Efficient precise blanking method for pipe thermal stress prefabrication microcracks

A technology of precise blanking and micro-cracks, applied in the field of metal pipe blanking, can solve the problems of low section precision, large blanking force, and reduced production efficiency, so as to promote rapid initiation and stable expansion, and increase stress concentration. effect, the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] A high-efficiency and precise blanking method for thermal stress prefabricated microcracks in pipe materials, comprising the following steps:

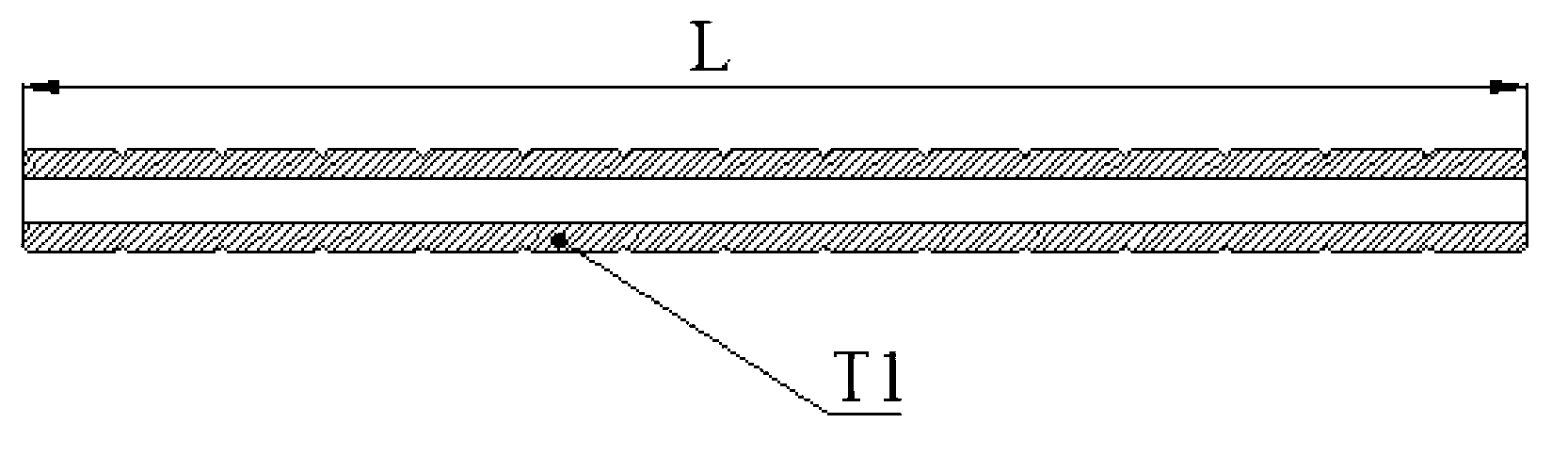

[0022] The first step, refer to figure 1 , take a long tube material T1, according to the required cutting length, open a V-shaped groove on each small section;

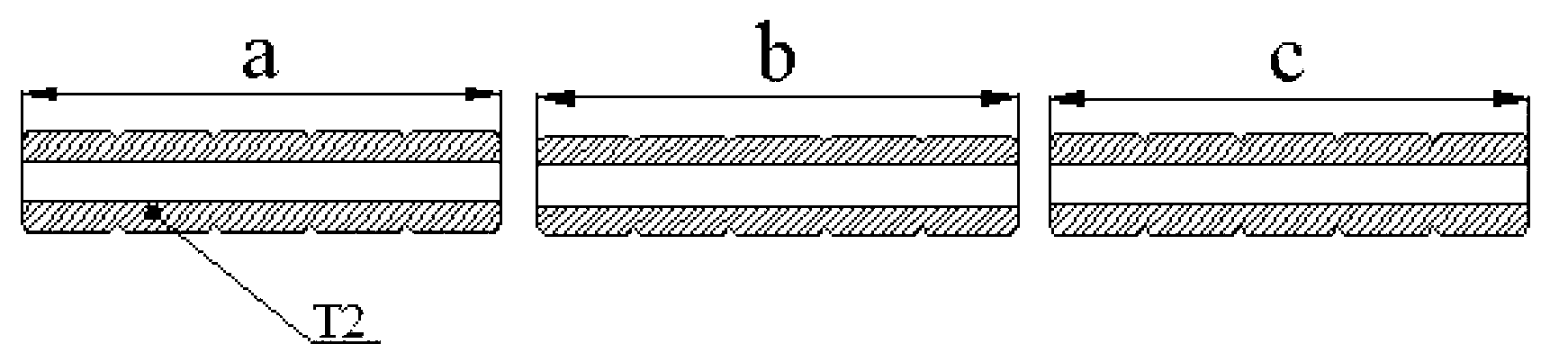

[0023] The second step, refer to figure 2 , divide the long tube material T1 into three short tube materials T2, as shown in a, b, and c in the figure, to facilitate subsequent heating and blanking;

