Feeding and discharging device for simultaneous eddy current flaw detection applied to inner and outer walls of stainless steel short pipe

An eddy current flaw detection, stainless steel technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that affect the efficiency of flaw detection, and achieve the effect of ensuring reliability and matching consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

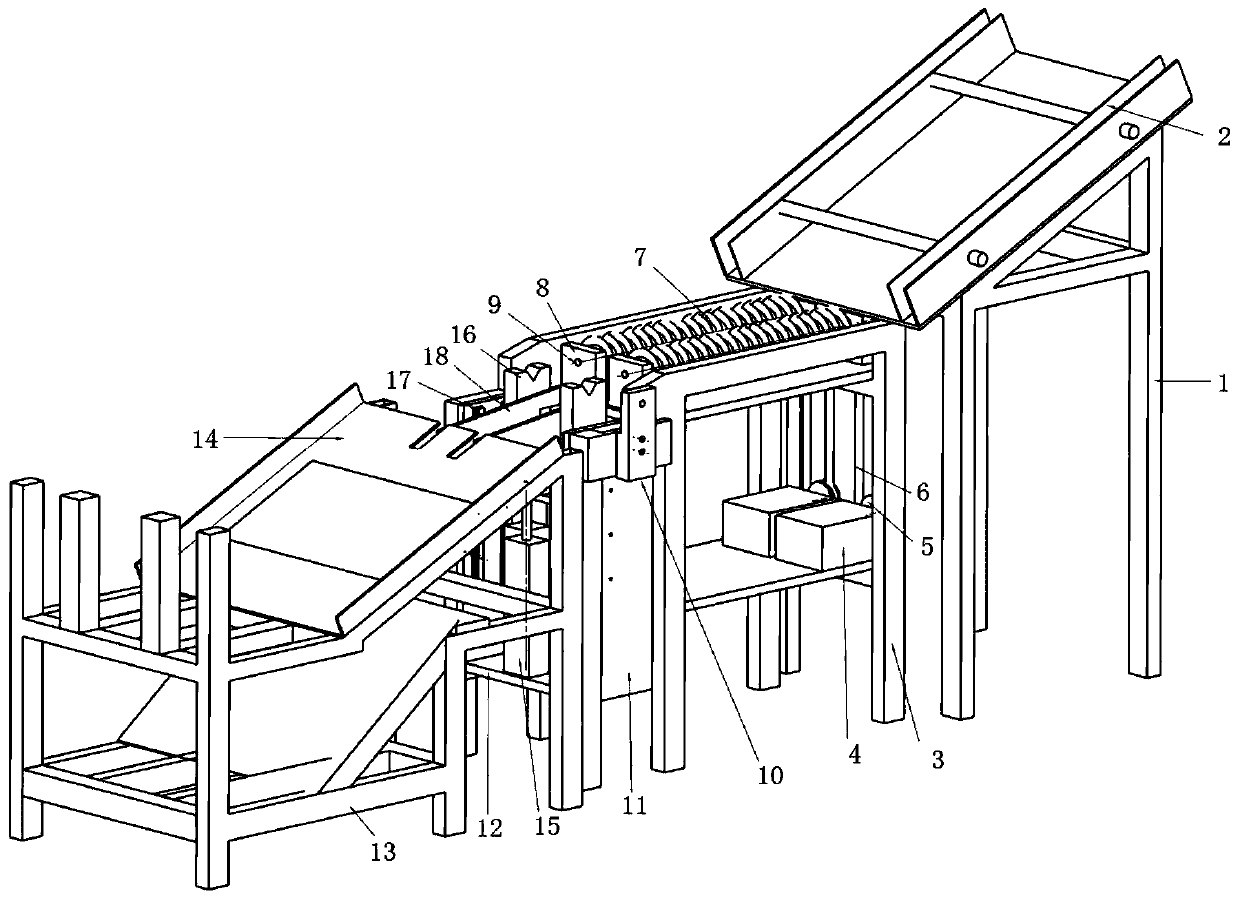

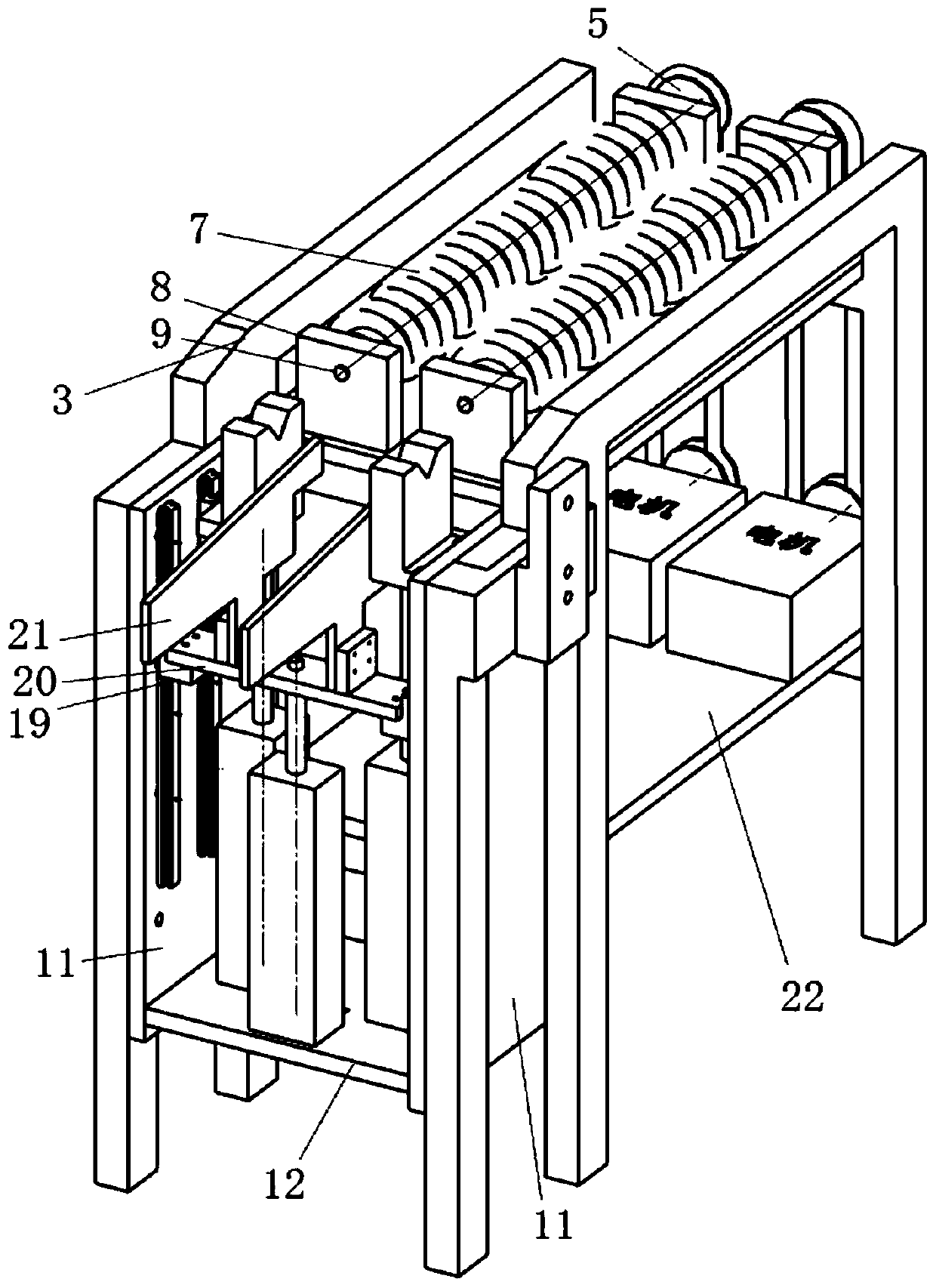

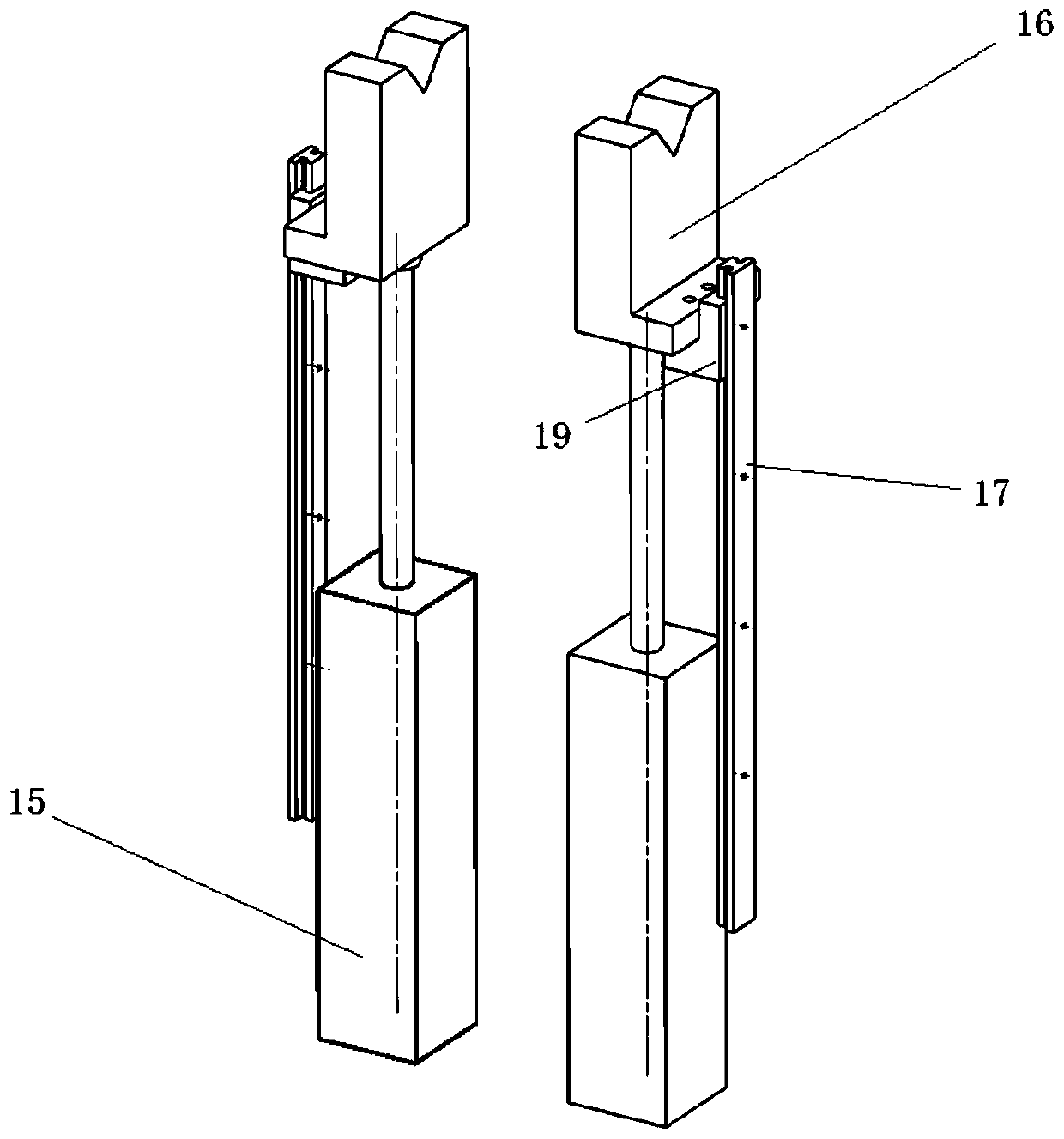

[0046] A loading and unloading device applied to simultaneous eddy current flaw detection on the inner and outer walls of short stainless steel pipes, see figure 1 As shown, it includes a feeding assembly, a conveying assembly, a detection fitting assembly and a blanking assembly arranged sequentially along the traveling direction of the short stainless steel pipe, wherein the detection fitting assembly includes two V-groove brackets 16 that can be vertically lifted up and down, and are arranged on two V-groove brackets. Between the groove supports 16 and the mobile platform 21 that can be lifted up and down, the top of the V groove support 16 is processed with a V-shaped groove that can stably place a short stainless steel pipe.

[0047] see you again figure 1 and image 3 As shown, a detection coordination frame composed of a mounting base plate 12 and two vertical mounting back plates 11 located on both sides of the mounting base plate 12 is provided between the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com