Process of repairing a component, a repair tool for a component, and a component

一种修理工具、部件的技术,应用在发动机元件、叶片的支承元件、机器/发动机等方向,能够解决减小应力、延长工作寿命、不去除等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a process for repairing a component, a repair tool for the component, and the component. Embodiments of the present invention result in extended service life of components, reduced or eliminated crack growth, increased turbomachine operability, increased fatigue resistance, or combinations thereof.

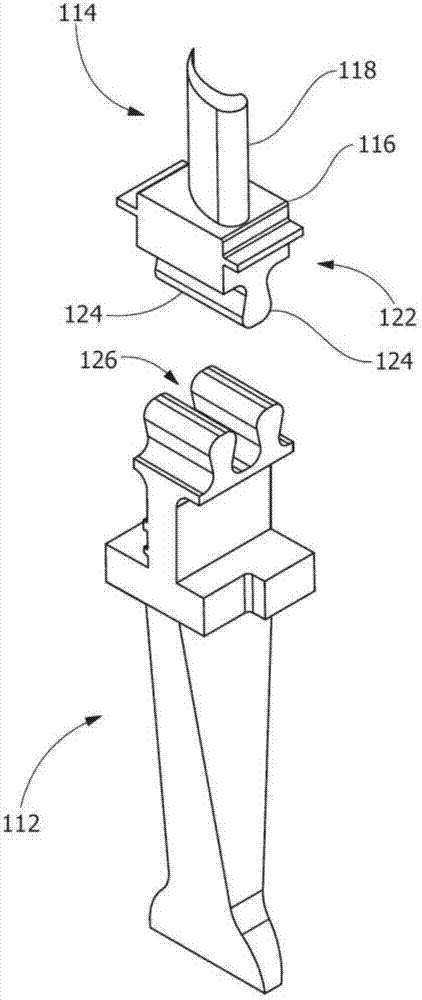

[0024] figure 1 is a perspective view of a portion of a turbine 110 including a rotor wheel 112 and blades 114 according to an embodiment. In general, turbine 110 includes a plurality of rotor wheels 112 , blades 114 , and other turbine components (eg, compressors, shafts, blades, rotor dovetails, and / or other suitable components). Fluid (eg, gas) enters the turbine 110 (eg, through an inlet) and is directed (eg, through the blades) downstream against the blades 114 , and passes through the remaining stages to exert force on the blades 114 , causing the rotor wheel 112 to rotate (eg, around the axis) and vice versa. Turbine 110 is operably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com