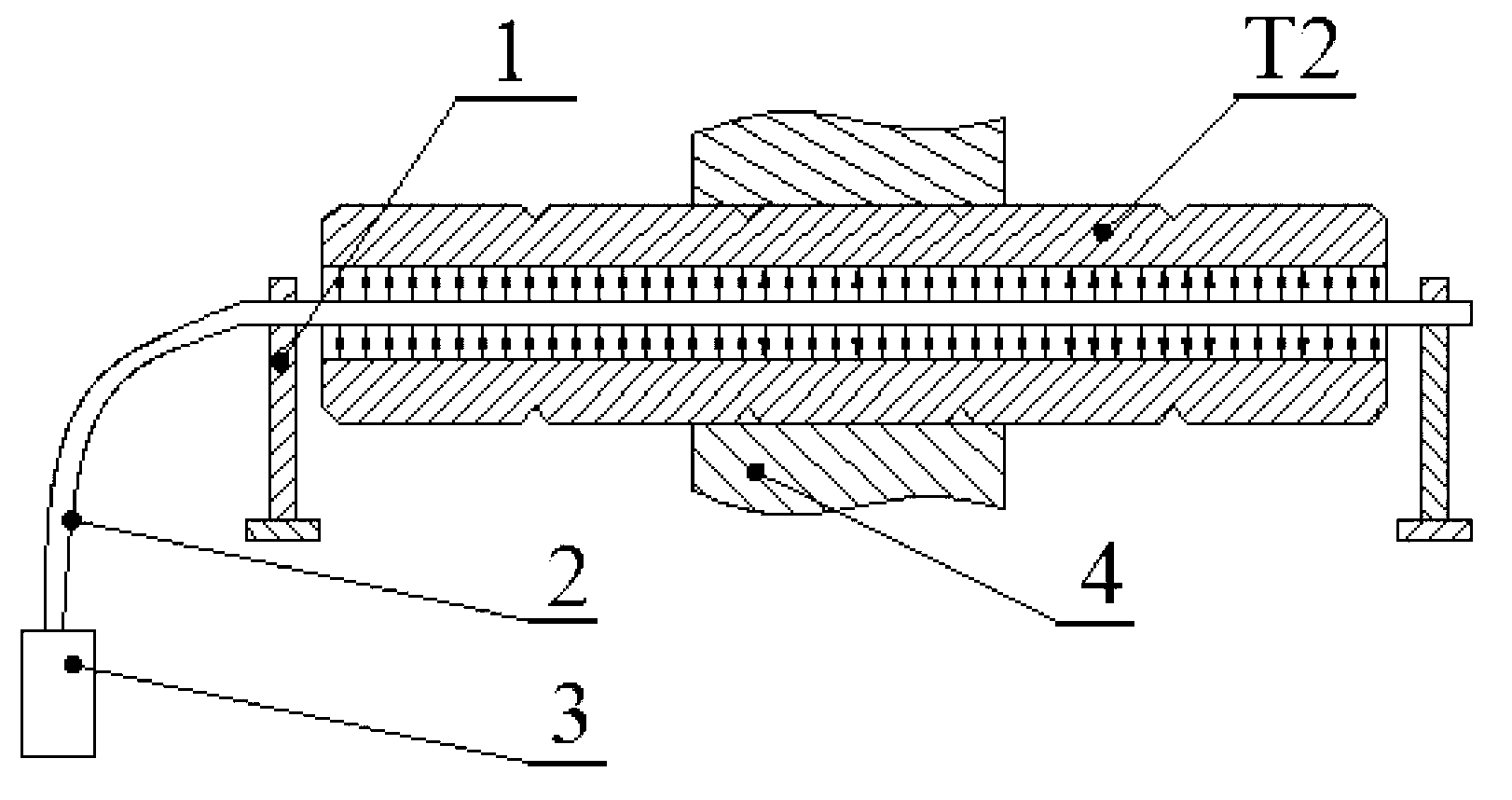

[0024] The third step, refer to image 3 , put the ceramic heating rod 2 in the heating device into the inner hole of the short tube material T2 for heating, the heating temperature range is 300°C-800°C, and the heating time is 10S-30S, which can meet the needs of various metal materials heating, wide heating range;

[0025] The fourth step, refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com