Ternary cathode material and production method thereof

A positive electrode material and production method technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of complex body process, high waste water treatment cost, poor processing performance, etc., and achieve simple process, good consistency, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

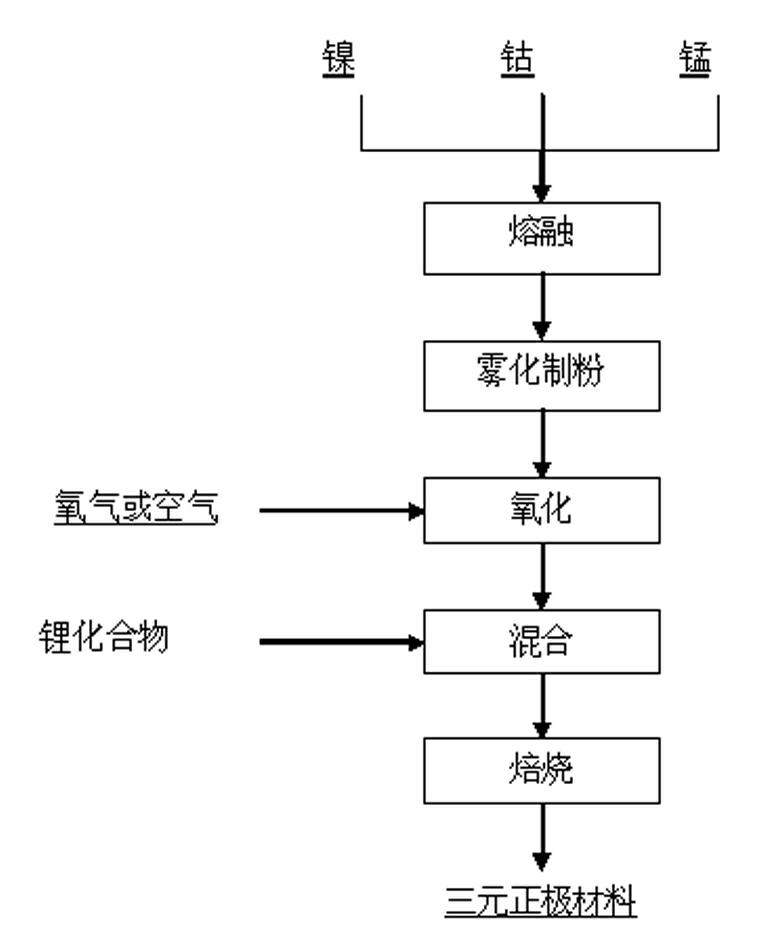

Method used

Image

Examples

Embodiment 1

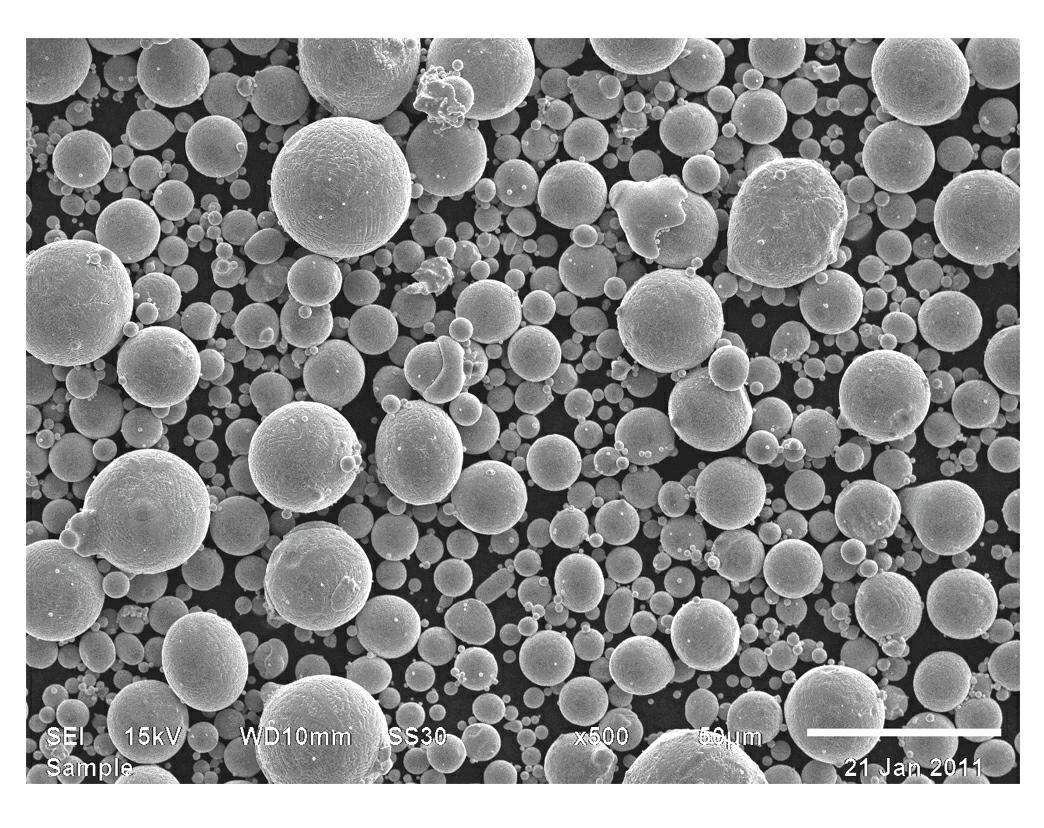

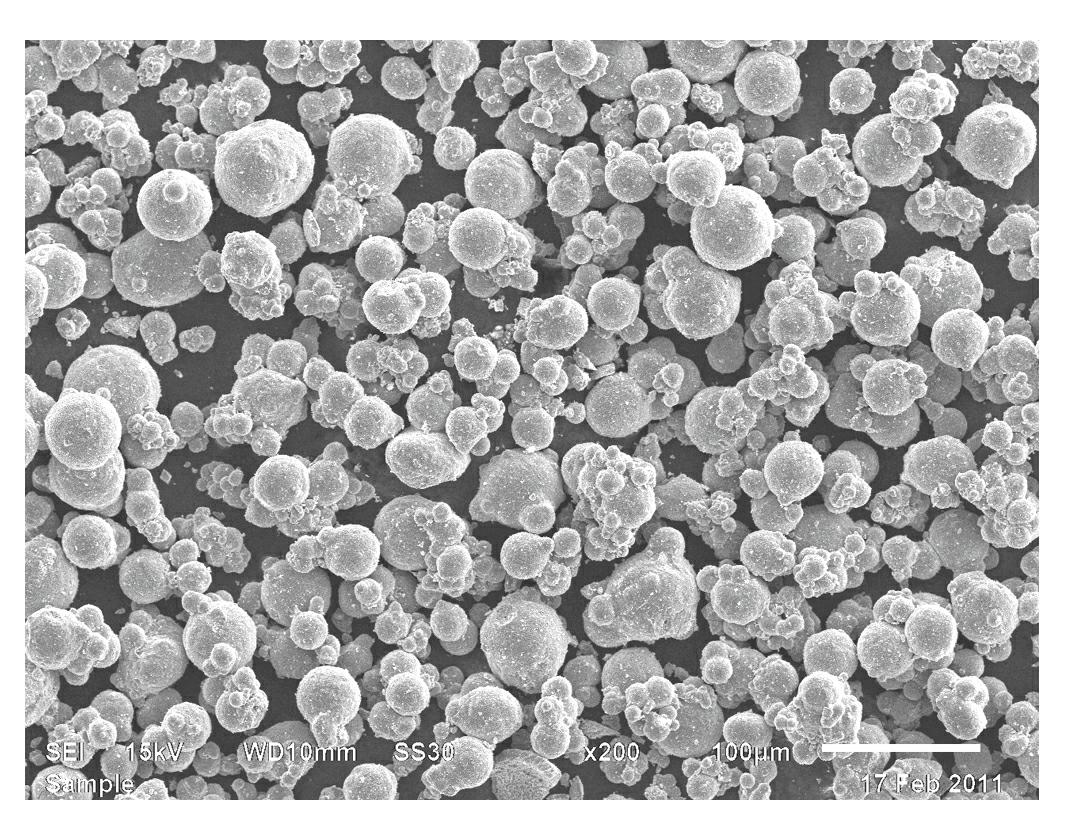

[0025] Step 1: Mix metal nickel, cobalt and manganese according to the molar ratio of 1: 1: 1. The mixture is heated and melted in an induction furnace under the condition of nitrogen protection, and the melted metal liquid is poured into an insulated crucible , sent into the guide tube and nozzle, the molten metal flow is atomized by the high-pressure nitrogen flow, the atomized metal powder is solidified and settled in the atomization tower, and finally falls into the powder collection tank for collection to obtain nickel-cobalt Manganese alloy powder. The SEM image of the analyzed nickel-cobalt-manganese alloy powder is as follows figure 2 As shown, the XRD pattern of nickel-cobalt-manganese alloy powder is as follows Figure 5 As shown, the composition of the alloy powder achieves uniform mixing at the atomic level, the powder particles are regular spherical, and the bulk density reaches 5.05 g / cm 3 , the tap density reaches 5.57 g / cm 3 .

[0026] Step 2: Oxidize the ...

Embodiment 2

