Patents

Literature

43results about How to "Flexible and precise positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

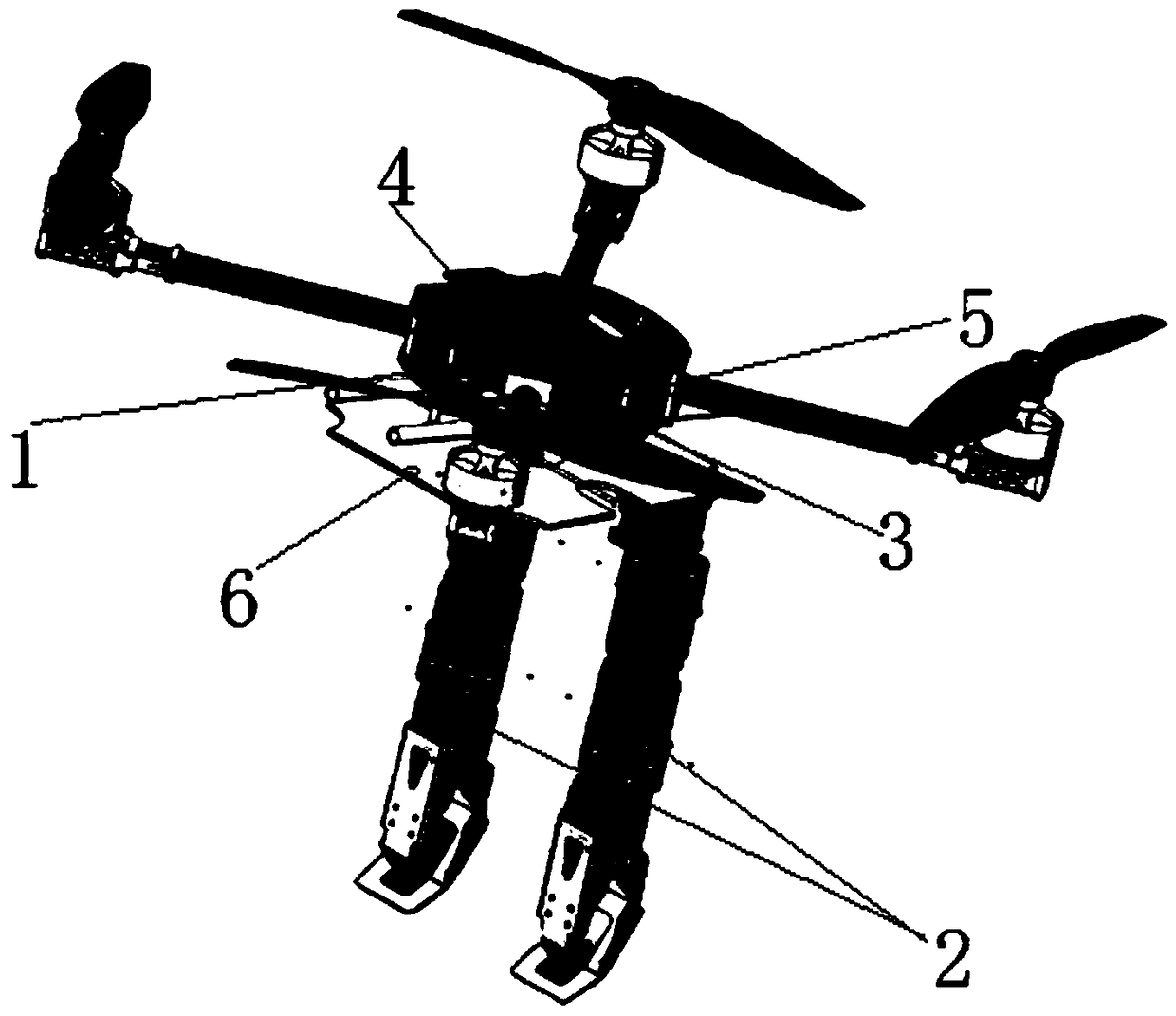

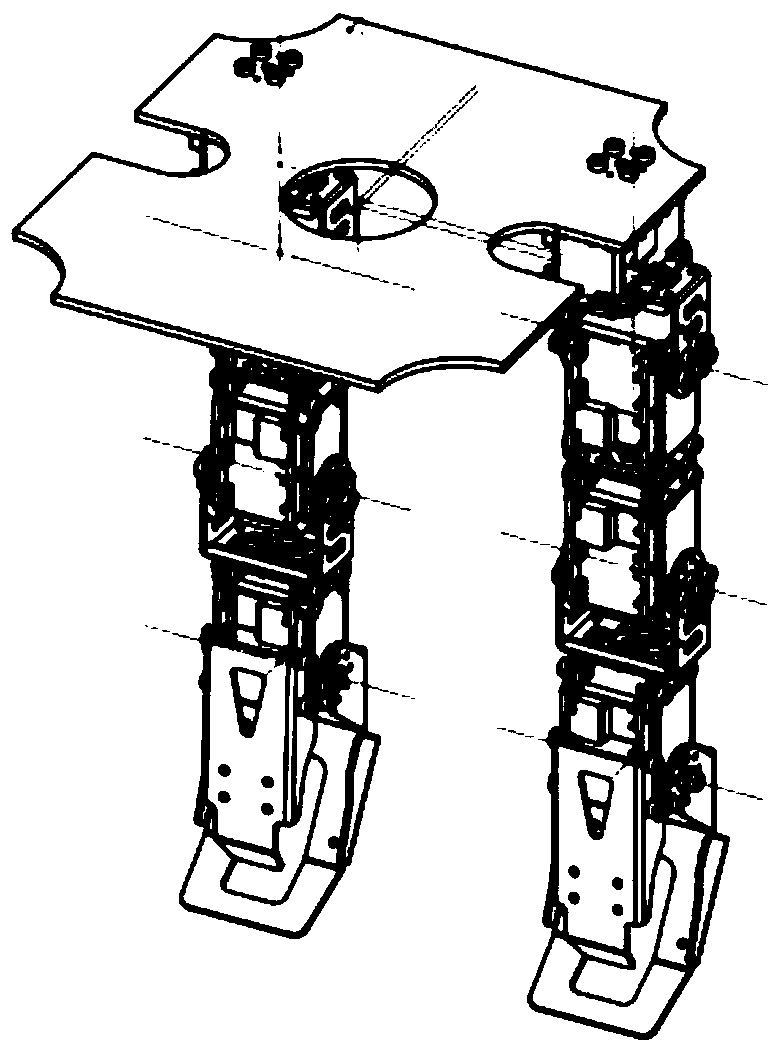

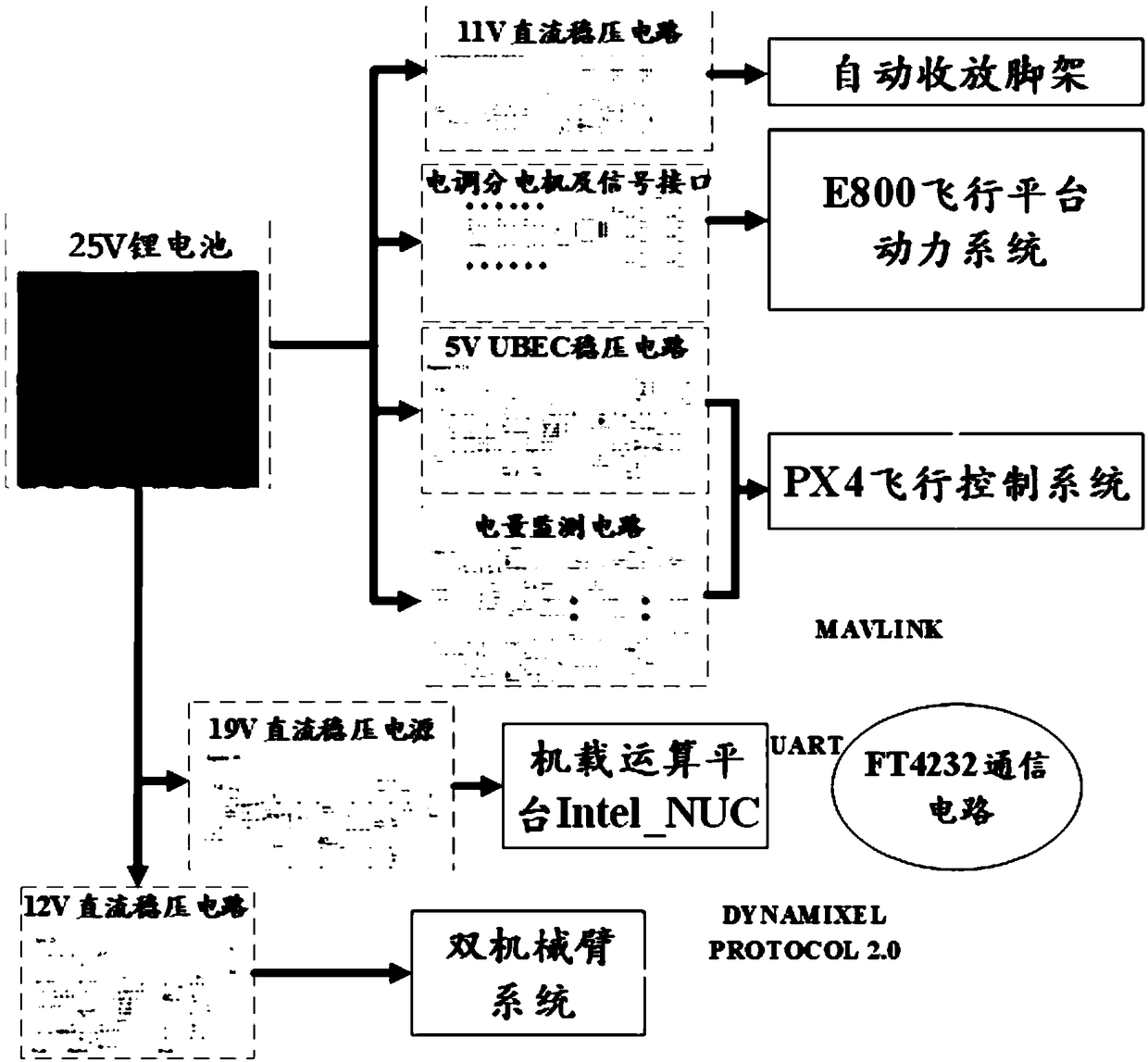

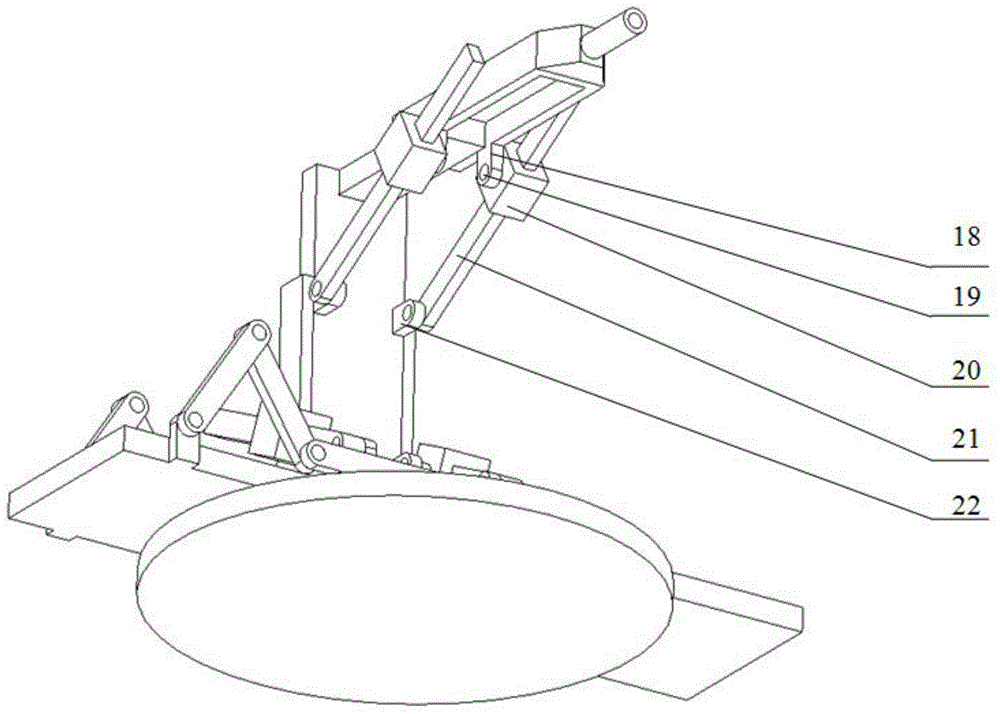

Rotorcraft double-mechanical-arm target positioning and grabbing system and method

ActiveCN109398688AImprove stabilityImprove reliabilityAircraft componentsProgramme-controlled manipulatorOnboard computerVision sensor

The invention belongs to the technical field of unmanned aerial vehicles and discloses a rotorcraft double-mechanical-arm target positioning and grabbing system and method. The rotorcraft double-mechanical-arm target positioning and grabbing system comprises a rotorcraft, an airborne computer, a double-mechanical-arm system, a flight controller, a power supply, a communication integrated circuit module and a visual sensor. The rotorcraft double-mechanical-arm target positioning and grabbing method comprises the steps that environmental video stream information is obtained in real time throughthe visual sensor, and a MobileNet-SSD model is adopted to train target recognizing and grabbing; a depth camera and AprilTag visual positioning are used in a switched mode so as to precisely obtain three-dimensional coordinate information of a recognized target; and FCL collision is introduced, and inverse kinematics operation of the mechanical arms are conducted through an RRT_Connect path planning algorithm, and thus spatial collision-free double-arm planning and grabbing are completed. According to the rotorcraft double-mechanical-arm target positioning and grabbing system and method, theability of an unmanned aerial vehicle to interact with the external environment can be effectively improved, and the autonomy property and accuracy of the rotor unmanned aerial vehicle from target recognizing, motion planning to stable grabbing is improved.

