Accumulator piezoelectric injector with variable injection rule

A fuel injection regular, pressure-accumulating technology, applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve problems such as fuel leakage from injectors, slow response speed of needle valve seating, and impact on fuel utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

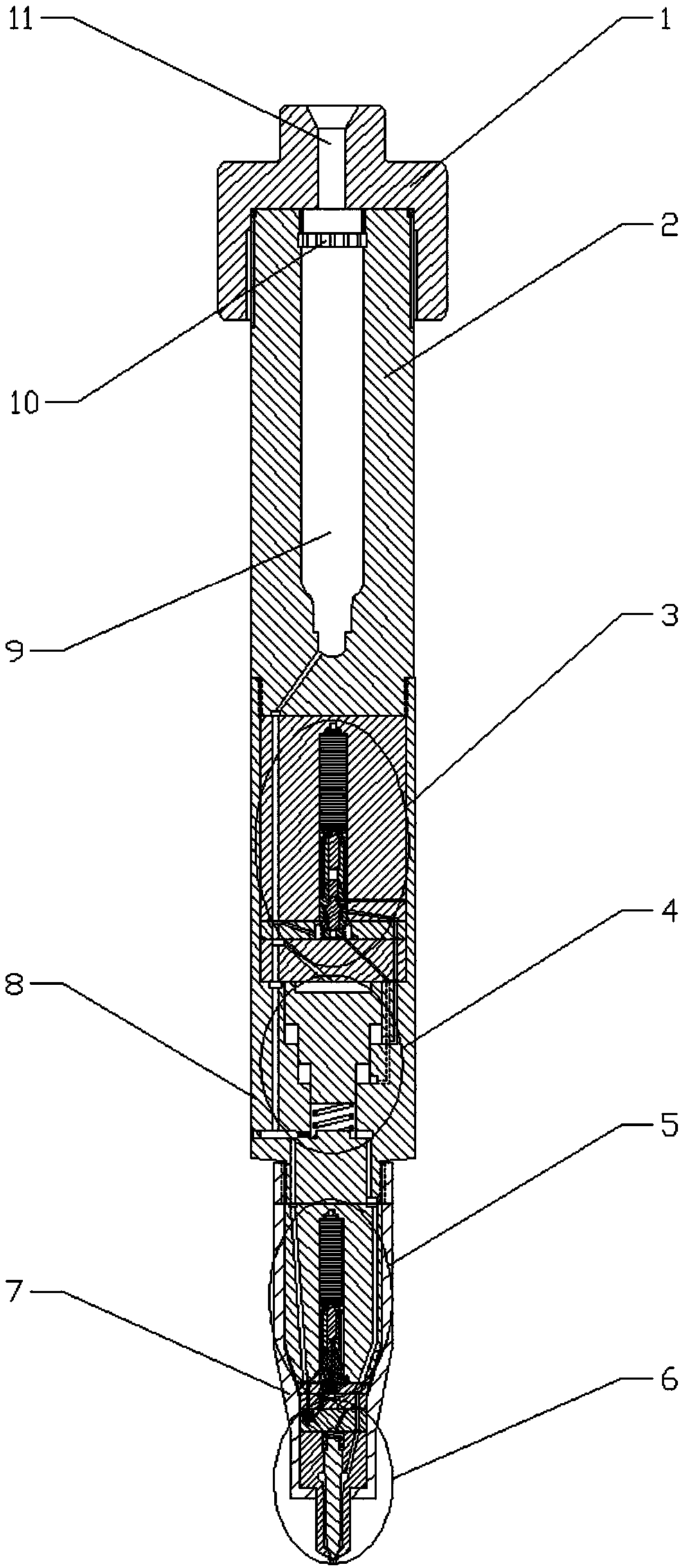

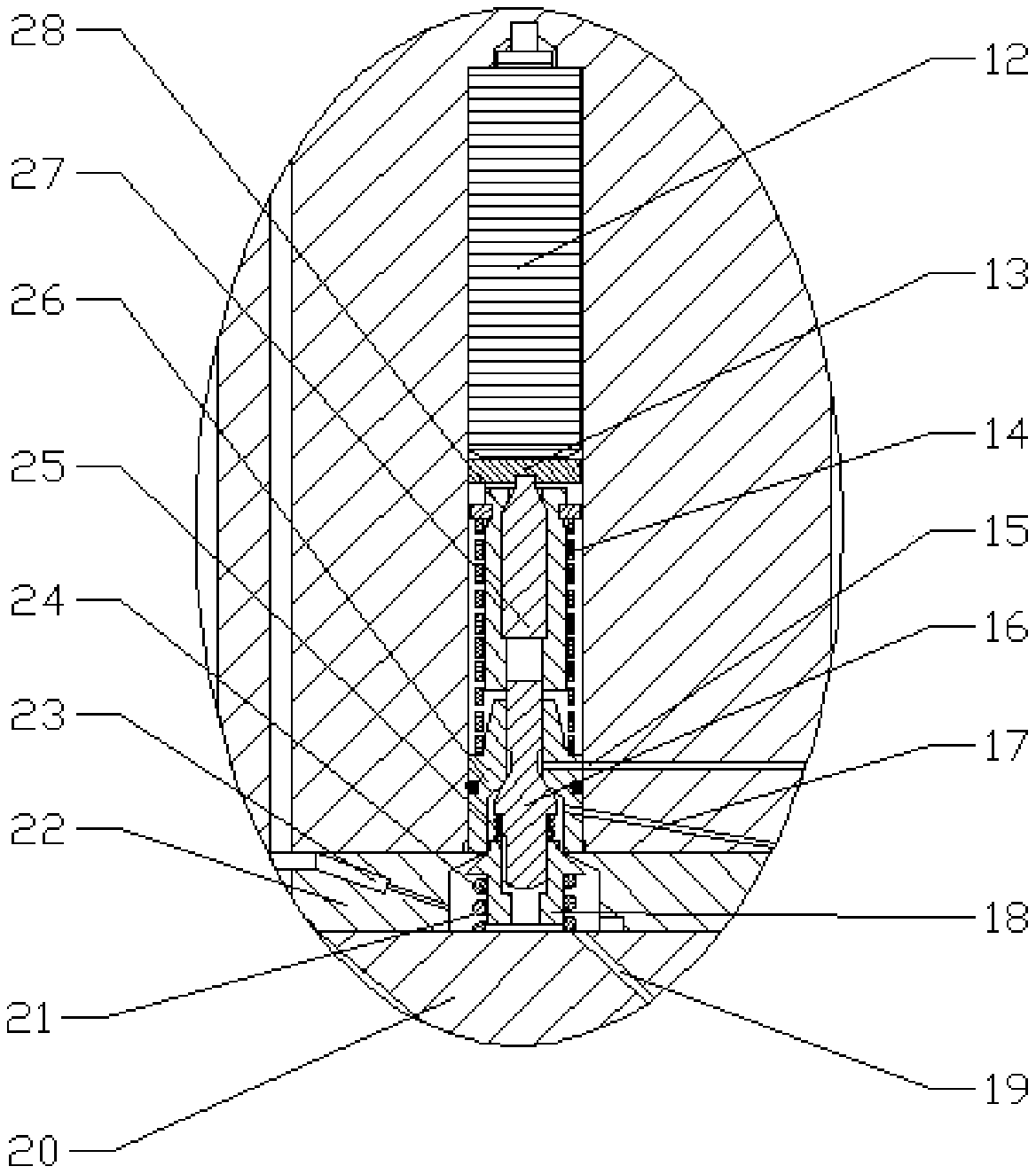

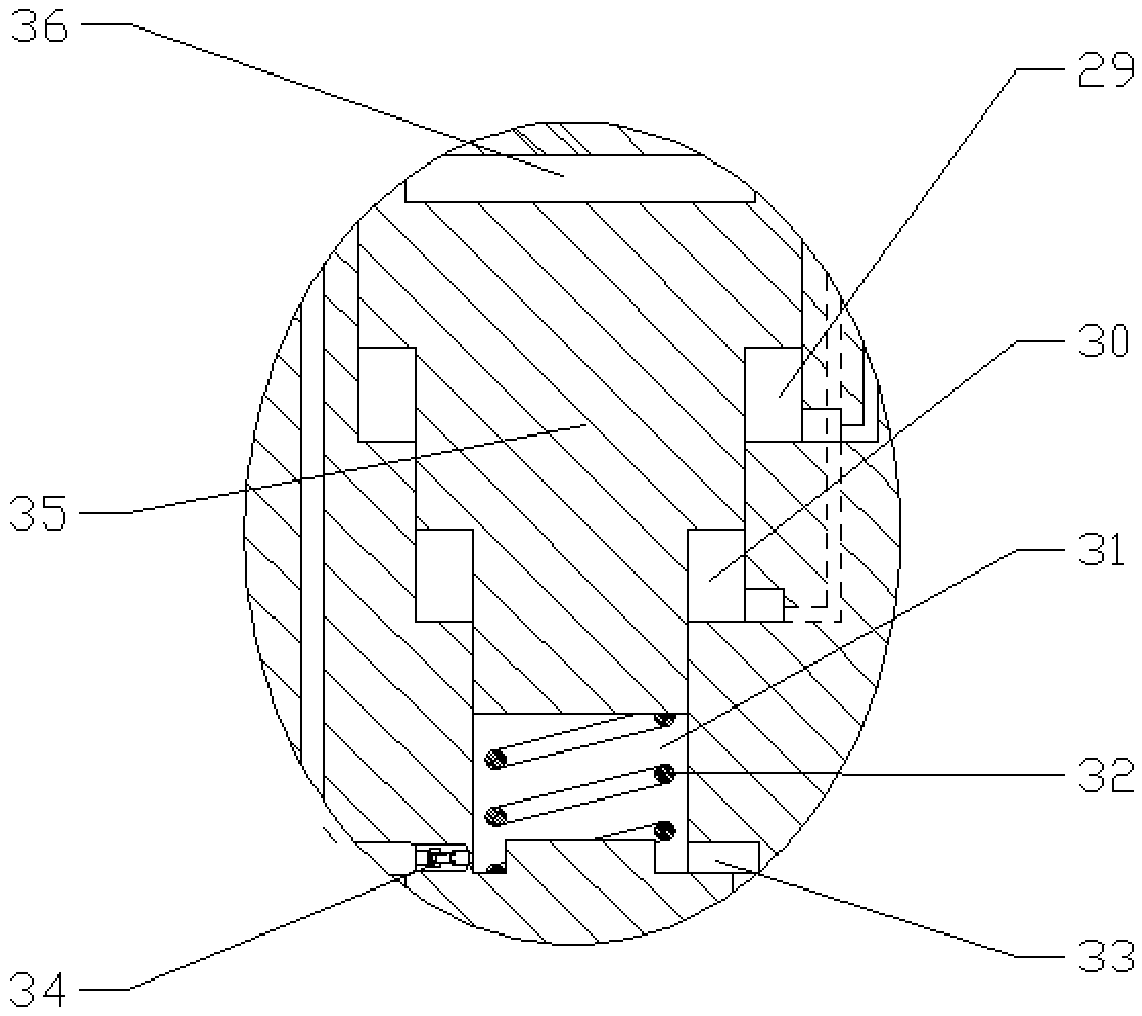

[0023] The present invention will be described in more detail below in conjunction with the accompanying drawings:

[0024] combine Figure 1-6 , the present invention is a pressure accumulating piezoelectric injector with variable fuel injection law, which is composed of a fastening cap 1, a pressure accumulating cavity wall 2, a pressure boosting control valve part 3, a three-stage piston assembly 4, an injection control valve part 5. The needle valve part 6, the injector body 8, the pressure accumulating chamber 9 and the filter orifice 10 are composed. The said booster control valve part 3 is mainly composed of a piezoelectric stack 12, a gasket 13, a plate spring 14, a booster control valve stem 16, a mushroom-shaped sleeve 18, a mushroom-shaped sleeve limiting orifice 22, and a bacteria-shaped sleeve. It is composed of a cylindrical sleeve spring 24 , a booster control valve stem spring 25 , a booster control valve stem sleeve 26 , a hydraulic core 27 and a hydraulic sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com