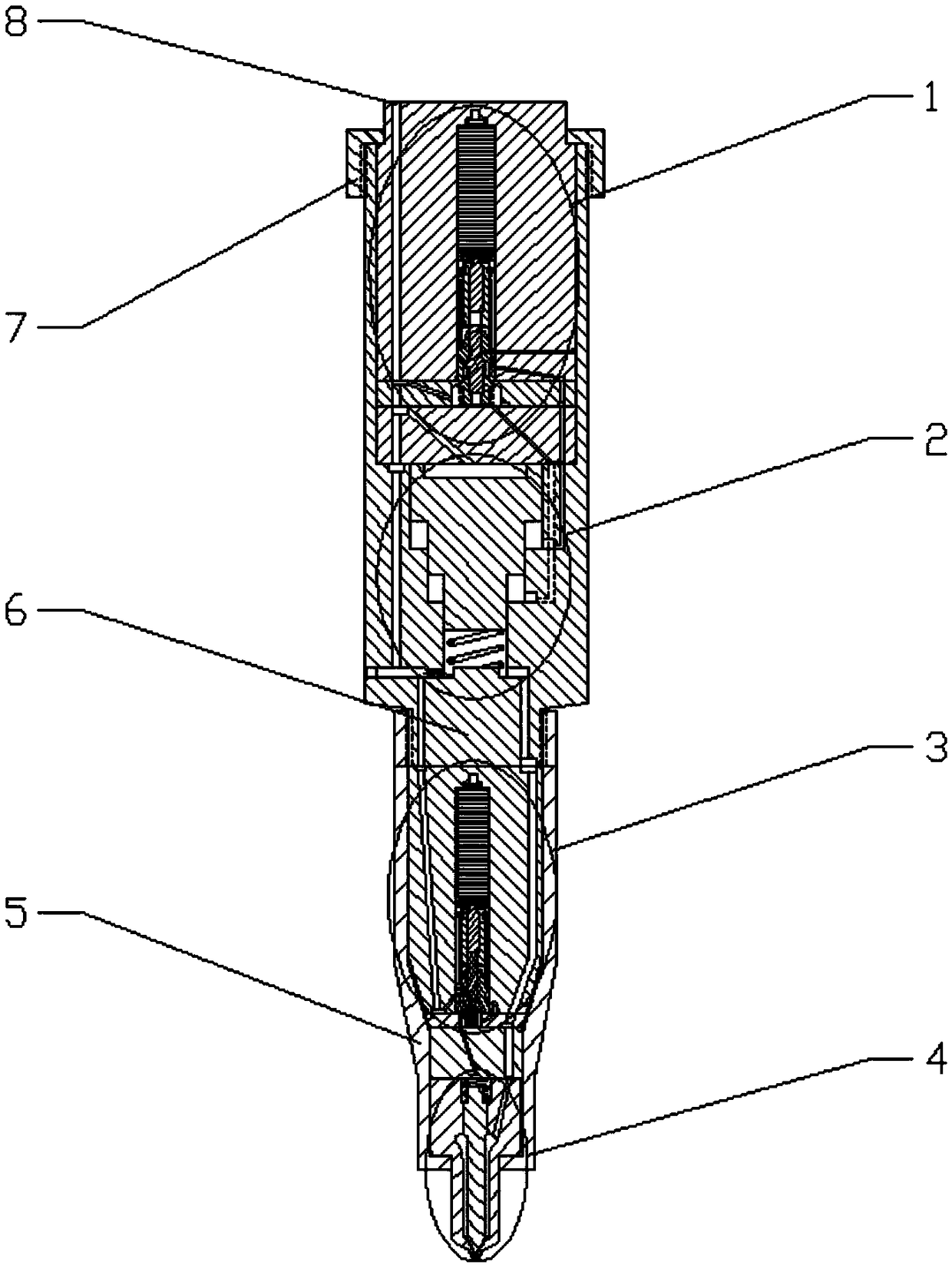

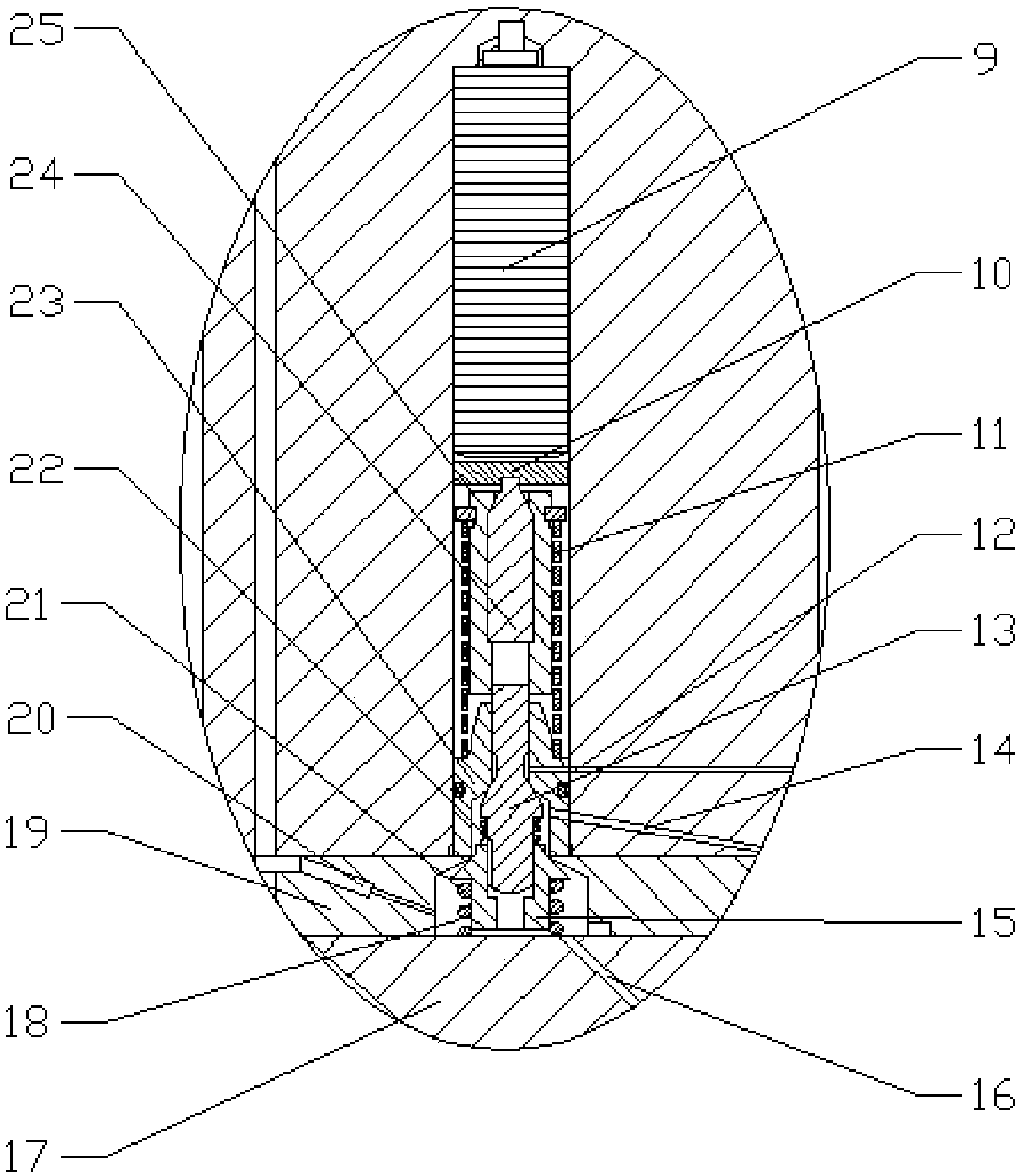

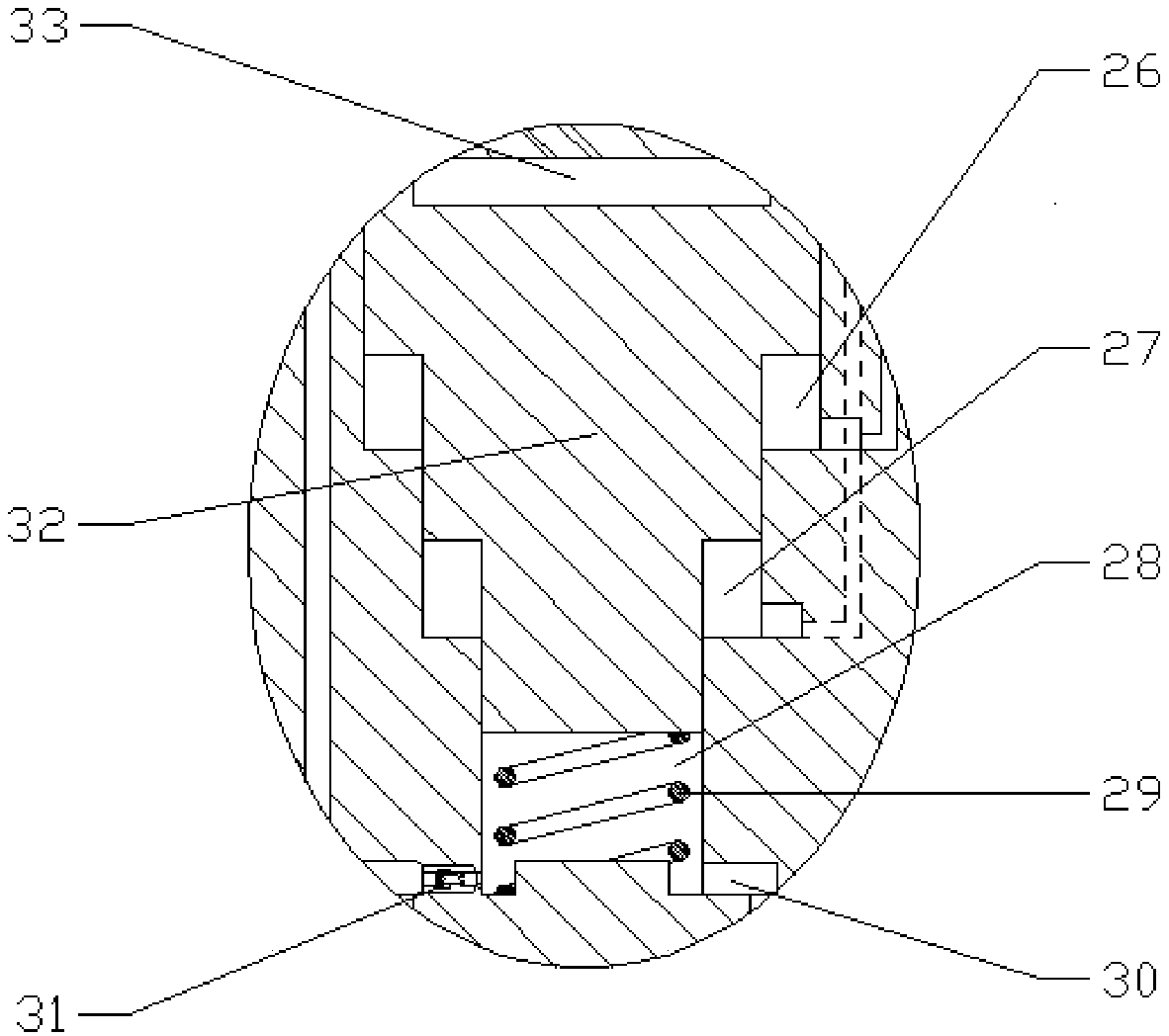

[0023] combine Figure 1-5 , the variable boost ratio piezoelectric fuel injector of the present invention is composed of a boost control valve part 1, a three-stage piston assembly 2, a fuel injection control valve part 3, a needle valve part 4, a nozzle tight cap 5 and a fuel injector body 6 composition. The boost control valve part 1 is mainly composed of a piezoelectric stack 9, a gasket 10, a plate spring 11, a boost control valve stem 13, a fungus sleeve 15, a fungus sleeve limiting orifice 19, a fungus Shape sleeve spring 21, boost control valve stem spring 22, boost control valve stem sleeve 23, hydraulic core 25 and hydraulic sleeve 24 are formed. There is a triangular fuel oil passage at the head of the valve stem 13 of the boost control valve, and the mushroom-shaped sleeve 15 is set on the head of the valve stem 13 of the boost control valve, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com