Owner:HUNAN UNIV

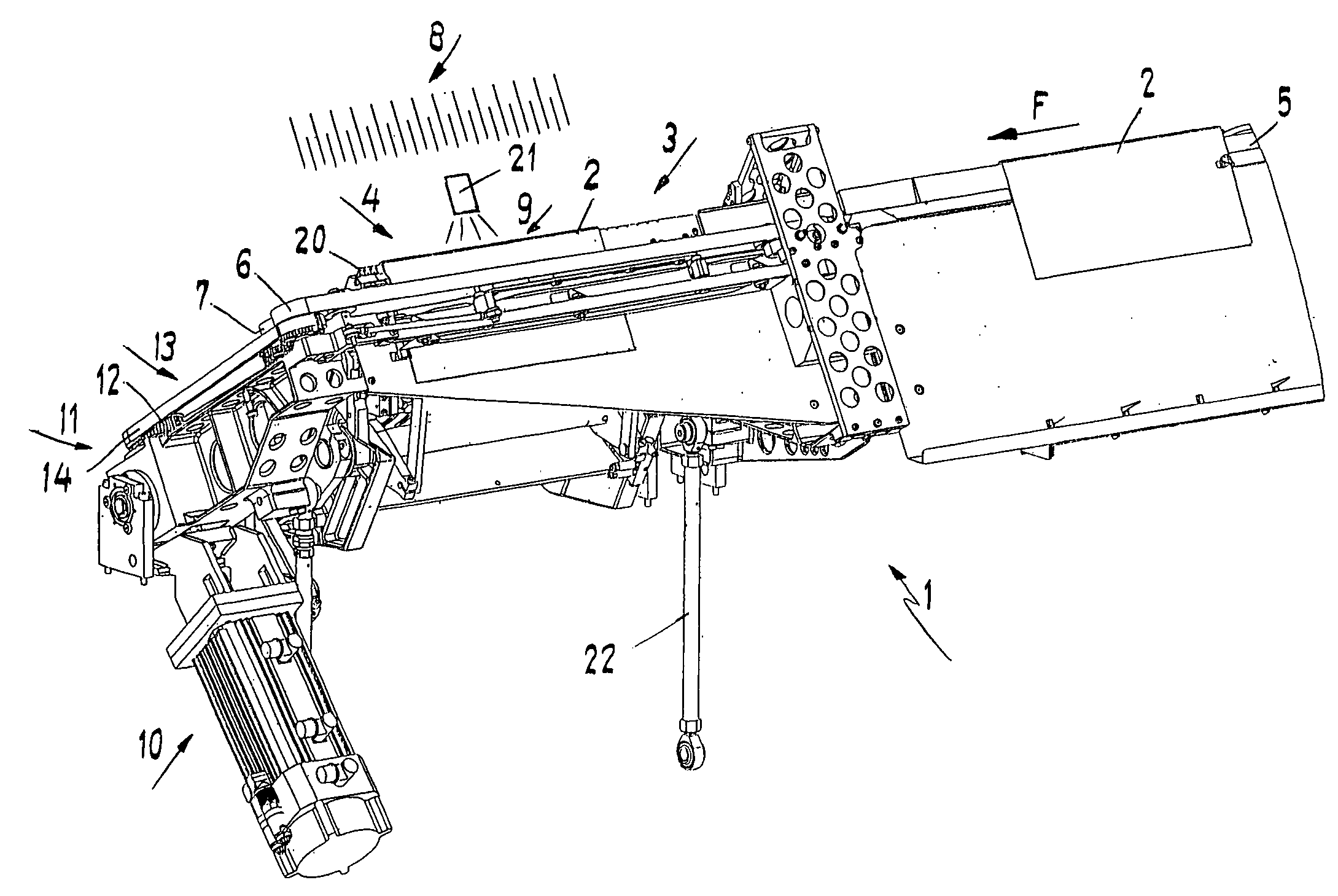

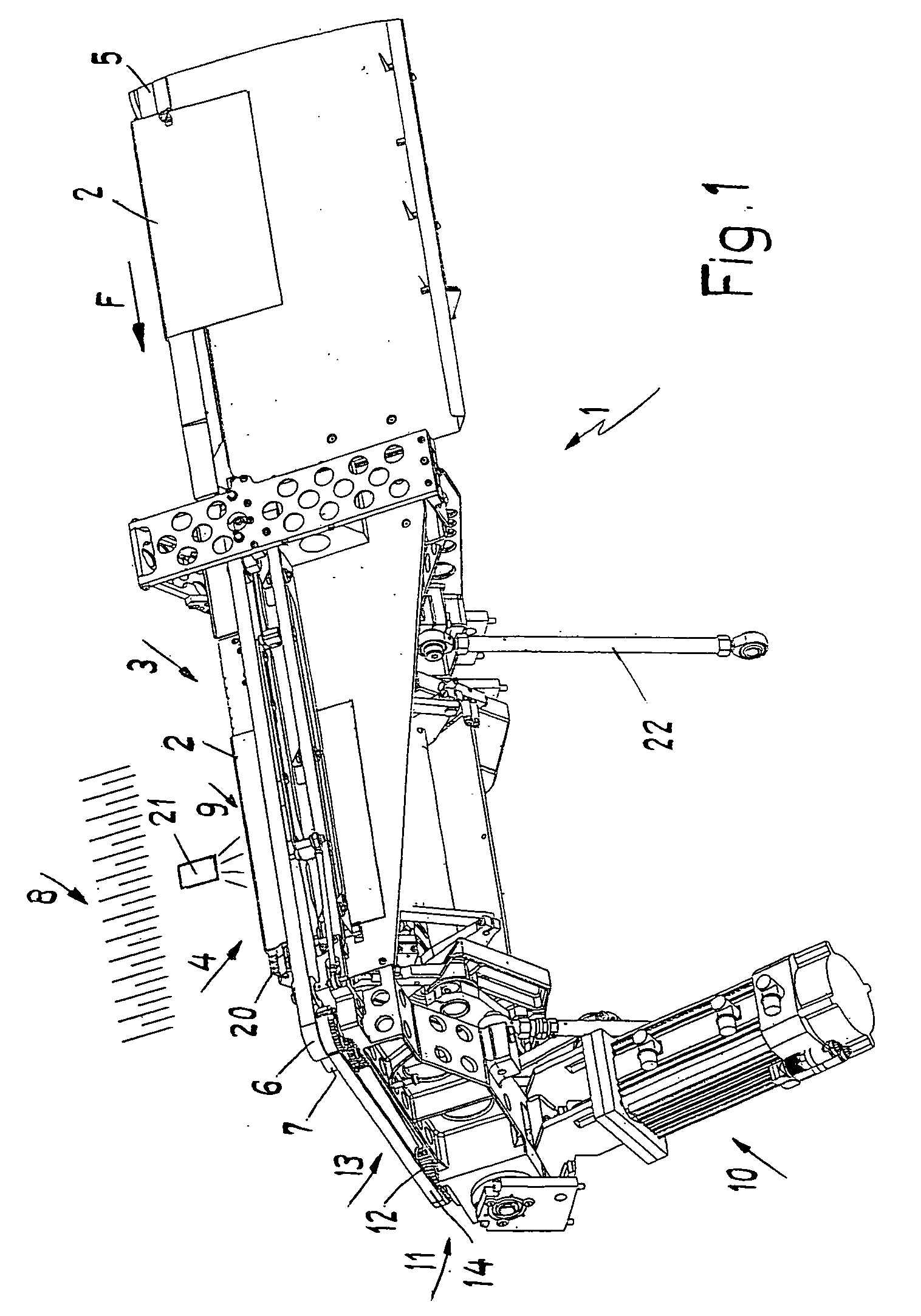

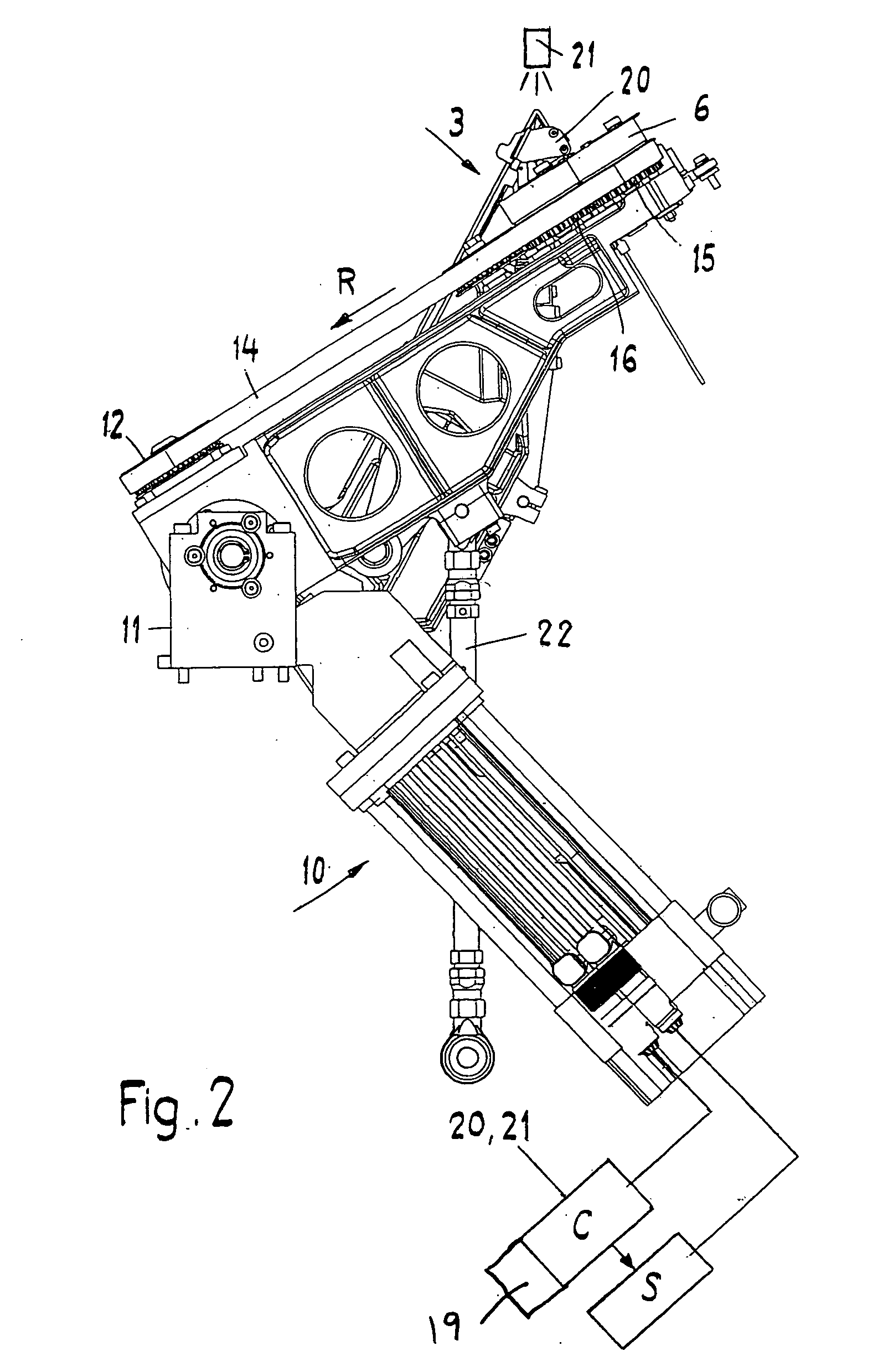

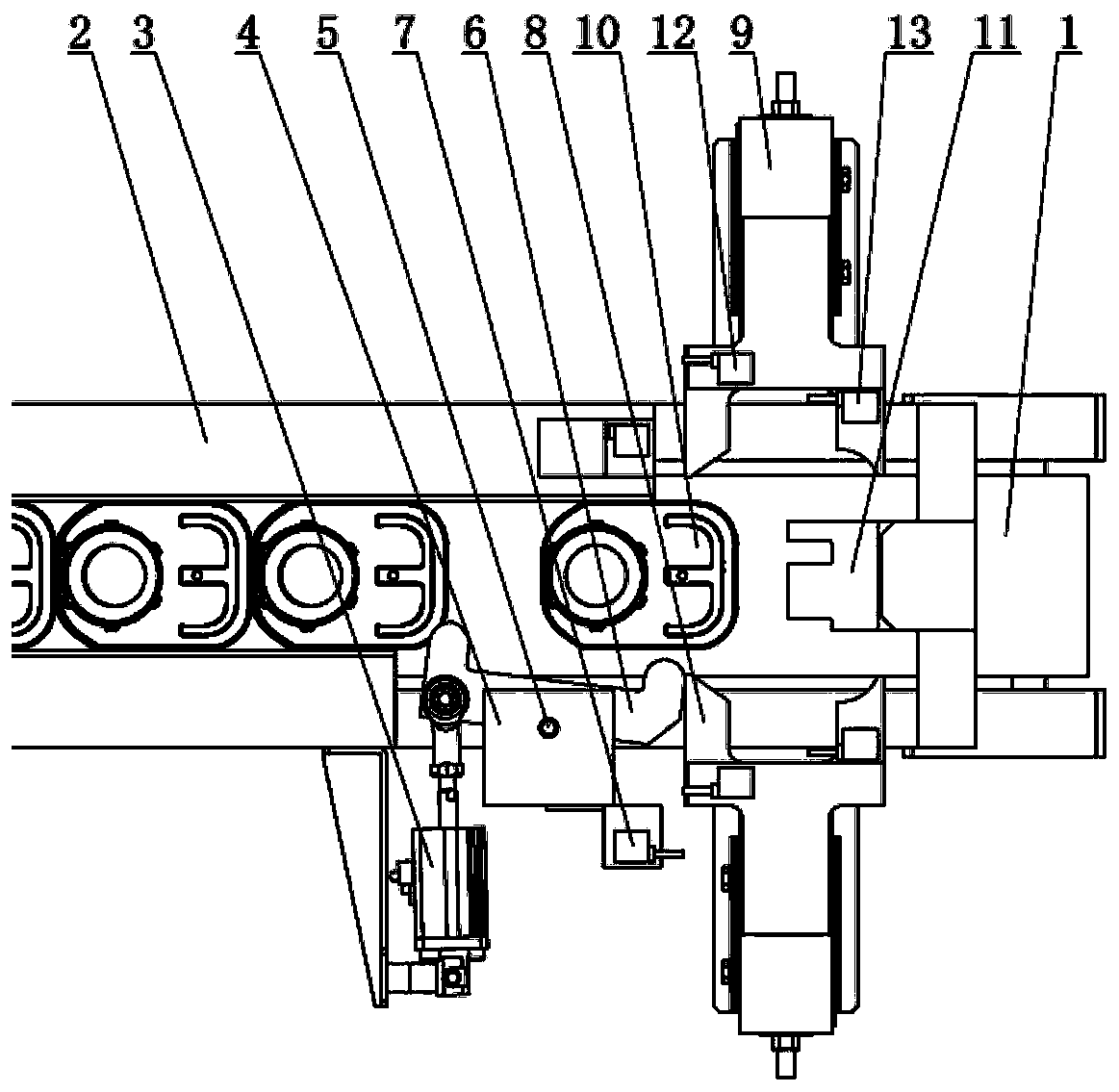

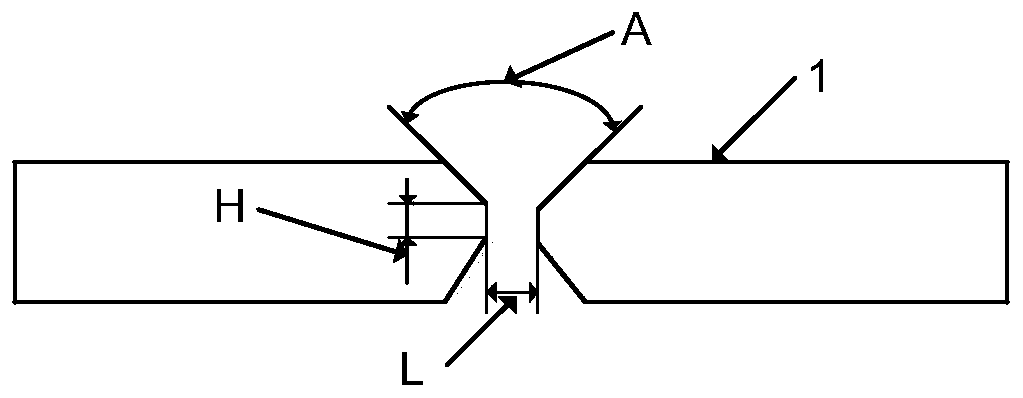

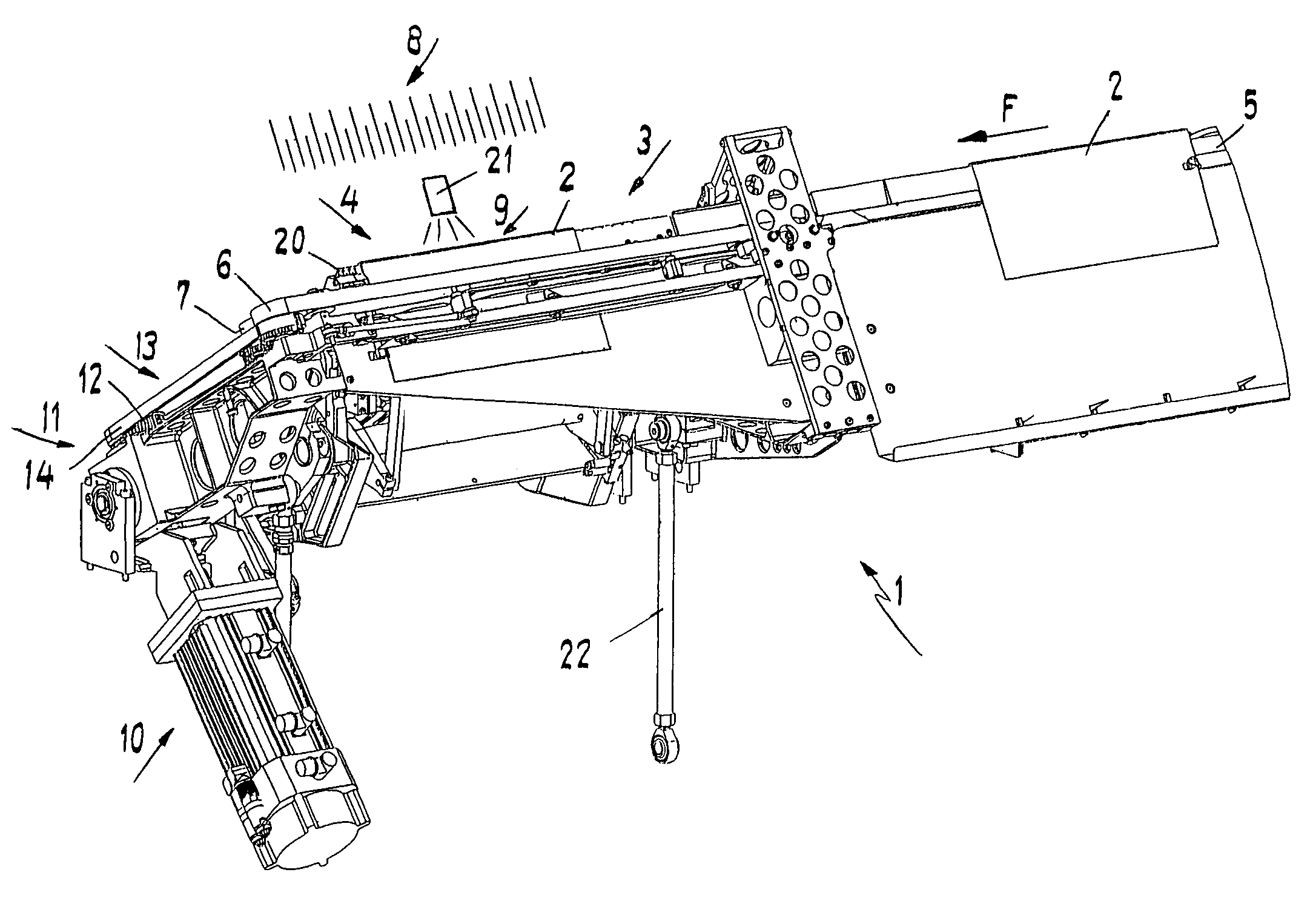

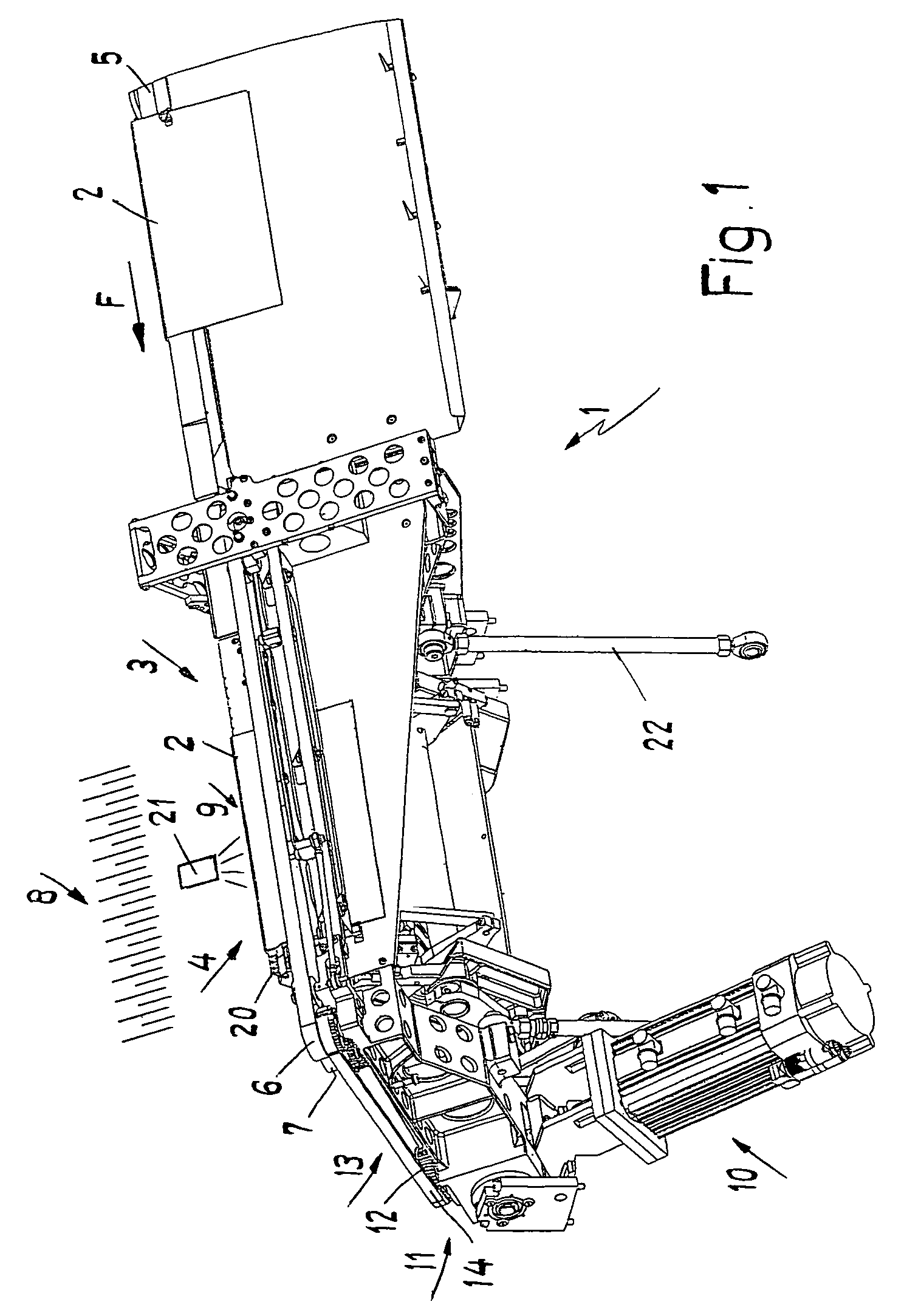

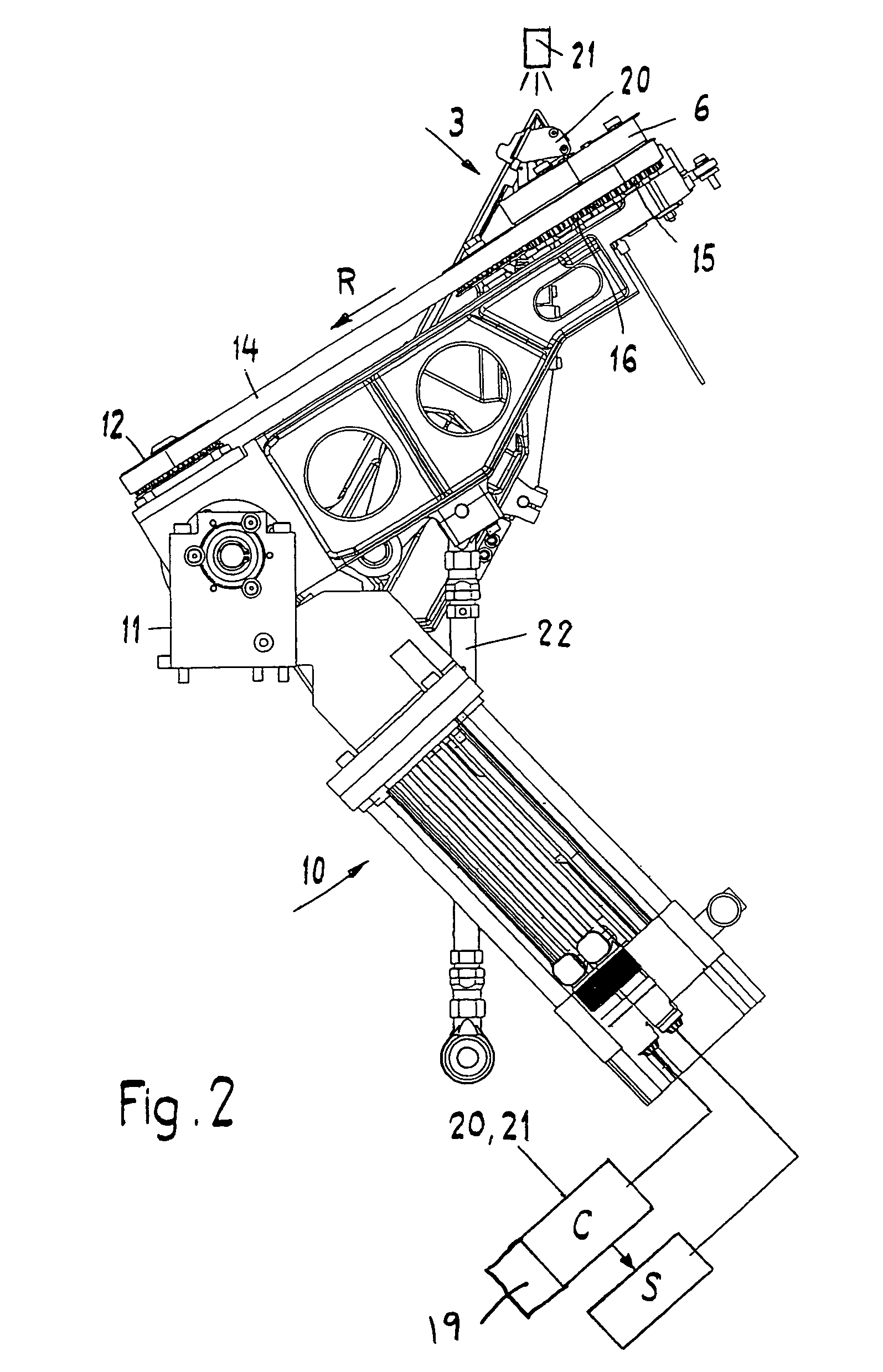

Device for manufacturing thread-stitched book blocks which comprise folded printed sheets

InactiveUS20050167902A1Avoid smearingAvoid damageArticle feedersSheet bindingEngineeringElectric motor

A device for manufacturing thread-stitched book blocks which comprise folded printed sheets has a conveying apparatus which transports the printed sheets astride a stitching saddle into a stitching position and to which the printed sheets are fed. A stitching apparatus is arranged at a lateral spacing from the stitching saddle which can be driven in an oscillating manner and can be supplied with printed sheets by the stitching saddle. The conveying apparatus is controlled in order to change the conveying speed and / or the stitching position of the printed sheets on the stitching saddle, in that the conveying apparatus is drive-connected to a controlled-rotation electric motor which is controlled by a computer-connected controller.

Owner:MULLER MARTINI HLDG

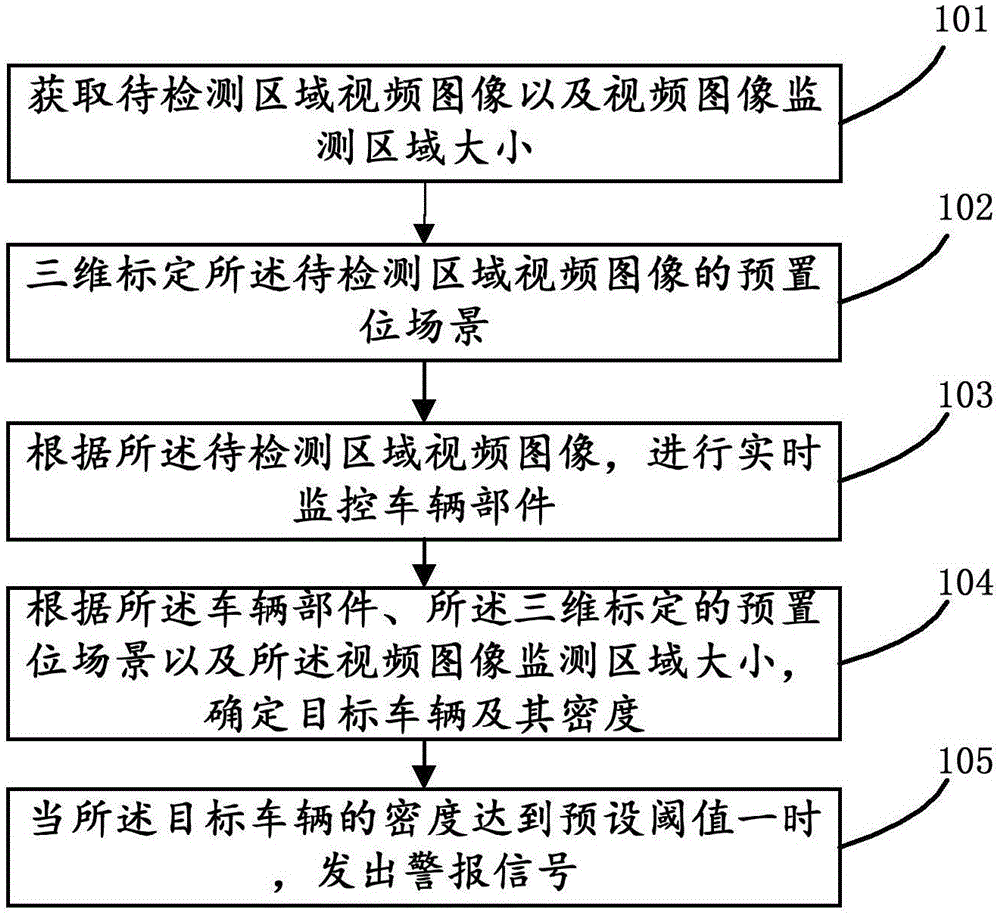

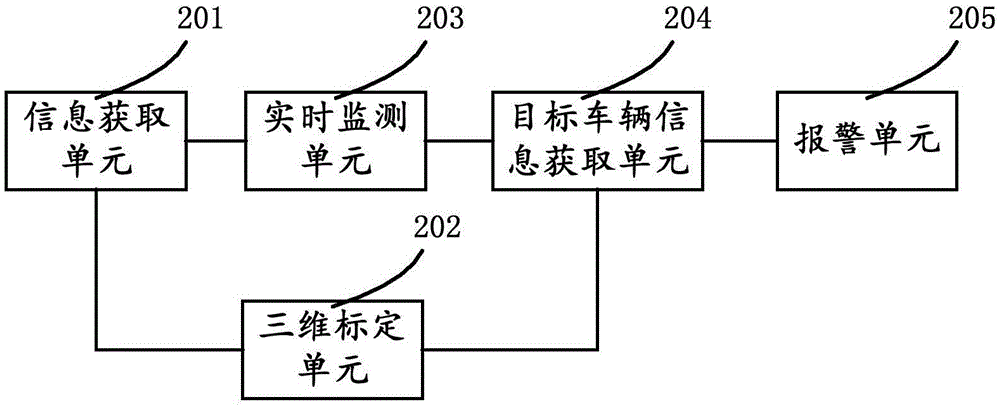

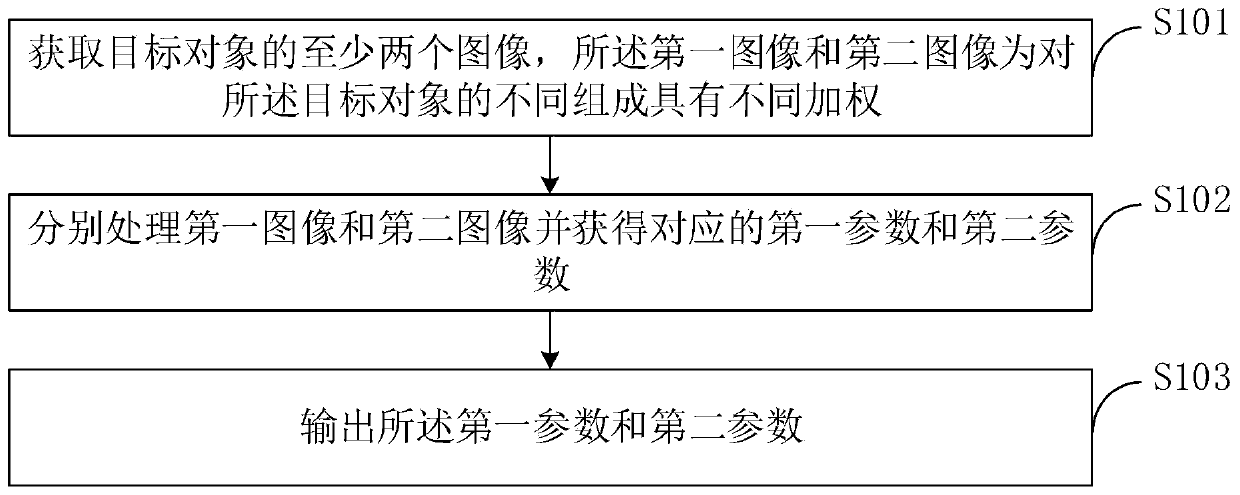

Method, device and system for monitoring illegally parked dense vehicles

PendingCN106571027AFlexible and precise positioningReduce labor costsDetection of traffic movementVideo imageAlarm signal

The present invention discloses a method, a device and a system for monitoring illegally parked dense vehicles. The method for monitoring illegally parked dense vehicles comprises the steps of acquiring the video image of a to-be-detected area and the size of a monitored area in the video image; conducting the three-dimensional calibration of the presetting bit scene of the video image of the to-be-detected area; according to the video image of the to-be-detected area, monitoring vehicle parts in real time; according to the monitored vehicle parts, the three-dimensionally calibrated presetting bit scene and the size of the monitored area in the video image, determining target vehicles and the density of target vehicles; when the density of target vehicles reaches a first pre-set threshold, sending out an alarm signal. According to the technical scheme of the invention, target vehicles can be flexibly and accurately positioned, so that illegally parked dense vehicles can be accurately and timely judged. Meanwhile, the alarm is timely sent out for the condition of illegally parked dense vehicles. Moreover, a large amount of labor cost is reduced.

