Grit blasting appts.

A shot peening and equipment technology, which is applied in metal processing equipment, spray guns, explosion generating devices, etc., can solve the problems that the cooling efficiency of the workpiece cannot be fully improved, and the thermal deformation of the workpiece cannot be well prevented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

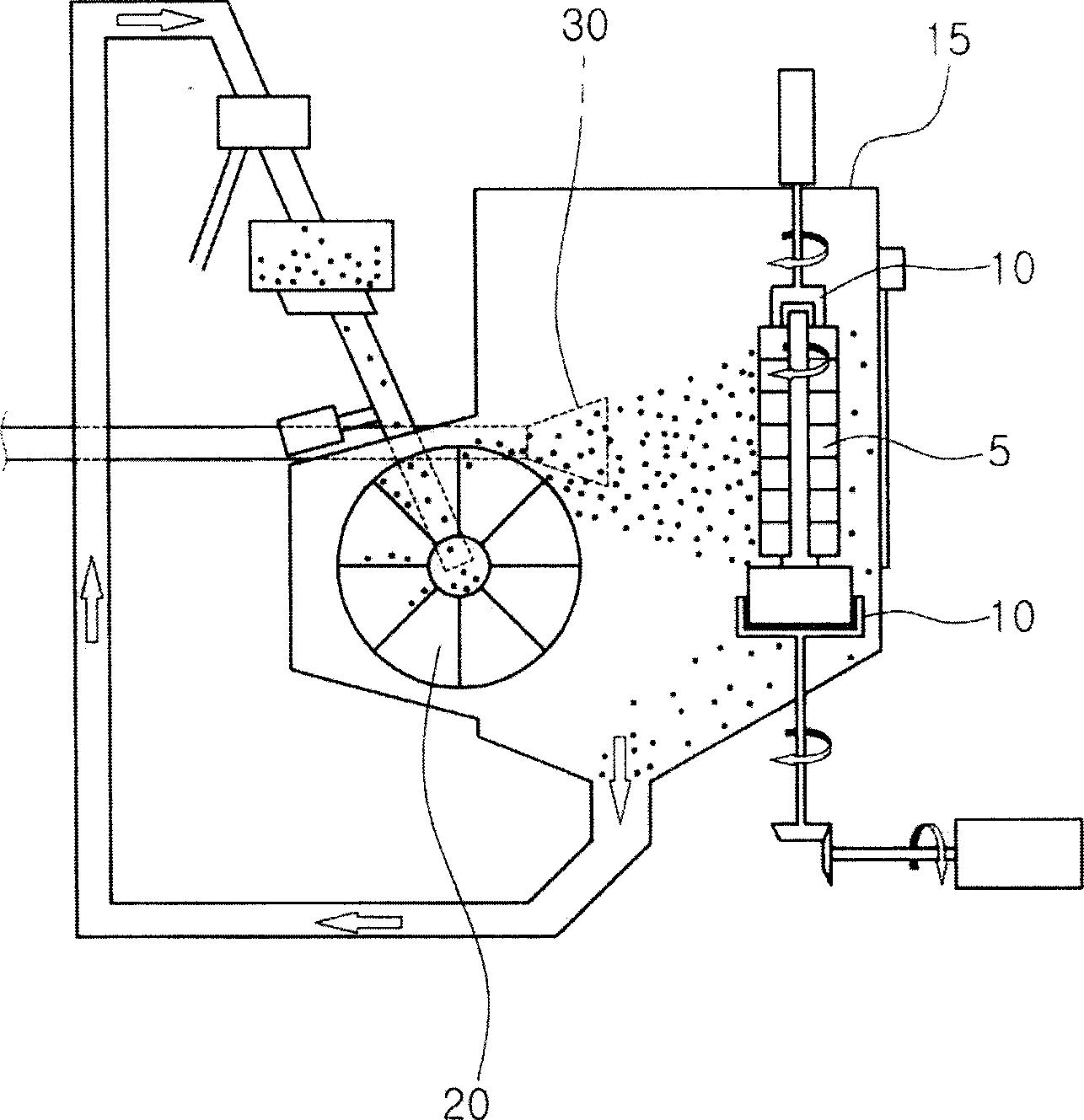

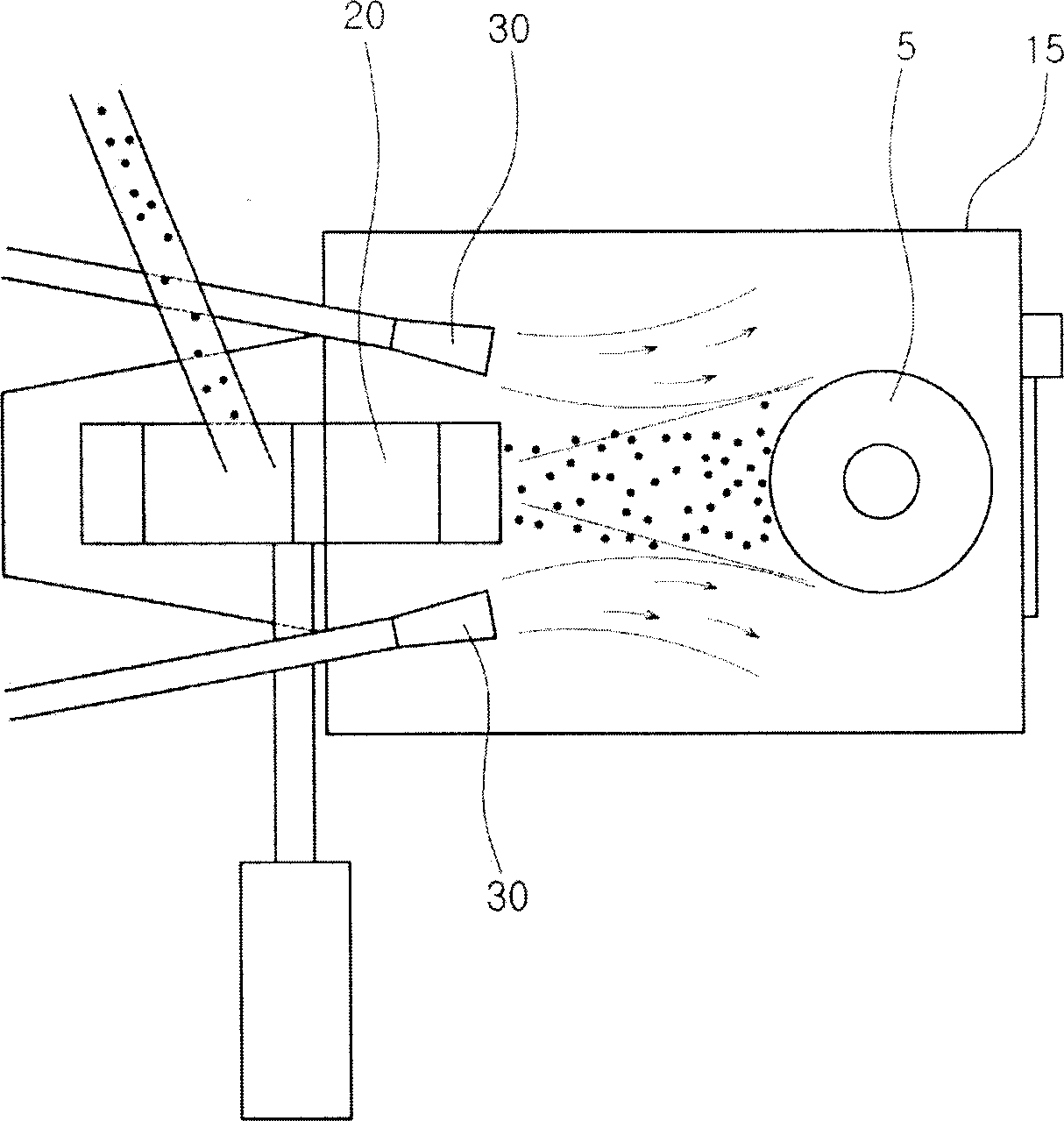