[0030] Step 1: Mix metal nickel, cobalt, and manganese according to the molar ratio of 5: 2: 3. The mixture is melted in an induction furnace under the protection of argon, and the molten metal liquid is poured into an insulated crucible , sent into the guide tube and nozzle, the molten metal flow is atomized by the high-pressure argon flow, the atomized metal powder is solidified and settled in the atomization tower, and finally falls into the powder collection tank for collection to obtain nickel-cobalt Manganese alloy powder. The alloy powder is uniformly mixed at the atomic level, the powder particles are regular spherical, and the bulk density reaches 5.12 g / cm 3 , the tap density reaches 5.61 g / cm 3 .

[0031] Step 2: Oxidize the alloy powder obtained in step 1 in an oxidation furnace, the oxidation temperature is 900°C, and the oxidation time is 1 hour, keeping the alloy powder oxidized and calcined under dynamic conditions, heating evenly, and no hardening phenomenon...

Embodiment 3

[0035] Step 1: Mix metal nickel, cobalt, and manganese according to the molar ratio of 4: 2: 4. The mixture is melted in an induction furnace under the protection of helium, and the molten metal liquid is poured into an insulated crucible , sent into the guide tube and nozzle, the molten metal flow is atomized by the high-pressure helium flow, the atomized metal powder is solidified and settled in the atomization tower, and finally falls into the powder collection tank for collection to obtain nickel-cobalt Manganese alloy powder. The alloy powder is uniformly mixed at the atomic level, the powder particles are regular spherical, and the bulk density reaches 5.01 g / cm 3 , the tap density reaches 5.47g / cm 3 .

[0036] Step 2: Oxidize the alloy powder obtained in step 1 in an oxidation furnace, the oxidation temperature is 1000°C, and the oxidation time is 0.5 hours, and the alloy powder is oxidized and calcined under dynamic conditions, with uniform heating and no hardening p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com