Owner:BEIJING WENAN INTELLIGENT TECH CO LTD

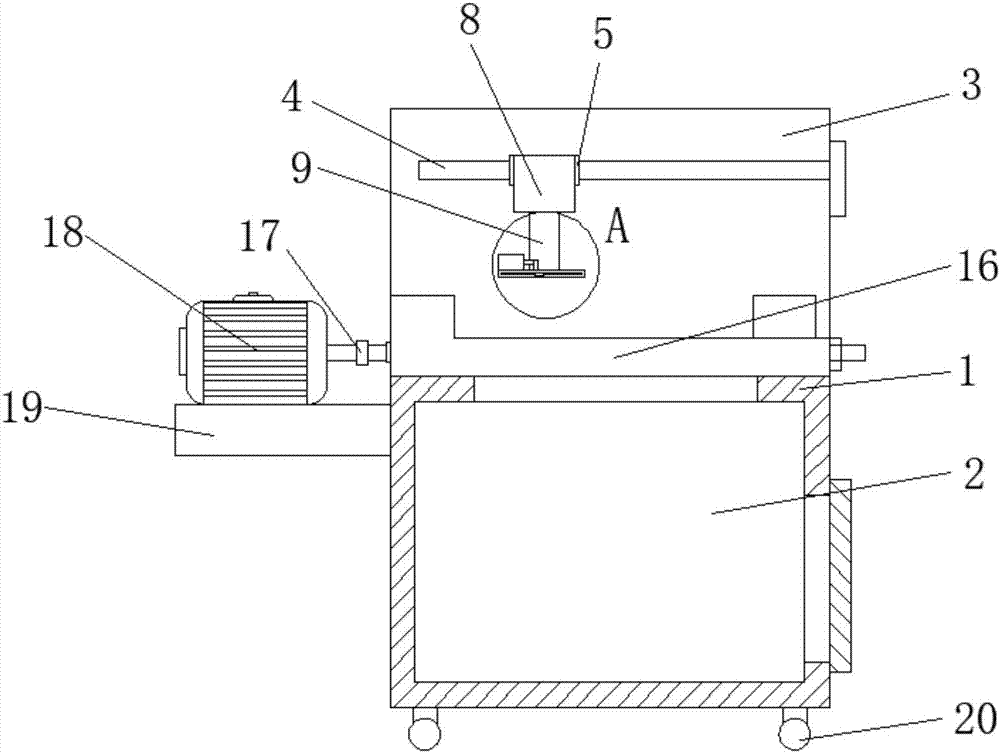

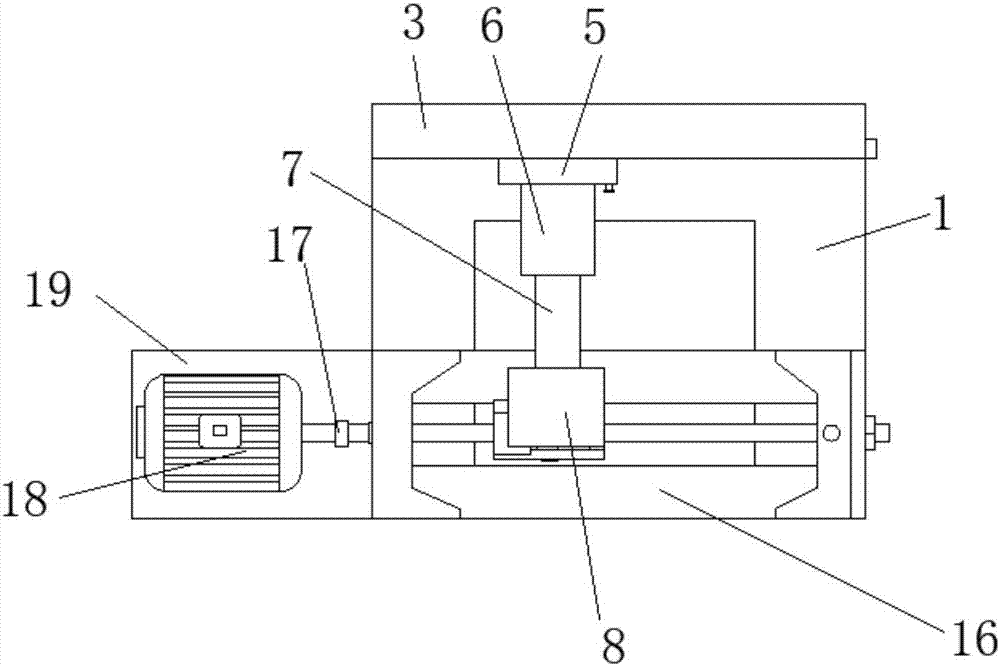

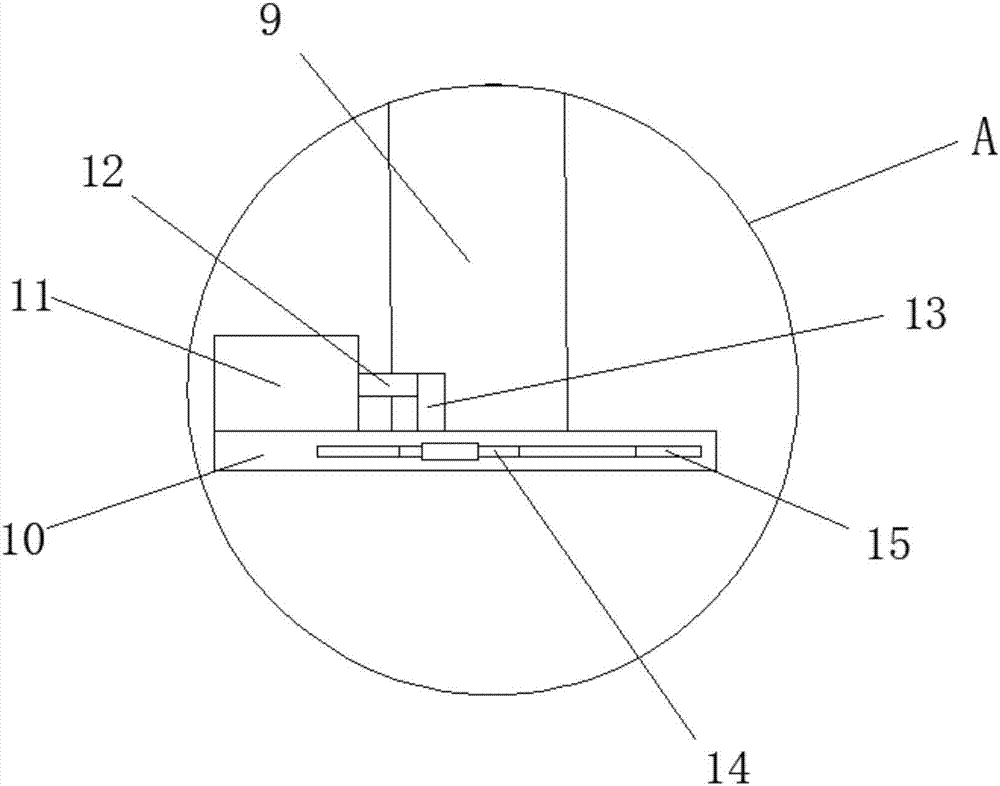

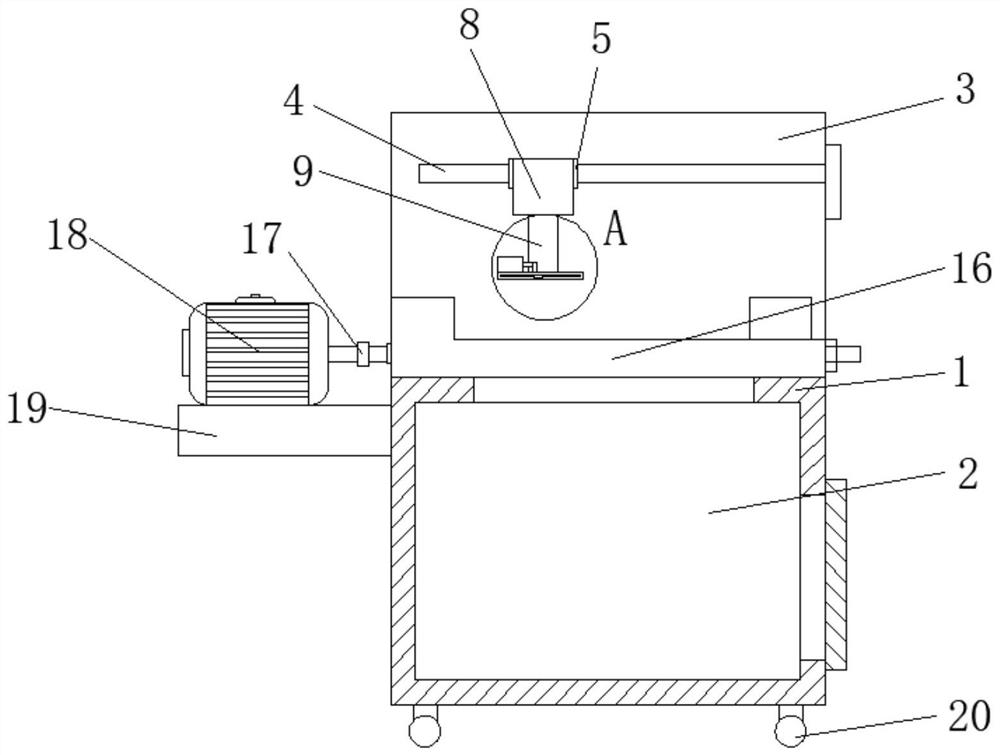

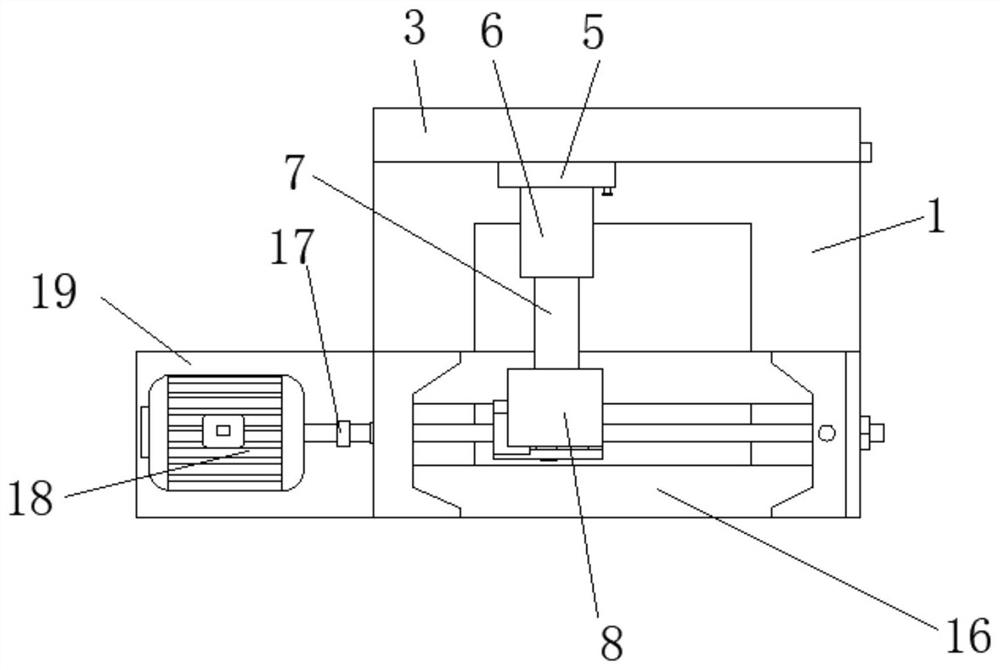

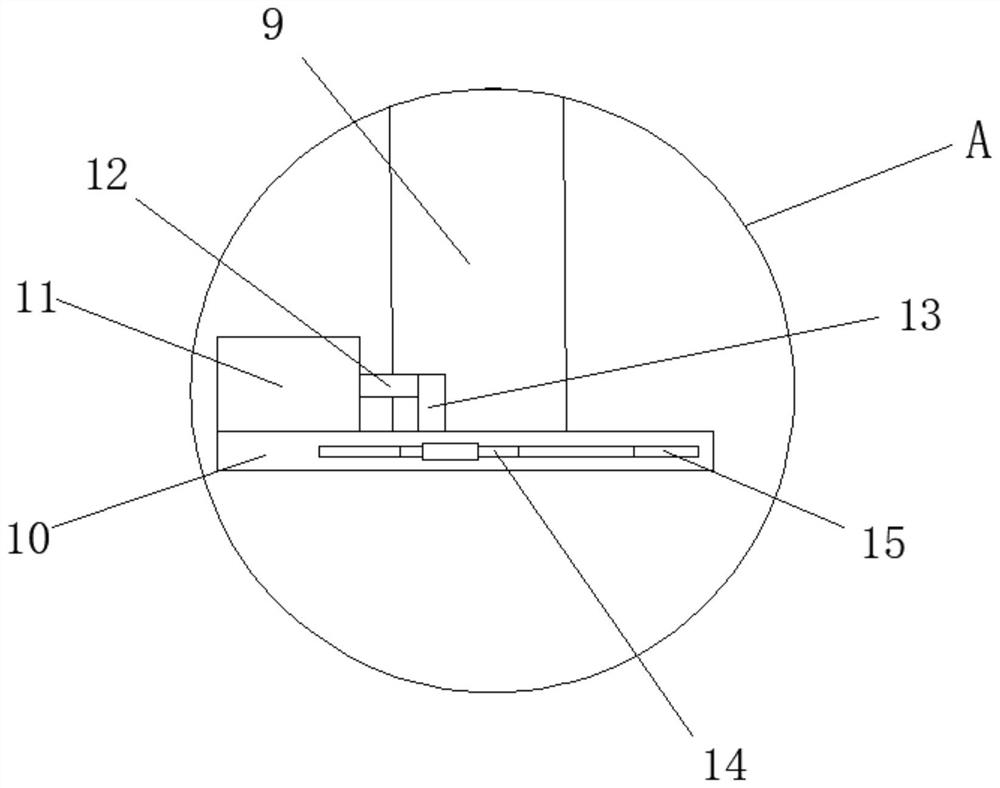

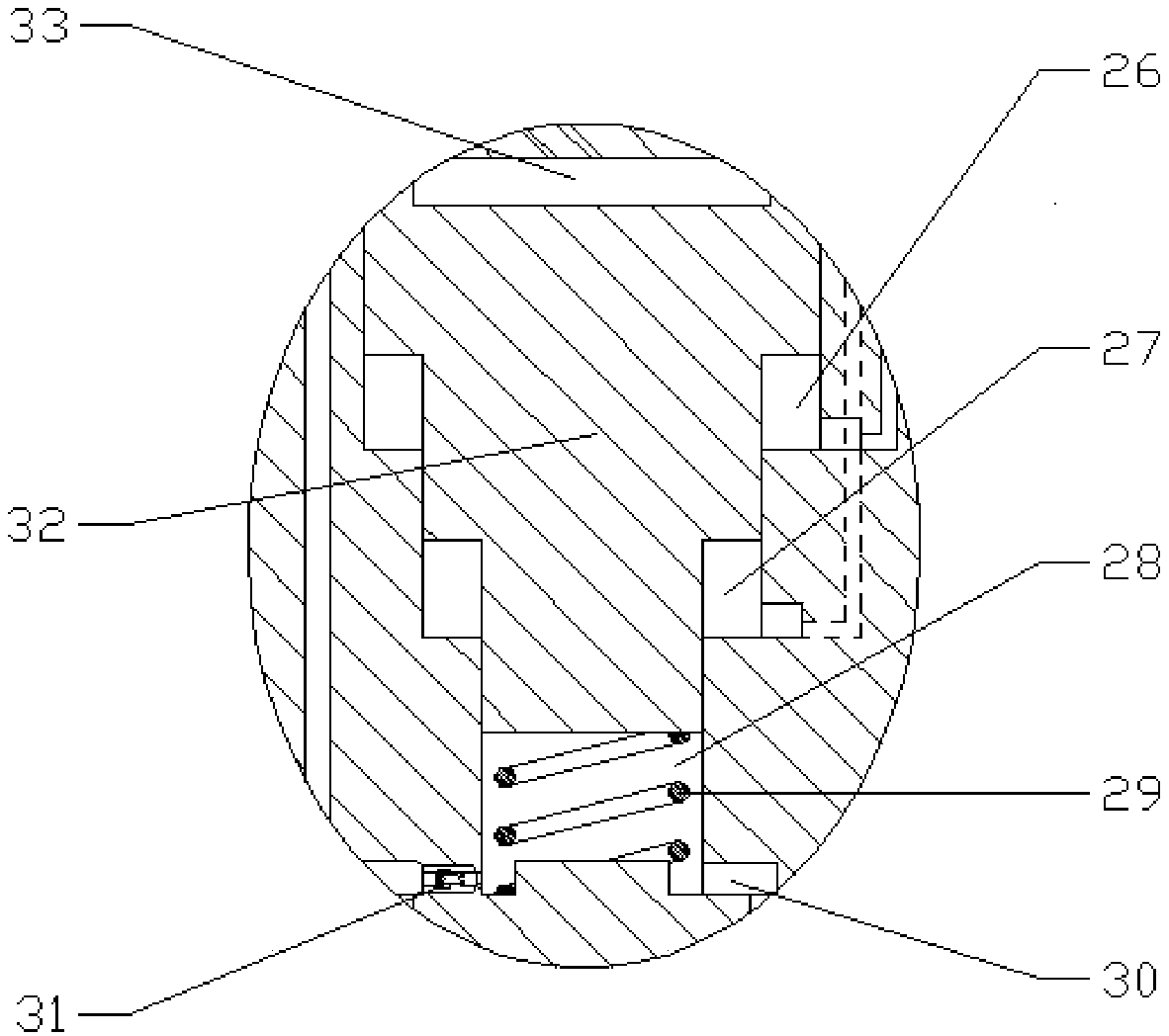

Automatic shearing device for plastic product runner

The invention discloses an automatic shearing device for a plastic product runner and belongs to the technical field of automatic shearing of the plastic product runner. The automatic shearing devicecomprises a shearing platform; a collecting cabinet is arranged at the bottom of the shearing platform; the upper side of the front end face of a rear plate is provided with a sliding chute; the sliding chute is provided with a corresponding slider; a fixing rod is arranged at the front end of the slider; the fixing rod is connected with a telescopic rod in an insertion manner; the front end of the telescopic rod is provided with a height adjusting cylinder; a piston rod is arranged at the bottom of the height adjusting cylinder; a shearing supporting plate is arranged at the bottom of the piston rod; a shearing pneumatic cylinder is arranged at the left side of the top of the shearing supporting plate; a shearing piston rod is arranged at the right end of the shearing pneumatic cylinder;a fixed blade matched with a movable blade is arranged inside the shearing supporting plate; and the front side of the top end of the shearing platform is provided with plastic product clamping pincers. By adopting the automatic shearing device to remove the runner on the plastic product, the cut is flat and smooth and do not affect the surface quality of the plastic product, and high work efficiency is realized.

Owner:聊城市飓风工业设计有限公司

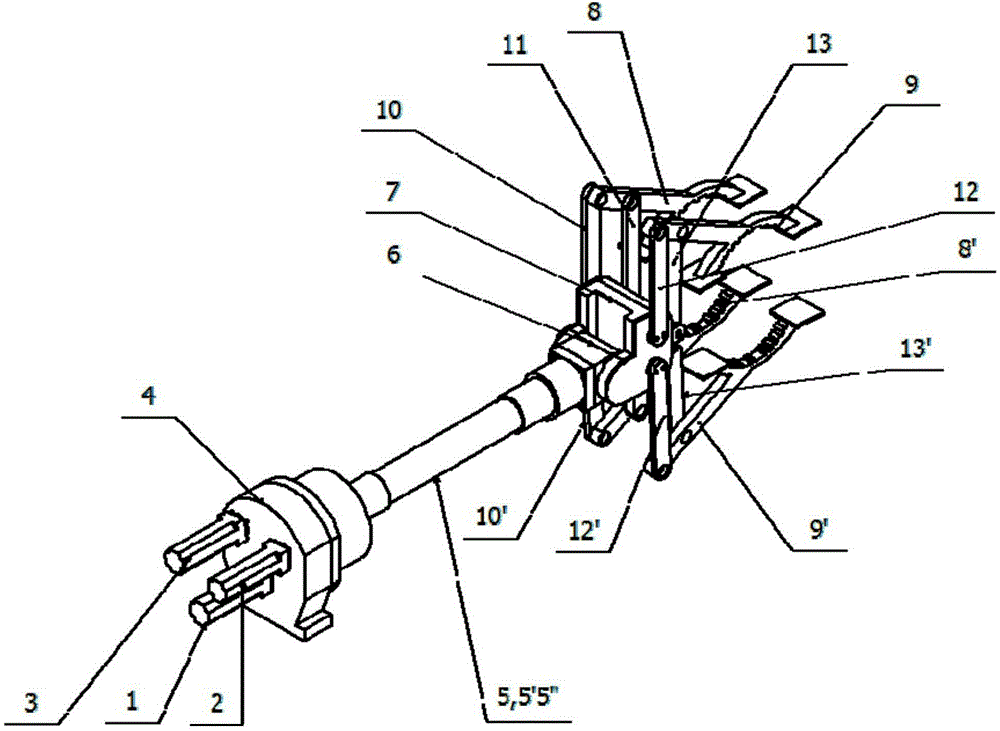

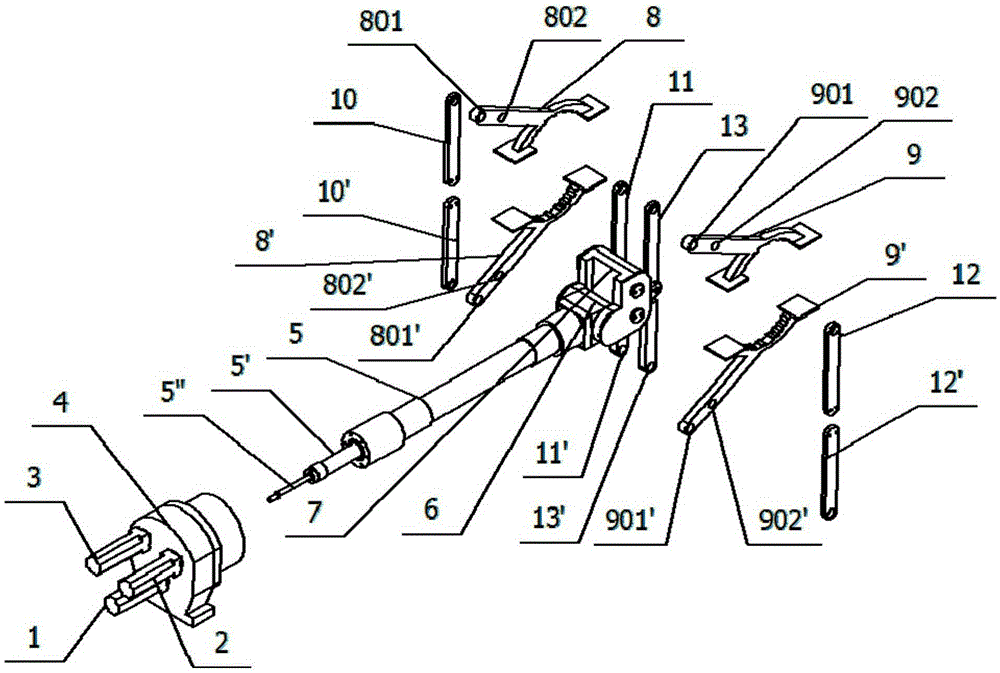

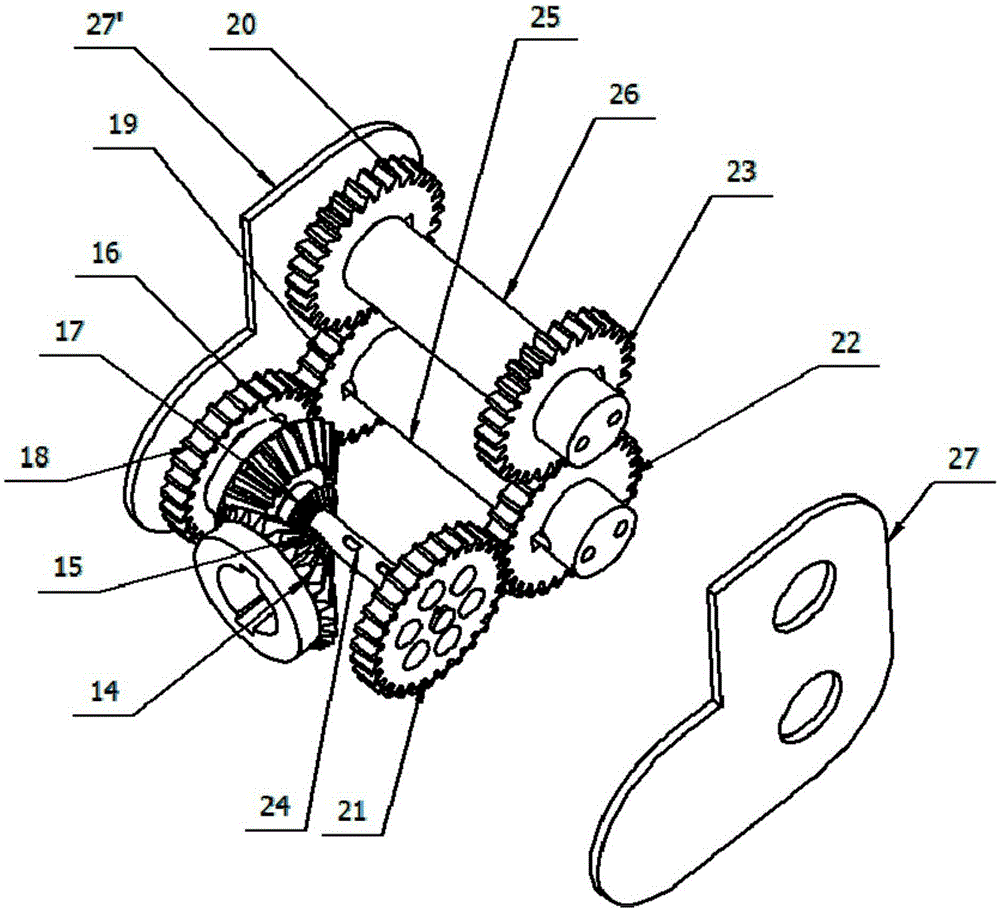

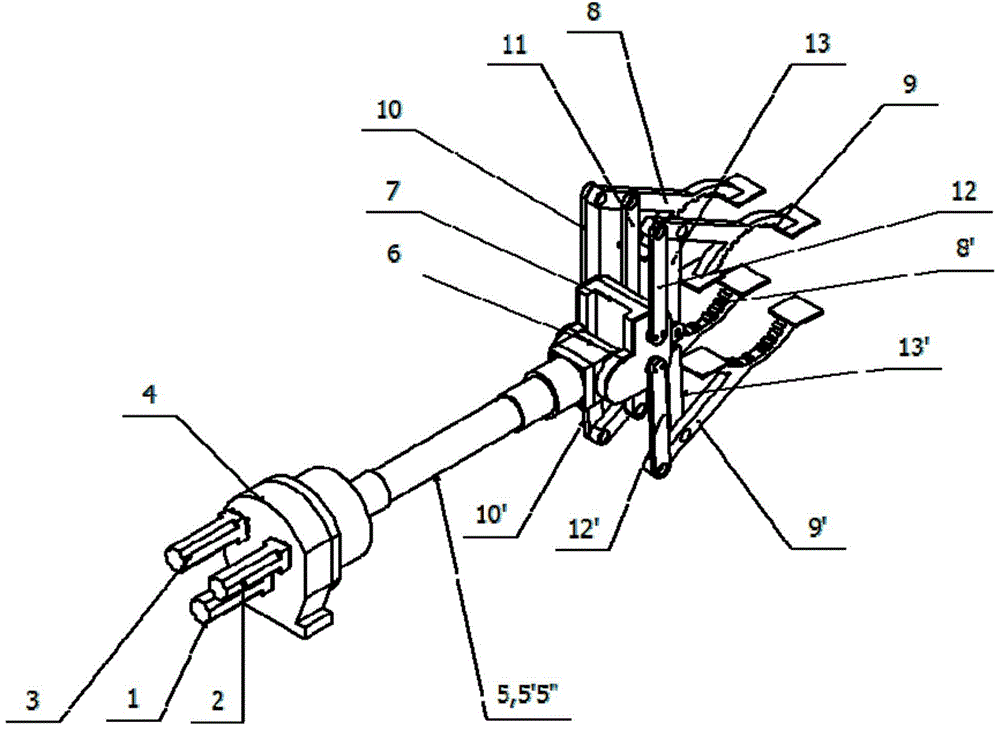

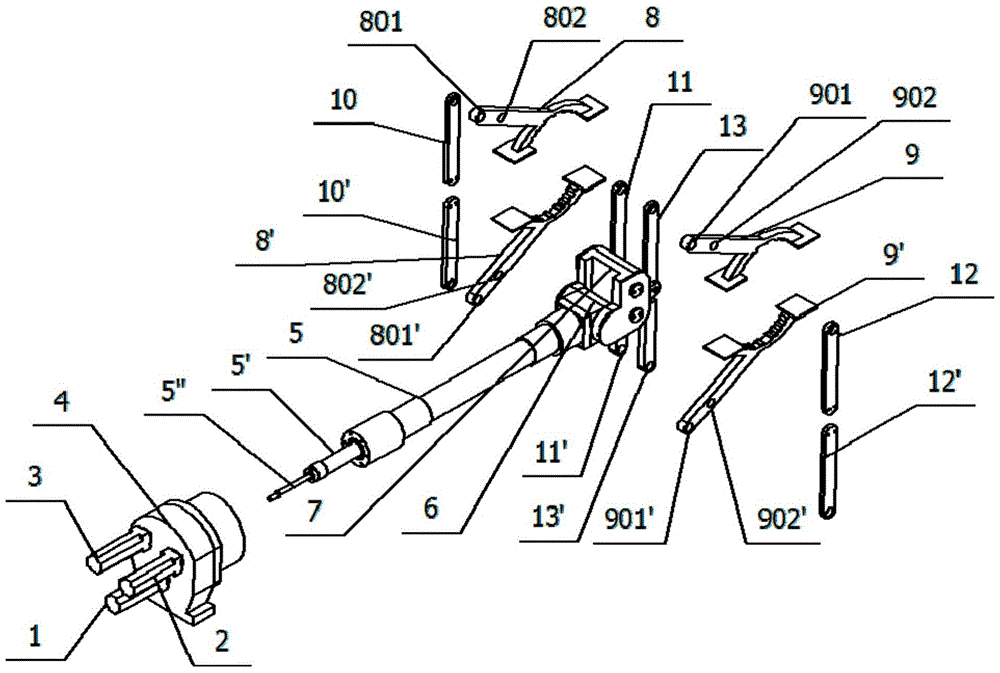

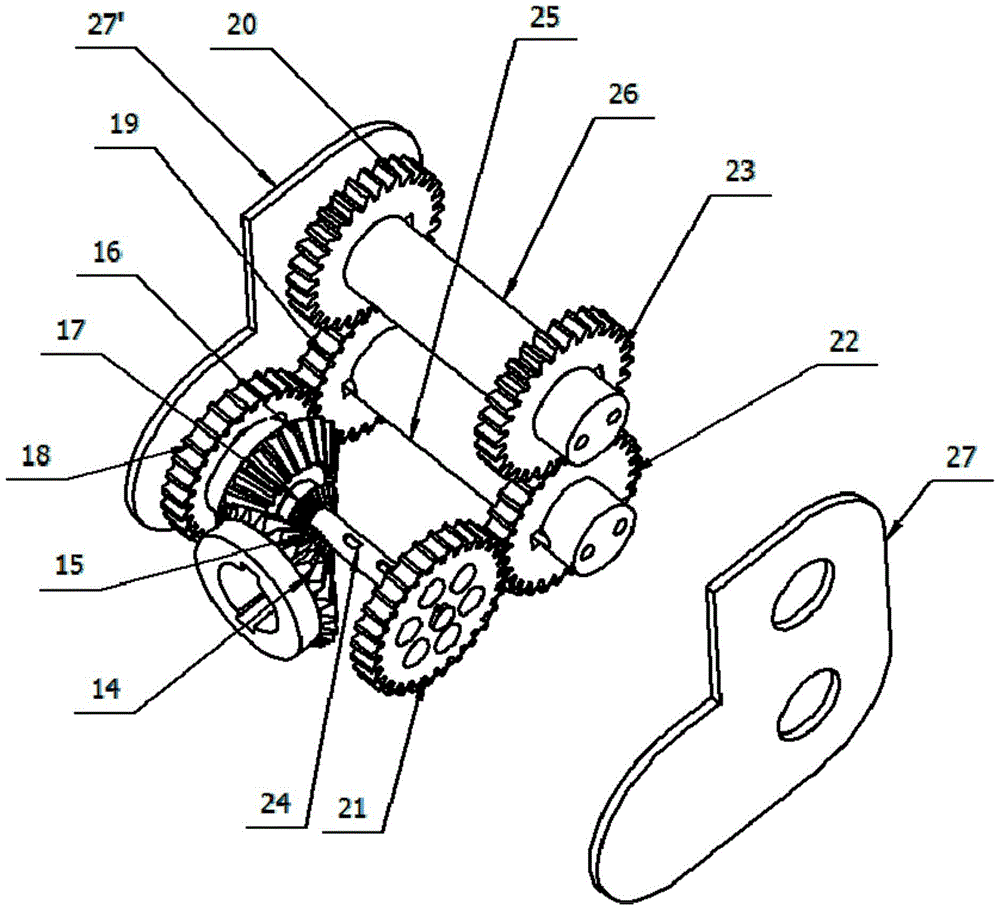

Three-freedom-degree controllable mechanical manipulator

InactiveCN105382834ARealize safe productionFlexible and precise positioningProgramme-controlled manipulatorStub axleManipulator

The invention discloses a three-freedom-degree controllable mechanical manipulator, and belongs to the field of manipulators. The three-freedom-degree controllable mechanical manipulator is characterized in that a first shaft, a second shaft and a third shaft are connected with a first controllable motor, a second controllable motor and a third controllable motor on a machine frame respectively; the first shaft and the second shaft are hollow shafts; the second shaft is sleeved with the first shaft; the third shaft is a solid shaft and sleeved with the second shaft; the first shaft is fixedly connected with a first gearbox, the first gearbox is installed in a second gearbox to achieve linkage, and the head of the manipulator can rotate by 360 degrees through the first controllable motor. The other end of the second shaft is in key connection with a first driving bevel gear, the first driving bevel gear is engaged with a first driven bevel gear, the first driven bevel gear is connected with the second gearbox, and the head of the manipulator can swing by 180 degrees vertically through the second controllable motor. The other end of the third shaft is in key connection with a second driving bevel gear, the second driving bevel enables a first short shaft, a second short shaft and a third short shaft to rotate by driving a driven gear, and clamping movement of a swing rod, an upper claw and a lower claw is achieved. The three-freedom-degree controllable mechanical manipulator has the advantages of being simple in structure, safe and reliable.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

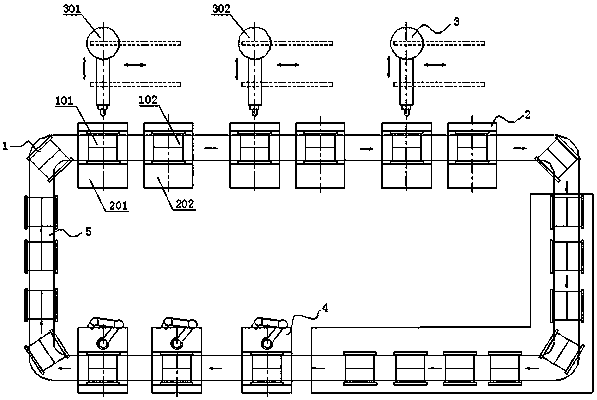

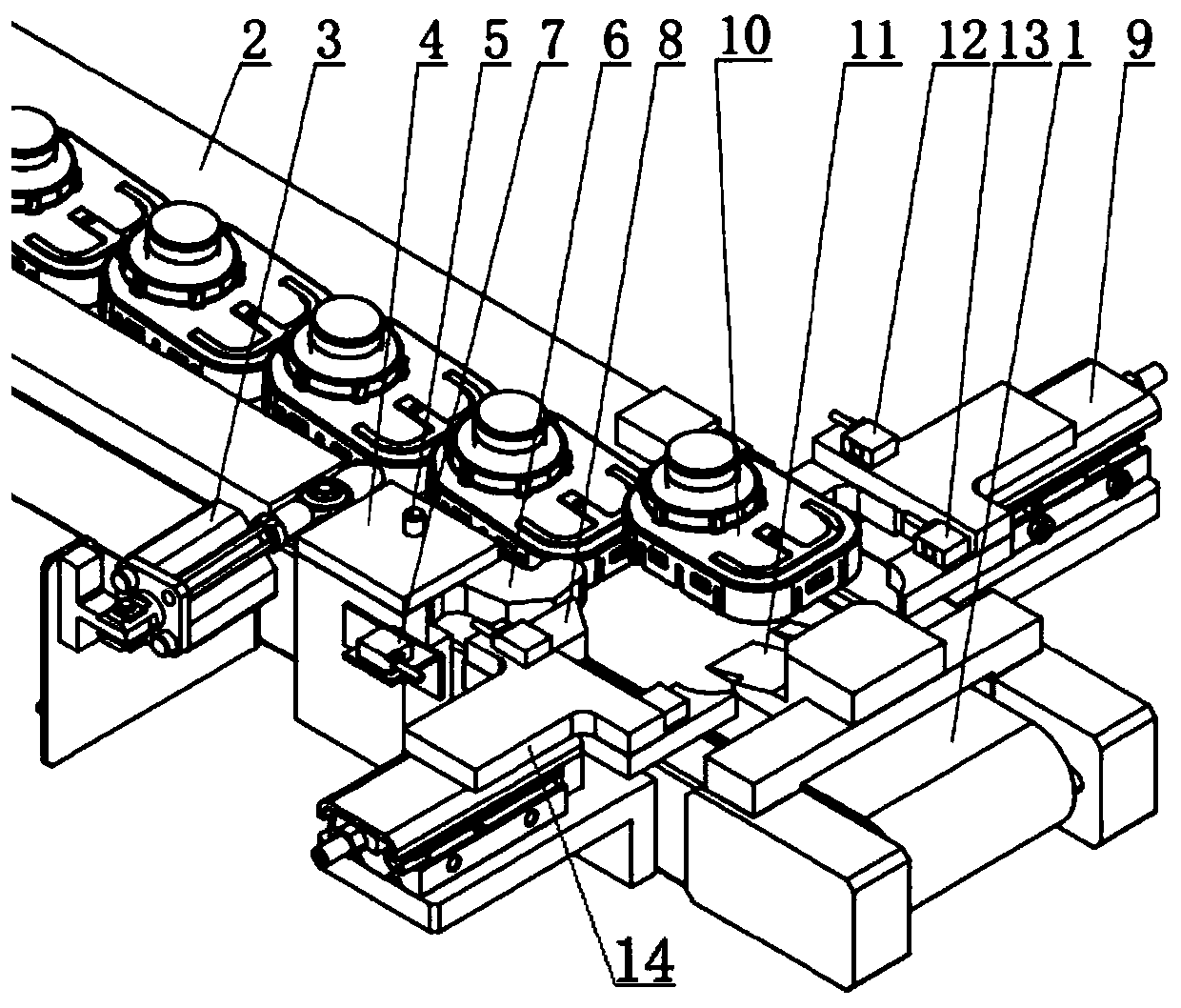

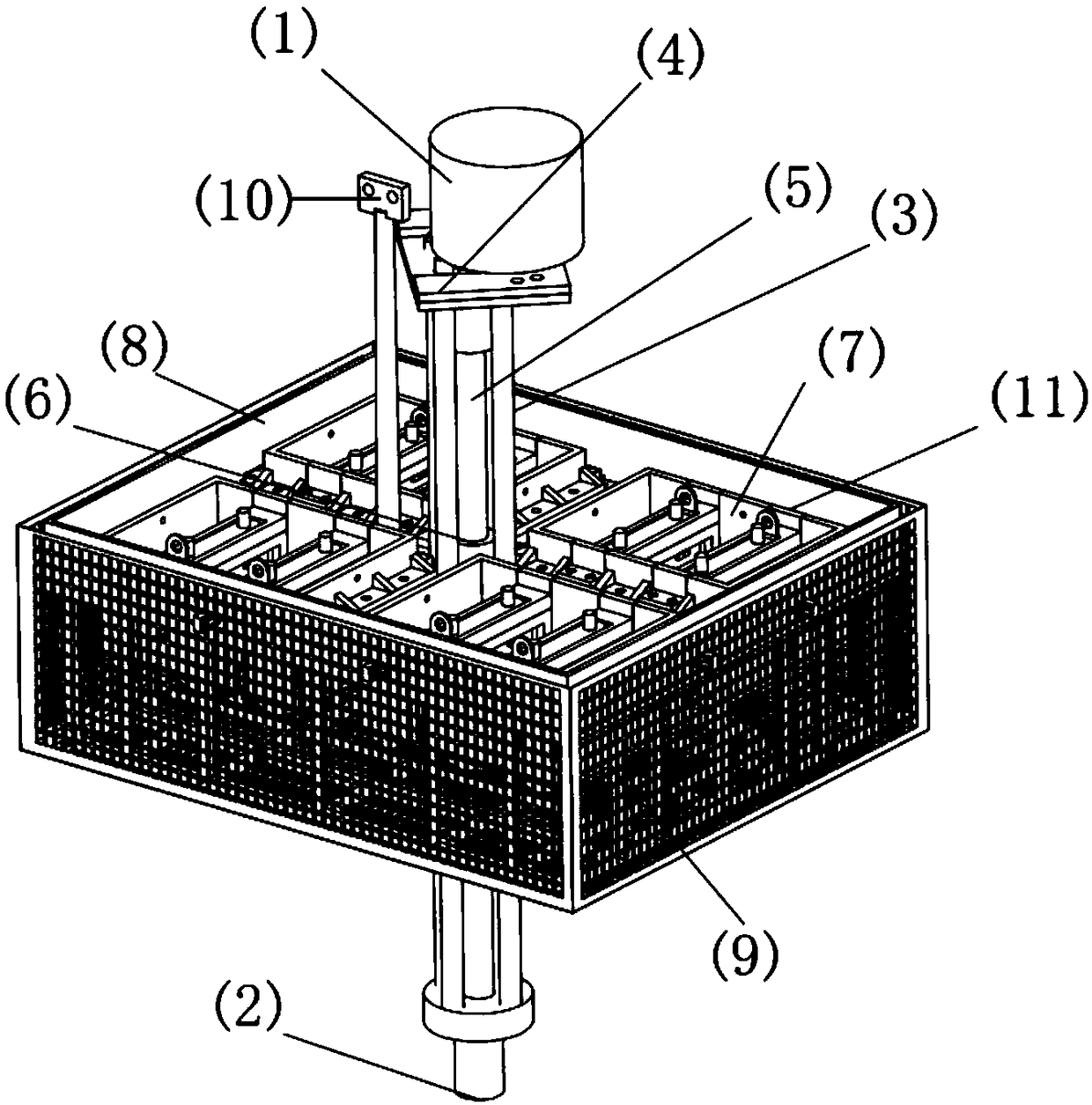

Intelligent injection molding forming equipment

InactiveCN107718417AMeet the requirements of small batch customized molding productionReduce manufacturing costLocking mechanismInjection molding process

The invention discloses an intelligent injection molding forming equipment. An injection molding forming system comprises a plurality of die assemblies, a plurality of high-pressure die assembling units, a plurality of movable injection molding units, a plurality of material taking units, an intelligent conveying and positioning unit and a control unit. Each die assembly comprises a die and a low-pressure die locking mechanism, wherein the low-pressure die locking mechanism can lock the die during die conveying, and the control unit can call the corresponding technology of the die for injection molding forming. The high-pressure die assembling units can tightly lock the die assemblies according to the corresponding die assembling technology requirements. The movable injection molding unitscan conduct glue shooting to the interiors of the die assemblies according to the corresponding injection molding technology requirement. The material taking units can conduct die sinking and take out formed plastic parts. The intelligent conveying and positioning unit can convey and position the die assemblies. By adoption of the intelligent injection molding forming equipment, small-batch customized forming production can be achieved, equipment energy consumption is reduced, and the equipment efficiency is improved.