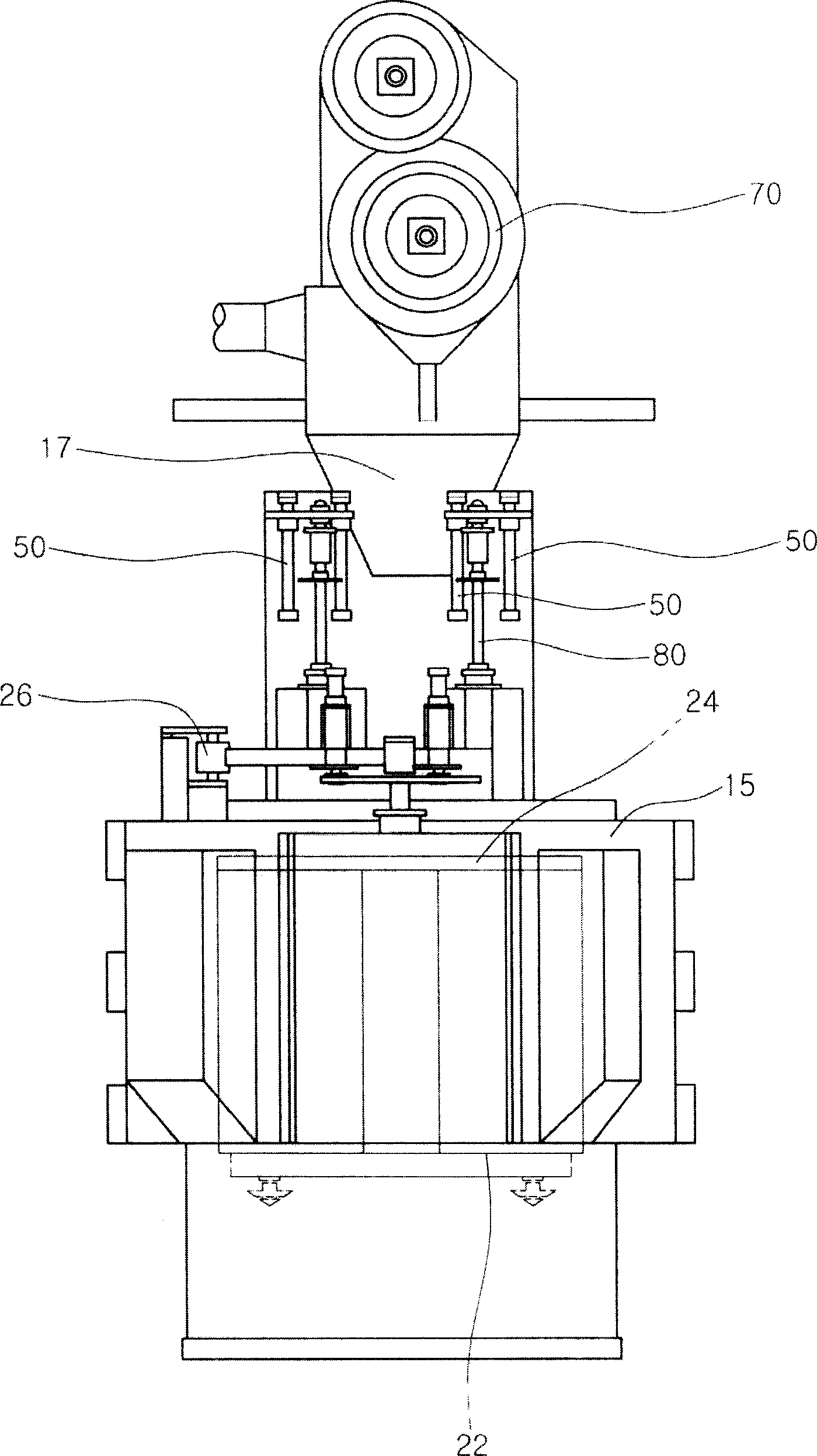

[0029] image 3 For a view representing an embodiment of the present invention, Figure 4 is a view showing the main part of the present invention, and Figure 5 for image 3 schematic top view of . With reference to accompanying drawing, like existing shot peening treatment equipment, the present invention comprises box-type main body 15; Upper and lower clamping device 12,14, this device is rotatably installed in main body 15, and can approach each other along the axis of rotation And rotate the workpiece 5; the pump wheel 20 located on one side of the clamping device 12, 14; and the steel ball feeder 17 connected with the pump wheel 20. Also, the present invention also includes the first air nozzle 45 , the reflector 55 , the second air nozzle 60 installed on the reflector 55 , and the cooling air supplier 50 . Reference numeral 70 repr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com