Conveying roller for a paper web, machines equipped therewith and methods of use

a technology of conveying roller and paper web, which is applied in the direction of thin material processing, article separation, and folding thin materials, etc., can solve the problems of paper jamming and stoppage of production, loss of vacuum and channel return to atmospheric pressure, and limited maximum air flow ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

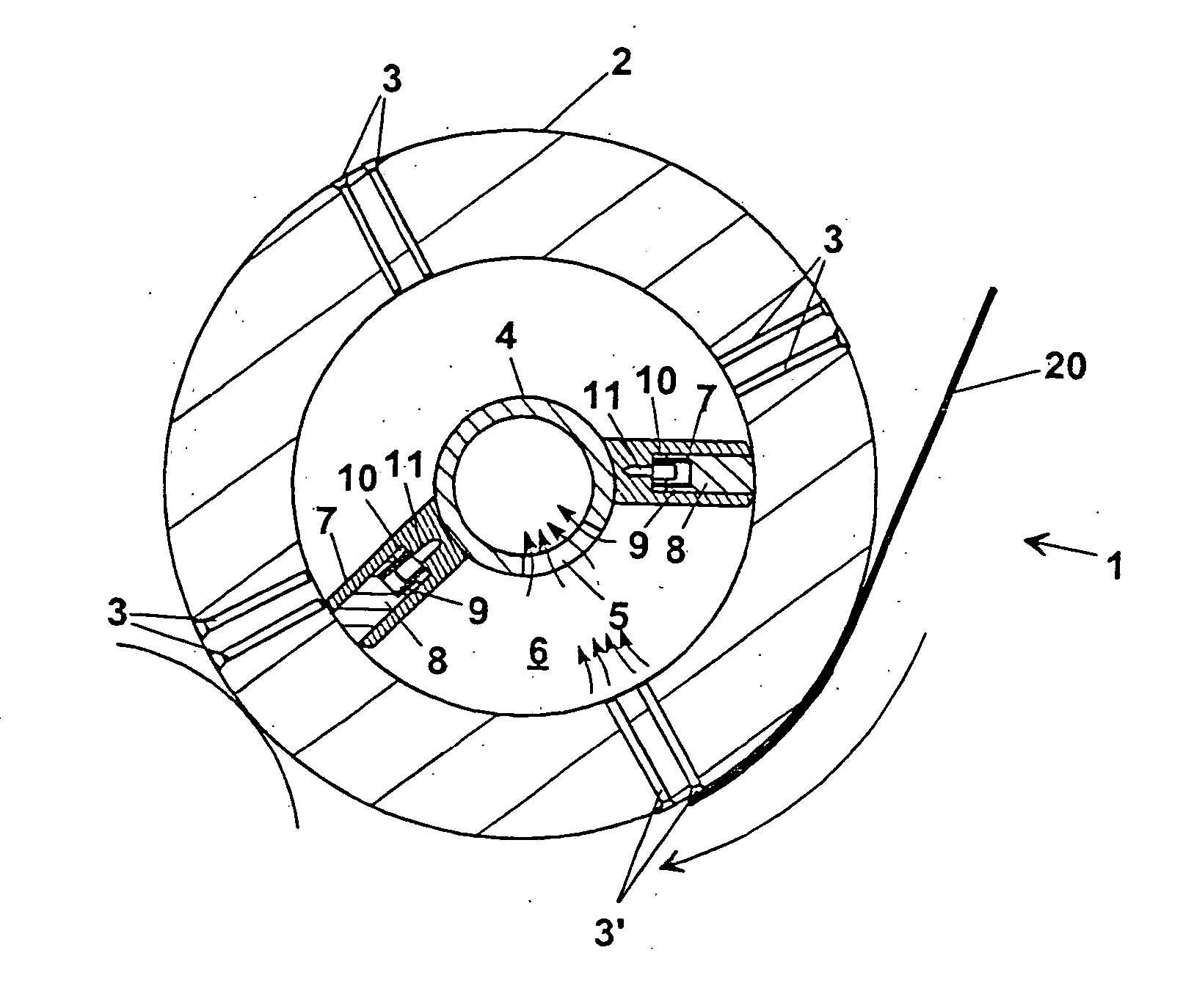

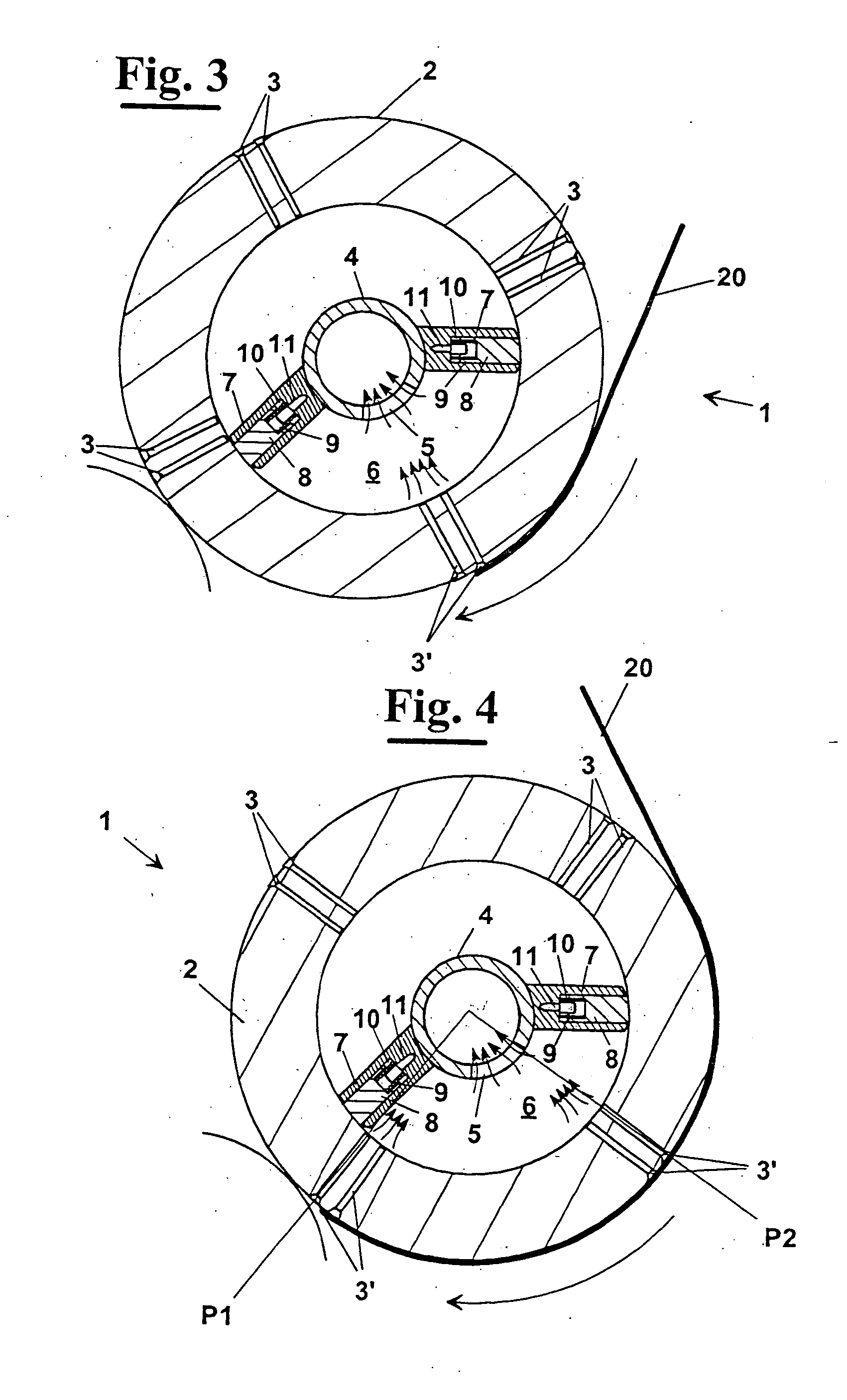

[0036] In FIGS. 3 and 4 a cross sectional view is shown of. a roller 1 used for conveying a web or sheet of paper 20 for paper converting machines, for example, a rewinding machine, a winding machine, an interfolding machine. It comprises a first outer cylindrical tubular body 2, equipped with a plurality of radial holes 3 arranged according to substantially longitudinal rows, capable of rotating with respect to a second inner fixed body 4, co-axial to the former and connected to a suction system not shown. The second body 4, which as shown in the embodiments of FIGS. 3 and 4 has tubular cylindrical geometry like first body 2, has a plurality of apertures 5 and two radial boards 7 at opposite sides with respect to apertures 5.

[0037] The inner surface of first cylindrical tubular body 2, radial boards 7 and the external surface of second tubular body 4 define a suction chamber 6 that, during the relative rotation of the two bodies, brings selectively in communication some rows of hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| atmospheric pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com