Owner:XIAMEN TUBETECH INC

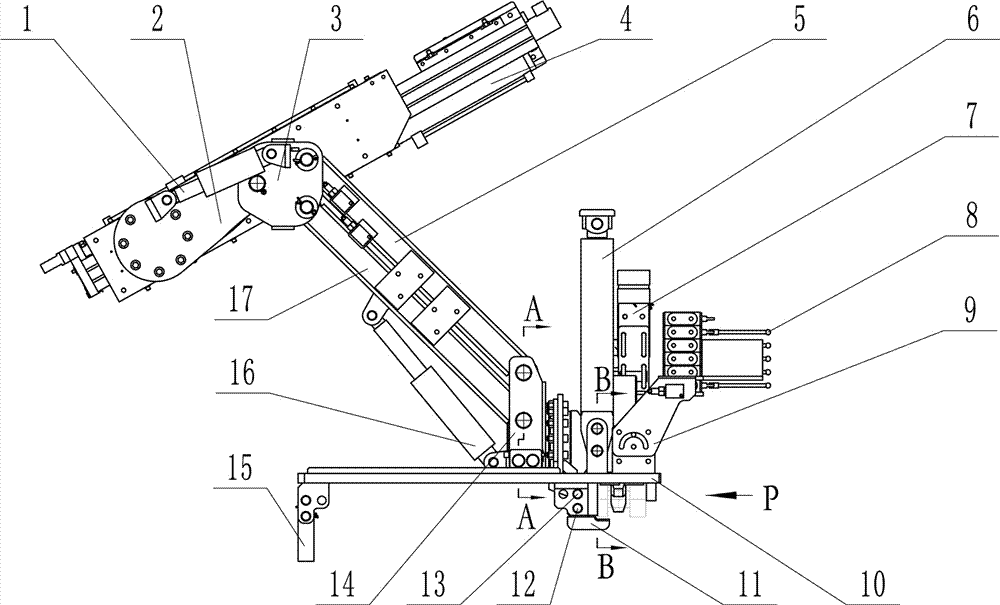

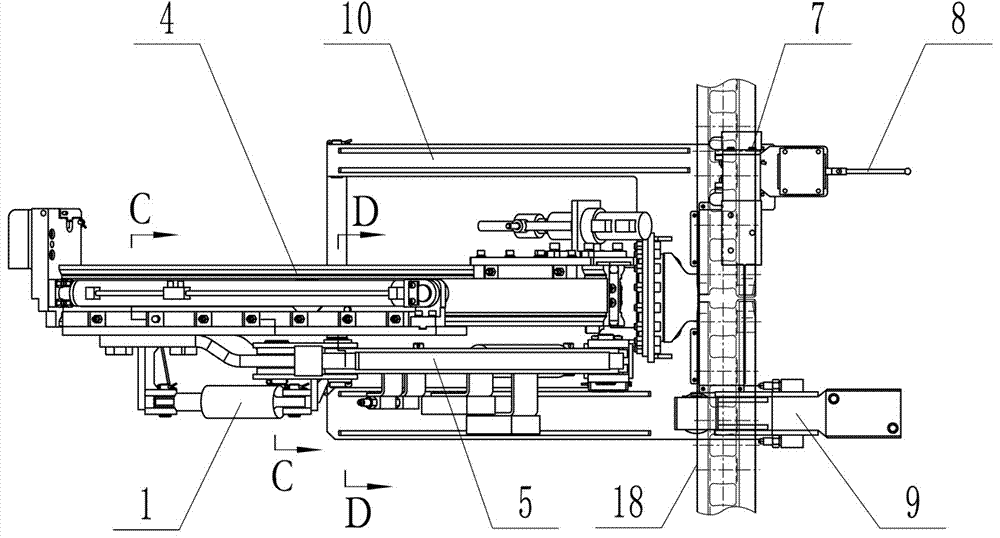

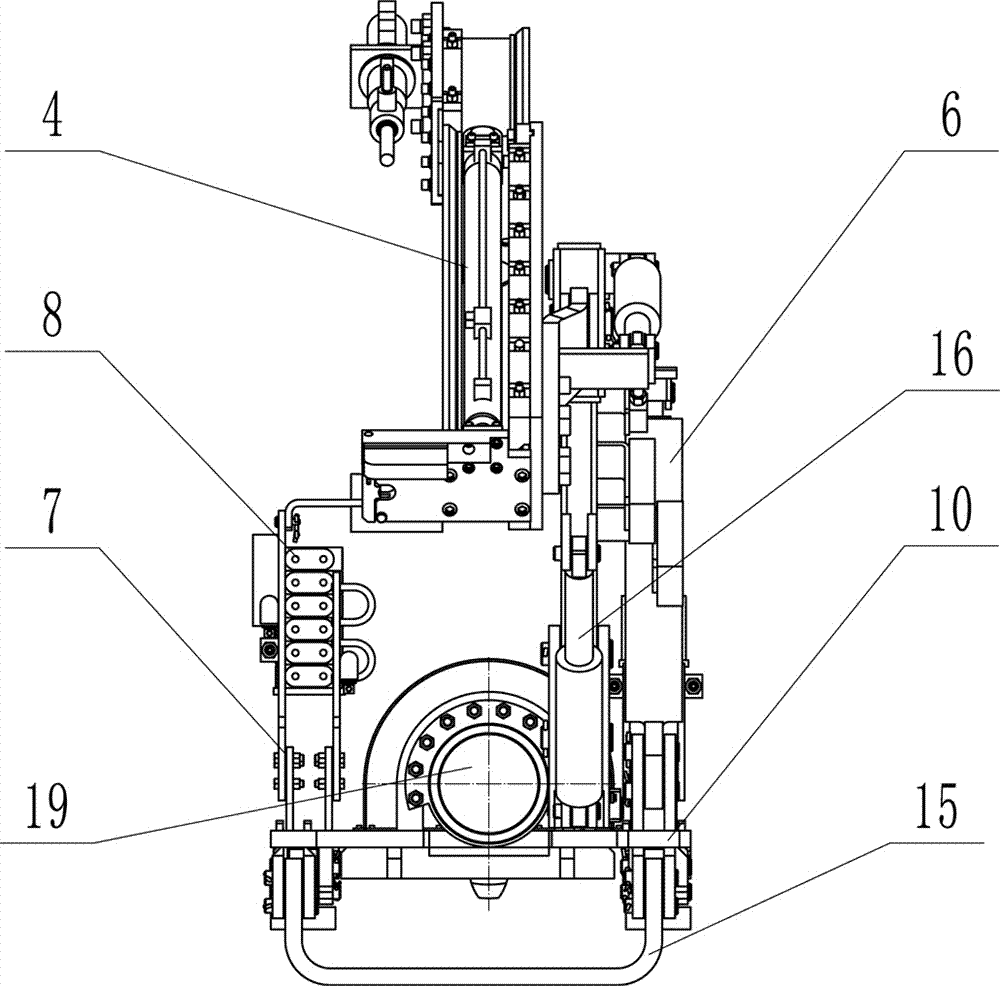

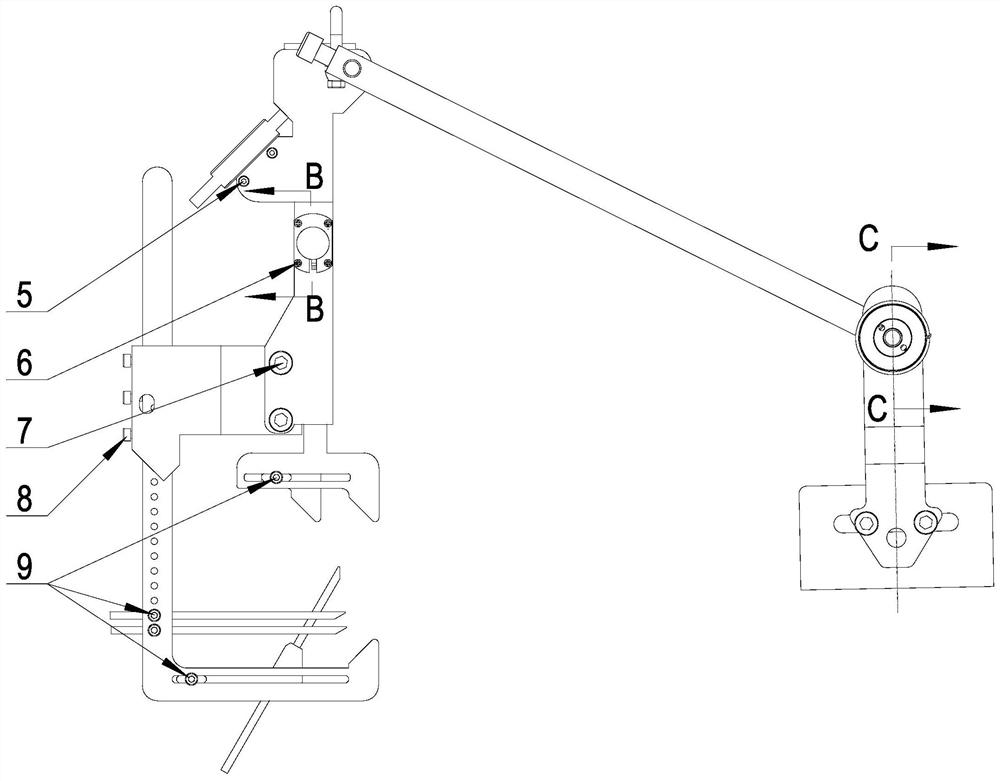

Machine-blast combined mining device for fully-mechanized coal mining working face

ActiveCN107023262ASmooth vertical liftAdapt to quick loading and unloadingReciprocating drilling machinesConstructionsSingle supportRock cutting

The invention discloses a machine-blast combined mining device for a fully-mechanized coal mining working face. The problems that an existing rock drilling device is uneven in stressing, influences the running stability, can not meet the machine-blast combined mining requirement and the like are solved. The machine-blast combined mining device comprises a supporting platform, a rock drilling device, a hydraulic support column, a motor with a brake and a hydraulic control device, wherein the supporting platform is assembled on a ledge and a pin rail of a scraper conveyer and driven by the motor with the brake to move in the length direction of the scraper conveyer. According to the machine-blast combined mining device for the fully-mechanized coal mining working face, an original telescopic cantilever single supporting structure is replaced with linkage-type double supporting arms, and by cooperating with telescoping of an angle adjusting hydraulic cylinder and a lifting hydraulic cylinder, steady vertical lifting of the rock drilling device is achieved; the machine-blast combined mining device is reasonable in design, compact in structure, balanced in stressing, convenient and fast to assemble and disassemble, flexible to move, precise in positioning and stable in operation, can safely and reliably cooperate with drilling and blasting work of a tunnel cross section, can meet the quick assembling, disassembling and moving requirements of machine-blast combined mining work, and significantly improves the production efficiency and the work quality of the fully-mechanized coal mining working face.

Owner:SHENYANG TIAN AN TECH CO LTD

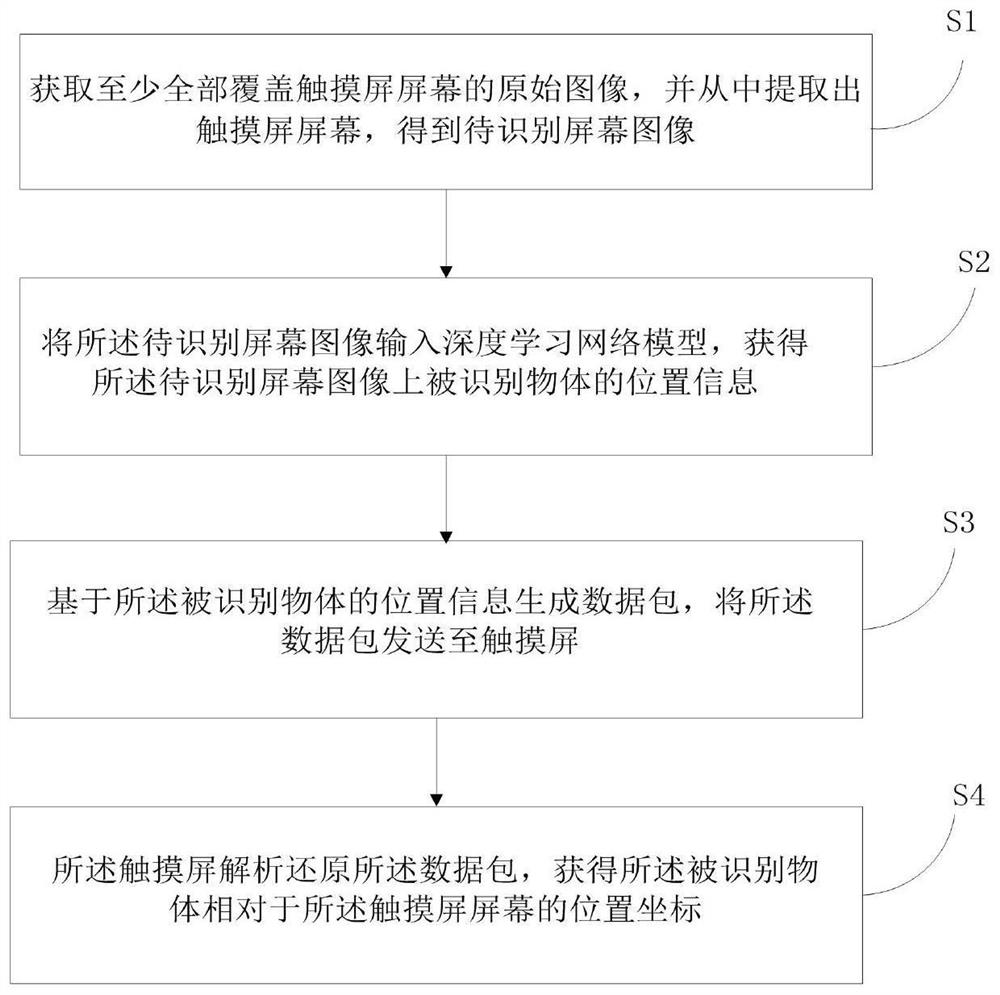

Material segregation device with materials accurately positioned and material segregation method of material segregation device

PendingCN111268403AFlexible and precise positioningSimple structureConveyorsControl devices for conveyorsStructural engineeringControl theory

Owner:SHANGHAI WEISONG IND AUTOMATION

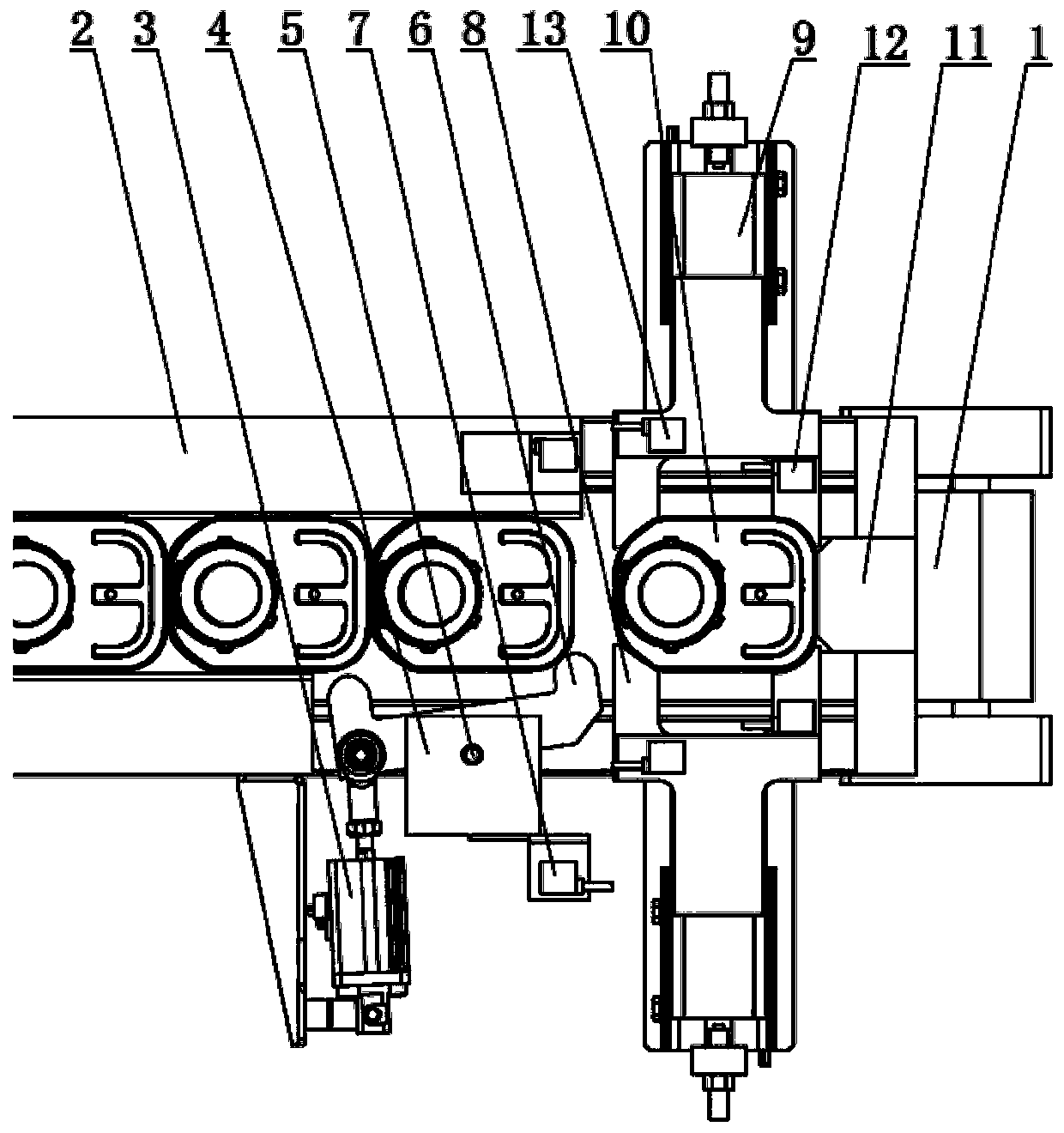

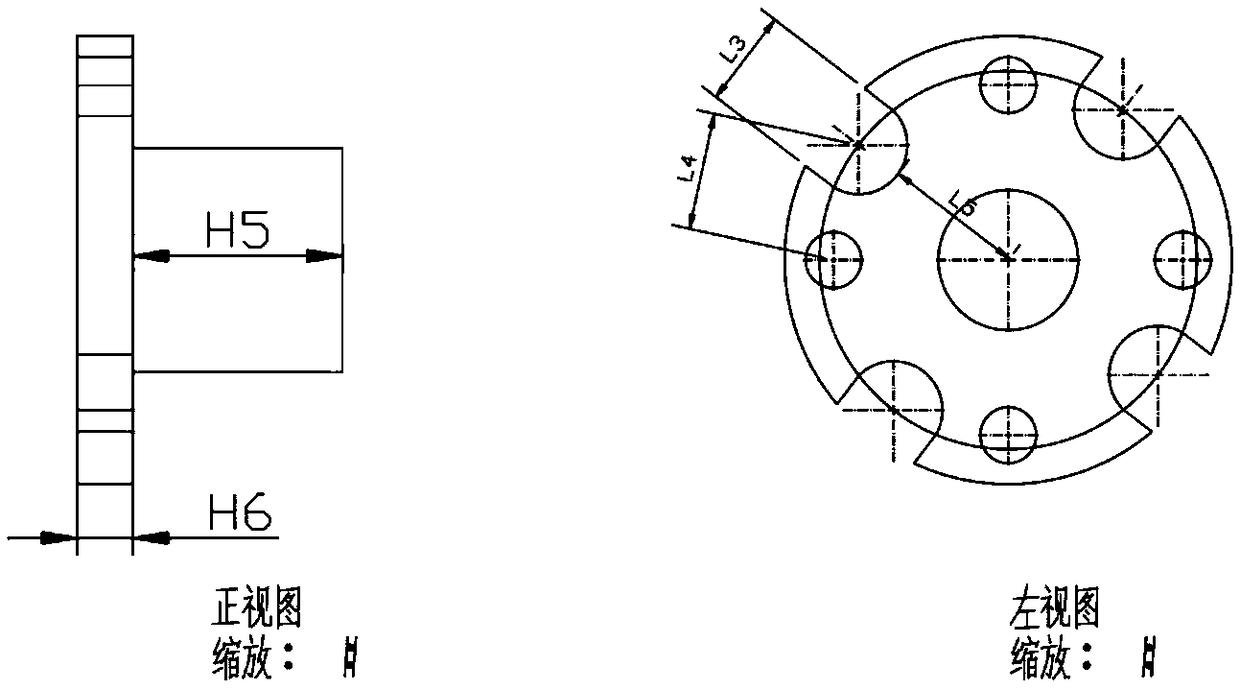

Positioning supporting frame of inductive head

InactiveCN103499002ASimple structureReasonable designMachine supportsEngineeringMechanical engineering

Owner:ANHUI YINRUI GLASS MACHINERY

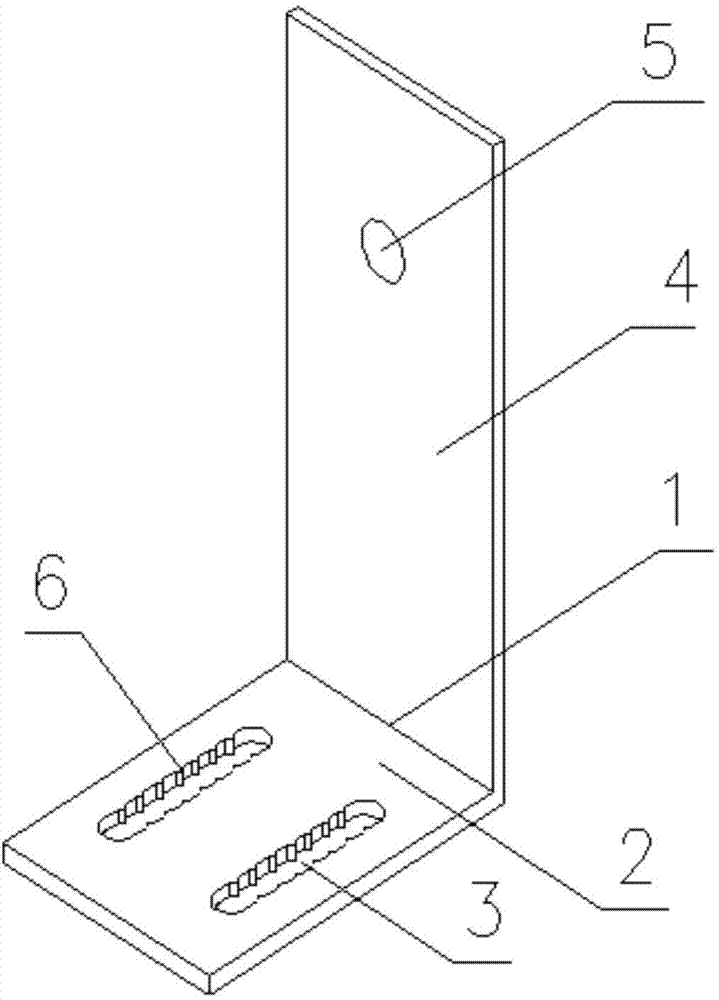

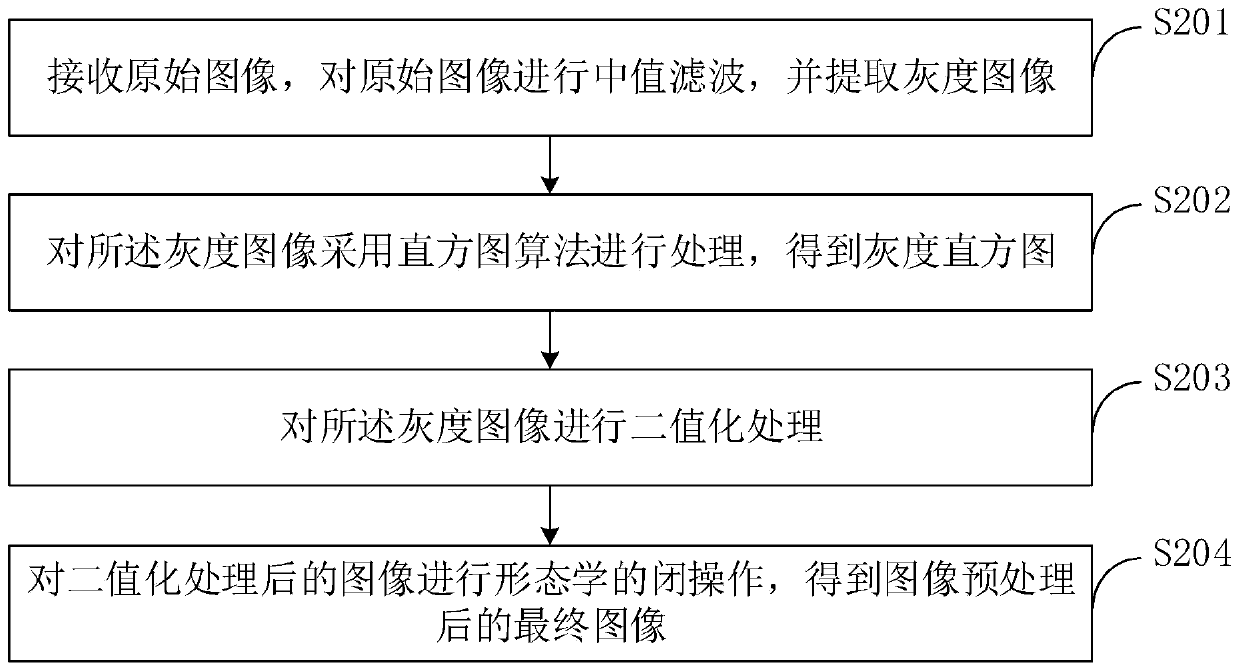

Touch screen object positioning method and device based on artificial intelligence

PendingCN114647361AImprove scalabilitySolve the low recognition accuracyImage enhancementImage analysisPattern recognitionData pack

The invention discloses a touch screen object positioning method and device based on artificial intelligence, and the method comprises the steps: obtaining an original image which at least completely covers a touch screen, extracting the touch screen from the original image, and obtaining a to-be-recognized screen image; inputting the to-be-recognized screen image into the deep learning network model to obtain position information of a recognized object on the to-be-recognized screen image; generating a data packet based on the position information of the identified object, and sending the data packet to the touch screen; and the touch screen analyzes and restores the data packet to obtain the position coordinates of the identified object relative to the touch screen. According to the method, positioning and object recognition of any object on the capacitive touch screen can be achieved, the position of the object relative to the touch screen can be reported in real time, the problem that the recognition accuracy is low when different objects and moving objects are recognized can be effectively solved, positioning is more accurate and flexible, and the user experience is improved. And great expansibility is brought to human-computer interaction facilities based on the touch screen.

Owner:BEIJING DANG HONG QI TIAN INT CULTURE DEV GRP CO LTD

Manual material dispersing valve

PendingCN108861308AFlexible material distributionConvenient and efficient dispensingChutesEngineeringMechanical engineering

The invention provides a manual material dispersing valve, and belongs to the field of material dispersing equipment. The manual material dispersing valve comprises a main chute, a material dispersingopening, a material dispersing chute, a rotary shaft, a turning plate, a handle, an inserting pin and an inserting hole structure, wherein the material dispersing opening is formed in the material dispersing side wall of the main chute and communicated with the material dispersing chute, the central axis of the rotary shaft is parallel to the material dispersing side wall, the rotary shaft is located on the lower side of the material dispersing opening, the turning plate is rotatably connected with the material dispersing side wall through the rotary shaft, the handle is fixedly connected toone end of the rotary shaft, the inserting pin is clamped on the handle, and the inserting hole structure is arranged in the main chute or / and the material dispersing chute, used for being in inserting fit with the inserting pin and provided with multiple inserting holes. The length of the turning plate in the direction perpendicular to the direction of the rotary shaft is larger than the width ofthe inner cavity of the main chute in the direction perpendicular to the direction of the rotary shaft. The manual material dispersing valve avoids that since material caking occurs on the turning plate, rotating of the turning plate and opening and closing of the main chute and the material dispersing chute are affected; positioning is flexible and accurate, the on-off degree of a valve body canbe accurately controlled, materials can be accurately, conveniently and efficiently distributed, and the manual material dispersing valve is simple in structure, low in using cost and further capableof being used for rapid dispersion of materials in process accidents.

