Fattening feed for house-feeding sheep and preparation method thereof

A sheep and barn feeding technology, applied in the direction of animal feed, animal feed, application, etc., can solve the asynchronous fermentation of carbohydrates and nitrogenous compounds, the asynchronous utilization of fermentation products and rumen microorganisms, and the catabolism characteristics of sheep are not fully considered, etc. problems, to achieve the effect of improving bioavailability, avoiding human and animal competition for food, and promoting production performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

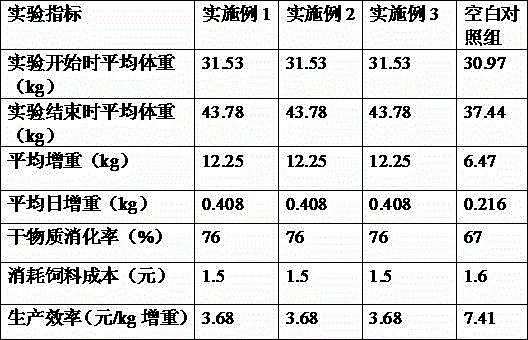

Examples

preparation example Construction

[0019] The preparation method of the fattening feed for feeding sheep in the house comprises the following steps:

[0020] Step 1. Take dry peanut stalks and fresh corn stalks according to the mass percentage of each raw material, and make them into 1.0-1.5 cm peanut stalks and corn stalks, and mix them evenly to obtain peanut stalks and corn stalks. Mixture; add 5% water by weight to the mixture of peanut seedling stalks and corn stalks, and mix uniformly to obtain mixture A; then add Bacillus natto with 1-2% of the mass of mixture A to carry out anaerobic fermentation 36 After -45 hours, the fermented mixture A was obtained, dried at 50-60°C for 8-10 hours, cooled to room temperature, and set aside;

[0021] Step 2, according to the mass percentage of each raw material, take rapeseed meal and peanut meal and pulverize them with a ball mill, and pass through a 200-mesh sieve to obtain a mixed powder of rapeseed meal and peanut meal; then add its mass to the mixed powder of ra...

Embodiment 1

[0025] A kind of fattening feed for feeding sheep, its raw materials are composed of biscuit residue, soybean hulls, DDGS, molasses, urea, rapeseed meal, peanut meal, fresh corn stalks, dried peanut seedlings and additives; the mass percentage of each raw material is : Fermented biscuit residue 15%, soybean hulls 10%, DDGS 25%, molasses 1.5%, urea 0.5%, rapeseed meal 7%, peanut meal 8%, fresh corn stalks 18%, dried peanut seedlings 10% and additives 5% ;

[0026] The additive is composed of additive A and additive B with a mass ratio of 1:1; the additive A is composed of copper sulfate, ferrous sulfate, zinc sulfate, manganese sulfate, cobalt chloride, stone powder, calcium hydrogen phosphate, and fat-soluble vitamins. Composed of mixture and salt, every 100g of Additive A contains 1 gram of copper sulfate, 1 gram of ferrous sulfate, 1 gram of zinc sulfate, 1 gram of manganese sulfate, 0.002 gram of cobalt chloride, 9 grams of stone powder, and 1 gram of fat-soluble vitamin pr...

Embodiment 2

[0034] A kind of fattening feed for feeding sheep, its raw materials are composed of biscuit residue, soybean hulls, DDGS, molasses, urea, rapeseed meal, peanut meal, fresh corn stalks, dried peanut seedlings and additives; the mass percentage of each raw material is : Fermented biscuit residue 15%, soybean hulls 10%, DDGS 25%, molasses 1.5%, urea 0.5%, rapeseed meal 7%, peanut meal 8%, fresh corn stalks 18%, dried peanut seedlings 10% and additives 5% ;

[0035] The additive is composed of additive A and additive B with a mass ratio of 1:1; the additive A is composed of copper sulfate, ferrous sulfate, zinc sulfate, manganese sulfate, cobalt chloride, stone powder, calcium hydrogen phosphate, and fat-soluble vitamins. Composed of mixture and salt, every 100g of Additive A contains 1-3 grams of copper sulfate, 1-3 grams of ferrous sulfate, 1-3 grams of zinc sulfate, 1-3 grams of manganese sulfate, 0.002-0.003 grams of cobalt chloride, stone powder 9-15 grams, 1-4 grams of fat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com