Electromagnetic actuating device

一种调整装置、电磁的技术,应用在电磁体、阀装置、阀的操作/释放装置等方向,能够解决不利尺寸偏差、调整装置径向结构空间扩大等问题,达到生产成本减少、减小组件的数量、能耗减少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

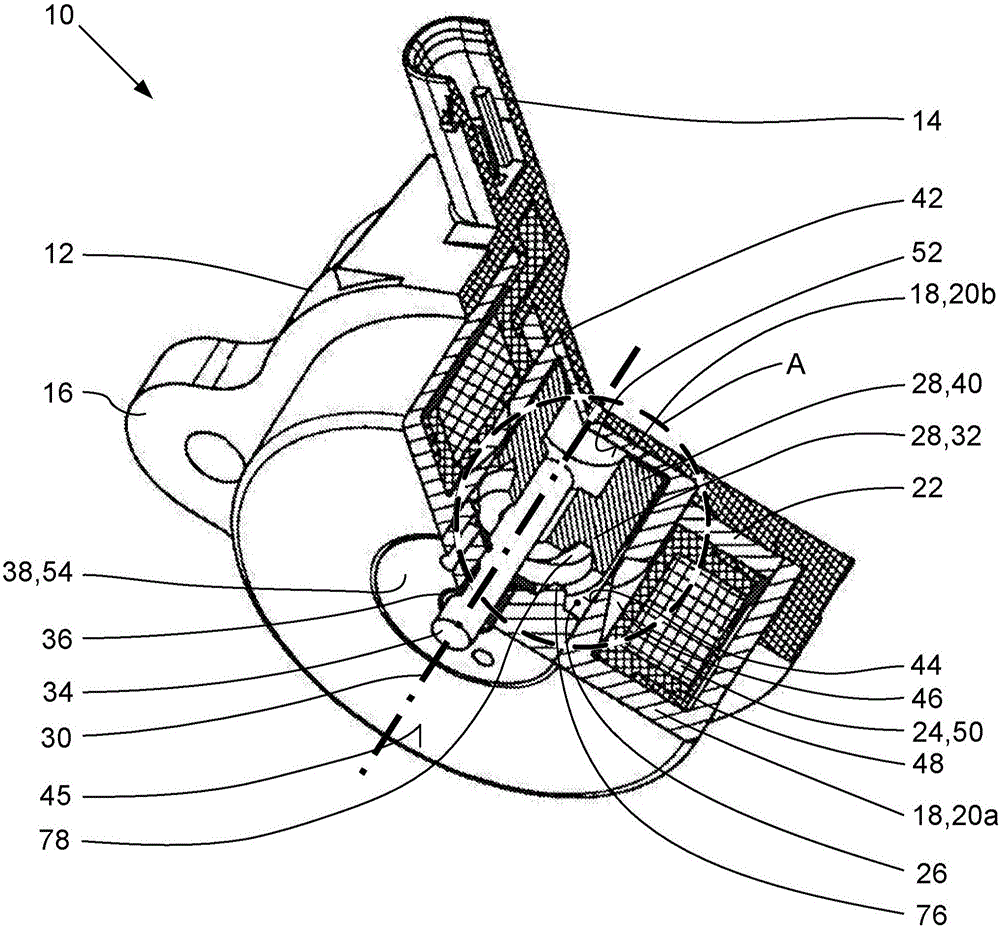

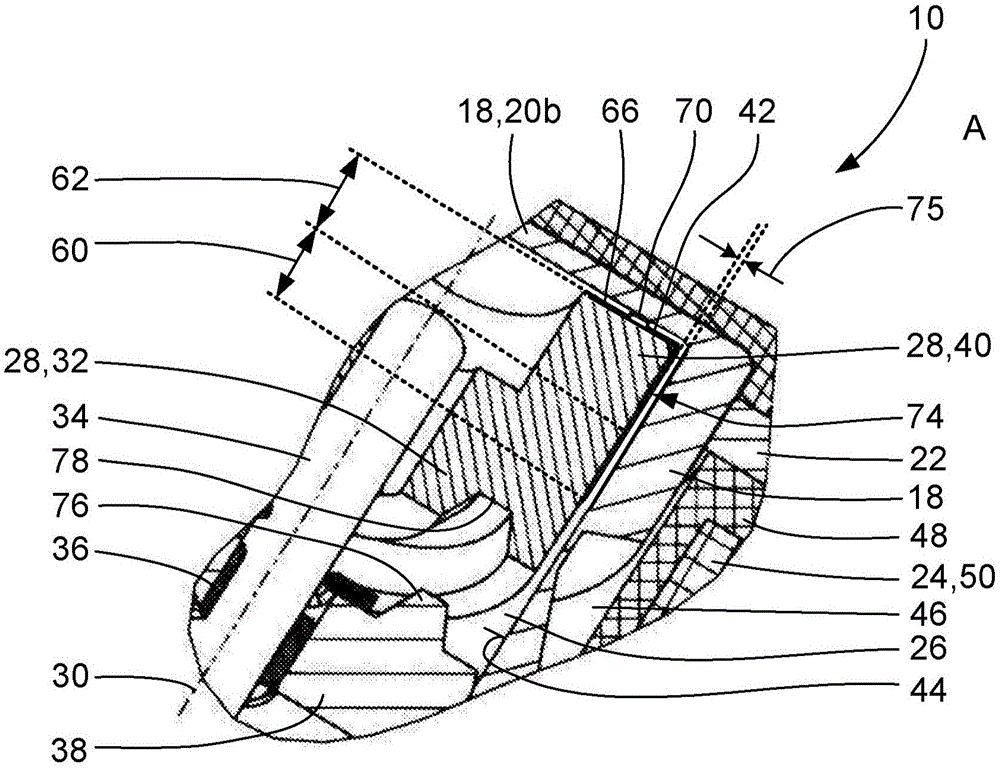

[0034] An electromagnetic adjusting device 10 for a valve not shown here, for example hydraulic or pneumatic, has a pot-shaped housing 12 and at least one fastening flange 16 integrally formed on the housing 12 , which The body has a bipolar electrical plug 14 . Through holes are formed in the fastening flange 16 , into which fastening screws can be inserted.

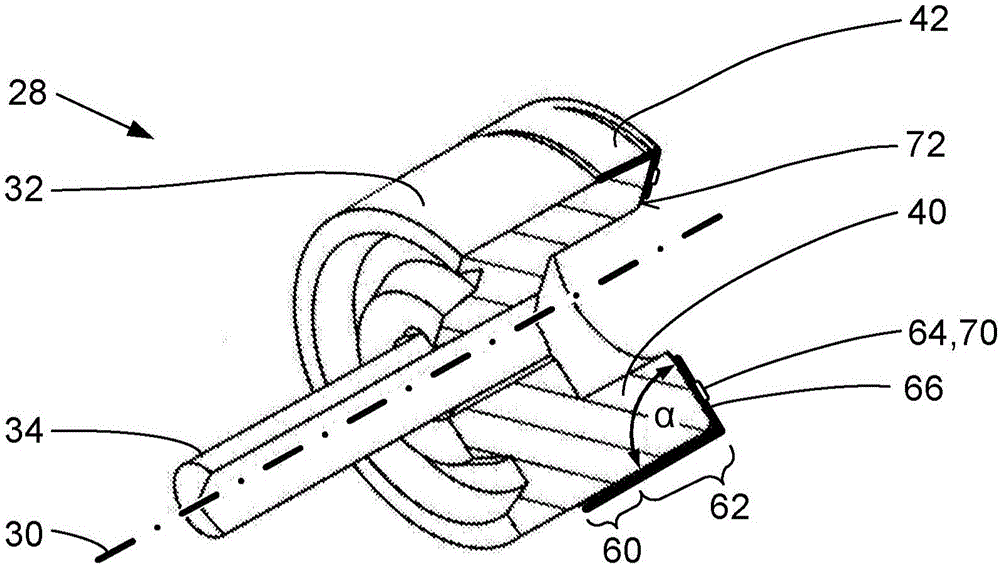

[0035] A two-part yoke is axially partially inserted into the housing 12 and is formed from a first yoke section 18 and a second yoke section 22 . The first yoke section 18 is designed in the shape of a double pot and has a radially outer, disk-shaped base 20 a at its axial end facing away from the housing, and at its end facing the housing. It has a radially inner circular bottom 20b. The first yoke section 18 protrudes axially partly from the housing 12, while the second yoke section 22 is arranged inside the pot space of the housing 12 and terminates the first magnet axially close to the bottom of the housing. A t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com