Owner:HEBEI IRON AND STEEL

Offshore floating type metal-air power generation module at sea

InactiveCN109119729AEfficient use ofFlexible determination of take-off and landing statusFuel and primary cellsFuel and secondary cellsElectrical batteryNew energy

The invention designs an offshore metal air power generation module, and belongs to the field of new energy batteries. The offshore floating type metal-air power generation module designed by the invention is composed of a plurality of floating type metal air power generation units, a frame and an electric lifting mechanism. The power generation units are fixed on the frame, the frame is fixed onthe electric lifting mechanism, and the metal electrodes are replaceable. When power generation is required, all the power generation units are lowered into the seawater by the electric lifting mechanism, and the positive and negative electrodes are connected to output the DC electric energy outward. When outward electric energy output is not required, the electric lifting mechanism lifts all thepower generation units out of the electrolyte seawater and stops power generation. The power generation module is provided with a two-stage washboard around the water and a two-stage protective net under the water. A telegraph pole is erected on the frame, and the positive and negative poles of the power generation module are connected to the positive and negative terminals of the telegraph pole after the power generation units inside the power generation module are serially and parallelly connected, and are connected with other power generation modules through the terminals to realize the modular power generation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

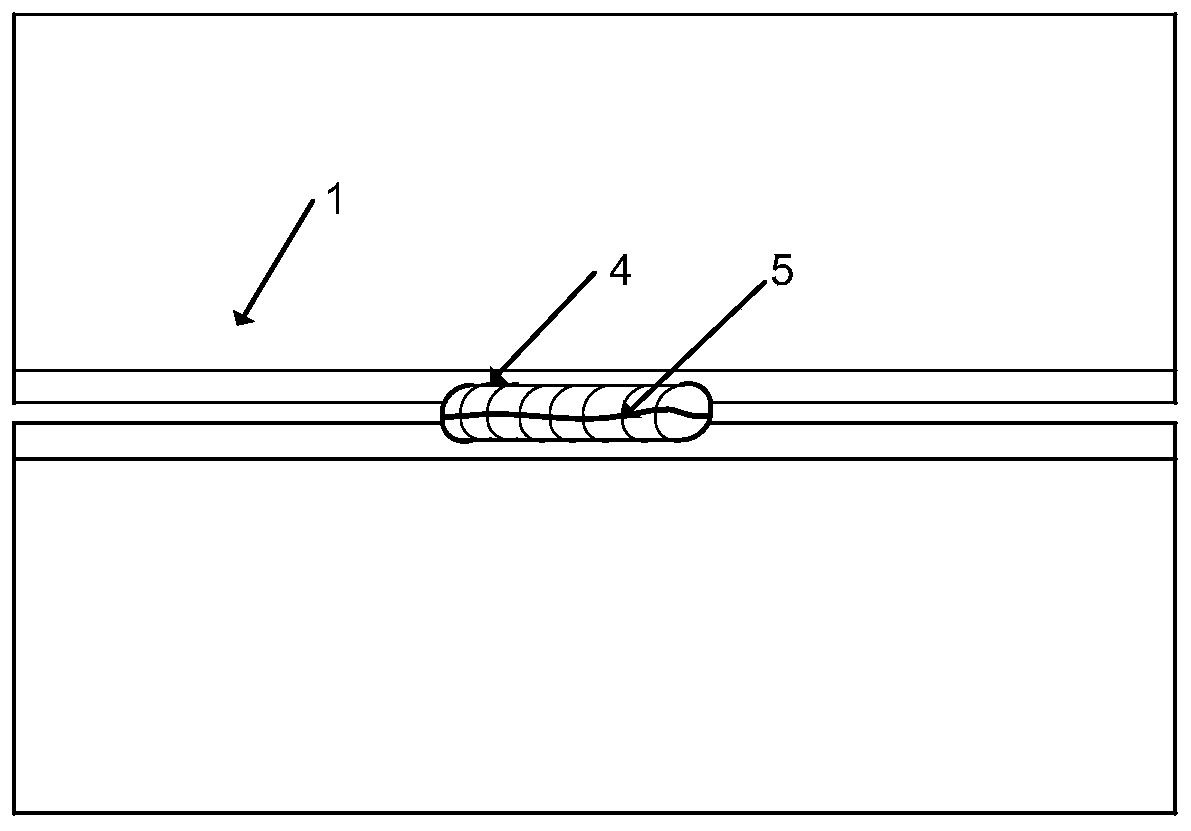

Manufacturing method of internal crack defect testing plate for non-destructive testing teaching

ActiveCN111195807AImprove sensibilityEnhance rational understandingAnalysing solids using sonic/ultrasonic/infrasonic wavesEducational modelsButt jointDestructive testing

The invention discloses a manufacturing method of an internal crack defect testing plate for non-destructive testing teaching. The manufacturing method comprises the steps that the welded joint cold crack generation mechanism in the welding process is utilized, the high-constraint testing plate butt joint mode is adopted, a high-carbon-equivalent welding material is utilized, normal-temperature welding is conducted and supplemented by application of the forced rapid cooling measure after welding is accomplished, a product is placed for 24 hours, and therefore a welded joint internal crack which meets the requirements for the designed crack position, the depth and the length can be formed; and then a clamp and a testing plate point fixation are disassembled, bottoming welding is conducted in the region without the designed crack, a defect testing plate is filled and subjected to face covering welding, finally the welded joint surface cleaning is conducted, and the manufacture of the testing plate is accomplished. The welded joint internal crack formed according to the manufacturing method is different from the artificial defect in a common non-destructive testing standard testing plate, the crack defect is real, and the method is feasible, can be used for conducting non-destructive testing such as ultrasonic non-destructive testing, and training and examining non-destructive testing personnel, and has the important significance in enhancing the understanding of the non-destructive testing personnel for crack defect detection signals. The manufacturing method of the internalcrack defect testing plate for non-destructive testing teaching has the advantages of being flexible and accurate in locating, meeting the requirement of actual teaching and training and being broad in application range.

Owner:XI AN JIAOTONG UNIV

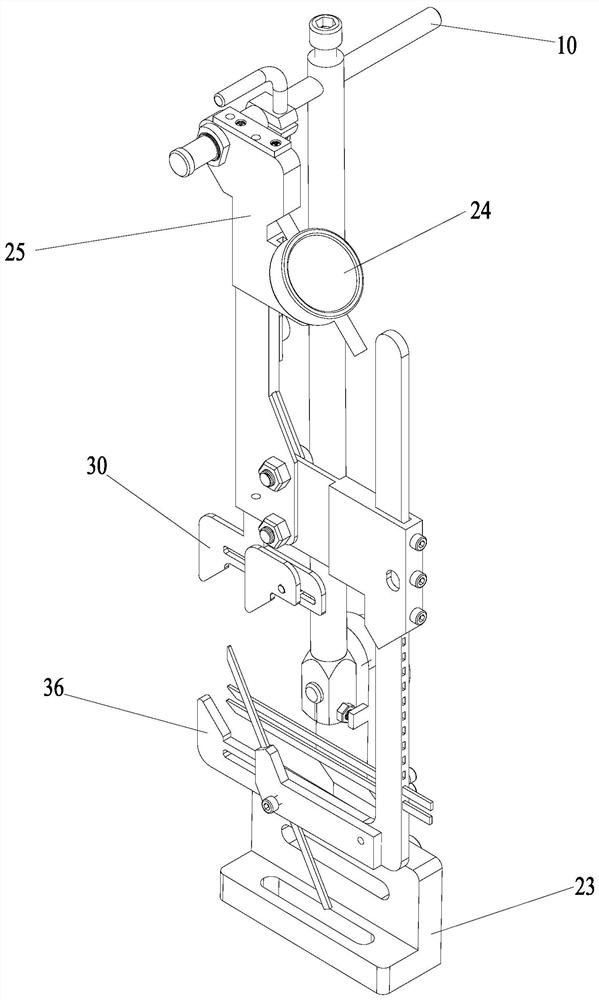

Manual laser cursor image positioning apparatus for camera

InactiveCN101303512ASimple structureLow costCamera body detailsOptical elementsCouplingOptical instrument

A manual laser-cursor image location device used in cameras pertains to cursor image location devices of optical instruments. The technical problem to be solved is to provide a manual laser-cursor image location device used in cameras. The manual laser-cursor image location device of the invention comprises a joint base, a step-hole, a camera coupling screw, a bulb, a bulb clamping ring, a laser-cursor balopticon, etc. The step-hole is positioned in the position which is slightly left-skewed in the middle of the joint base; a pit of the bulb and a thread hole of the bulb clamping ring are positioned at the right end of the joint base; a connection screw hole of a tripod is positioned at the center of the bottom of the camera coupling screw; the camera coupling screw runs through the step-hole on the joint base and is then connected with the step-hole by thread; the bulb runs through the thread hole of the bulb clamping ring and extends in the pit of the bulb and the connection between the bulb clamping ring and the thread hole of the bulb clamping ring is threaded connection; between the bulb and the pit of the bulb as well as the bulb clamping ring, rotary and sliding damping contact matching is adopted; the bulb is connected with a connection screw hole of the bulb on the laser-cursor balopticon by a bulb screw; the laser-cursor balopticon rotates internally and slides for damping matching through the pit of the bulb on the joint base.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

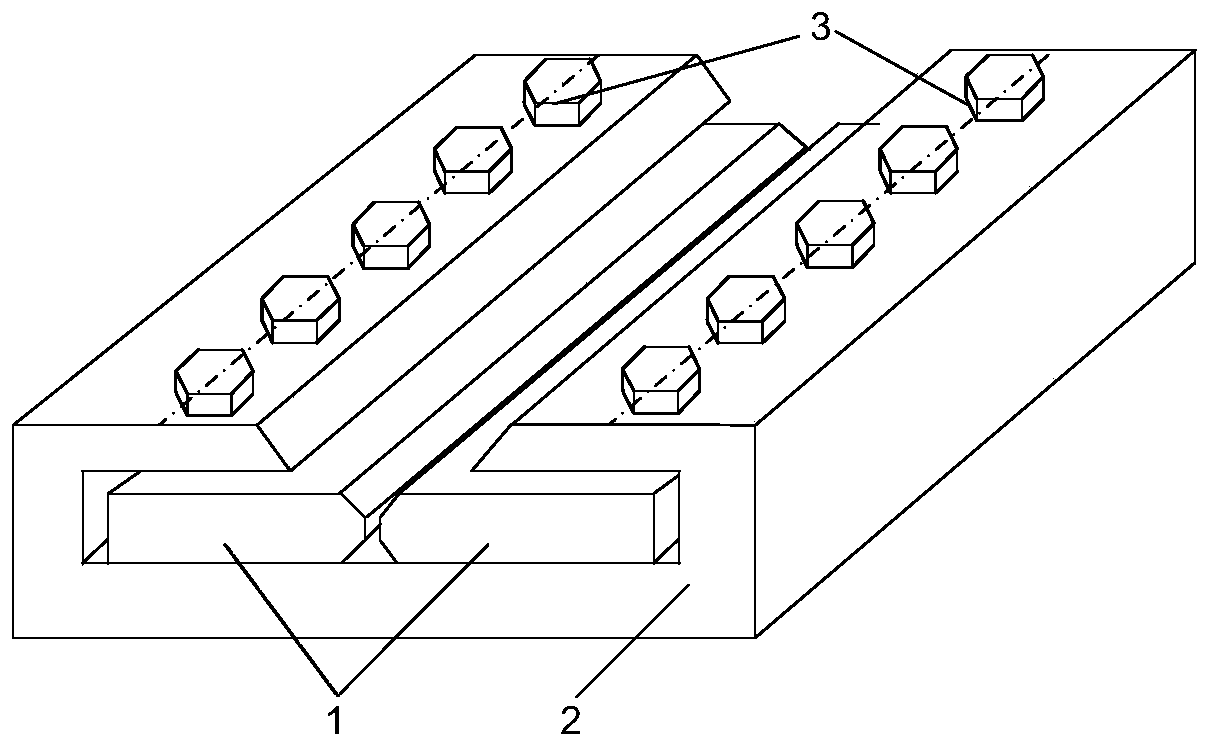

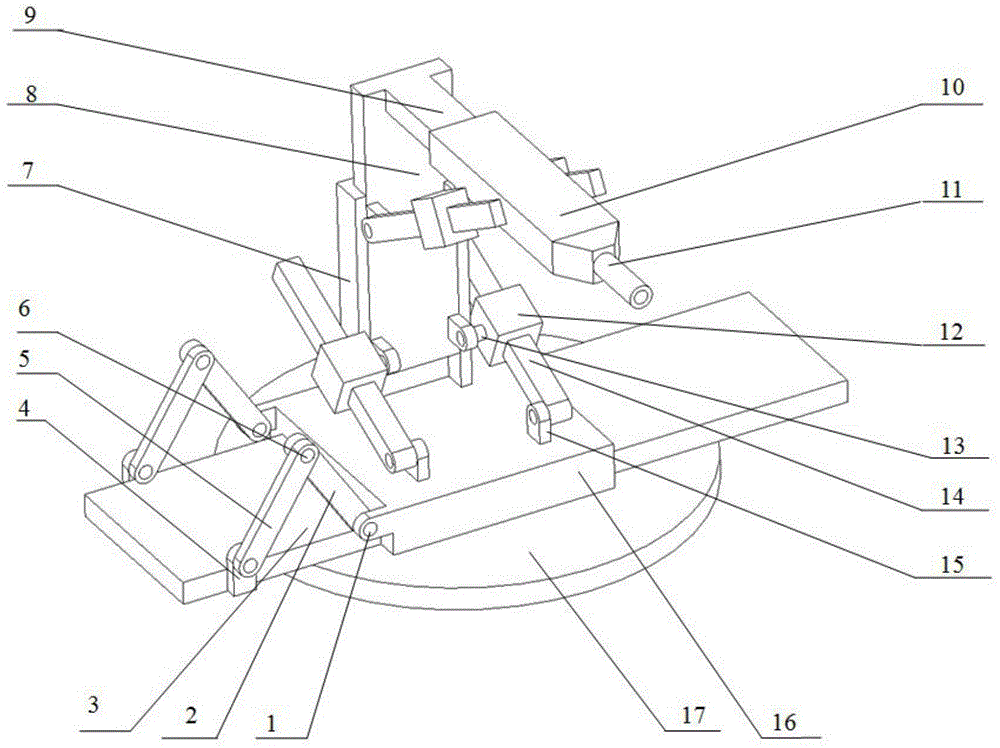

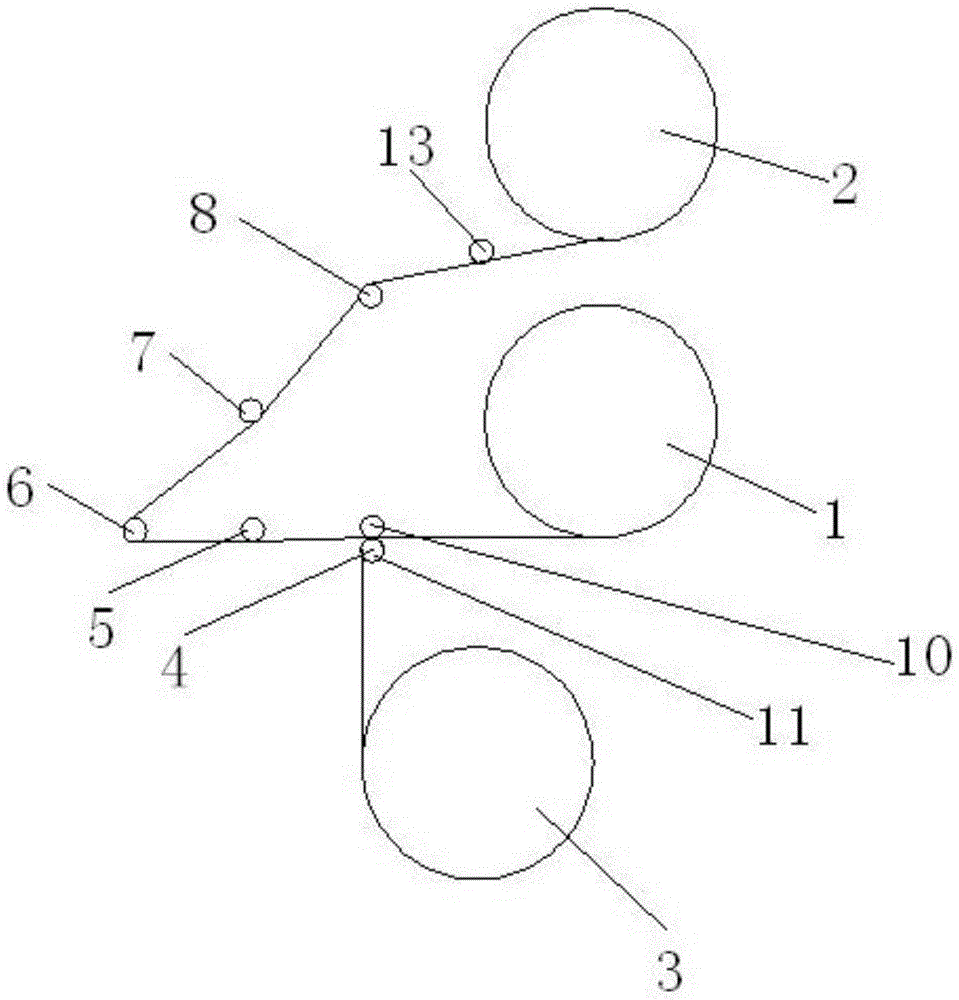

Large-space multi-DOF (degree of freedom) controlled mechanism type robot

ActiveCN104439813ASmooth motionLarge expansion spaceWelding/cutting auxillary devicesAuxillary welding devicesDegrees of freedomControllability

A large-space multi-DOF (degree of freedom) controlled mechanism type robot comprises motors, a rotating base, a base moving mechanism, a vertical moving mechanism, a horizontal moving mechanism and a welding gun. The motors are controllable and include a first controlled motor, a second controlled motor and a third controlled motor. The rotating base is in the cylindrical form. The large-space multi-DOF controlled mechanism type robot adopts the concept of cylindrical coordinates of advanced mathematics and has the advantages that accurate and flexible positioning in a large space is achieved, smooth welding in the operation is realized, structure is simple, excellent performances of controllability, adjustability, flexible output and electromechanical integration are imparted, and motion curve can be flexibly adjusted according to changes in functional requirements or environments.

Owner:GUANGXI UNIV

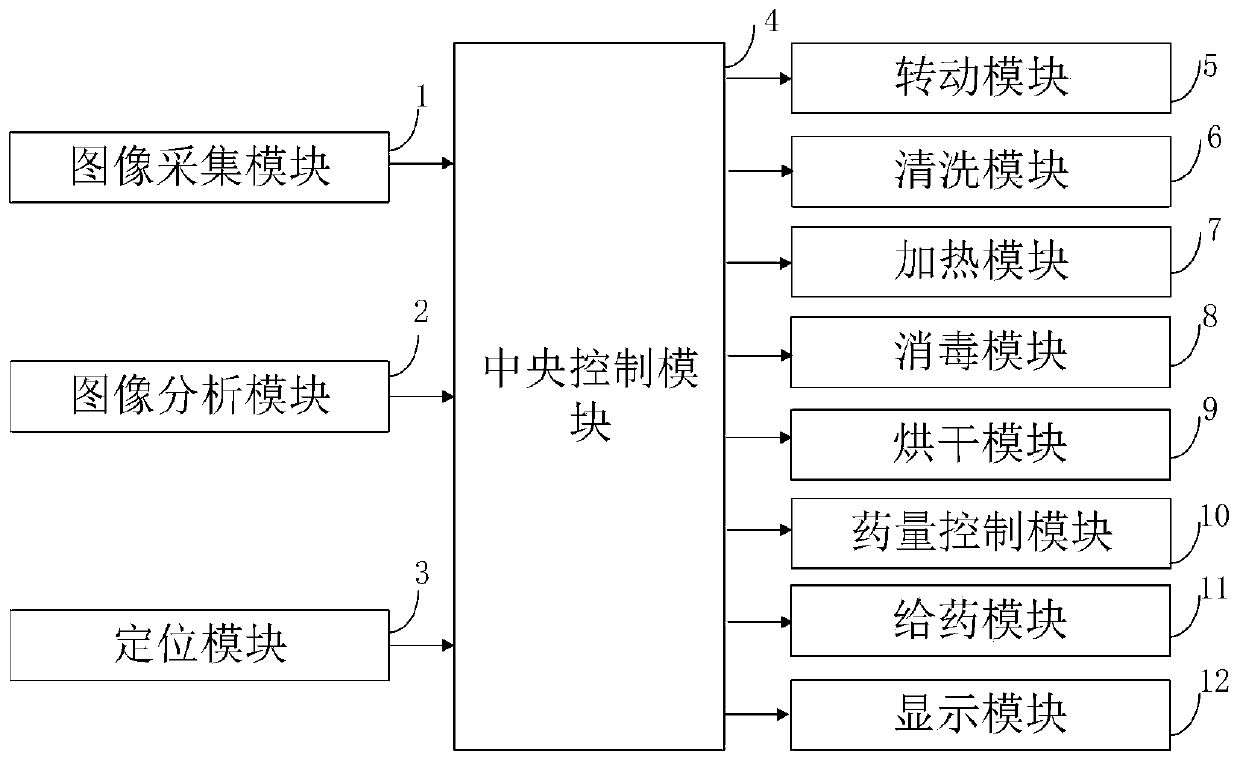

Gynecological nursing medicine application equipment capable of avoiding wound secondary infection

InactiveCN111420255AGuaranteed clarityPrecise positioningMedical devicesMedical equipmentPharmacy medicine

The invention belongs to the technical field of medical equipment, and discloses gynecological nursing medicine application equipment capable of avoiding wound secondary infection. In the gynecological nursing medicine application equipment capable of avoiding the wound secondary infection, an image acquisition module is used for image acquisition; an image analysis module analyzes image information; a positioning module locates a wound; a central control module controls the normal operation of each module; a rotating module moves a medicine delivery rod; a cleaning module cleans the wound; aheating module heats cleaning water; a disinfection module is used for wound disinfection; a drying module is used for drying; a medicine amount determination module uses a weighing device to determine a medicine amount; and a medicine delivery module uses a medicine delivery device to deliver a medicine to the wound. The equipment realizes the accurate positioning of the wound through the cooperation of the image acquisition module and the positioning module; and the drying module can dry a cleaning liquid to avoid dilution of the medicine, so that the medicine effect is better.

Owner:PEOPLES HOSPITAL OF DEYANG CITY

Device for manufacturing thread-stitched book blocks which comprise folded printed sheets

InactiveUS7815180B2Flexible and precise positioningSimple drive deviceArticle feedersSheet bindingComputer-aidedElectric motor

A device for manufacturing thread-stitched book blocks which comprise folded printed sheets has a conveying apparatus which transports the printed sheets astride a stitching saddle into a stitching position and to which the printed sheets are fed. A stitching apparatus is arranged at a lateral spacing from the stitching saddle which can be driven in an oscillating manner and can be supplied with printed sheets by the stitching saddle. The conveying apparatus is controlled in order to change the conveying speed and / or the stitching position of the printed sheets on the stitching saddle, in that the conveying apparatus is drive-connected to a controlled-rotation electric motor which is controlled by a computer-connected controller.

Owner:MULLER MARTINI HLDG

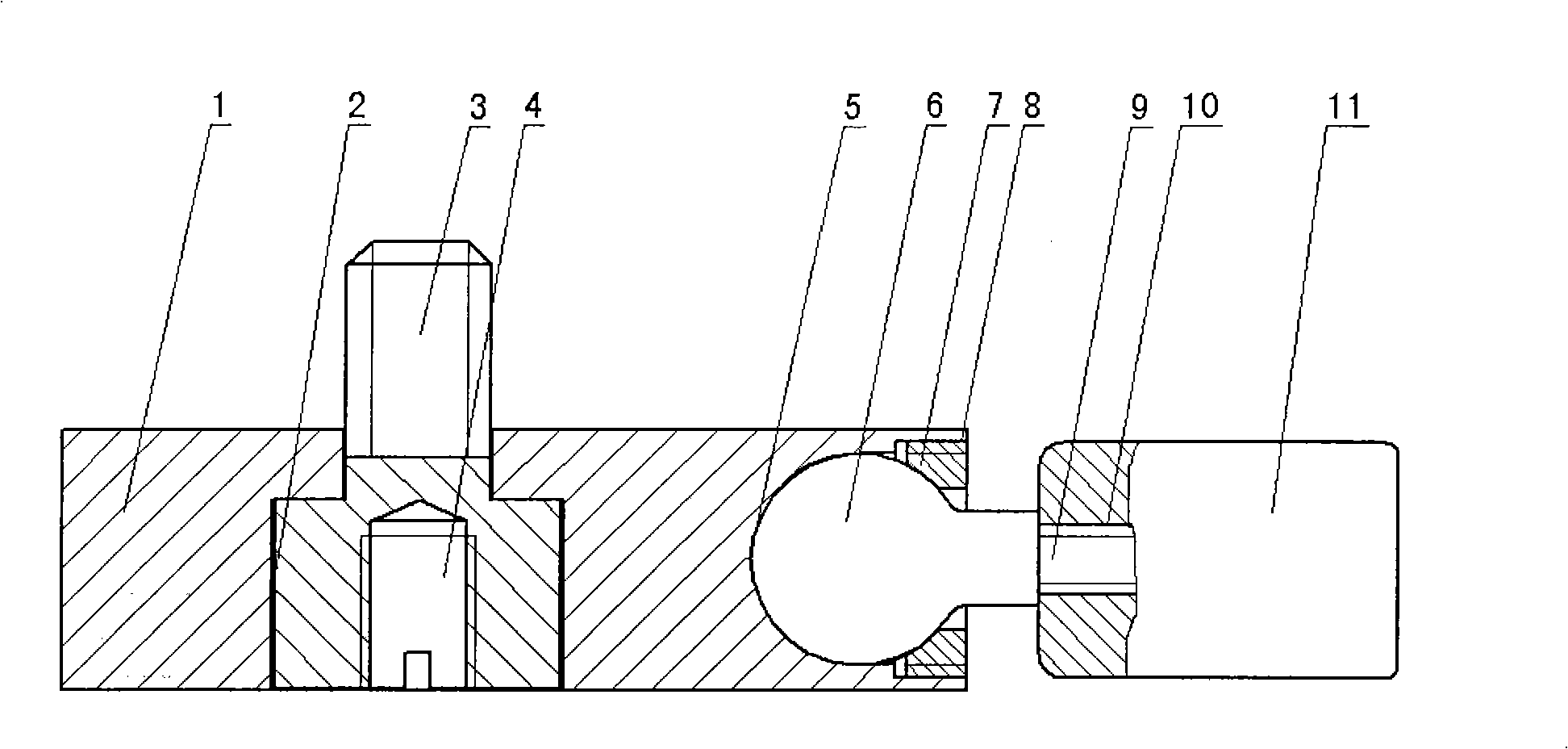

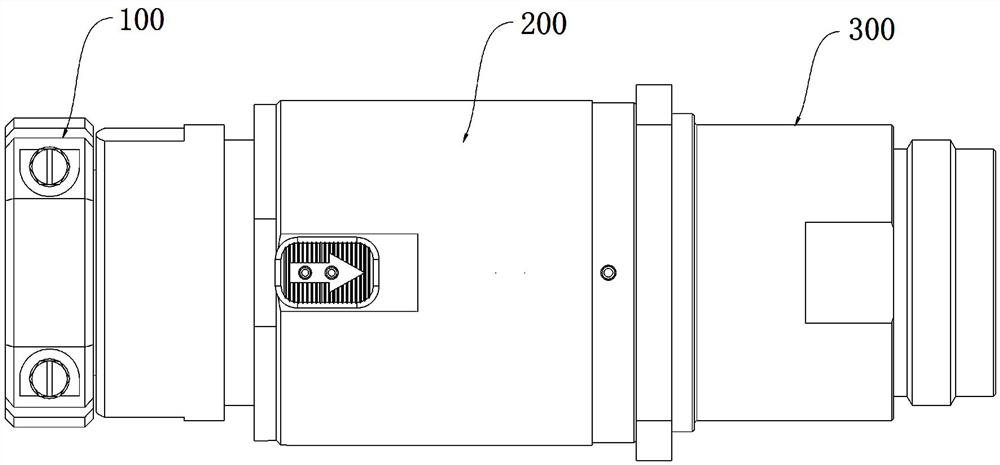

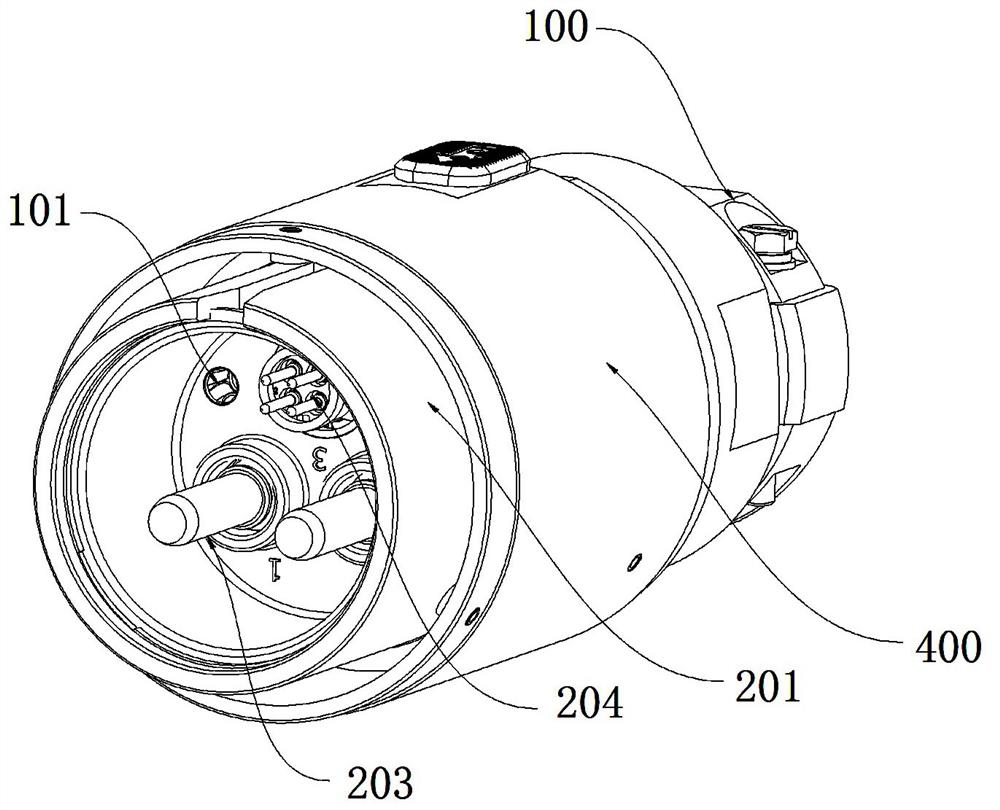

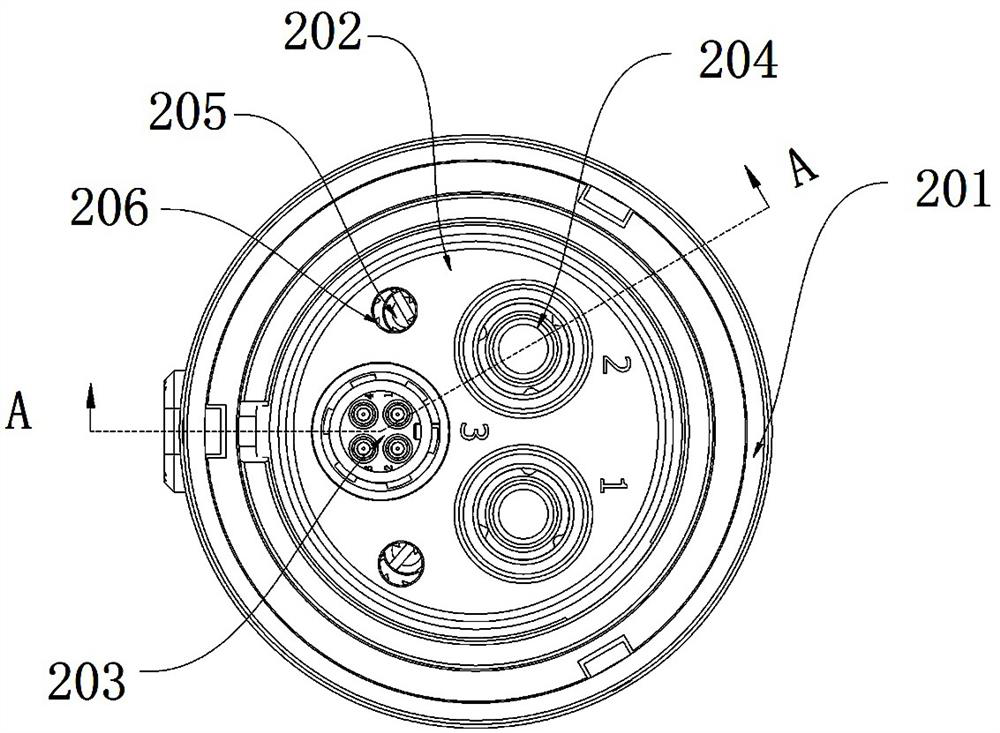

Combined connector

ActiveCN112563818AFlexible and precise positioningWon't bendEngagement/disengagement of coupling partsIncorrect coupling preventionEngineeringStructural engineering

