Food material purchasing management method and system

A procurement management and food material technology, applied in the field of material procurement management methods and systems, can solve the problems of food waste, precise control, and inconsistency, and achieve the effects of reducing food waste, maintaining freshness, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

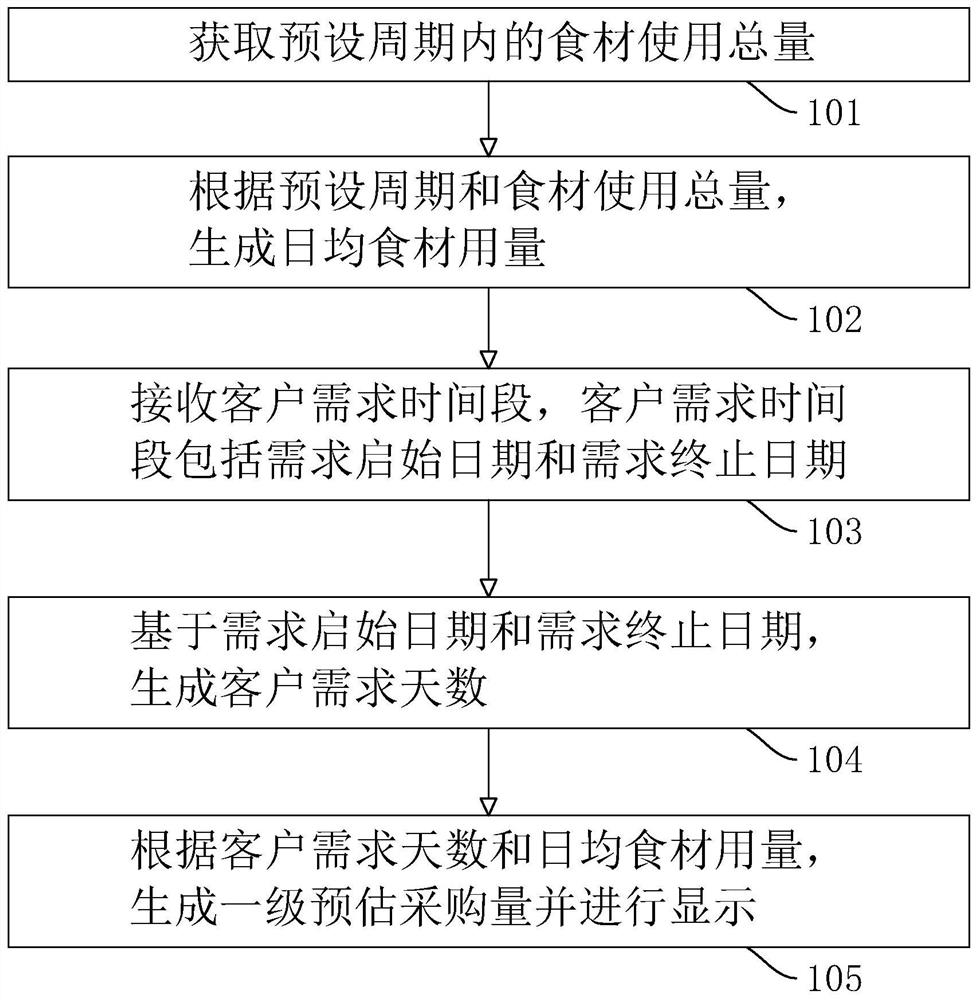

[0066] The following is attached Figure 1-6 The application is described in further detail.

[0067] The embodiment of the present application discloses a food material procurement management method. refer to figure 1 , this method is applied to the food material procurement management system. The specific execution subject of this method is the PC terminal or the mobile terminal. The main application scenario of this method is a restaurant. The demand for food materials is also different, and the food material procurement management method in this application can achieve the effect of facilitating the management of food material procurement.

[0068] Below in conjunction with the specific implementation, refer to figure 1 , to describe the processing flow in detail, the content can be as follows:

[0069] Step 101, acquiring the total amount of ingredients used within a preset period.

[0070] Step 102, generating the daily average food consumption according to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com