A pastry press forming filling device

A technology for filling and pastry, which is applied to dough extruders, dough processing, baking, etc., and can solve problems such as extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

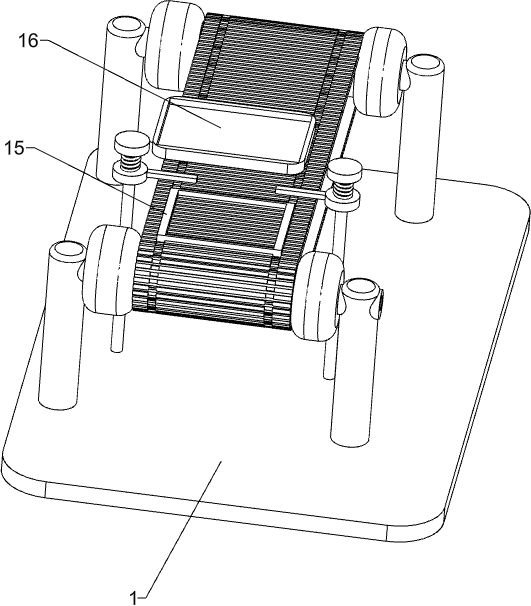

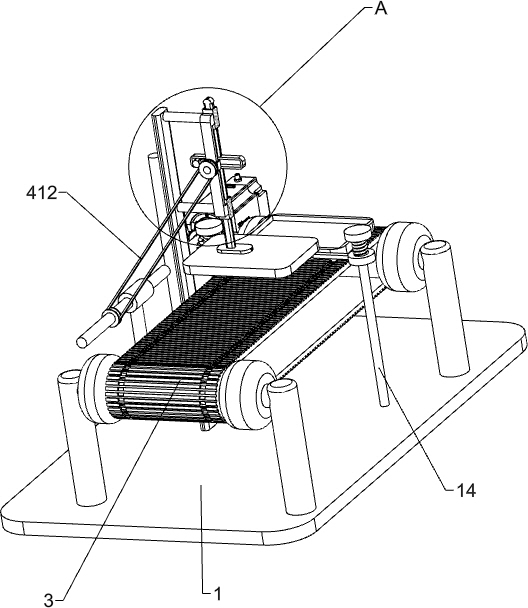

[0023] A pastry press forming filling device, such as figure 1 As shown, it includes a base 1, a servo motor 2, a transmission mechanism 3, a pressing mechanism 4 and a feeding mechanism 5. The servo motor 2 is provided on the right front side of the upper part of the base 1, the transmission mechanism 3 is provided on the upper part of the base 1, and the upper part of the base 1 is provided with The pressing mechanism 4 is provided with a blanking mechanism 5 on the top of the base 1 .

[0024] When the user needs to cut and unload the pastry, this equipment can be used. First, the dough to be unloaded is placed on the conveying mechanism 3, and then the servo motor 2 is turned on, and the servo motor 2 drives the conveying mechanism 3 to move, so that The dough can be moved to the bottom of the pressing mechanism 4 for pressing and forming, and then continue to move the dough to the bottom of the unloading mechanism 5, and unload the pressed position of the dough through th...

Embodiment 2

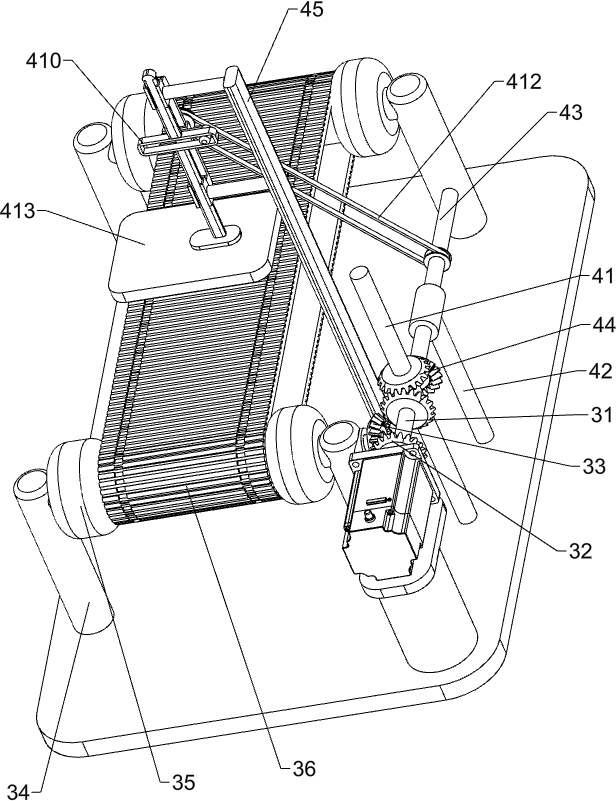

[0026] On the basis of Example 1, such as Figure 2-5 As shown, the transmission mechanism 3 includes a first circular shaft 31, a missing bevel gear 32, a first bevel gear 33, a first support column 34 and a first transmission assembly 35, and the output shaft of the servo motor 2 is provided with a first circular shaft 31, the first circular shaft 31 is provided with missing bevel gear 32, and the upper part of the base 1 is evenly provided with four first support columns 34, and the first support column 34 on the right front side is provided with a first bevel gear 33, and the first bevel gear 33 meshes with the missing bevel gear 32 , and the first supporting column 34 is provided with a first transmission assembly 35 in the form of a rotating shaft, and grooves 36 are evenly spaced on the first transmission assembly 35 .

[0027] The user can clamp the tray containing the dough in the groove 36 on the first transmission assembly 35, and then drive the missing bevel gear 3...

Embodiment 3

[0033] On the basis of Example 2, such as image 3 and Figure 6 As shown, it also includes a third support rod 6, a third fixed block 7, a second material storage port 8, a fifth circular shaft 9, a third transmission assembly 10, a limit block 11, a fourth support rod 12, a second The torsion spring 13, the third toggle block 14, the fixed frame 15 and the storage box 16, the base 1 upper front side is provided with the third support rod 6, the second circular shaft 41 top is provided with the third fixed block 7, the third fixed The block 7 and the third support rod 6 are provided with the second material storage port 8, the second circular shaft 41 top is provided with the third fixed block 7, and the third fixed block 7 bottom is rotatably provided with the fifth circular shaft 9, the fifth The third transmission assembly 10 is connected to the round shaft 9 and the second round shaft 41, and the fifth round shaft 9 is provided with two limit blocks 11. The positions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com