The invention discloses a combined connector. An installation plate a is installed in a shell a, a stepped hole is further formed in the installation plate a, the stepped hole is located in one side of a signal pin assembly, a spring ring is installed in the stepped hole, a connecting sleeve assembly is further installed on the shell a in a sleeving mode, a clamping nail is arranged on the connecting sleeve assembly, a socket comprises a shell b, and an installation plate b is installed in the shell b. A positioning rod is arranged on the installation plate b, after the plug is inserted into the socket, the positioning rod is inserted into the spring ring, and the clamping nail is located at the bottom of the spiral groove. When the plug and the socket are plugged, the spring ring and thepositioning rod can be combined to form second floating positioning, thereby realizing flexible and accurate positioning of the connector, and ensuring that the signal pin assembly and the signal jackassembly are not easy to bend in the plugging process. And the connecting sleeve assembly has an anti-reverse function, the shell can only rotate in one direction, so that the connection reliabilityof the socket and the plug is ensured, and the connecting sleeve assembly can be unlocked by axially moving the sliding part, so that the separation of the socket and the plug is realized.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

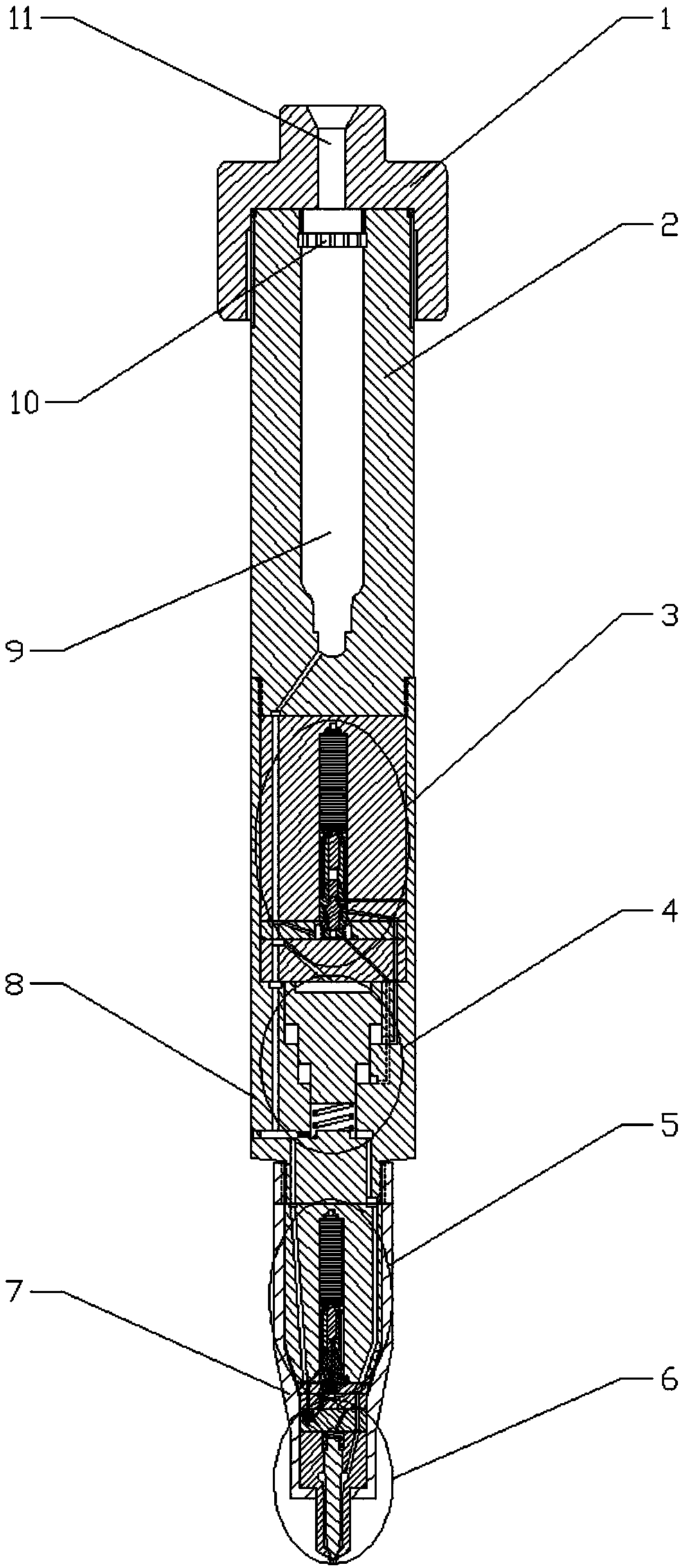

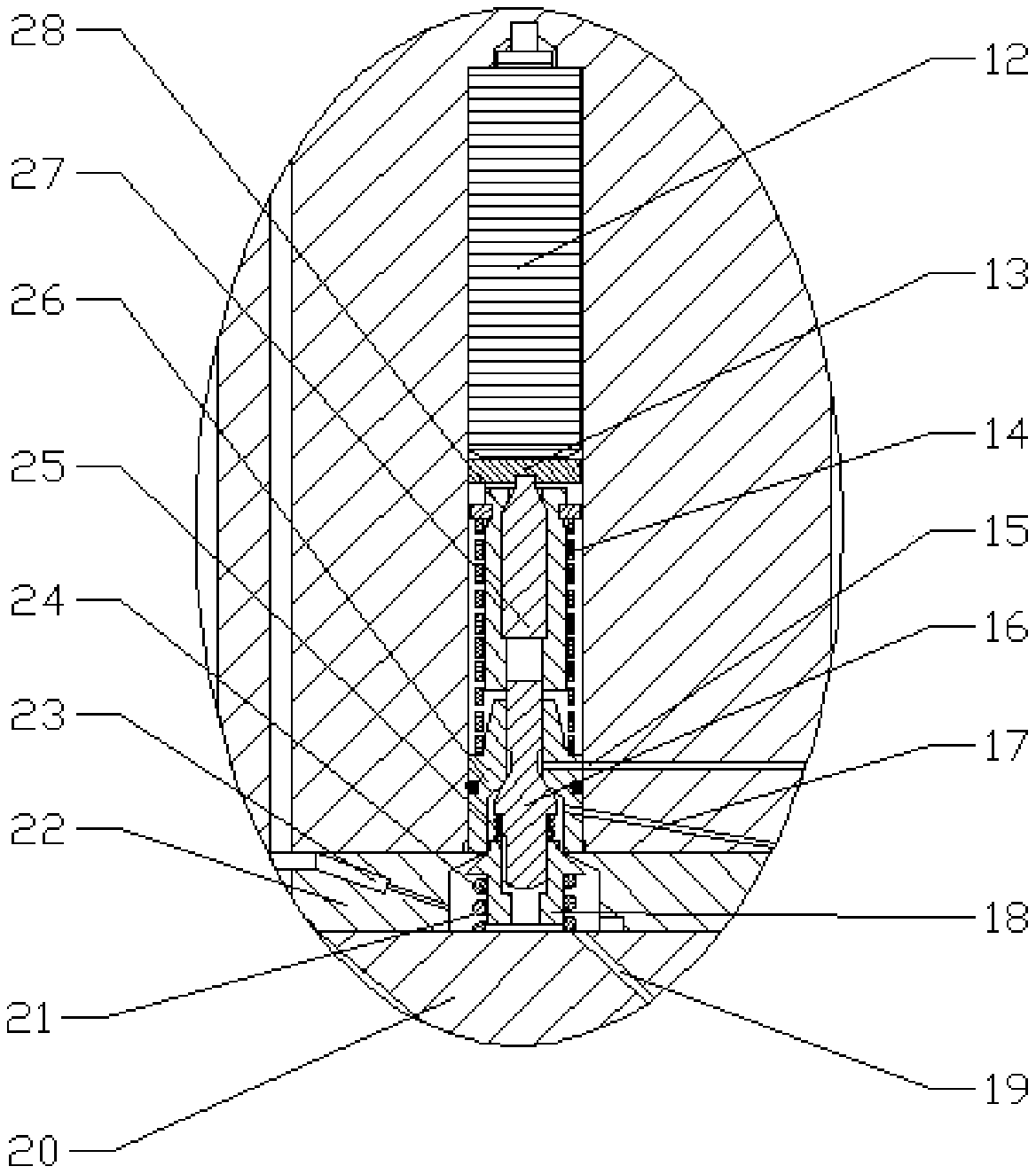

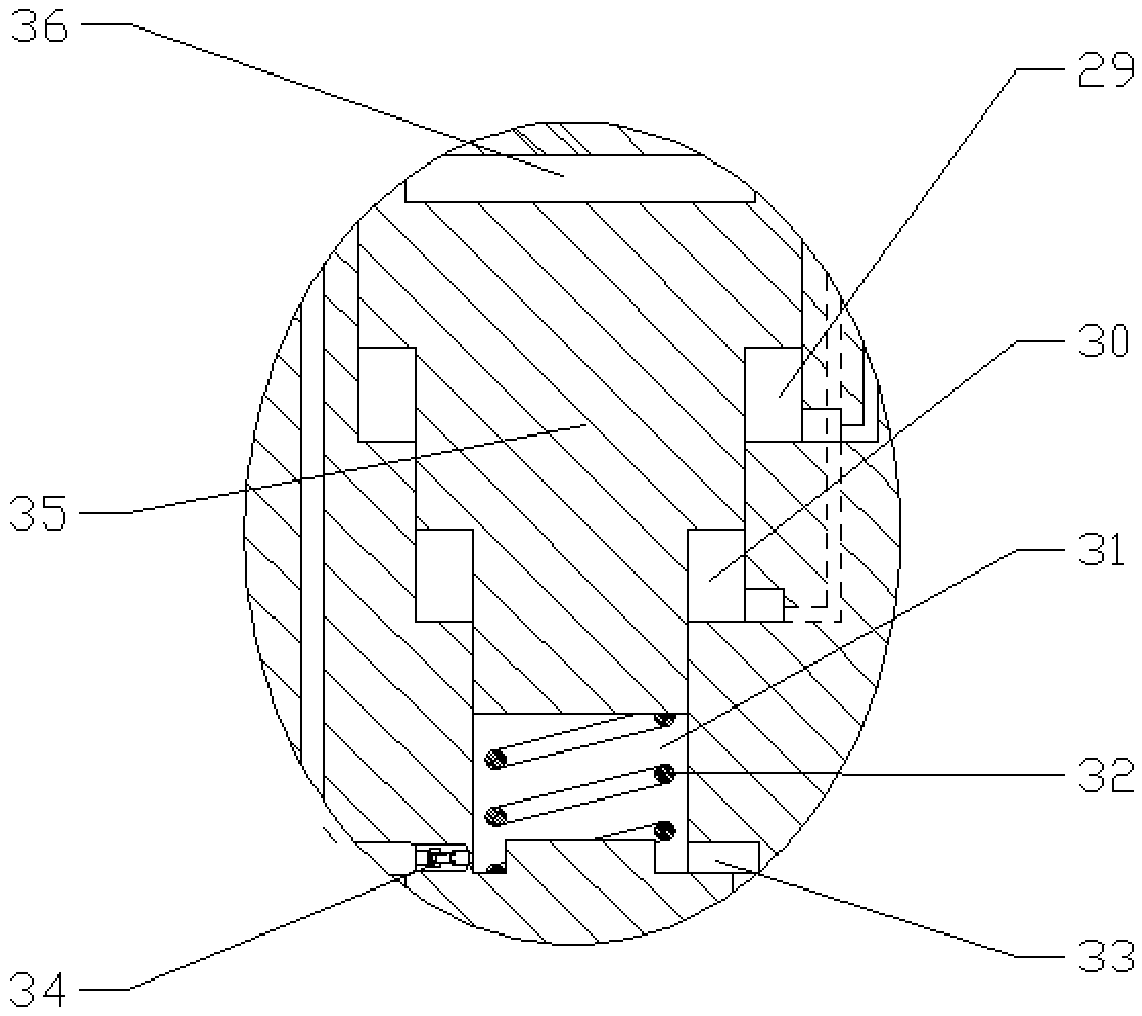

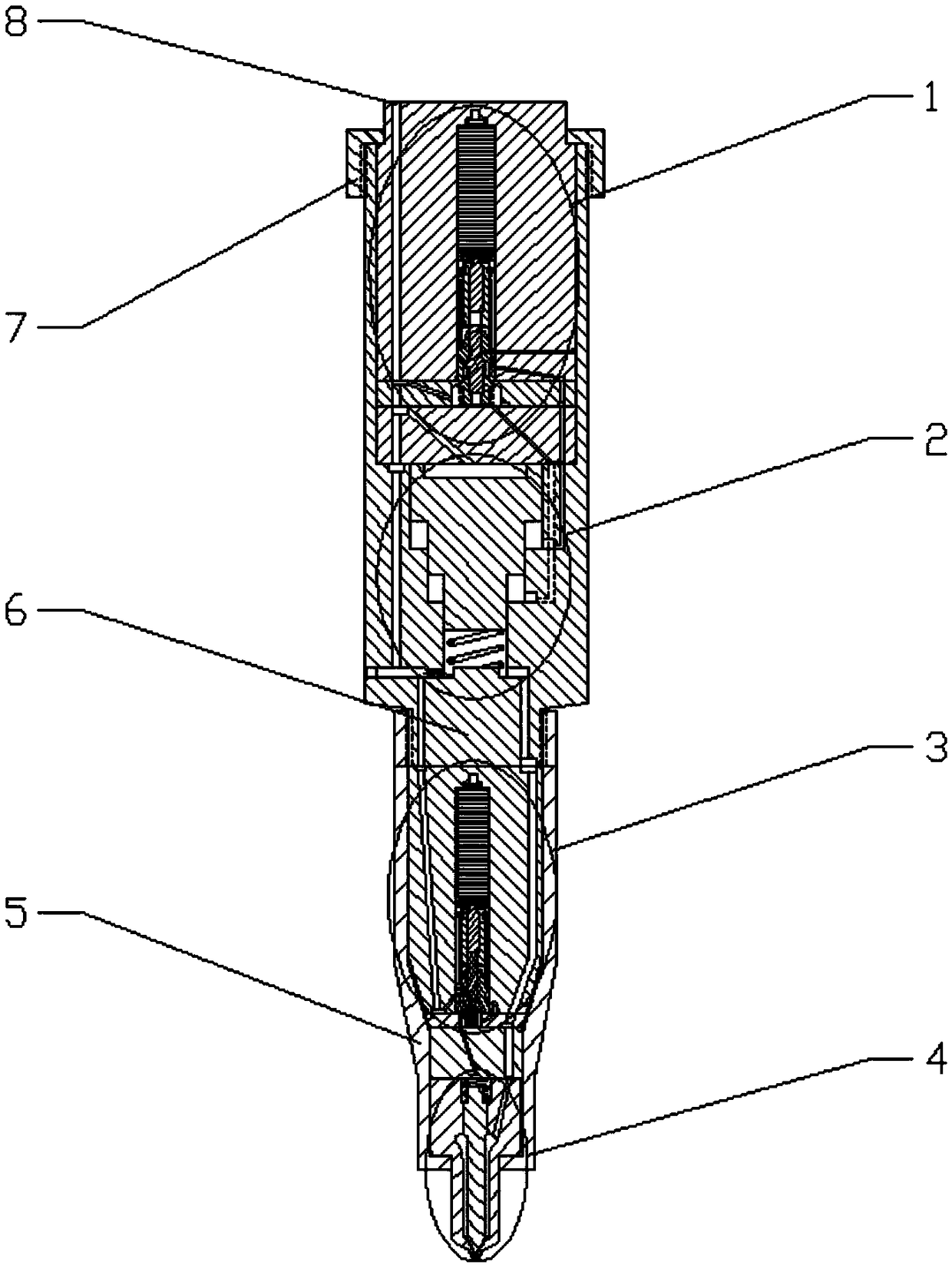

Accumulator piezoelectric injector with variable injection rule

InactiveCN109026476AReduce descent speedRelieve pressureFuel injection apparatusMachines/enginesCommon railThree stage

The invention aims to provide an accumulator piezoelectric injector with a variable injection rule. The accumulator piezoelectric injector with the variable injection rule comprises a pressurized control valve part, a three-stage piston assembly, an injection control valve part, and a needle valve part. The accumulator piezoelectric injector with the variable injection rule adopts a pressurized control valve structure to control the pressurized area of a three-stage piston, different pressurized ratios can be effectively achieved, thus the injection rule is more flexible. The operating processof a needle valve is driven by a piezoelectric reactor, the response speed of the needle valve is high, the freedom degree of controlling is large, and the injection rule is flexible and controllable, thus the power performance and fuel economy of a diesel engine are effectively improved, and more stringent emission regulations can be met through the diesel engine; in addition, pressure fluctuation caused by fuel injection can be slowed down by a pressure accumulation cavity, accurate control of the fuel-injection quantity is facilitated, and especially for the control accuracy of small amount of oil can be significantly improved; and the pressure stabilizing effect of the pressure accumulation cavity reduces the size of a common rail pipe, thus the service life of the common rail pipe isprolonged.

Owner:HARBIN ENG UNIV

A large-space multi-degree-of-freedom controllable mechanism welding robot

ActiveCN104439813BLarge expansion spaceFlexible and precise positioningProgramme-controlled manipulatorWelding/cutting auxillary devicesMulti degree of freedomDegrees of freedom

A large-space multi-DOF (degree of freedom) controlled mechanism type robot comprises motors, a rotating base, a base moving mechanism, a vertical moving mechanism, a horizontal moving mechanism and a welding gun. The motors are controllable and include a first controlled motor, a second controlled motor and a third controlled motor. The rotating base is in the cylindrical form. The large-space multi-DOF controlled mechanism type robot adopts the concept of cylindrical coordinates of advanced mathematics and has the advantages that accurate and flexible positioning in a large space is achieved, smooth welding in the operation is realized, structure is simple, excellent performances of controllability, adjustability, flexible output and electromechanical integration are imparted, and motion curve can be flexibly adjusted according to changes in functional requirements or environments.

Owner:GUANGXI UNIV

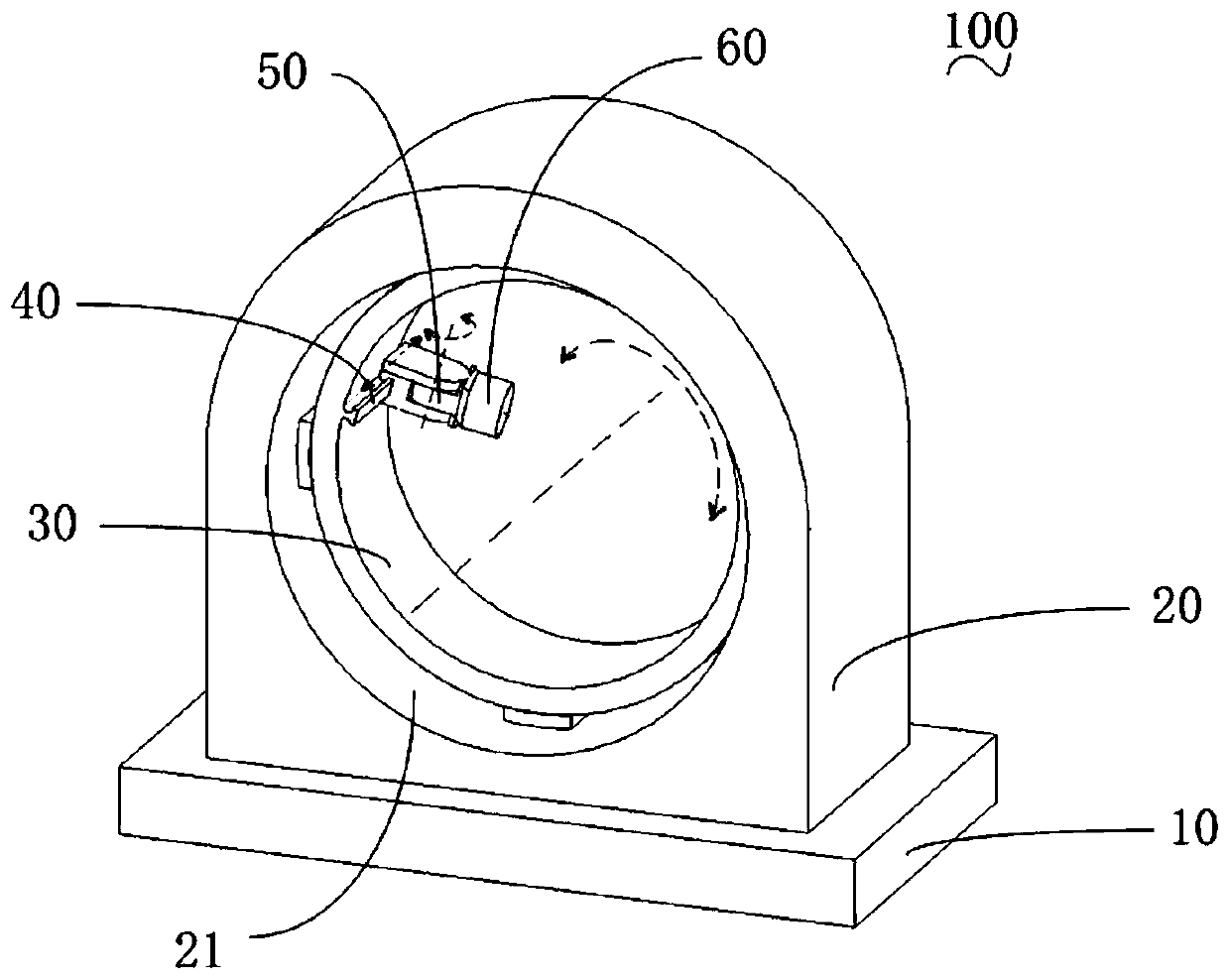

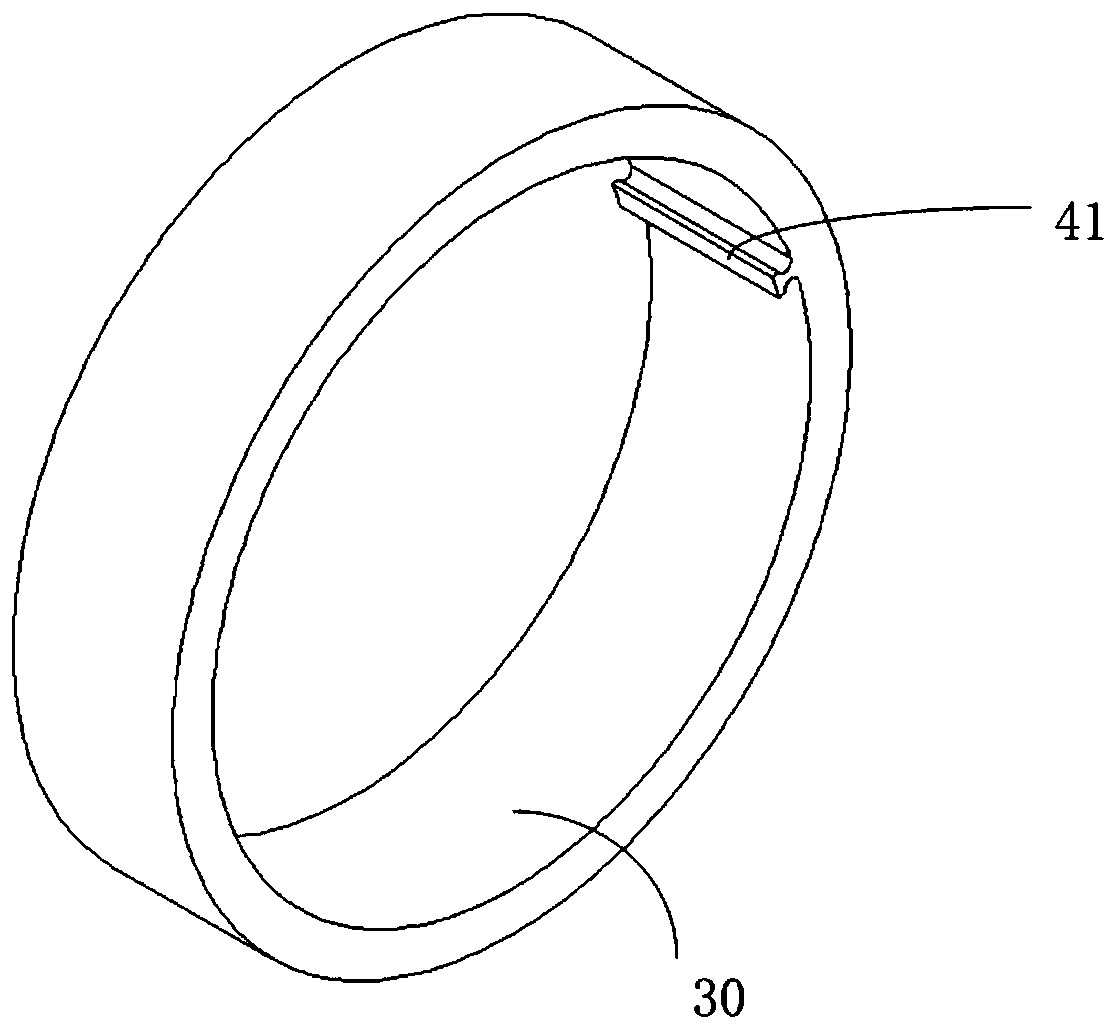

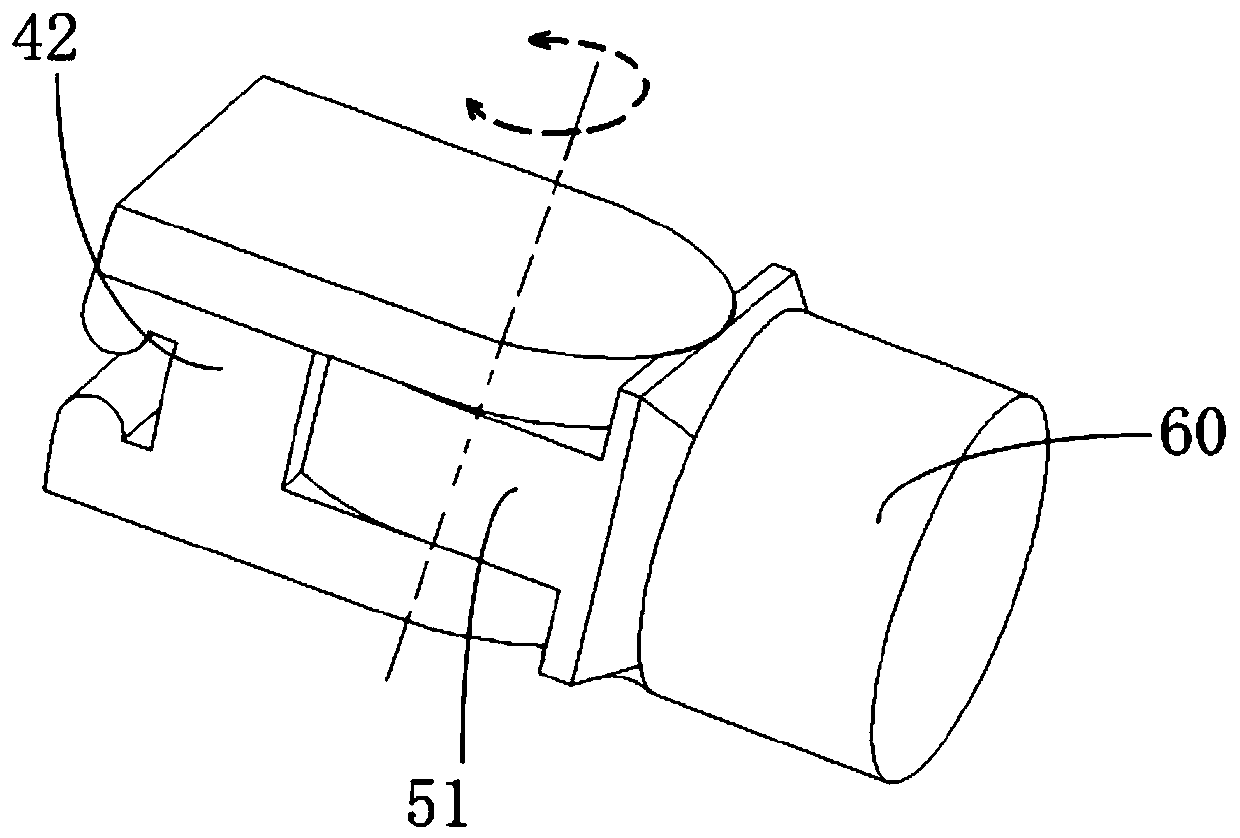

radiotherapy device

ActiveCN106730408BImprove efficiencyRapid positioningRadiation diagnosticsX-ray/gamma-ray/particle-irradiation therapyCancer cellNuclear engineering

