Full-automatic production line for heating radiators

An automatic production line, radiator technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as misoperation, poor product consistency, etc., achieve high efficiency, strong product consistency, and improve market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

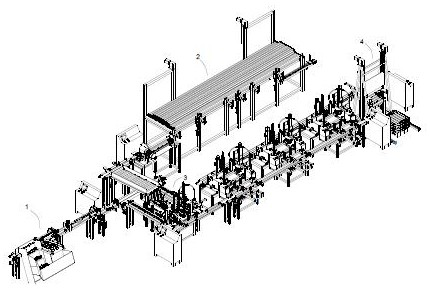

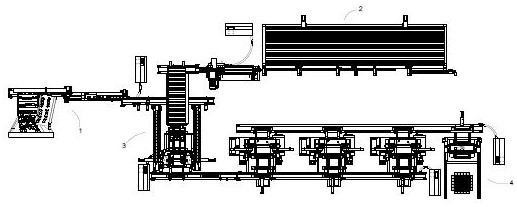

[0061] Such as figure 1 , 2 As shown, the present invention includes an automatic sorting and directional discharge device 1 for film headers, an automatic pipe material distribution device 2, an automatic welding device 3, and a finished product stacking device 4, and the automatic sorting and directional discharge device 1 for film headers and the automatic pipe material distribution device 2 are respectively The automatic welding device 3 transports the chip headers and short tubes cut into equal lengths; the automatic welding device 3 combines the chip headers and short tubes and welds them into finished products; the finished products are sent to the finished product palletizing device 4 and sent out for palletizing.

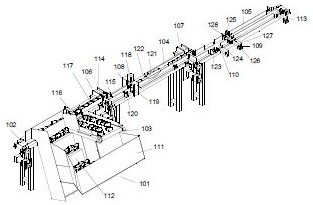

[0062] Such as image 3 , 4 As shown, the film header automatic sorting and directional discharge device 1 includes a ladder feeding device 101, a first conveyor belt 102, a return conveyor belt 103, a second conveyor belt 104, a third conveyor belt 105, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com