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

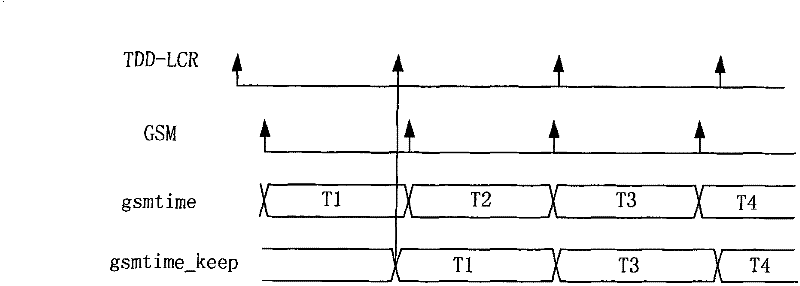

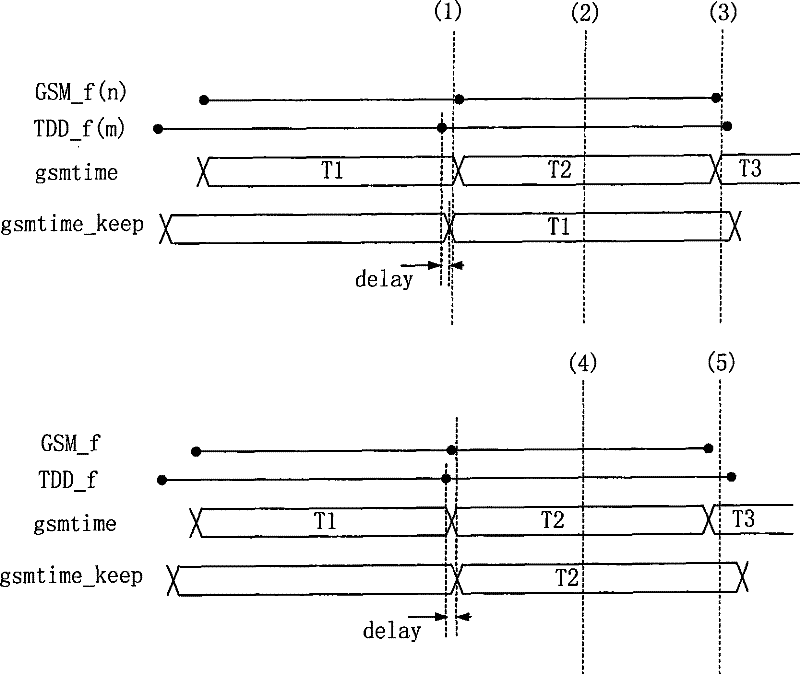

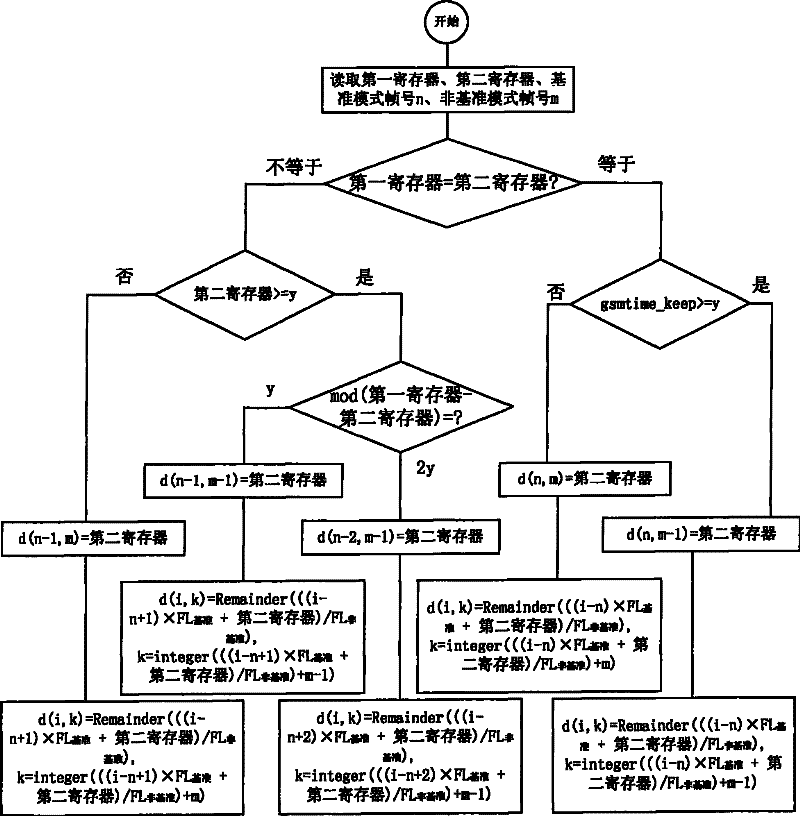

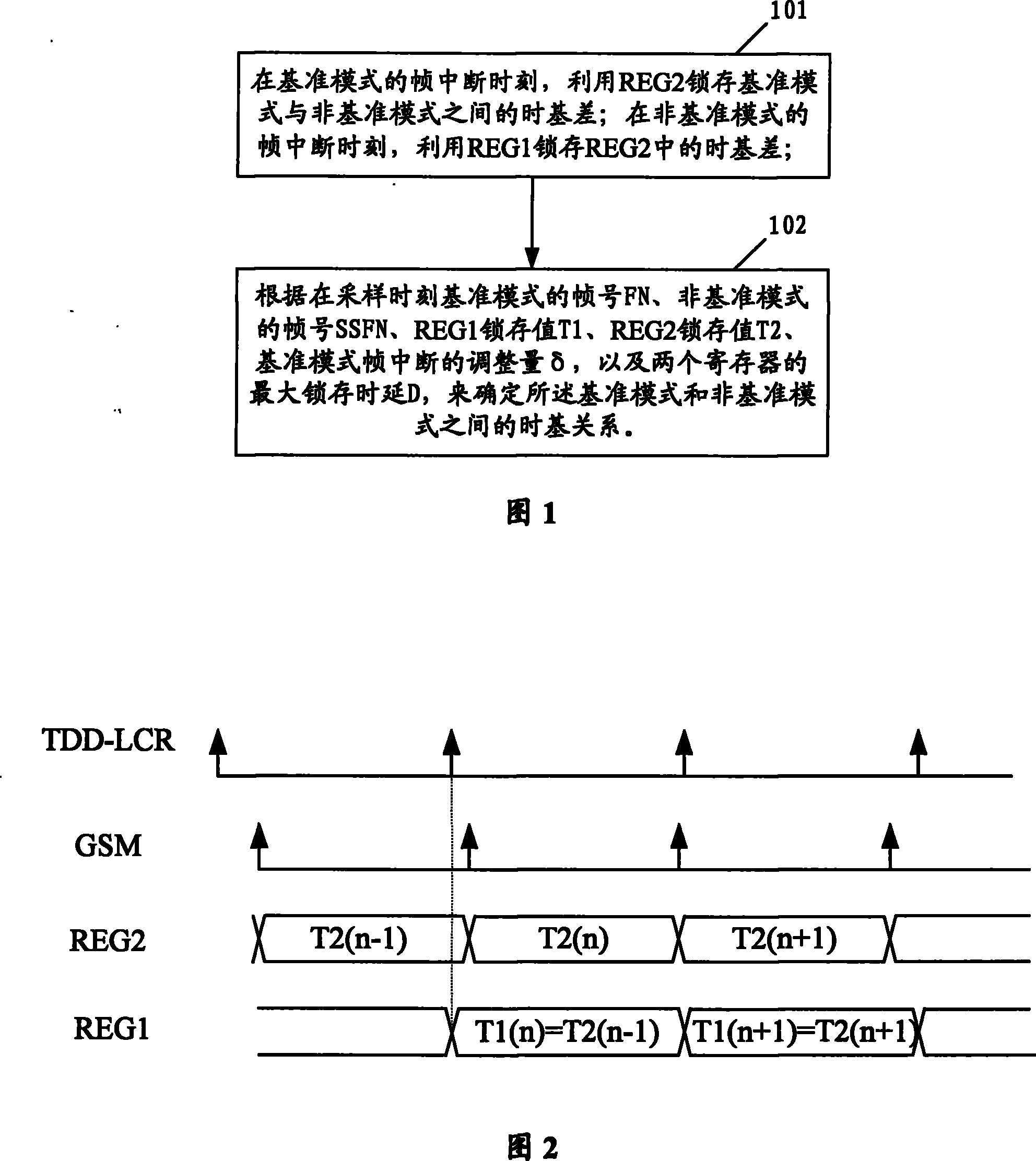

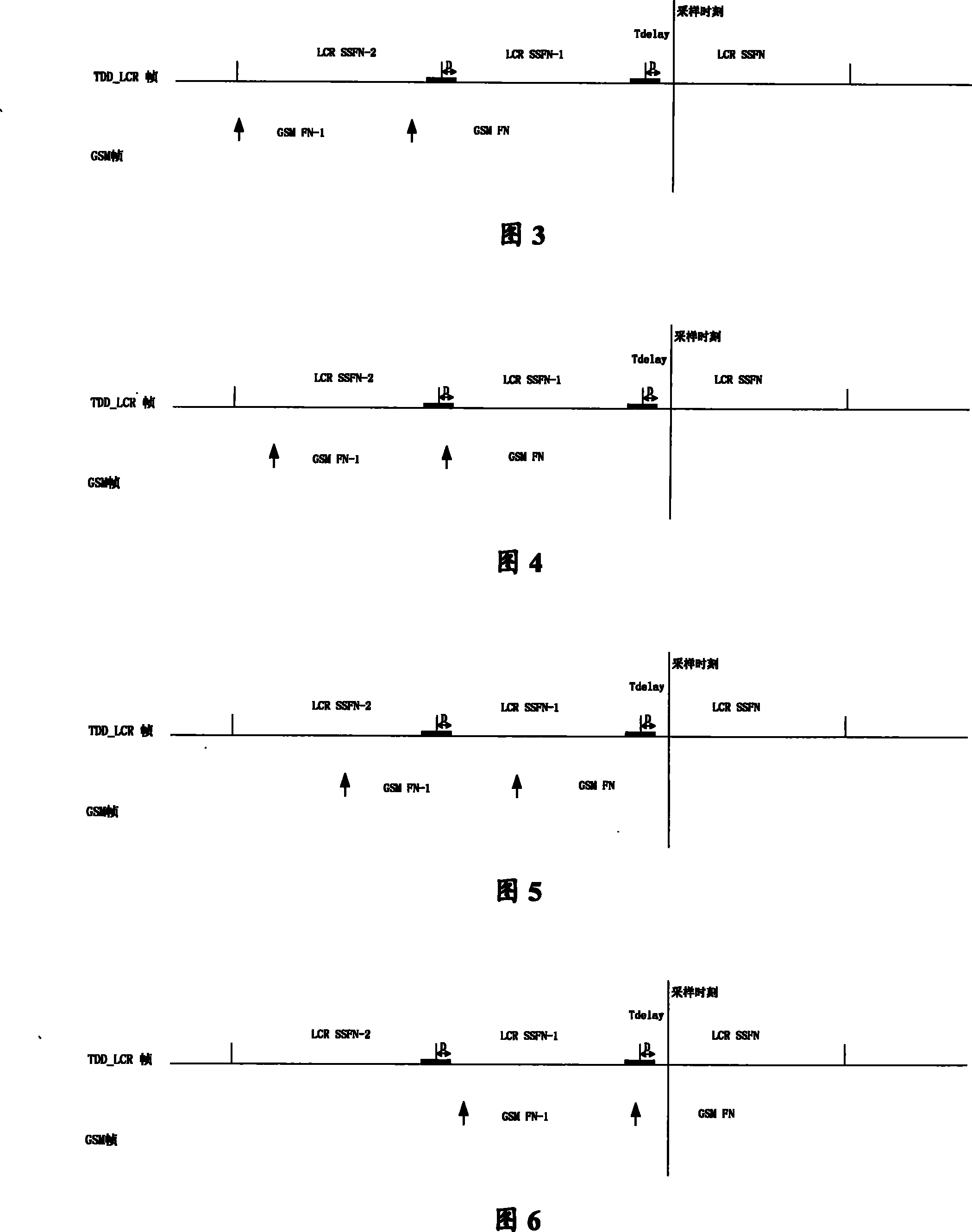

Method and device for obtaining time-base relationship in multiple mode mobile communication

InactiveCN101051877BFlexible and precise positioningRealize automatic dual modeSynchronisation arrangementRadio transmission for post communicationProcessor registerStart up

The method includes steps: (1) at time of starting up frame in reference communication mode (RCM), using first register to latch time base difference between RCM and non-RCM; at time of starting up frame in non-RCM, using second register to latch time base difference (TBD) in the first register; (2) based on frame number n in RCM at sampling time, frame number m in non-RCM, difference value Y of frame length between RCM and non-RCM, and relation of big and small between latched value in first register and latched value in second register to determine corresponding relation between TBD represented by latched value in second register and frame number at sampling time; based on the corresponding relation to obtain time base value. The invention lists all five corresponding relations between TBD and frame number, and also discloses method for determining each corresponding relation. The invention can decide time base relation between two modes precisely and smartly.

Owner:ST ERICSSON SEMICON BEIJING

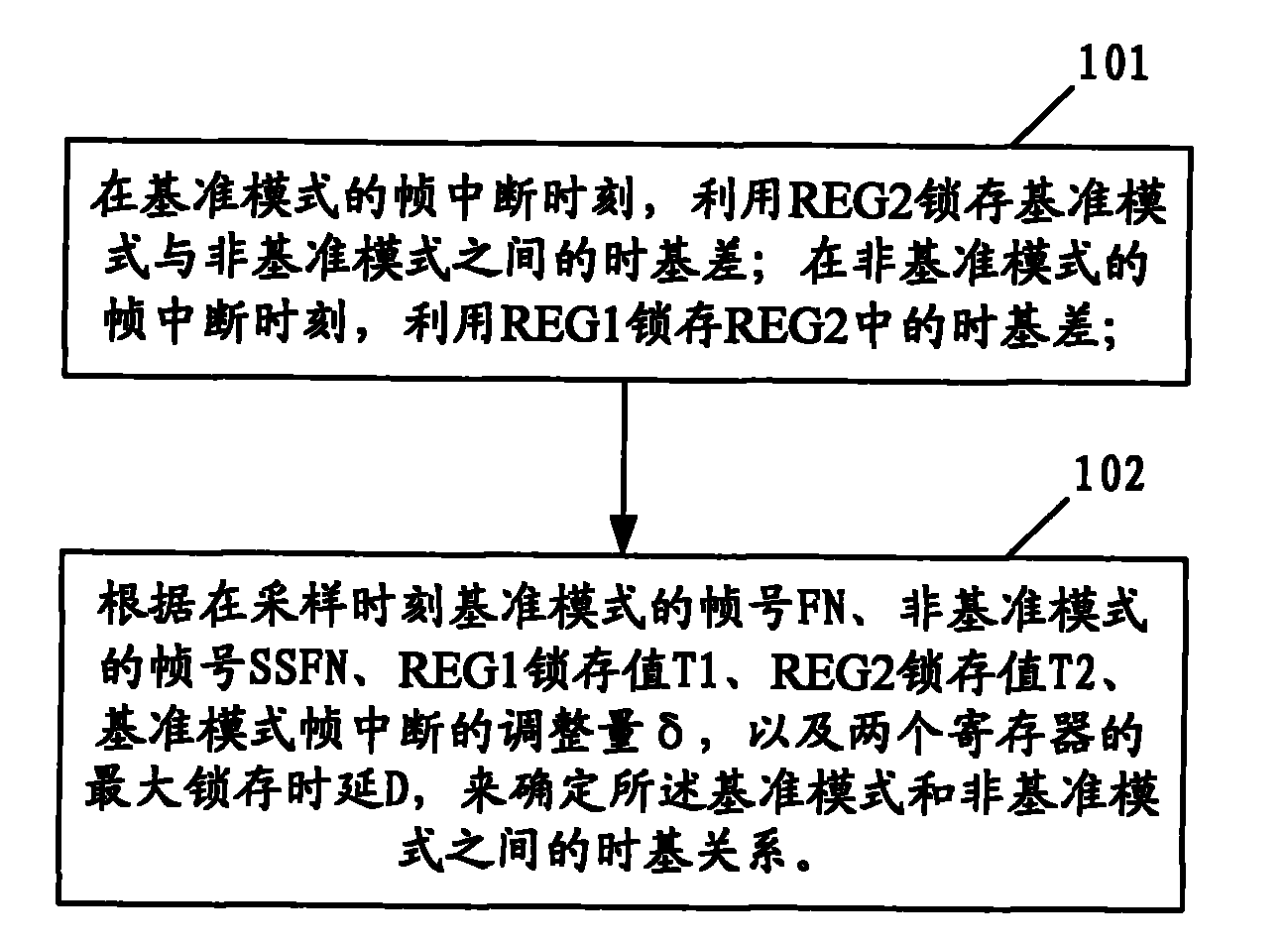

Double module terminal and method for obtaining timing base relationship

ActiveCN101203009BFlexible and precise positioningRealize automatic dual modeSynchronisation arrangementReal-time computingTime based

The invention discloses a double-mode terminal and an acquisition method of time base relationship. The method comprises the steps: A. at the moment of a frame interrupt of a basis mode, a second register is used for latching a time base difference between the basis mode and a non-basis mode; at the moment of the frame interrupt of the non-basis mode, a first register is used for latching a time base difference of the second register; B. according to a frame number FN of the basis mode, a frame number SSFN of the non-basis mode, a first register latch value T1, a second register latch value T2, an adjustment quantity Delta of the frame interrupt of the basis mode and an ultimate latch delay D of two registers at the moment of sampling, the time base relationship between the basis mode andthe non-basis mode is determined. The invention lists out five corresponding relations of GSM frame and TDD-LCR frame one by one and provides a method for determining every corresponding relation, sothe time base relationship between the two modes can be positioned accurately and flexibly and GSM / TDD-LCR automatic double-mode is favored to be realized.

Owner:ST ERICSSON SEMICON BEIJING

A three-degree-of-freedom controllable mechanical manipulator

InactiveCN105382834BRealize safe productionFlexible and precise positioningProgramme-controlled manipulatorStub axleManipulator

The invention discloses a three-freedom-degree controllable mechanical manipulator, and belongs to the field of manipulators. The three-freedom-degree controllable mechanical manipulator is characterized in that a first shaft, a second shaft and a third shaft are connected with a first controllable motor, a second controllable motor and a third controllable motor on a machine frame respectively; the first shaft and the second shaft are hollow shafts; the second shaft is sleeved with the first shaft; the third shaft is a solid shaft and sleeved with the second shaft; the first shaft is fixedly connected with a first gearbox, the first gearbox is installed in a second gearbox to achieve linkage, and the head of the manipulator can rotate by 360 degrees through the first controllable motor. The other end of the second shaft is in key connection with a first driving bevel gear, the first driving bevel gear is engaged with a first driven bevel gear, the first driven bevel gear is connected with the second gearbox, and the head of the manipulator can swing by 180 degrees vertically through the second controllable motor. The other end of the third shaft is in key connection with a second driving bevel gear, the second driving bevel enables a first short shaft, a second short shaft and a third short shaft to rotate by driving a driven gear, and clamping movement of a swing rod, an upper claw and a lower claw is achieved. The three-freedom-degree controllable mechanical manipulator has the advantages of being simple in structure, safe and reliable.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

An automatic shearing device for a nozzle of a plastic product

The invention discloses an automatic shearing device for a plastic product runner and belongs to the technical field of automatic shearing of the plastic product runner. The automatic shearing devicecomprises a shearing platform; a collecting cabinet is arranged at the bottom of the shearing platform; the upper side of the front end face of a rear plate is provided with a sliding chute; the sliding chute is provided with a corresponding slider; a fixing rod is arranged at the front end of the slider; the fixing rod is connected with a telescopic rod in an insertion manner; the front end of the telescopic rod is provided with a height adjusting cylinder; a piston rod is arranged at the bottom of the height adjusting cylinder; a shearing supporting plate is arranged at the bottom of the piston rod; a shearing pneumatic cylinder is arranged at the left side of the top of the shearing supporting plate; a shearing piston rod is arranged at the right end of the shearing pneumatic cylinder;a fixed blade matched with a movable blade is arranged inside the shearing supporting plate; and the front side of the top end of the shearing platform is provided with plastic product clamping pincers. By adopting the automatic shearing device to remove the runner on the plastic product, the cut is flat and smooth and do not affect the surface quality of the plastic product, and high work efficiency is realized.

Owner:聊城市飓风工业设计有限公司

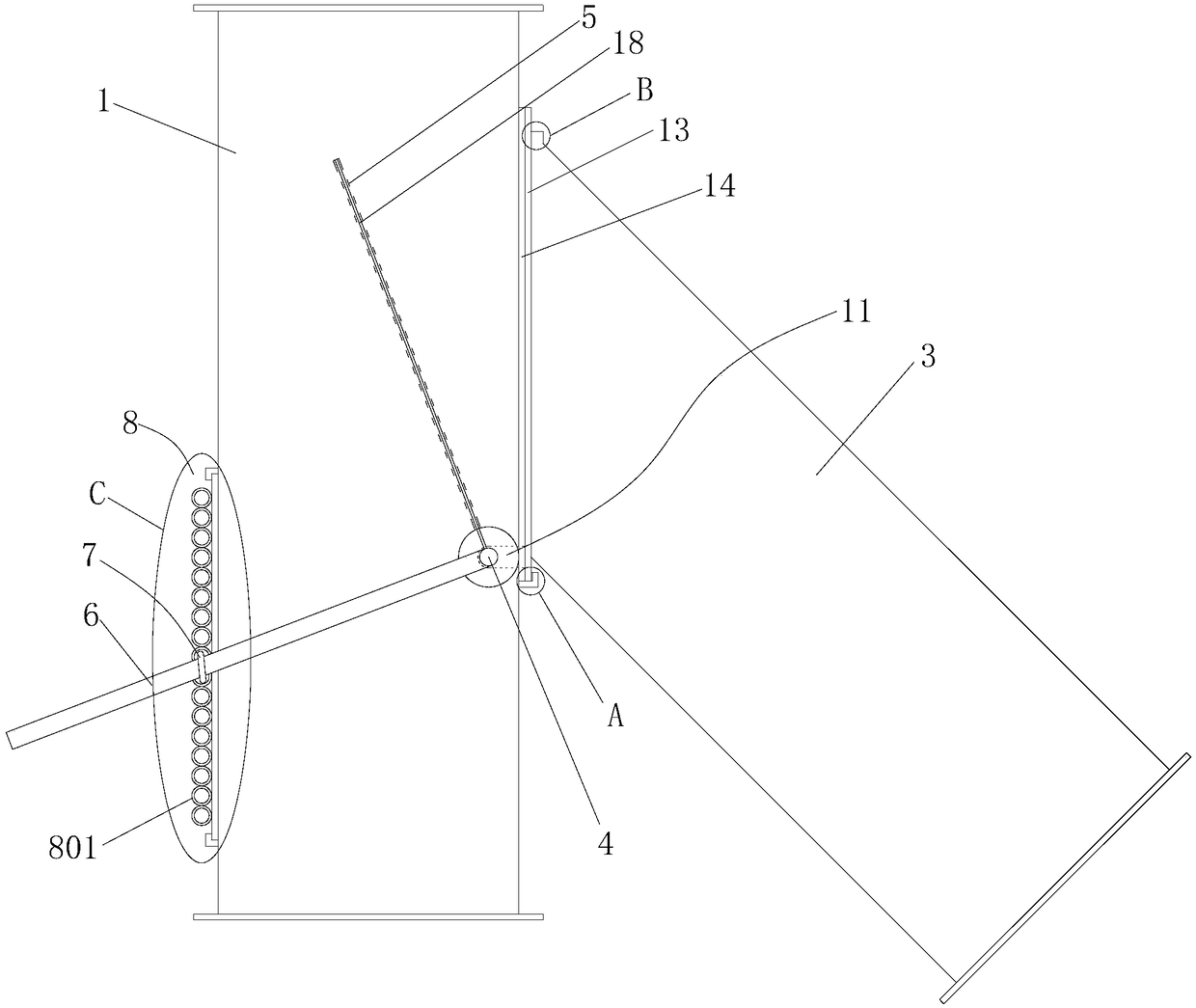

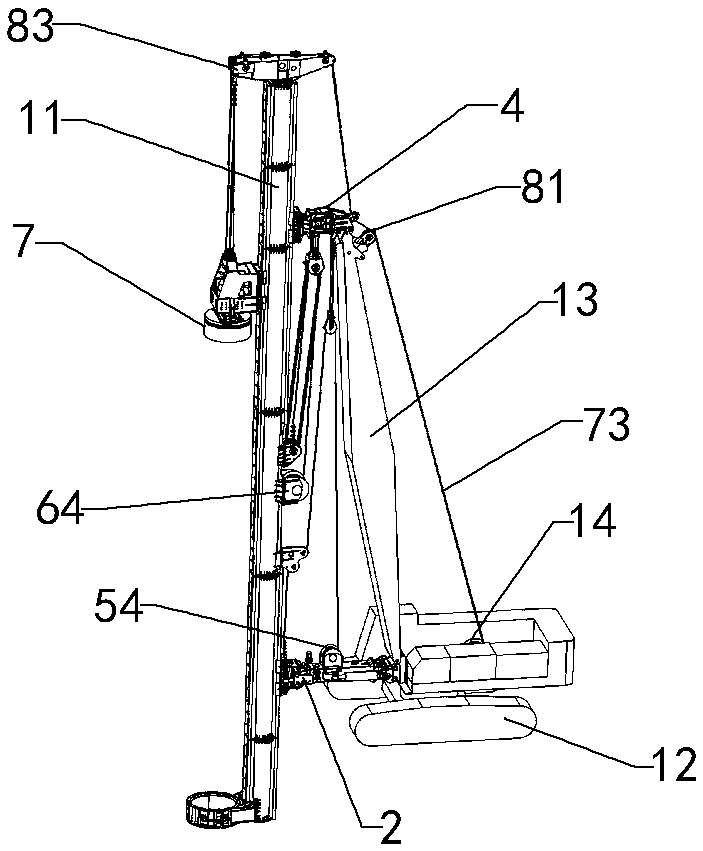

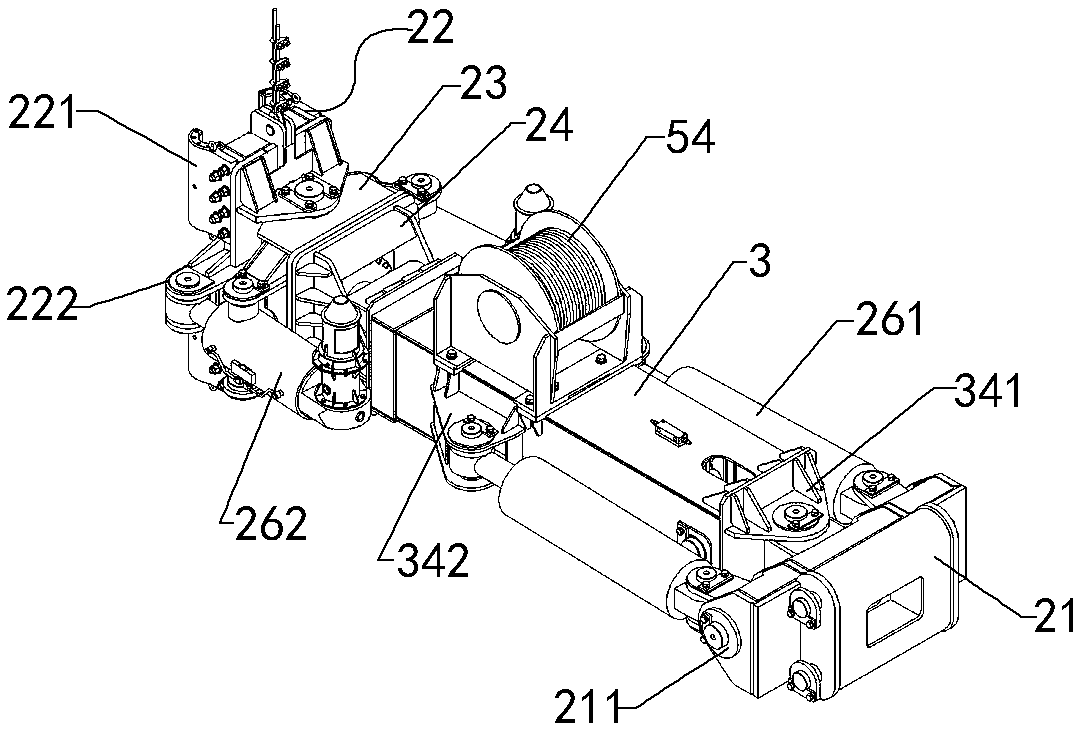

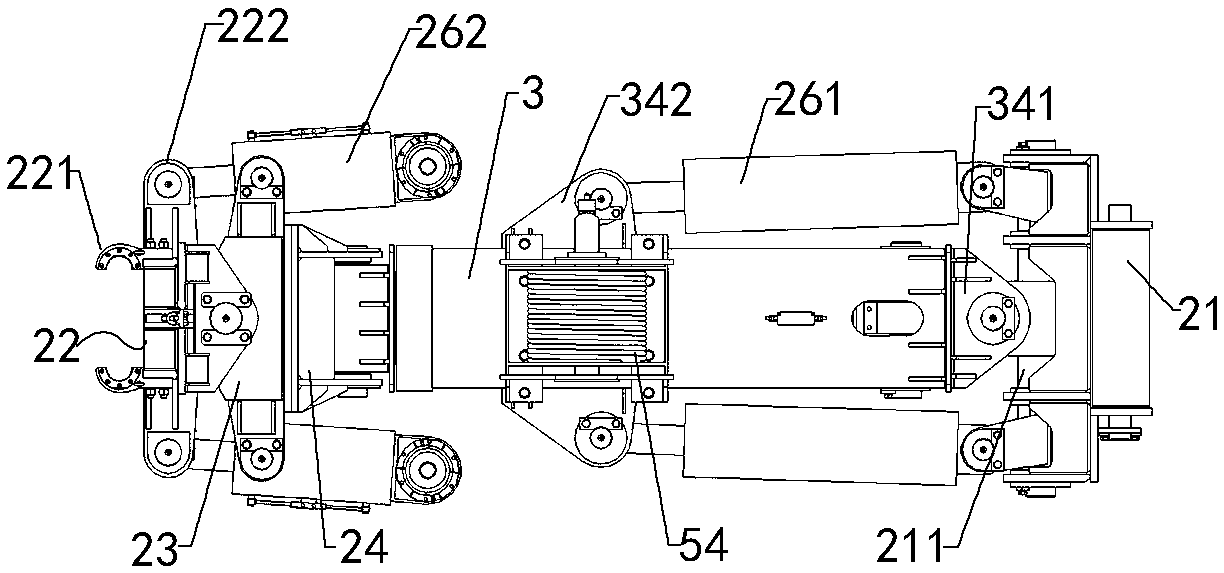

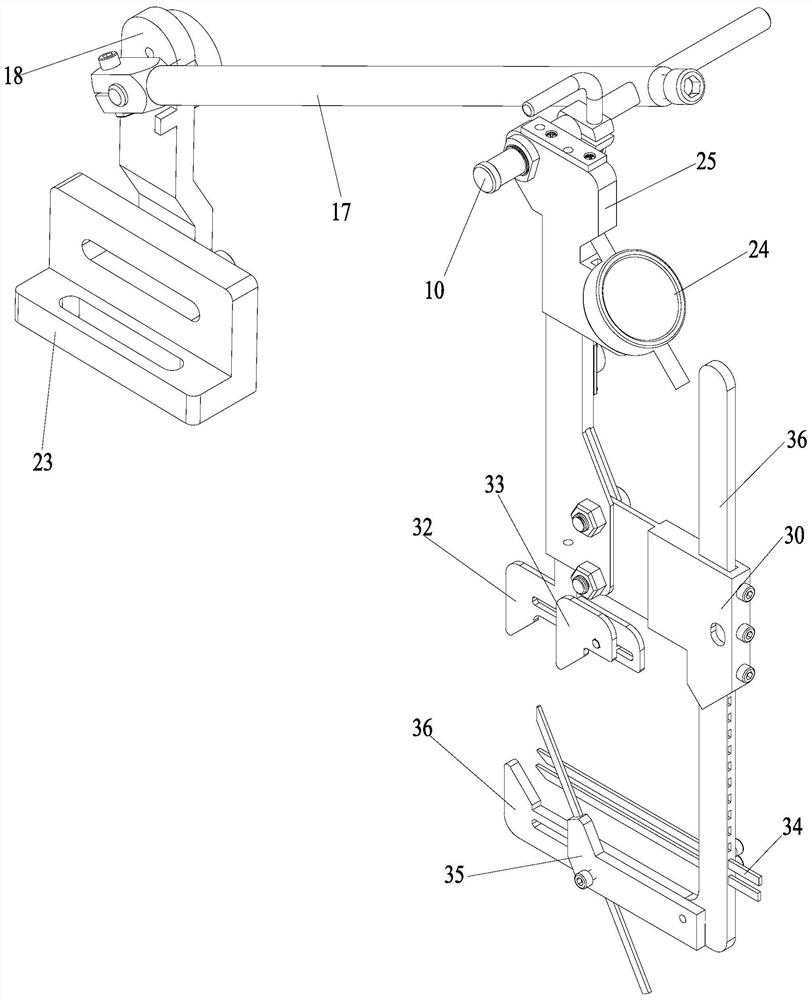

Suspended-type pile frame capable of being constructed by multiple angles and using method thereof

PendingCN108383017ALarge construction coverageFlexible and precise positioningCranesControl systemEngineering

The invention relates to the technical field of suspended-type drilling equipment and discloses a suspended-type pile frame capable of being constructed by multiple angles and a using method thereof.The suspended-type pile frame comprises a crane, a vertical column arranged on a crane boom of the crane, a top supporting mechanism connecting the vertical column with the crane boom, a bottom supporting mechanism connecting the vertical column with a crane platform, a first control system used for controlling the bottom supporting mechanism to swing up and down, and a second control system usedfor controlling the vertical column to move up and down. The bottom supporting mechanism serves as a driving control mechanism to drive the vertical column to move in the up-down dimension direction,the front-rear dimension direction and the left-right dimension direction. The top supporting mechanism serves as a driven mechanism to change the angle in a driven mode under driving of the bottom supporting mechanism, and through cooperation of the top supporting mechanism and the bottom supporting mechanism, up-down, front-rear and left-right motion of the vertical column is achieved. The degree of freedom is high, practicability is high, the drilled vertical column can be moved and finely adjusted conveniently at any time, and angle adjustment is conducted.

Owner:CABR CONSTR MACHINERY TECH +1

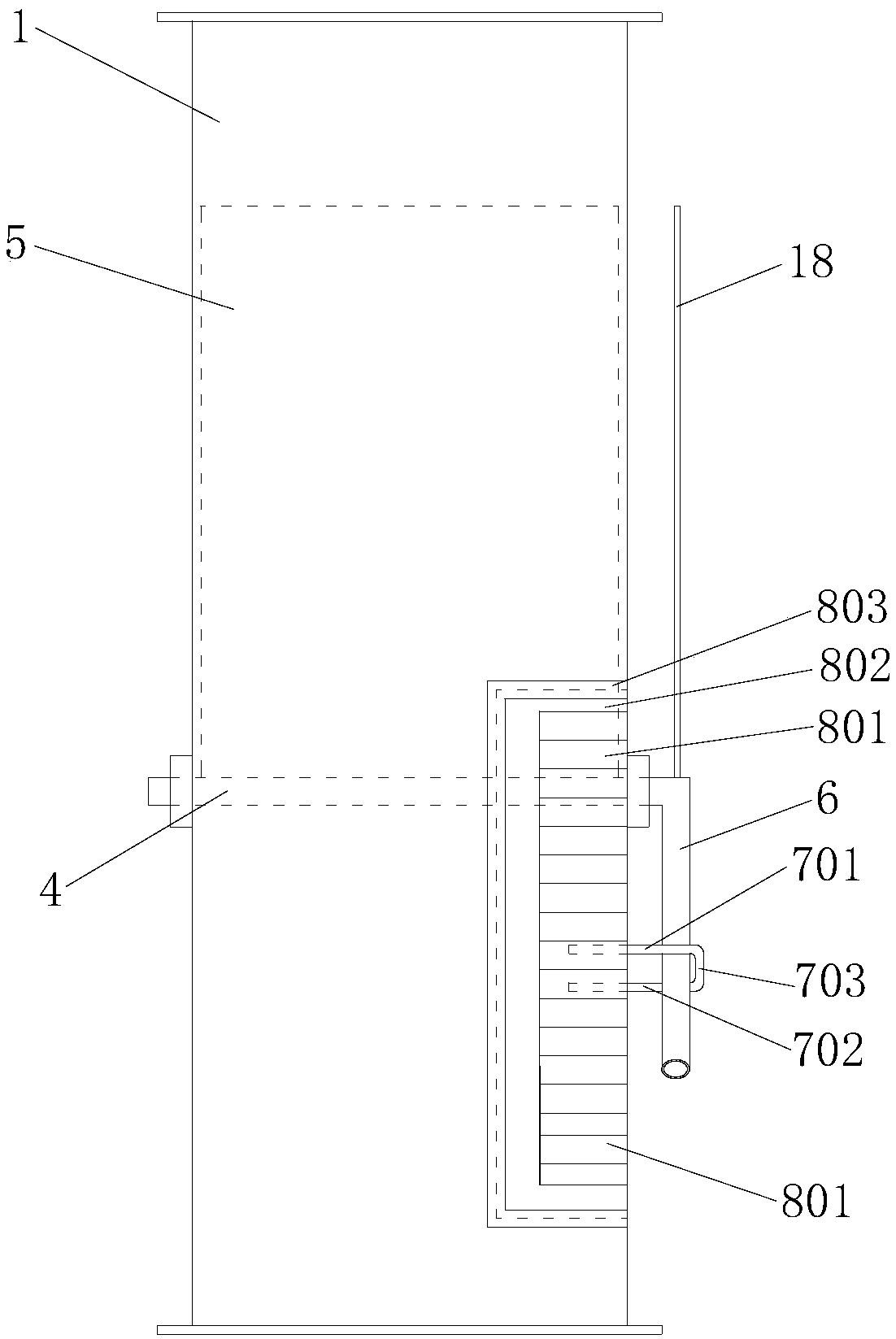

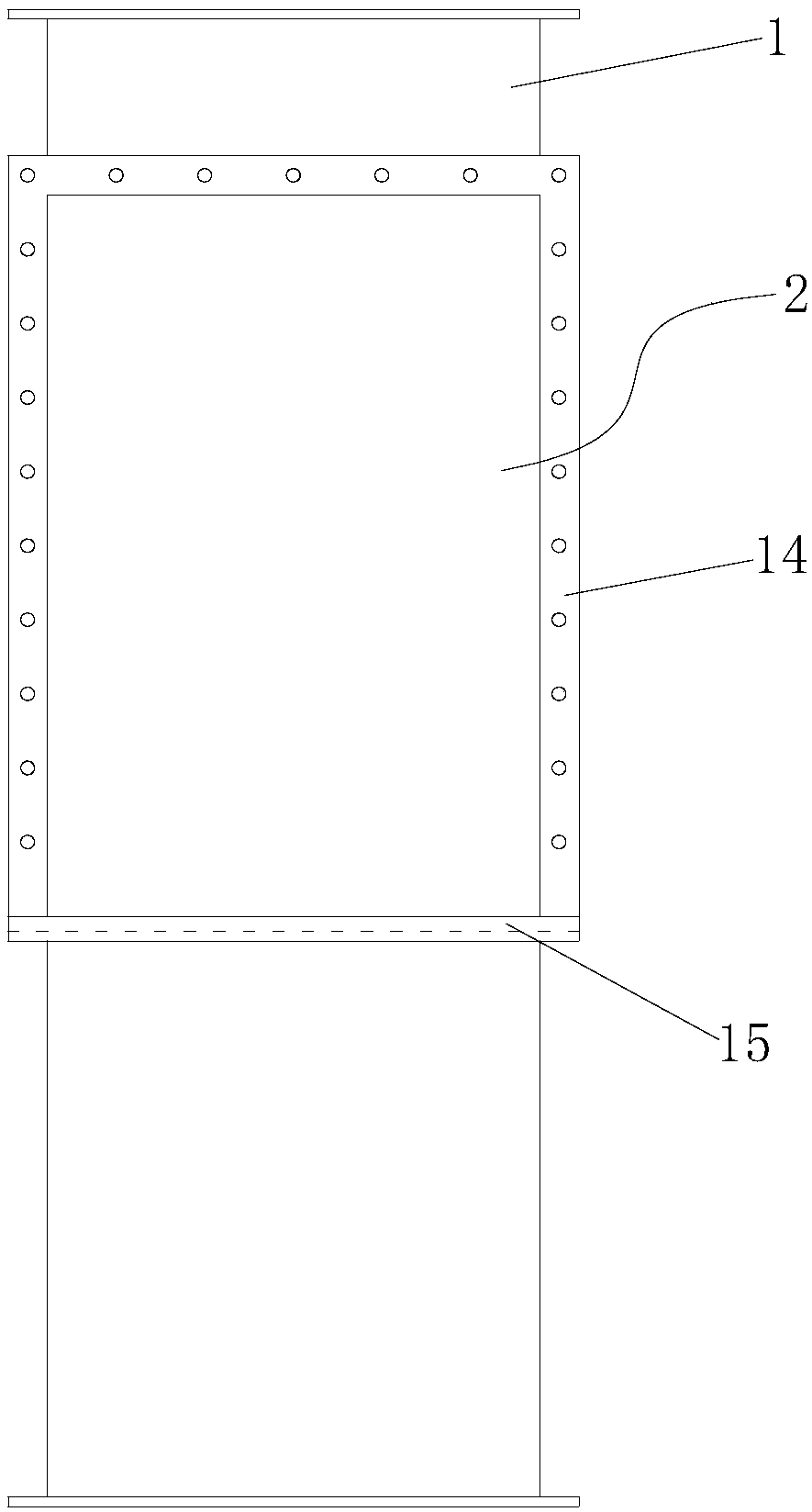

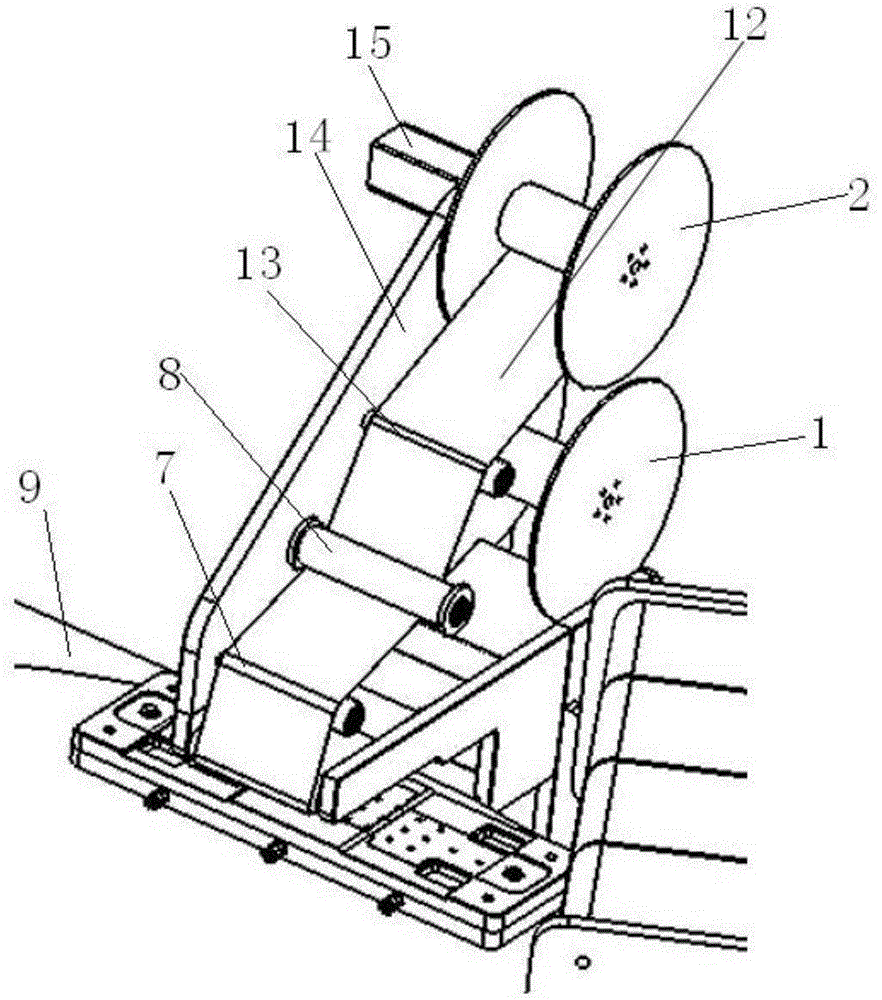

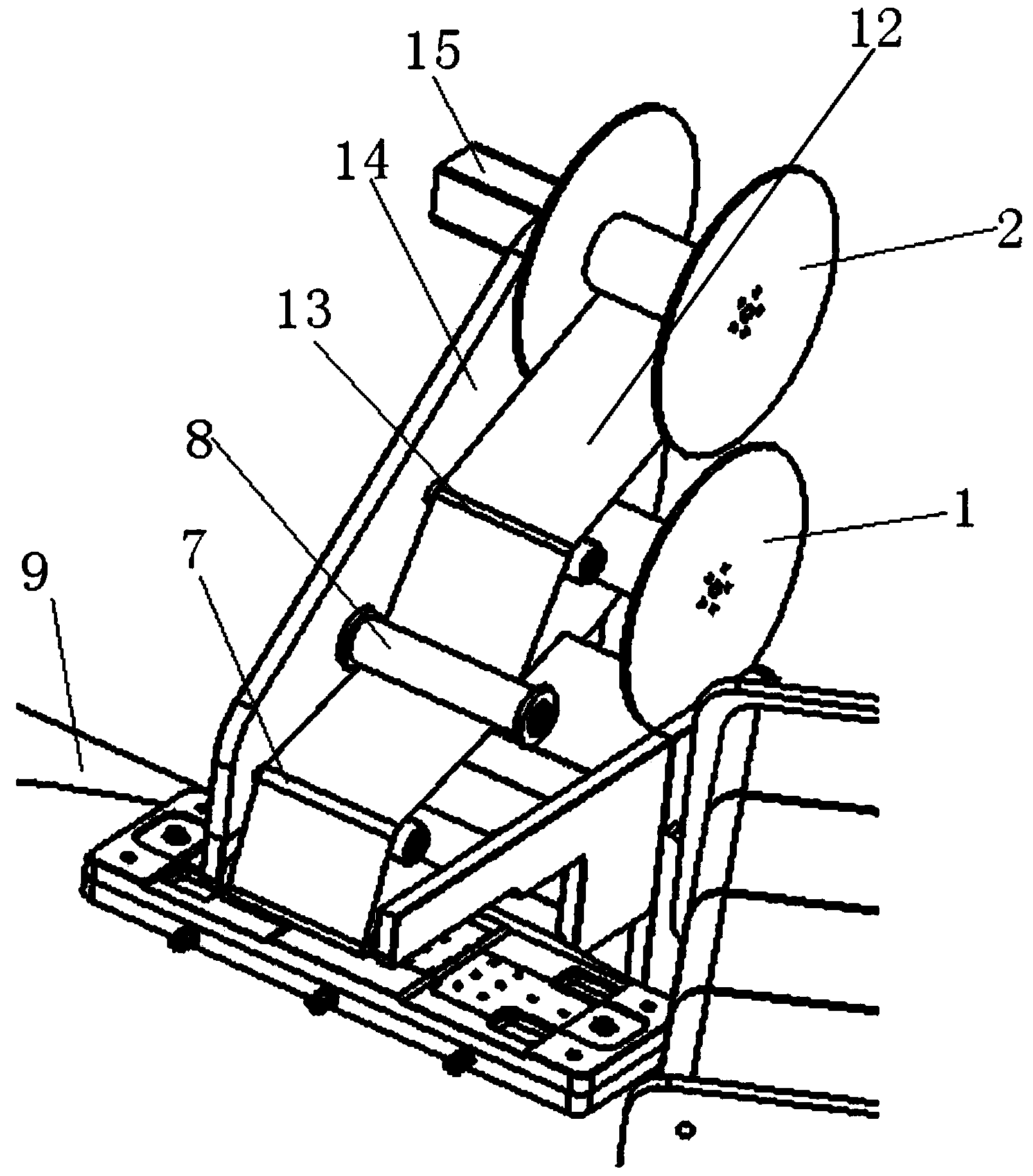

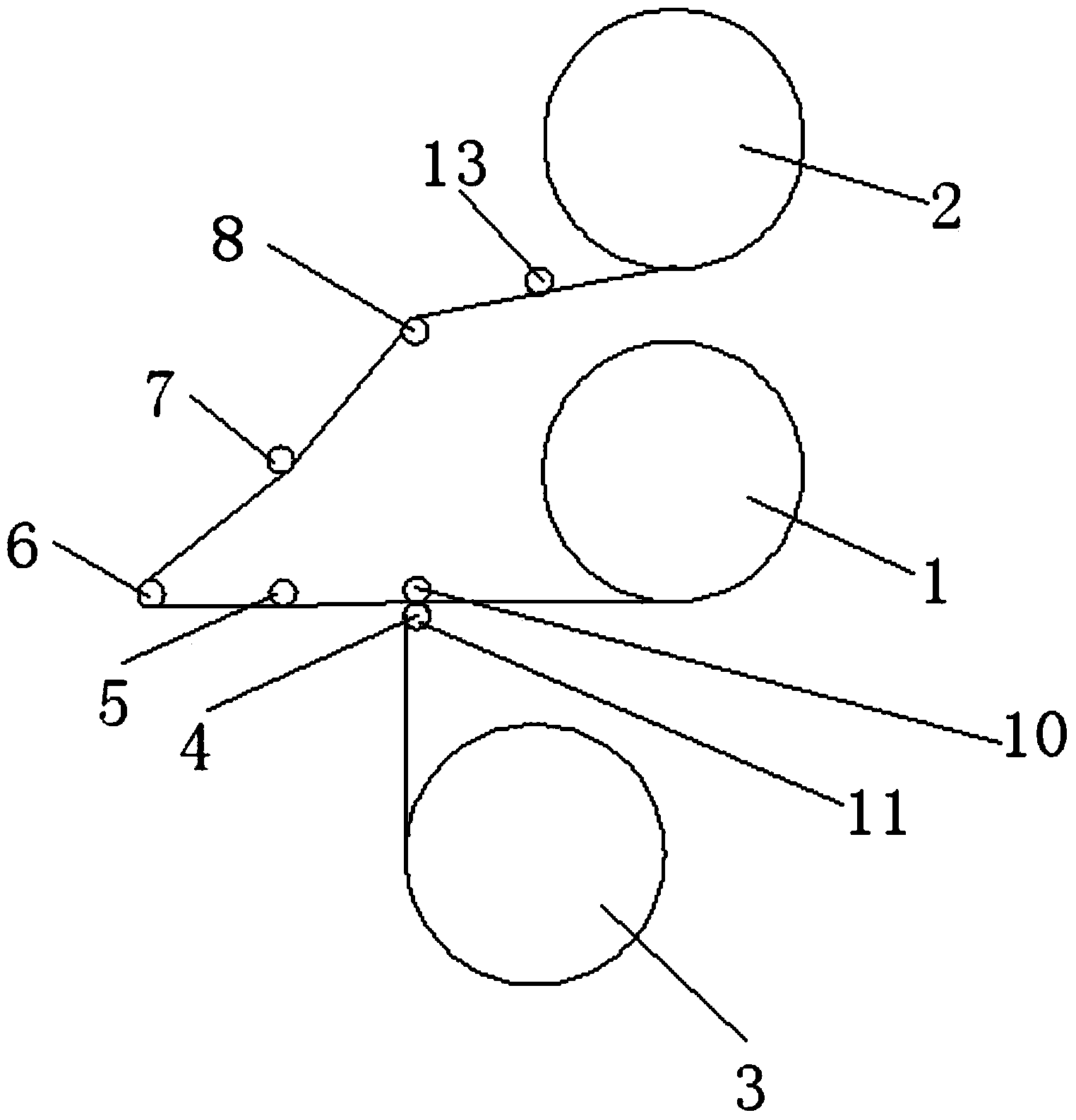

Bracket lifting type release paper laminating device

ActiveCN104385756BAchieve adsorptionRealize intelligent fitLamination ancillary operationsLaminationMiniaturizationMechanical engineering

The invention discloses a bracket lifting type release paper bonding device, which is characterized in that it comprises: a discharge roller (1), a receiving roller (2) and a separation roller (3), the release paper bonding device It is arranged on the support (14), and the lower part of the support (14) is provided with a cylinder for lifting. The invention provides a bracket-lifting type release paper bonding device, the bracket can be lifted up and down, the positioning is flexible and accurate, the positioning speed is fast, the working hours are effectively saved, and it also has the characteristics of full automation, intelligence and miniaturization, especially suitable for small Material placement.

Owner:KUSN MAIZHI FIXTURE TECH

Lift support type release paper fit device

ActiveCN104385756AAchieve adsorptionRealize intelligent fitLamination ancillary operationsLaminationControl engineeringMiniaturization

The invention discloses a lift support type release paper fit device. The lift support type release paper fit device is characterized by comprising a discharge roller (1), a collecting roller (2) and a separation roller (3), wherein the release paper fit device is arranged on a support (14); an air cylinder for lifting is arranged below the support (14). According to the lift support type release paper fit device provided by the invention, the support is liftable, the lift support type release paper fit device is flexible and accurate in positioning, and is high in positioning speed, labor time is effectively saved, and the lift support type release paper fit device also has the characteristics of full automation, intelligentization and miniaturization, and is especially suitable for fitting minitype materials.

Owner:KUSN MAIZHI FIXTURE TECH

Cylindrical grinding machine hook gauge

PendingCN112476086AIngenious and reasonable structureImprove efficiencyRevolution surface grinding machinesGrinding feed controlCylindrical grindingEngineering

The invention belongs to the technical field of grinding machines, and relates to a cylindrical grinding machine hook gauge, which comprises a lever, one end of the lever is fixedly connected with a connecting plate through a coil spring assembly, and the connecting plate is connected with fixing angle iron; a supporting rod is slidably connected to the lever; a hook gauge body is rotatably arranged on the supporting rod; an upper ejector rod is installed in the hook gauge body; a first spring is arranged on the top face of the upper ejector rod; and a dial indicator is further installed on the hook gauge body, and the top of the dial indicator abuts against a guide portion of the upper ejector rod. The cylindrical grinding machine hook gauge provided by the invention can get rid of the problem of low efficiency and inconvenience of cylindrical grinding size detection in the prior art. The cylindrical grinding efficiency is higher, the control target size can be determined while various slotted or slotless parts are machined, and the cylindrical grinding machine hook gauge is quite rapid and convenient to use.

Owner:无锡启胜进出口有限公司

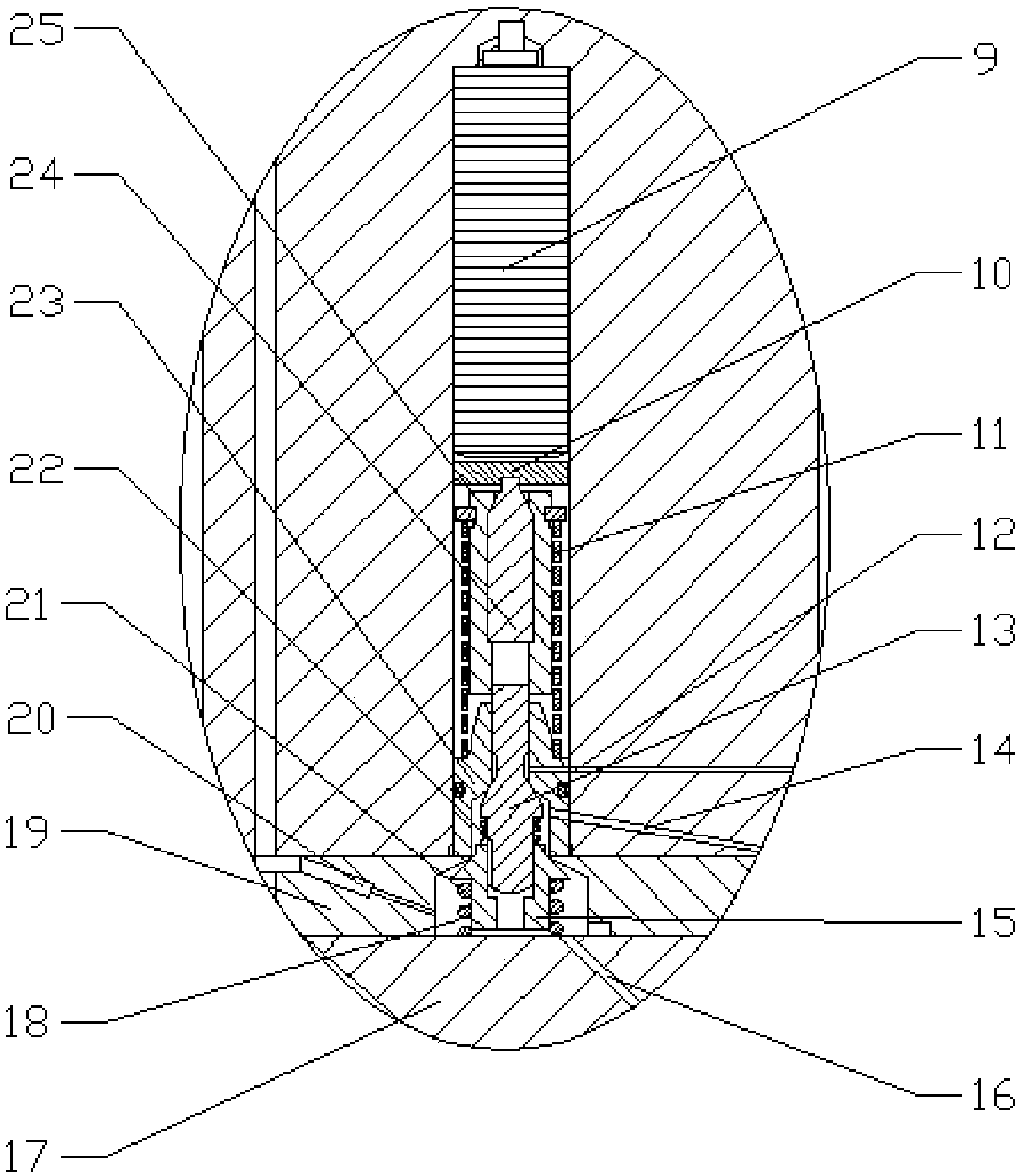

Variable-pressure-ratio piezoelectric fuel injector

InactiveCN109236529AIncrease flexibilityFast adjustmentFuel injection apparatusMachines/enginesThree stageEngineering

It is an object of the present invention to provide a variable-pressure-ratio piezoelectric fuel injector including a pressurizing control valve portion, a three-stage piston assembly, a fuel injection control valve portion, a needle valve portion, and a fuel injector body. The piezoelectric fuel injector uses a pressurizing control valve structure to control the pressurizing area of the three-stage piston, can effectively realize different pressure ratios, and makes a fuel injection law more flexible. The pressurizing control valve is driven by a piezoelectric stack so as to be positioned accordingly and accurately, and the adjustment speed of the pressurizing ratio of the pressurizing piston is increased and the control precision of the fuel injection law is improved. The operation process of the needle valve is driven by the piezoelectric stack. The needle valve is fast in respond speed and large in control freedom. The fuel injection law is flexible and controllable, and effectively improves the power property and the economical efficiency of a diesel engine, so that the diesel engine can meet more stringent emission regulations.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com